Phenolic resin based solid acid, preparation method and application thereof

A technology of phenolic resin and solid acid, which is applied in the dehydration of hydroxyl-containing compounds to prepare ethers, the reaction preparation of carboxylic acids/symmetric anhydrides and saturated hydrocarbons, and the preparation of ethers. It can solve unsatisfactory problems and achieve high thermal stability and high catalytic performance. The effect of activity and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Synthesis of phenolic resin-based solid acid:

[0024] The first step, the synthesis reaction of carbon-based solid acid: PF phenolic resin and isethionic acid are stirred and mixed evenly in the ratio of 1:1 by mass, then placed in a quartz tube muffle furnace, and replaced by nitrogen gas The air was heated to 200°C in a nitrogen atmosphere for carbonization reaction for 12 hours to obtain a black solid;

[0025] Step 2, water washing, suction filtration and drying: After the solid is cooled to room temperature, add hot water above 80°C for washing, and filter until the filtrate is clear and acidic, and then put the solid in an oven at 120°C Drying was carried out for 1 day, and the acid value of the obtained catalyst was 1.3 mmol / g, and the thermal decomposition temperature was 160°C;

Embodiment 2-4

[0027] The preparation method is the same as in Example 1, the difference is that the carbonization condensation reaction time is adjusted, and the influence results of different reaction times are shown in Table 1.

[0028] Table 1: Different carbonation condensation reaction times and their results

[0029] Example

Embodiment 5-7

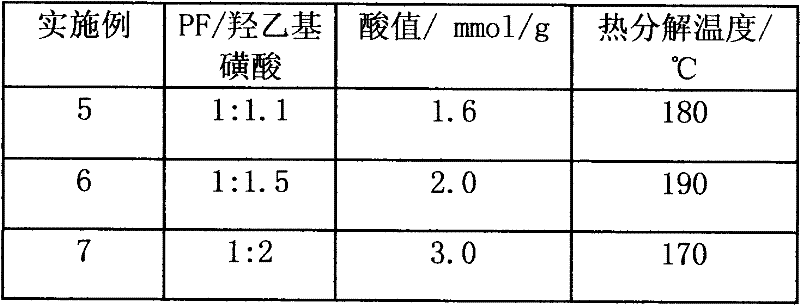

[0031] The preparation method is the same as that in Example 1, the difference is that the dosage of isethionic acid is adjusted, and the influence results of different dosages of isethionic acid are shown in Table 2.

[0032] Table 2. The amount of different isethionic acids and their results

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com