Ferrocene modified polyoxyethylene ether monomer, ferrocene modified anti-mud polycarboxylic acid water reducer and preparation method of ferrocene modified anti-mud polycarboxylic acid water reducer

A technology based on polyoxyethylene ether and polycarboxylate, which is applied in the field of polycarboxylate water reducer for cement concrete, can solve the problems of instability of diphenylphosphoryl chloride, limited steric hindrance effect, and insufficient inhibition ability. Achieve the effect of improving anti-adsorption capacity, excellent performance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

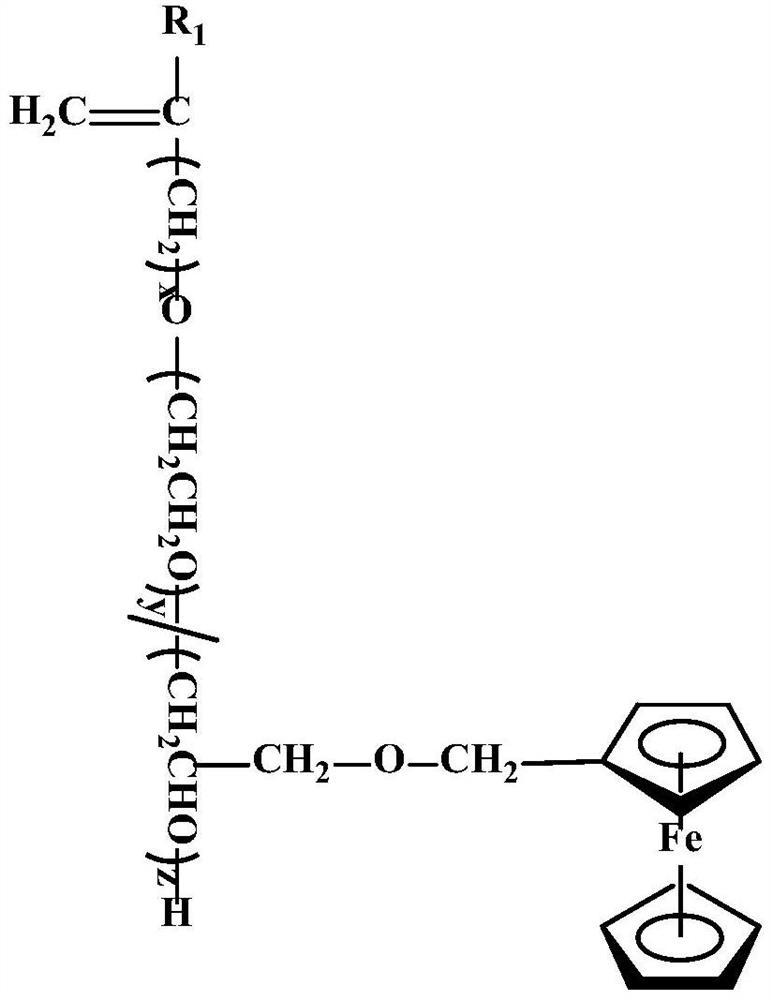

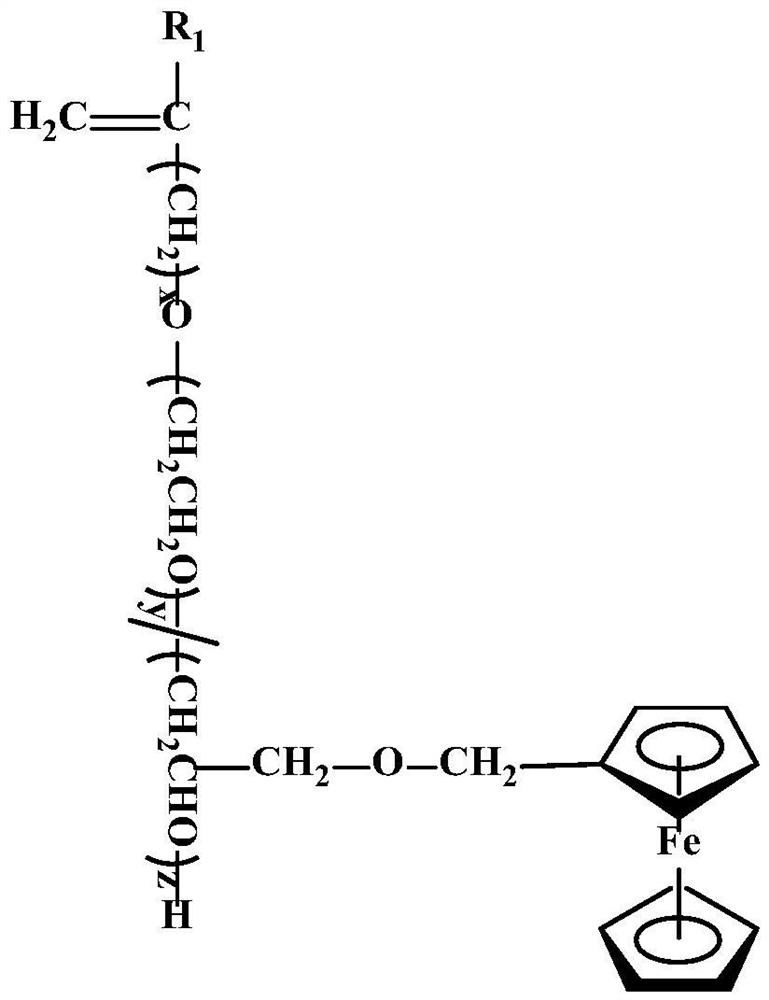

[0032] (1) Preparation of ferrocene-modified polyoxyethylene ether monomer: 1mol allyl alcohol and 0.02mol sodium are added to the autoclave, and 20mol ethylene oxide and 3mol ferrocenyl glycidyl ether are added at 110 ℃ for ring-opening polymerization for 5 hours to obtain an unsaturated macromonomer containing a ferrocene group;

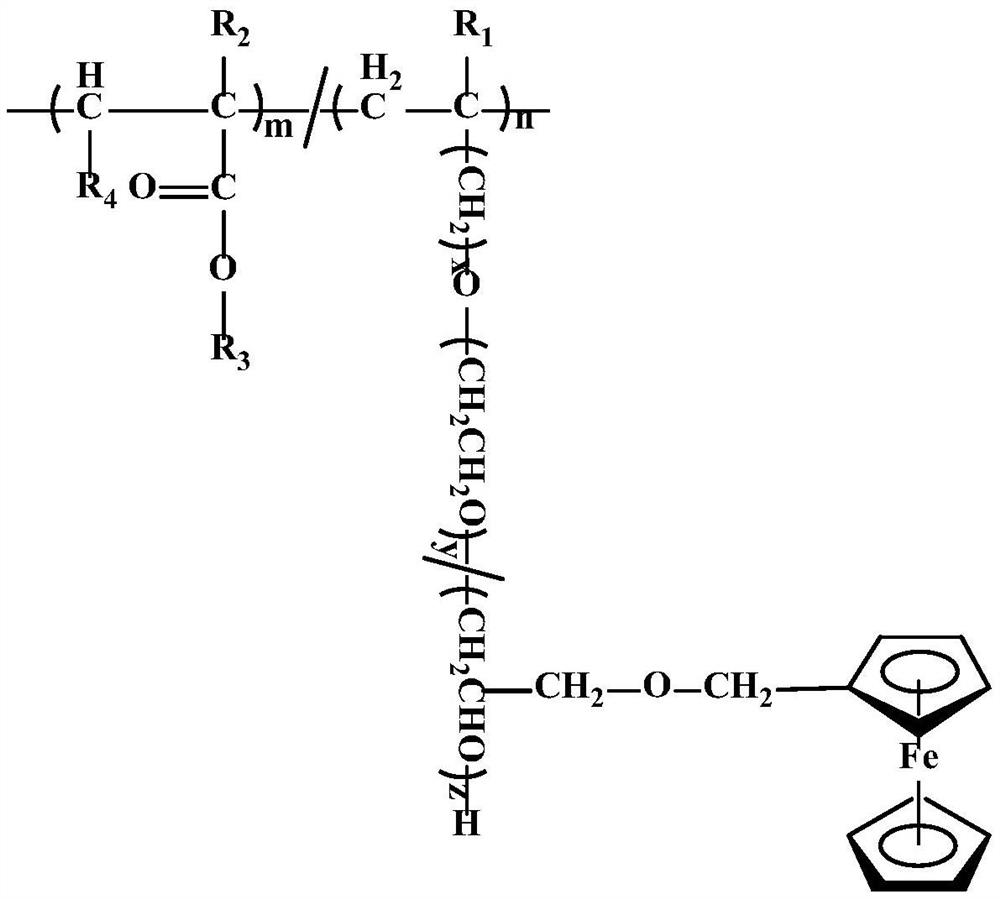

[0033] (2) Preparation of ferrocene-modified anti-mud type polycarboxylate water reducer: 1 mol of unsaturated macromonomer containing ferrocene group prepared in step (1), 3 mol of acrylic acid, in 0.02 mol of persulfuric acid Under the joint action of sodium, 0.01mol ascorbic acid and 0.02mol mercaptopropionic acid, carry out free radical polymerization reaction at 10°C for 3 hours, and add sodium hydroxide to adjust the pH to 6 to obtain ferrocene-modified anti-sludge type polycarboxylate Liquid:

[0034]

Embodiment 2

[0036] (1) Preparation of ferrocene-modified polyoxyethylene ether monomer: 1mol isopentenol and 0.04mol potassium are added to the autoclave, and 50mol ethylene oxide and 5mol ferrocenyl glycidyl ether are added at 125 ℃ for ring-opening polymerization for 6 hours to obtain an unsaturated macromonomer containing a ferrocene group;

[0037] (2) Preparation of ferrocene-modified anti-mud type polycarboxylate water reducer: the unsaturated macromonomer containing ferrocene group prepared in 1mol step (1), 4mol maleic anhydride, in 0.1mol Under the joint action of potassium persulfate, 0.04mol sodium ascorbate and 0.06mol sodium methacrylate, carry out free radical polymerization reaction at 40°C for 4 hours, and then add sodium hydroxide to adjust the pH to 7 to obtain ferrocene modified anti-sludge Type polycarboxylate water reducer:

[0038]

Embodiment 3

[0040] (1) Preparation of ferrocene-modified polyoxyethylene ether monomer: 1mol isopentenol and 0.05mol sodium are added to the autoclave, and 10mol ethylene oxide and 1mol ferrocenyl glycidyl ether are added at 100 The ring-opening polymerization reaction was carried out at ℃ for 4 hours to obtain an unsaturated macromonomer containing a ferrocene group;

[0041] (2) Preparation of ferrocene-modified anti-mud type polycarboxylate water reducer: the unsaturated macromonomer containing ferrocene group prepared by 1mol step (1), 2mol methacrylic acid, in 0.06mol Under the joint action of sodium persulfate, 0.02 mol of white block and 0.03 mol of mercaptoethanol, carry out free radical polymerization reaction at 25°C for 3 hours, and add potassium hydroxide to adjust the pH to 6.5 to obtain ferrocene-modified mud-resistant polycarboxylate Acid water reducer:

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com