A kind of phenolic modified mud resistant polycarboxylate water reducer and preparation method thereof

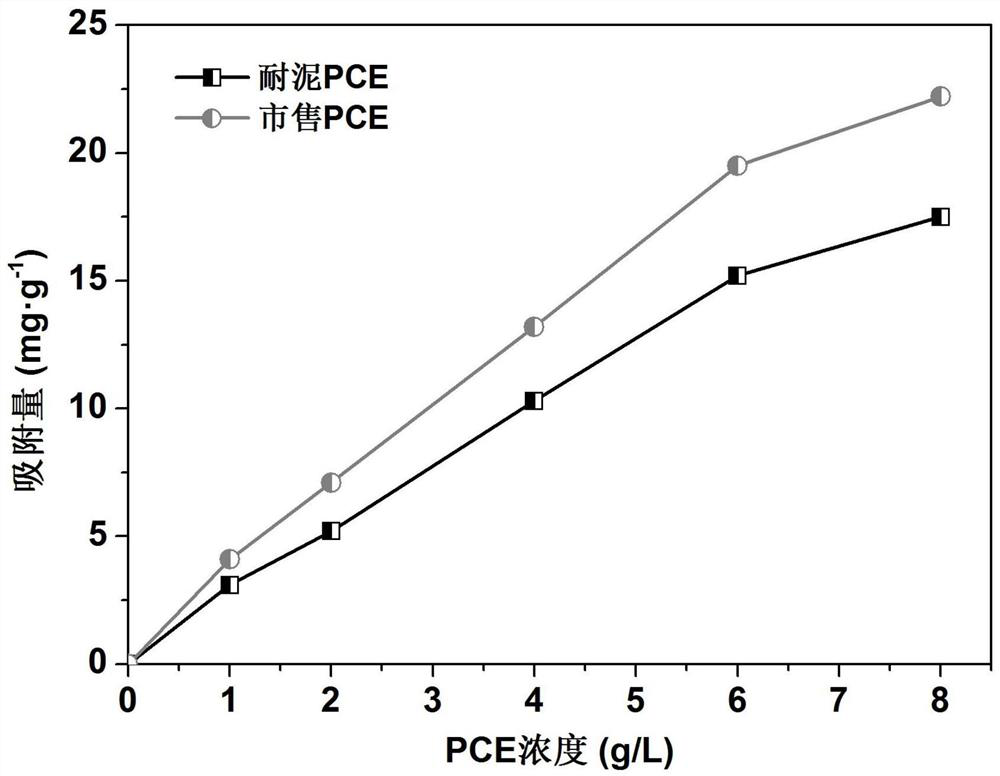

A phenolic modification and polycarboxylic acid technology, which is applied in the field of concrete admixtures, can solve the problems of difficult preparation of polyethylene glycol derivatives and inappropriate application of water reducing agents in the market, achieve good steric hindrance effect, improve resistance to Adsorption capacity, reducing the effect of intercalation adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

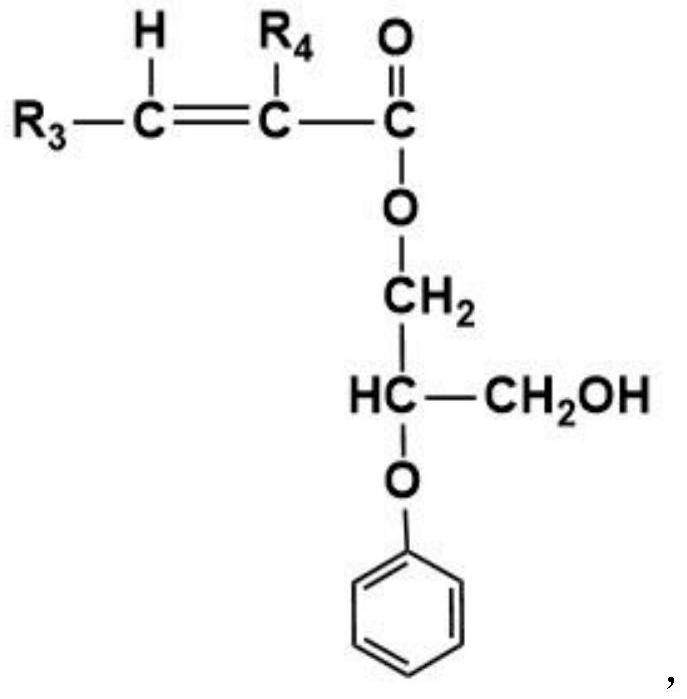

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of a phenolic modified mud-resistant polycarboxylate water reducer, the specific steps are as follows:

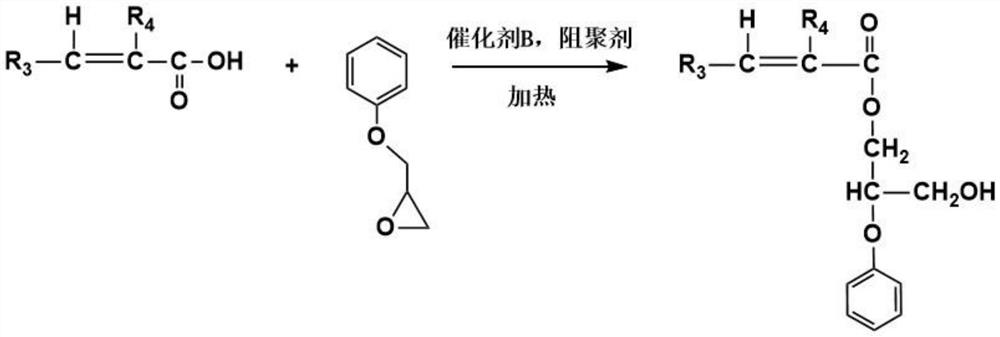

[0039] S1, the preparation of phenyl unsaturated ester:

[0040] Add 0.3 mol itaconic acid, 0.3 mol phenyl glycidyl ether, 0.42 g sulfuric acid, 0.25 g 2-tert-butylhydroquinone and continuously feed N 2 In a reaction vessel, keep stirring, control the reaction temperature at 80°C, and react for 5 hours to obtain the phenyl unsaturated ester.

[0041] S2, 68g of methacrylic acid, 58g of phenyl unsaturated ester, 25g of deionized water are prepared into material A, and 1.5g of mercaptoethanol, 0.42g of saffron, and 20g of deionized water are prepared into material B;

[0042] S3, take 2.0g of potassium persulfate and 20g of deionized water and add and continuously feed N 2 In the reaction container, stir at room temperature until the mixture is uniform, as the bottom material;

[0043] S4, continuous access to N 2 , control the temperature in t...

Embodiment 2

[0046] A preparation method of a phenolic modified mud-resistant polycarboxylate water reducer, the specific steps are as follows:

[0047] S1, the preparation of phenyl unsaturated ester:

[0048] Add 0.4mol acrylic acid, 0.4mol phenyl glycidyl ether, 0.9g p-toluenesulfonic acid, 0.42g p-hydroxyanisole and continuously feed N 2 In a reaction vessel, keep stirring, control the reaction temperature at 90°C, and react for 6 hours to obtain the phenyl unsaturated ester.

[0049] S2, 60g methacrylic acid, 45g phenyl unsaturated ester, 20g deionized water are prepared into material A, 1.1g thioglycolic acid, 0.54g vitamin C, 20g deionized water are prepared into material B;

[0050] S3, take 2.0g of hydrogen peroxide and 20g of deionized water and add it into N continuously 2 In the reaction container, stir at room temperature until the mixture is uniform, as the bottom material;

[0051] S4. Control the temperature in the reaction vessel to 40°C, drop materials A and B into the...

Embodiment 3

[0054] A preparation method of a phenolic modified mud-resistant polycarboxylate water reducer, the specific steps are as follows:

[0055] S1, the preparation of phenyl unsaturated ester:

[0056] Add 0.32mol methacrylic acid, 0.3mol phenyl glycidyl ether, 1g tetrabutylammonium bromide, 0.54g hydroquinone and continuously feed N 2 In a reaction vessel, keep stirring, control the reaction temperature at 80°C, and react for 7 hours to obtain the phenyl unsaturated ester.

[0057] S2, 35g maleic anhydride, 35g phenyl unsaturated ester, 45g deionized water are prepared into material A, 1.0g sodium hypophosphite, 0.4g vitamin C, 0.1g ferrous sulfate, 20g deionized water are prepared into Material B.

[0058] S3, take 2.0g of ammonium persulfate and 20g of deionized water and add and continuously feed N 2 In the reaction vessel, stir at room temperature until the mixture is uniform, as the base material.

[0059] S4. Control the temperature in the reaction vessel to 30°C, add m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com