High-water-reducing water reducing agent and preparation method thereof

A water-reducing type and water-reducing agent technology, applied in the field of concrete additives, can solve the problems of high mud content or powder content in sand and gravel, influence of water-reducing rate of water-reducing agent, uneven quality of sand and gravel, etc. Improve the water reduction rate, the water reduction effect is good, and the effect of improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

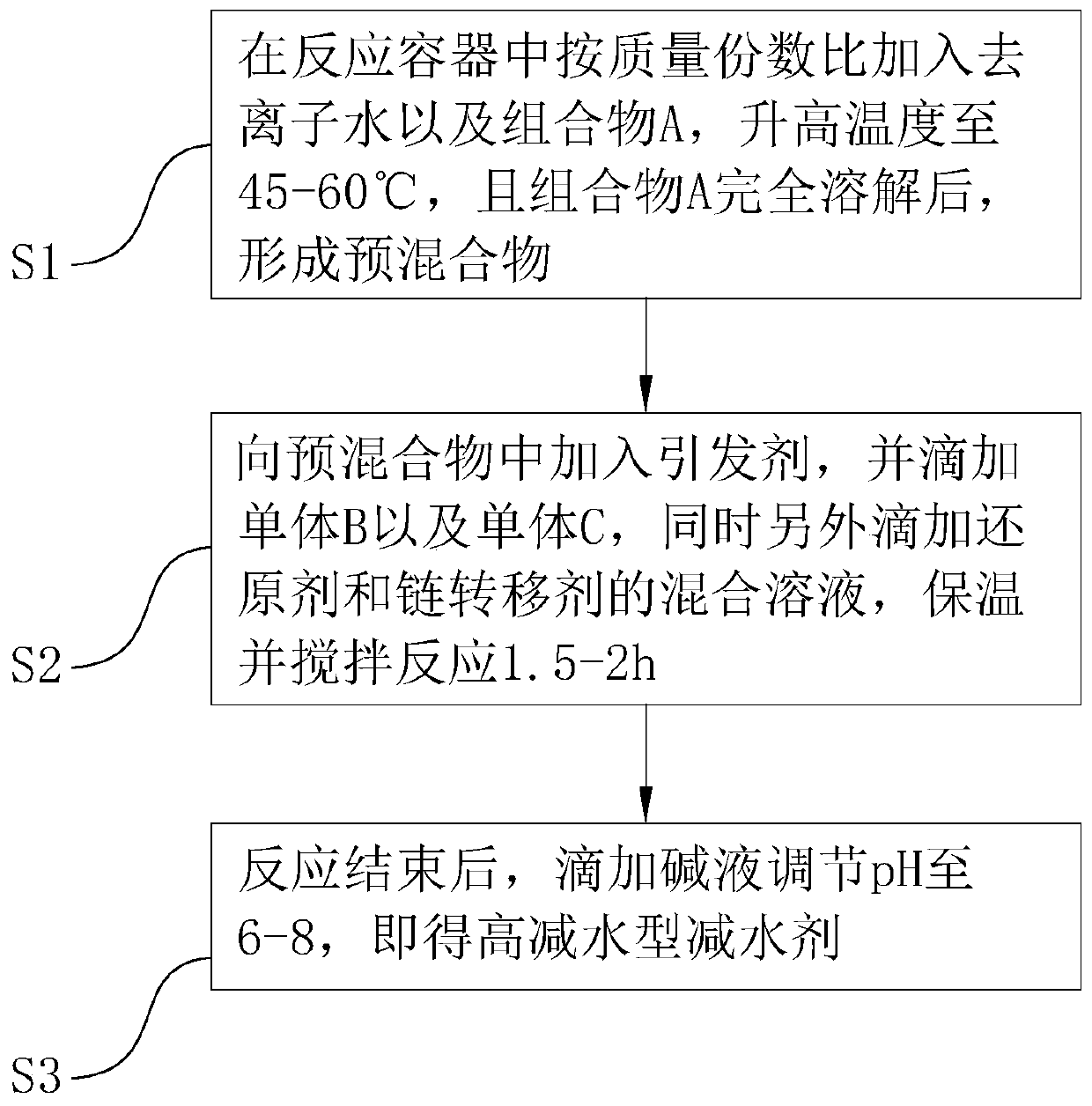

[0059] A preparation method of a high water reducing type water reducing agent, comprising the following steps:

[0060] S1. Add 3kg of deionized water and 35kg of composition A to a four-neck flask equipped with a stirrer and a thermometer, heat it in a water bath to 45°C, and stir until composition A is completely dissolved to form a premix.

[0061] S2. Keep the temperature in the four-necked flask at 45°C. First, mix and stir 3kg of reducing agent and 1kg of chain transfer agent evenly to form a mixed solution. Add 1kg of initiator to the premix while stirring, and then use a constant flow pump to control the flow rate. And sequentially add 10kg of monomer B and 15kg of monomer C dropwise, and at the same time, add dropwise the mixed solution formed by mixing the reducing agent and the chain transfer agent uniformly, so that the addition of monomer B, monomer C and the mixed solution is completed within 2 hours, and then continue Stir and insulate the reaction for 1.5h.

...

Embodiment 2

[0065] The difference with embodiment 1 is:

[0066] In step S1, the water bath is heated to 53°C.

[0067] In step S2, the temperature in the four-necked flask was kept constant at 53° C., and after adding monomer B, monomer C, reducing agent and the mixed solution, the reaction was stirred and kept for 1.8 h.

[0068] Adjust the pH to 7 in step S3.

[0069] Simultaneously, the consumption of each component of reaction is as follows:

[0070] 5kg of deionized water; 10kg of composition A; 2kg of initiator; 15kg of monomer B; 20kg of monomer C; 5kg of reducing agent; 2kg of chain transfer agent.

Embodiment 3

[0072] The difference with embodiment 1 is:

[0073] In step S1, the water bath is heated to 60°C.

[0074] In step S2, keep the temperature in the four-necked flask at 60° C., add monomer B, monomer C, reducing agent and the mixed solution, stir and keep warm for 2 hours.

[0075] Adjust the pH to 8 in step S3.

[0076] Simultaneously, the consumption of each component of reaction is as follows:

[0077] 4kg of deionized water; 22.5kg of composition A; 3kg of initiator; 12.5kg of monomer B; 17.5kg of monomer C; 4kg of reducing agent; 3kg of chain transfer agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com