Method for preparing 2, 5-dichlorophenol through continuous oxidation of p-dichlorobenzene

A technology for p-dichlorobenzene and dichlorophenol, which is applied in the field of producing 2,5-dichlorophenol, can solve problems that have not yet been seen, and achieve the effects of avoiding the phenomenon of flying temperature, maintaining the reaction temperature, and reducing the generation of by-products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

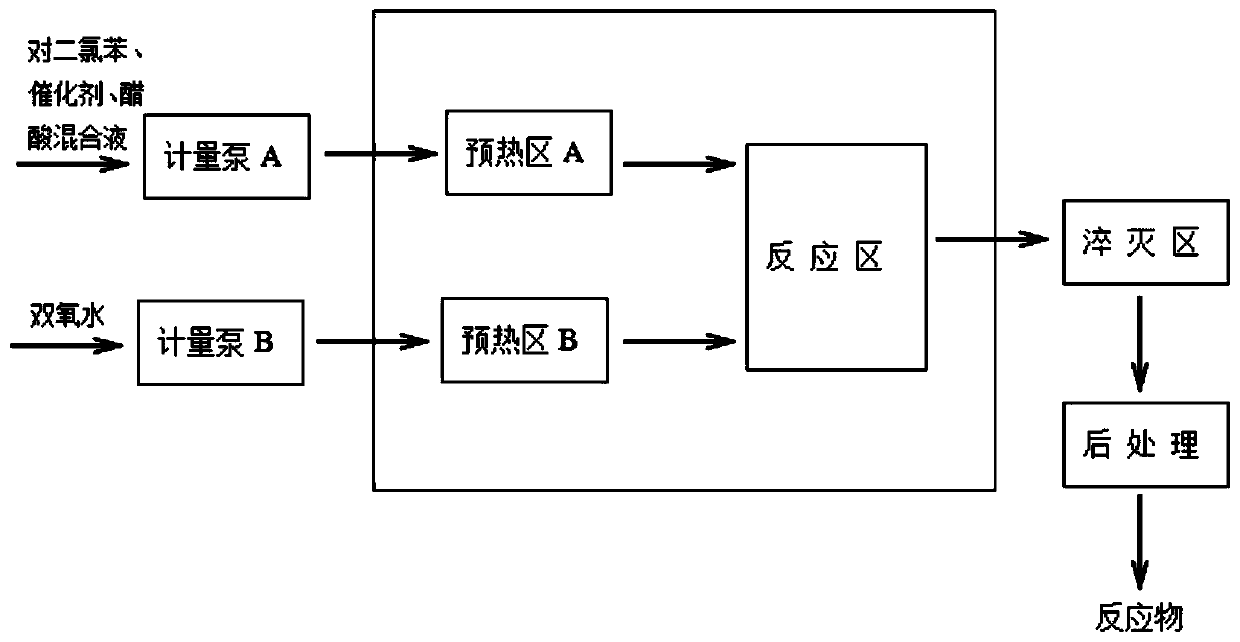

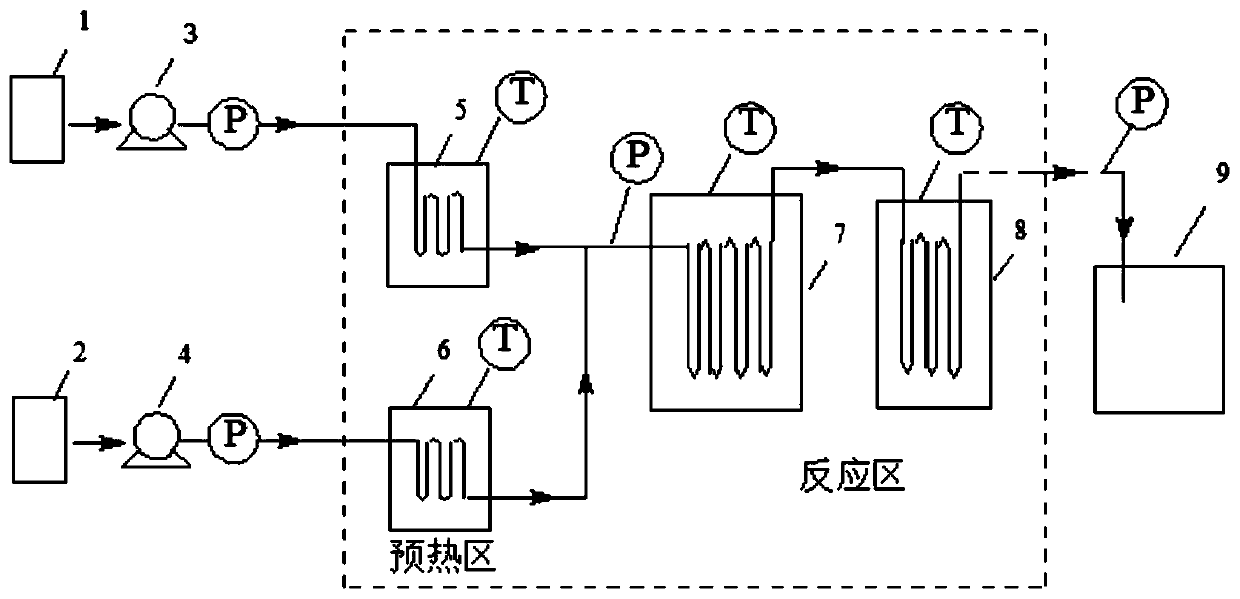

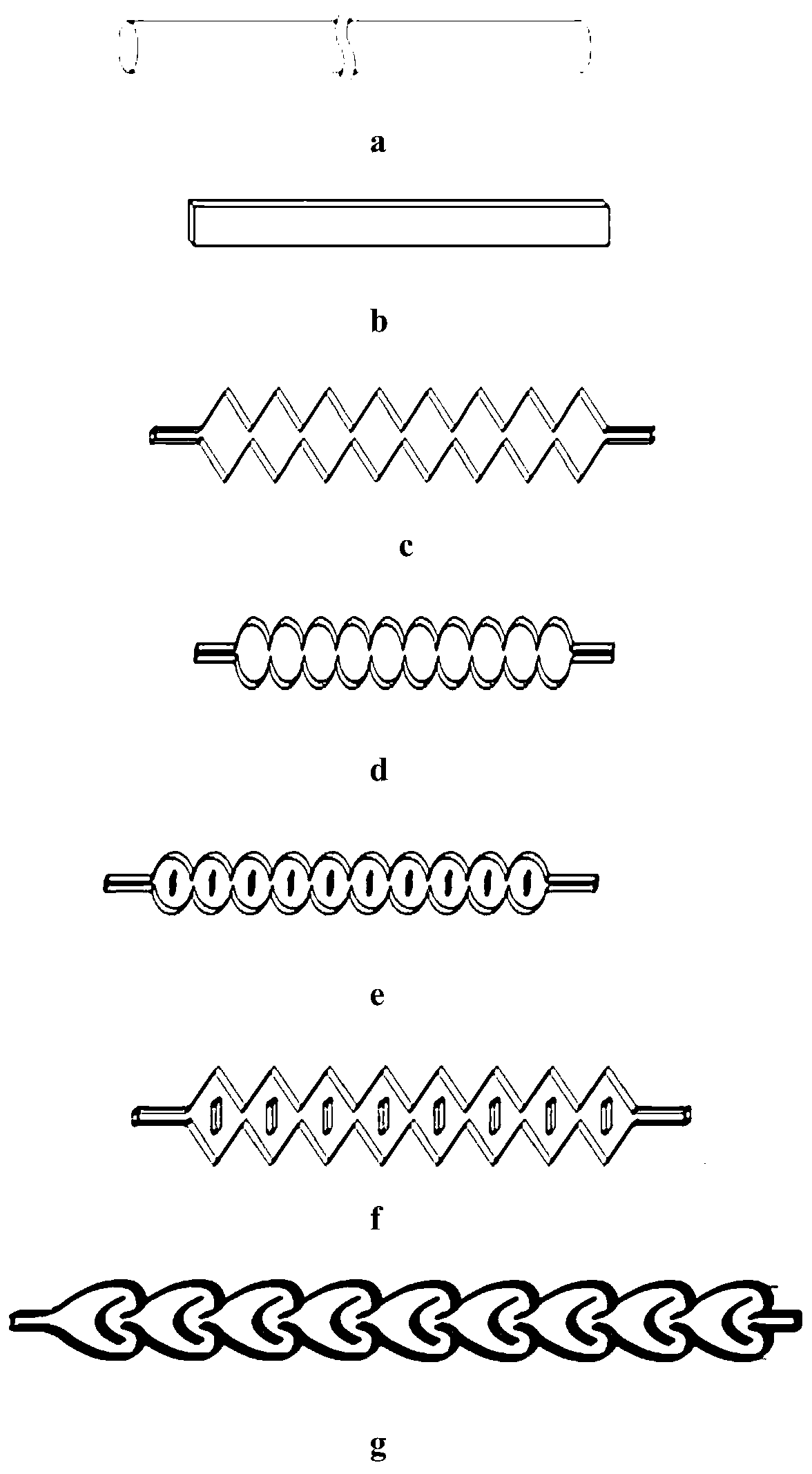

[0026] (1) Device: continuous flow microchannel reaction device (3a+3a), refer to figure 2 Determine the connection mode of the microchannel reactor, the length of the microchannel is determined according to the flow rate and the reaction residence time, and the heat transfer medium is heat transfer oil.

[0027] (2) Preparation of 2,5-dichlorophenol: adjust the microchannel reaction device to preheating zone, reaction zone and quenching zone according to the needs of the reaction process. By adjusting the flow rate of the pump and the channel length of the microchannel, the residence time of the reaction is controlled to be 60s, the preheating temperature and the reaction temperature are set to 50° C., and the reaction pressure is 5 bar. The mixed solution of the substrate p-dichlorobenzene, iron powder and acetic acid is passed through the preheating zone A of the metering pump 1 input device, and the hydrogen peroxide with a mass fraction of 10% is passed through the preheat...

Embodiment 2

[0029] (1) Device: continuous flow microchannel reaction device (3a+3b), refer to figure 2 Determine the connection mode of the microchannel reactor, the length of the microchannel is determined according to the flow rate and the reaction residence time, and the heat transfer medium is heat transfer oil.

[0030] (2) Preparation of 2,5-dichlorophenol: adjust the microchannel reaction device to preheating zone, reaction zone and quenching zone according to the needs of the reaction process. By adjusting the flow rate of the pump and the channel length of the microchannel, the residence time of the reaction is controlled to be 90s, the preheating temperature and the reaction temperature are set to 70° C., and the reaction pressure is 7 bar. The mixed solution of the substrate p-dichlorobenzene, ferric oxide and acetic acid is passed through the preheating zone A of the metering pump 1 input device, and the mass fraction is 20% hydrogen peroxide is passed through the preheating ...

Embodiment 3

[0032] (1) Device: continuous flow microchannel reaction device (3a+3c), refer to figure 2 Determine the connection mode of the microchannel reactor, the length of the microchannel is determined according to the flow rate and the reaction residence time, and the heat transfer medium is heat transfer oil.

[0033] (2) Preparation of 2,5-dichlorophenol: adjust the microchannel reaction device to preheating zone, reaction zone and quenching zone according to the needs of the reaction process. By adjusting the flow rate of the pump and the channel length of the microchannel, the residence time of the reaction is controlled to be 120s, the preheating temperature and the reaction temperature are set to 90° C., and the reaction pressure is 8 bar. The mixed solution of substrate p-dichlorobenzene, ferroferric oxide and acetonitrile is passed through the preheating zone A of the metering pump 1 input device, and the mass fraction is 30% hydrogen peroxide is passed through the preheati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com