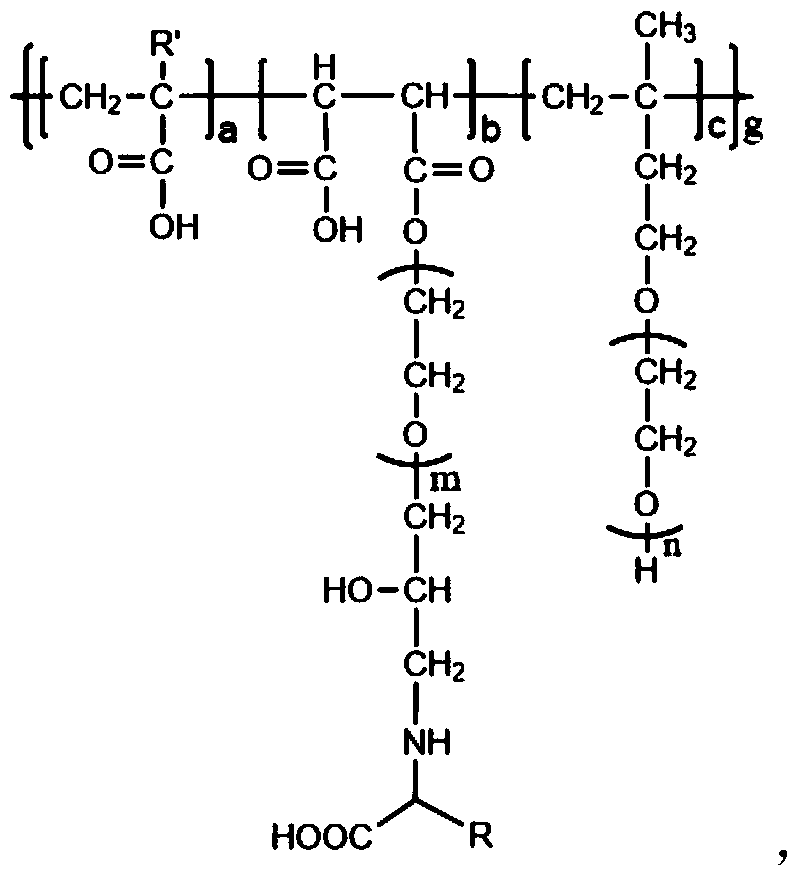

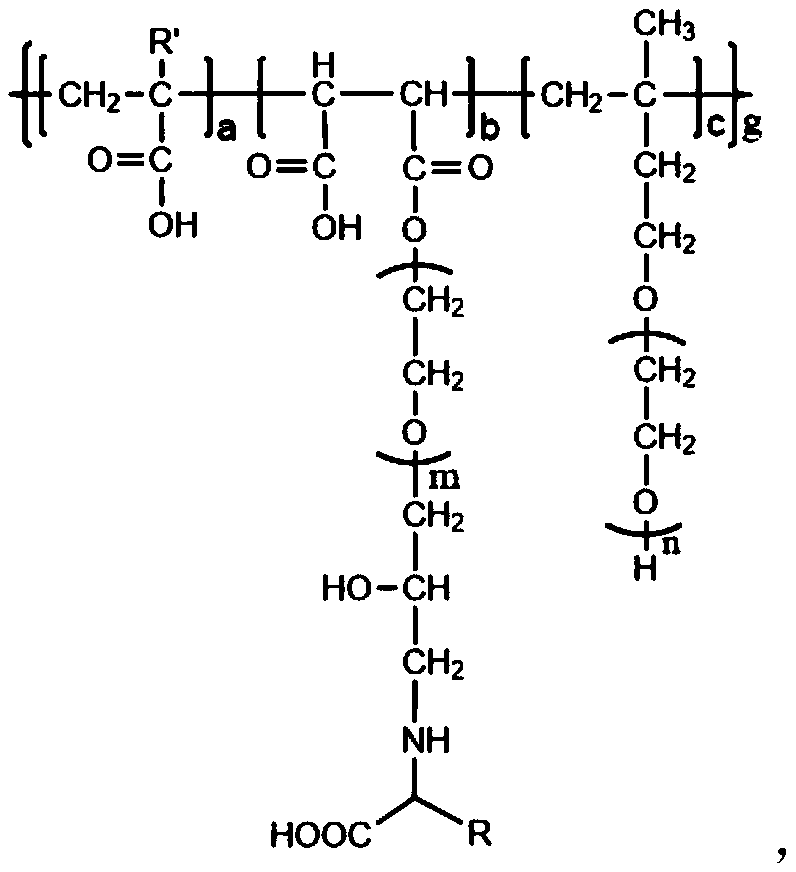

Amino acid-modified mud-resistant polycarboxylic acid water reducing agent and preparation method thereof

An amino acid and water reducing agent technology, which is applied in the preparation of carboxylic acid esters, the preparation of carboxylic acid/symmetric anhydrides and saturated hydrocarbons, and the preparation of cyanide reactions. It can solve the problems of insufficient anti-adsorption ability, harsh reaction conditions, short-chain steric hindrance It can improve the anti-adsorption capacity, simplify the synthesis steps, and improve the poor fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

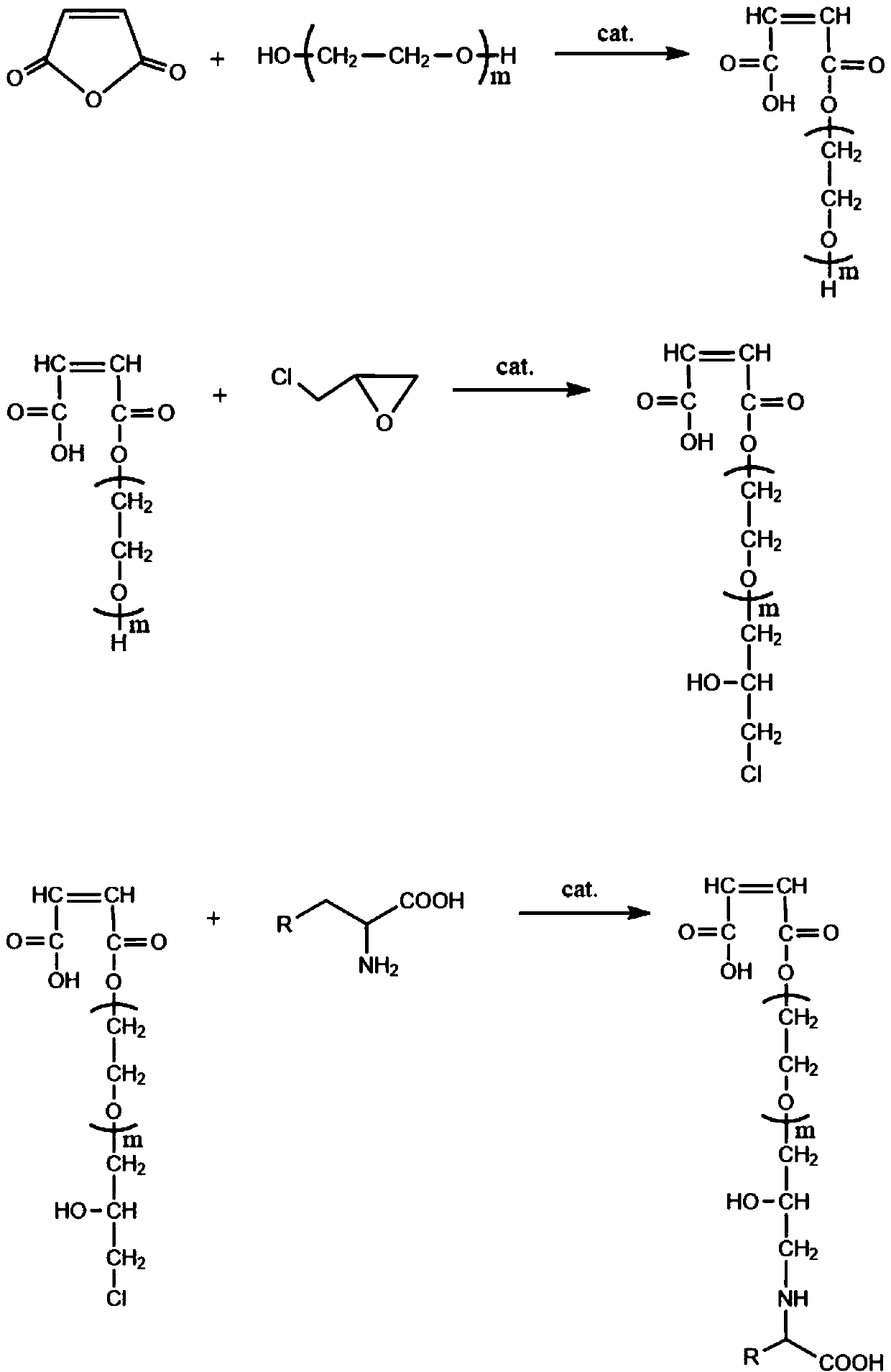

[0038] A preparation method of amino acid modified mud-resistant polycarboxylate water reducer, the specific steps are as follows:

[0039] S1, Preparation of Amino Acid Modified Unsaturated Ester:

[0040] S11. Place 0.15 mol of polyethylene glycol with a molecular weight of 400 in a reaction vessel, add 0.15 mol of maleic anhydride at one time under stirring conditions, and continuously feed N 2 , after the maleic anhydride is dissolved, add catalyst sulfuric acid, the amount of sulfuric acid is 0.4% of the total mass of polyethylene glycol and maleic anhydride, and stir and react at 40°C for 3h.

[0041] S12, take 0.12mol of the product of step S11 in the reaction vessel, and continuously feed N 2 , heat up to 50°C, add catalyst tetrabutylammonium chloride, add 0.12mol of epichlorohydrin dropwise within 1.5h, keep warm for 4h, the amount of catalyst added is 0.8% of the total mass of the product in step S11 and epichlorohydrin .

[0042] S13, take 0.10mol of the product ...

Embodiment 2

[0047] A preparation method of amino acid modified mud-resistant polycarboxylate water reducer, the specific steps are as follows:

[0048] S1, Preparation of Amino Acid Modified Unsaturated Ester:

[0049] S11. Place 0.13 mol of polyethylene glycol with a molecular weight of 800 in the reaction vessel, add 0.14 mol of maleic anhydride at one time under stirring conditions, and continuously feed N 2 , after the maleic anhydride is dissolved, add catalyst phosphoric acid, the dosage of phosphoric acid is 0.3% of the total mass of polyethylene glycol and maleic anhydride, and stir and react at 60°C for 2h.

[0050] S12, take 0.11mol of the product of step S11 in the reaction vessel, and continuously feed N 2 , the temperature was raised to 50° C., the catalyst tetrabutylammonium bromide was added, 0.12 mol of epichlorohydrin was added dropwise within 3 hours, and the reaction was kept for 5 hours. The amount of catalyst added was 0.6% of the total mass of the product of step S1...

Embodiment 3

[0056] A preparation method of amino acid modified mud-resistant polycarboxylate water reducer, the specific steps are as follows:

[0057] S1, Preparation of Amino Acid Modified Unsaturated Ester:

[0058] S11. Place 0.14 mol of polyethylene glycol with a molecular weight of 1600 in the reaction vessel, add 0.14 mol of maleic anhydride at one time under stirring conditions, and continuously feed N 2 After the maleic anhydride is dissolved, add the catalyst phosphorous acid, the amount of phosphorous acid is 0.7% of the total mass of polyethylene glycol and maleic anhydride, and stir and react at 70°C for 3h.

[0059] S12, take 0.13mol of the product of step S11 in the reaction vessel, and continuously feed N 2 , heat up to 60°C, add catalyst benzyltrimethylammonium bromide, add 0.13mol of epichlorohydrin dropwise within 2h, keep warm for 6h, the amount of catalyst added is 1.0% of the total mass of the product in step S11 and epichlorohydrin %.

[0060] S13, take 0.12mol o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com