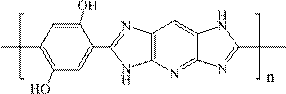

Preparation method for poly(2,5-dihydroxyl-1,4-phenylene pyridobisimidazole)

A technology of phenylene pyridine and hydroxyterephthalic acid, which is applied in the direction of one-component synthetic polymer rayon, textile and papermaking, fiber chemical characteristics, etc. and other problems, to achieve the effect of reducing the preparation cost, being easy to operate, and improving the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

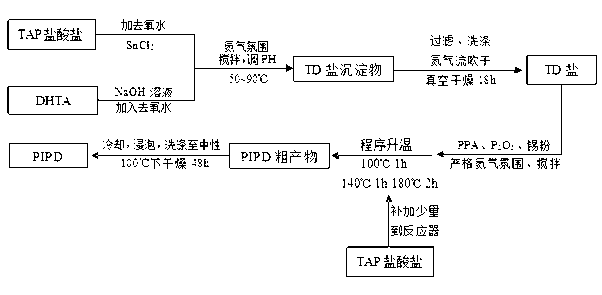

Method used

Image

Examples

Embodiment 1

[0029] (1) Under the protection of nitrogen, add 5.2g DHTA to the TD salt reactor, add 50ml nitrogen deoxygenated water, stir and disperse evenly; make 3.15g NaOH into 10~30% aqueous solution and add it to DHTA, add 0.026g SnCl 2 , heated to 50°C under stirring; 7.0gTAP·3HCl·H 2 O (i.e. the salt of TAP

[0030] acid salt) to make an 18~20% aqueous solution, and add the TAP aqueous solution to the DHTA sodium salt, react at 50°C for 30 minutes, adjust the pH value to neutral with deoxyacetic acid, and precipitate a large amount of yellow precipitate. Filtered under water and washed three times with deoxygenated water and deoxyethanol respectively, blown dry with nitrogen, then transferred the obtained TD salt into a vacuum oven, and dried at 50°C and 50mbar for 24h to obtain TD salt.

[0031] (2) Add 19.2g polyphosphoric acid (PPA), 8.9g phosphorus pentoxide (P 2 o 5 ), 0.007g tin powder, 7.0gTD salt. Stir slowly to gradually disperse into the solvent. After stirring evenly...

Embodiment 2

[0033] Same as Example 1, change the reaction temperature in step (1) to 60°C, add 0.035g TAP hydrochloride, the relative viscosity of the polymer measured at 25°C and 0.25g / dl methanesulfonic acid is 22.8.

Embodiment 3

[0035] Same as Example 1, change the reaction temperature in step (1) to 60°C, add 0.070g TAP hydrochloride to obtain poly(2,5-dihydroxy-1,4-phenylenepyridodiimidazole), at 25°C, The relative viscosity measured at 0.25g / dl methanesulfonic acid is 24.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com