Method for preparing m-dichlorobenzene by catalyzing isomerization of p-dichlorobenzene by using nano ZSM-12 molecular sieve

A ZSM-12, p-dichlorobenzene technology, applied in molecular sieve catalysts, chemical instruments and methods, preparation of halogenated hydrocarbons, etc., can solve the problem of inability to achieve continuous production process, carbon deposition inactivation m-dichlorobenzene selectivity, A large number of acidic wastewater and other problems, to achieve the effect of large-scale industrial production, strong anti-deactivation ability of carbon deposition, and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] Specific embodiment one: The method for preparing m-dichlorobenzene by catalyzing the isomerization of p-dichlorobenzene with nano ZSM-12 molecular sieve in this embodiment is as follows:

[0016] 1. Preparation of raw material liquid: mix p-dichlorobenzene and chlorobenzene evenly according to the mass ratio of 1: (3-8), to obtain the raw material liquid;

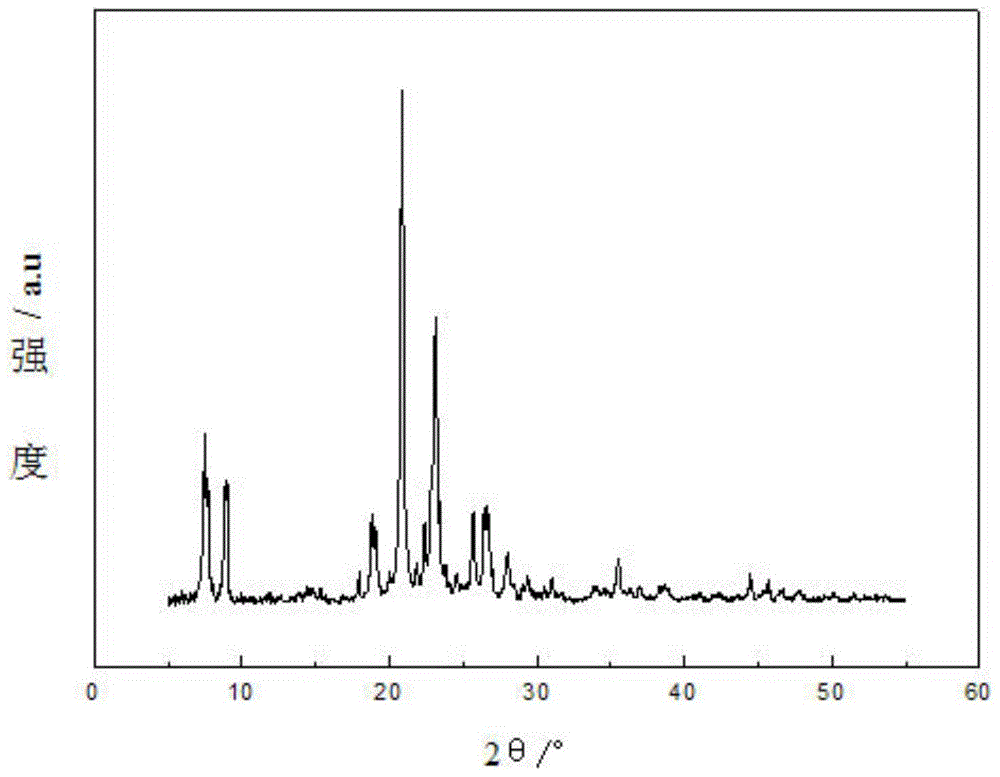

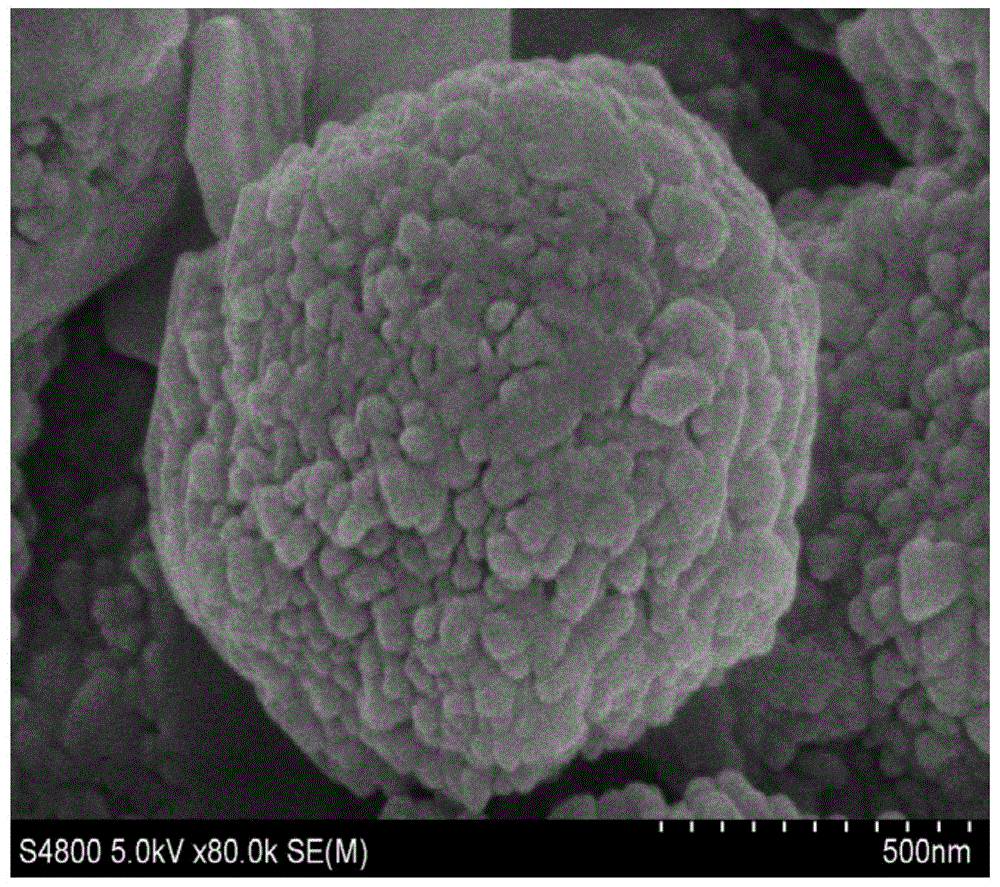

[0017] 2. Isomerization reaction: SiO with a molar ratio of (60-200): 1 2 with Al 2 o 3 , Nano ZSM-12 molecular sieves or ZSM-12 molecular sieves modified by alkali desiliconization are loaded into the constant temperature zone of the fixed bed reactor, and activated at a temperature of 500-550°C and a nitrogen flow rate of 20-80ml / min for 1~ 2h, inject the raw material solution prepared in step 1 into the fixed-bed reactor by continuous injection, and then inject it at a temperature of 400-550°C, a pressure of 0.5-5MPa, and a mass space velocity of 0.5-4.0h -1 1. Reaction under the condition that the flow rate o...

specific Embodiment approach 2

[0019] Embodiment 2: This embodiment differs from Embodiment 1 in that step 1 mixes p-dichlorobenzene and chlorobenzene uniformly at a mass ratio of 1:5. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

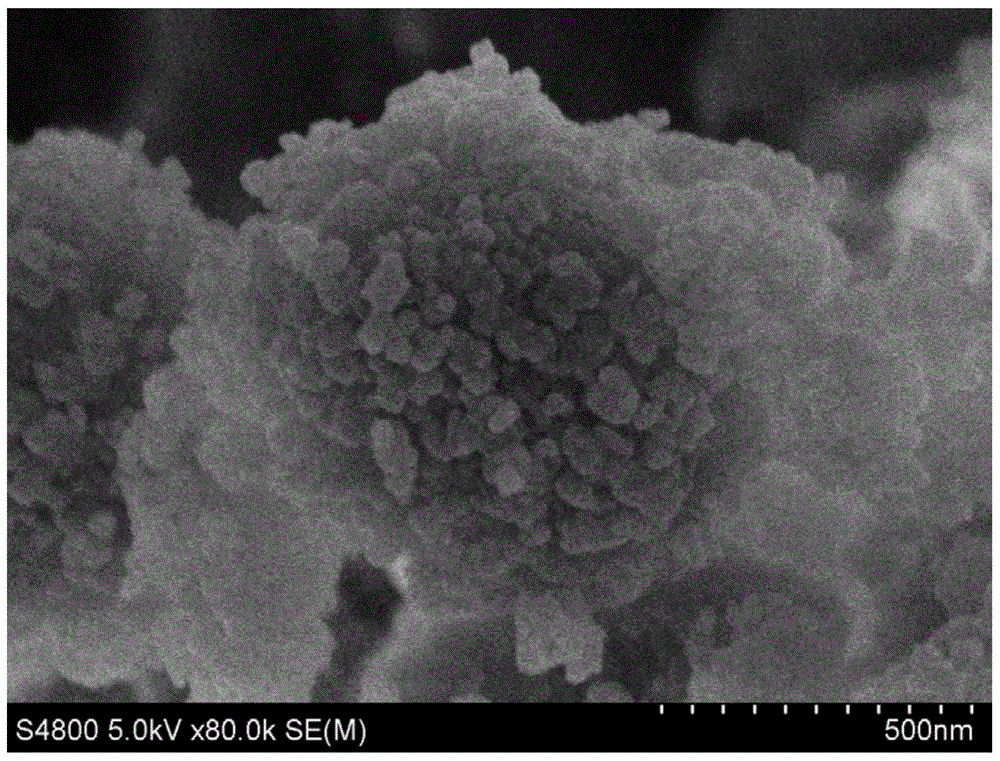

[0020] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the preparation method of the ZSM-12 molecular sieve modified by alkali desilication described in step 2 is as follows:

[0021] Mix nano ZSM-12 molecular sieves with NaOH solution with a concentration of 0.1-1.0 mol / L, and stir at 25°C-80°C for 1-10 hours, wash the collected solid phase with deionized water, dry it with 0.5mol / L L NH 4 NO 3 The aqueous solution is ion-exchanged, filtered, washed with deionized water, dried, and finally calcined to obtain the nanometer ZSM-12 molecular sieve modified by alkali desiliconization. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

[0022] In this embodiment, the nanometer ZSM-12 molecular sieve catalyst is modified by alkali treatment. The alkali treatment causes local defects and secondary mesopores in the molecular sieve lattice, which increases the mesopore volume and outer surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com