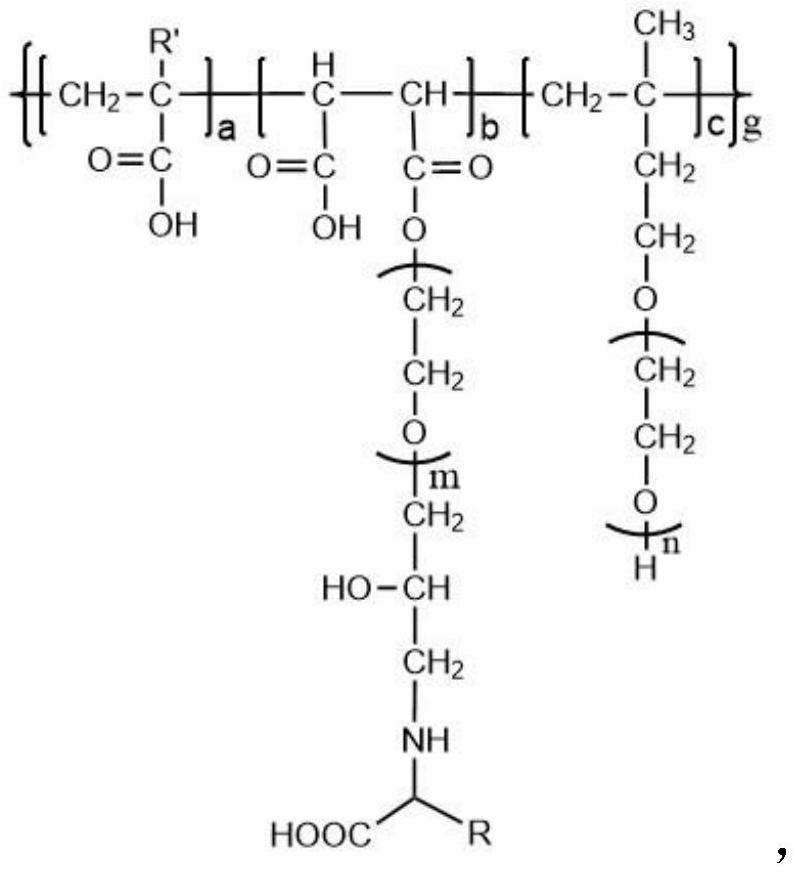

Amino acid modified mud-resistant polycarboxylate water reducer and preparation method thereof

A technology of amino acid and water reducer, which is applied to the preparation of carboxylic acid ester, reaction preparation of carboxylic acid/symmetric anhydride and saturated hydrocarbon, chemical instruments and methods, etc. It can solve the problems of limited short-chain steric hindrance effect, harsh reaction conditions, and anti-adsorption Insufficient capacity and other problems, to achieve the effect of improving anti-adsorption capacity, simplifying synthesis steps, and improving poor fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

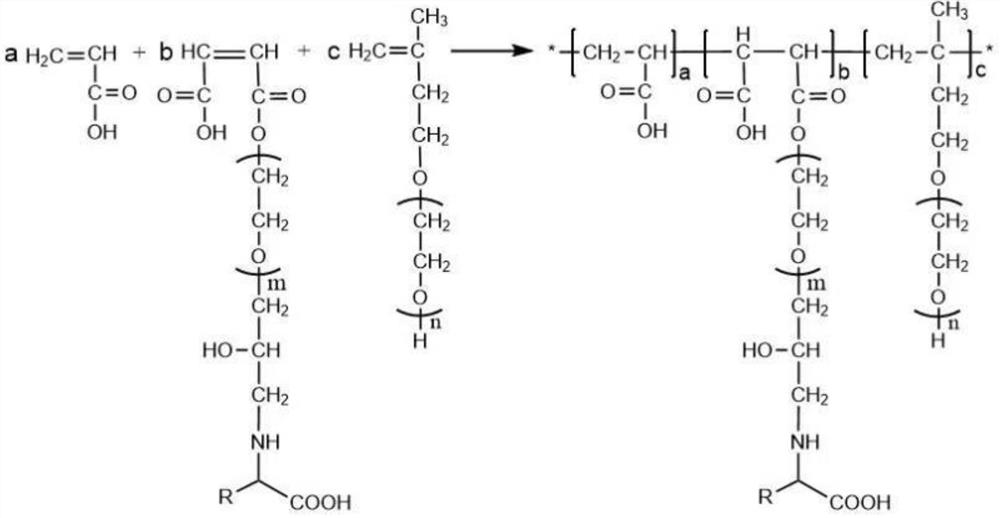

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of amino acid modified mud-resistant polycarboxylate water reducer, the specific steps are as follows:

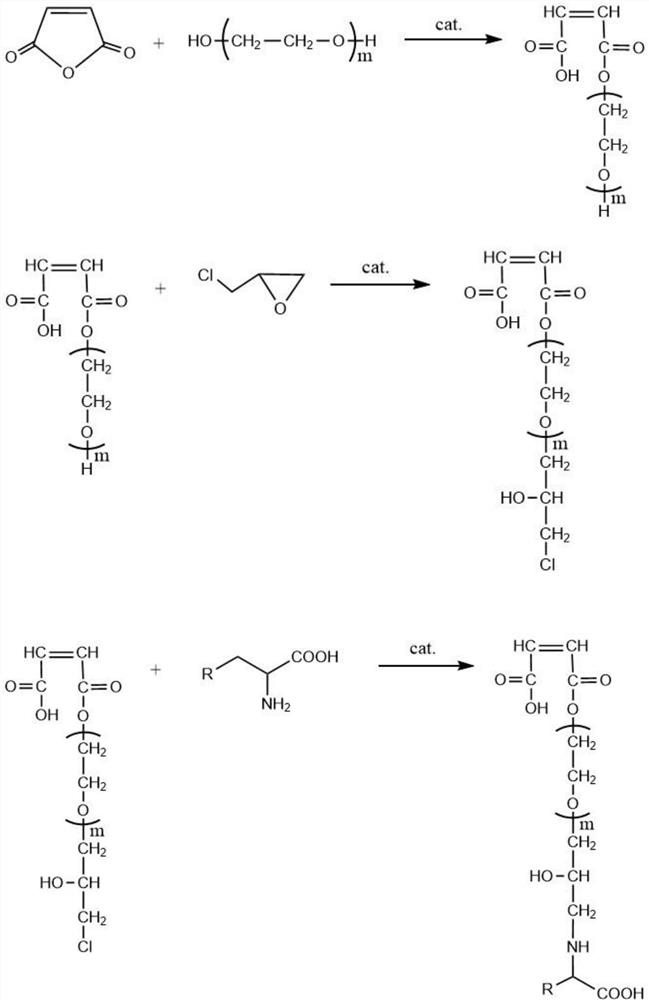

[0039] S1, Preparation of Amino Acid Modified Unsaturated Ester:

[0040] S11. Place 0.15 mol of polyethylene glycol with a molecular weight of 400 in a reaction vessel, add 0.15 mol of maleic anhydride at one time under stirring conditions, and continuously feed N 2 , after the maleic anhydride is dissolved, add catalyst sulfuric acid, the amount of sulfuric acid is 0.4% of the total mass of polyethylene glycol and maleic anhydride, and stir and react at 40°C for 3h.

[0041] S12, take 0.12mol of the product of step S11 in the reaction vessel, and continuously feed N 2 , heat up to 50°C, add catalyst tetrabutylammonium chloride, add 0.12mol of epichlorohydrin dropwise within 1.5h, keep warm for 4h, the amount of catalyst added is 0.8% of the total mass of the product in step S11 and epichlorohydrin .

[0042] S13, take 0.10mol of the product ...

Embodiment 2

[0047] A preparation method of amino acid modified mud-resistant polycarboxylate water reducer, the specific steps are as follows:

[0048] S1, Preparation of Amino Acid Modified Unsaturated Ester:

[0049] S11. Place 0.13 mol of polyethylene glycol with a molecular weight of 800 in the reaction vessel, add 0.14 mol of maleic anhydride at one time under stirring conditions, and continuously feed N 2 , after the maleic anhydride is dissolved, add catalyst phosphoric acid, the dosage of phosphoric acid is 0.3% of the total mass of polyethylene glycol and maleic anhydride, and stir and react at 60°C for 2h.

[0050] S12, take 0.11mol of the product of step S11 in the reaction vessel, and continuously feed N 2 , the temperature was raised to 50° C., the catalyst tetrabutylammonium bromide was added, 0.12 mol of epichlorohydrin was added dropwise within 3 hours, and the reaction was kept for 5 hours. The amount of catalyst added was 0.6% of the total mass of the product of step S1...

Embodiment 3

[0056] A preparation method of amino acid modified mud-resistant polycarboxylate water reducer, the specific steps are as follows:

[0057] S1, Preparation of Amino Acid Modified Unsaturated Ester:

[0058] S11. Place 0.14 mol of polyethylene glycol with a molecular weight of 1600 in the reaction vessel, add 0.14 mol of maleic anhydride at one time under stirring conditions, and continuously feed N 2 After the maleic anhydride is dissolved, add the catalyst phosphorous acid, the amount of phosphorous acid is 0.7% of the total mass of polyethylene glycol and maleic anhydride, and stir and react at 70°C for 3h.

[0059] S12, take 0.13mol of the product of step S11 in the reaction vessel, and continuously feed N 2 , heat up to 60°C, add catalyst benzyltrimethylammonium bromide, add 0.13mol of epichlorohydrin dropwise within 2h, keep warm for 6h, the amount of catalyst added is 1.0% of the total mass of the product in step S11 and epichlorohydrin %.

[0060] S13, take 0.12mol o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com