Process for fractional crystallization of p-dichlorobenzene

A technology of p-dichlorobenzene and fractional crystallization, which is used in the preparation of halogenated hydrocarbons, chemical instruments and methods, organic chemistry, etc., can solve the problem of low product purity, improve processing capacity and product quality, ensure continuity and Stability, effect of reducing sublimation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable the public to fully understand the technical essence and beneficial effects of the present invention, the applicant will describe in detail the specific implementation of the present invention below in conjunction with the accompanying drawings, but the applicant's description of the embodiments is not a limitation to the technical solution. Changes in the form of the inventive concept rather than in substance should be regarded as the protection scope of the present invention.

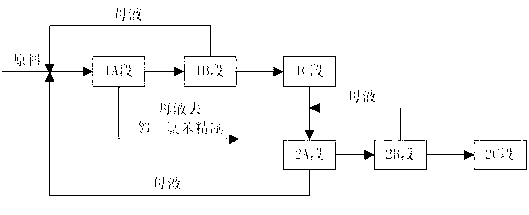

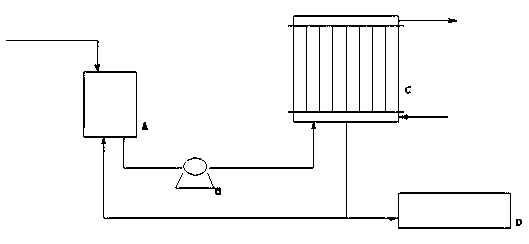

[0024] Such as figure 1 , 2 Shown: the present invention relates to a fractional crystallization process of p-dichlorobenzene, the raw materials are 80wt% p-dichlorobenzene, 18wt% ortho-dichlorobenzene, and the rest are low-boiling impurities, using two-stage six-stage melting crystallization Refining, adding the above-mentioned raw materials into the storage tank A, and sending the raw materials into the step-by-step crystallizer C by the pump A for the first-stage crystal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com