Dehydration process for polyphenyl thioether resin synthesis solvent system

A polyphenylene sulfide resin and solvent technology, which is applied in the field of resin synthesis of polymer materials, can solve the problems of large initial investment, large recovery loss, and long recovery cycle, and achieve the goals of increasing reaction speed, saving costs, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

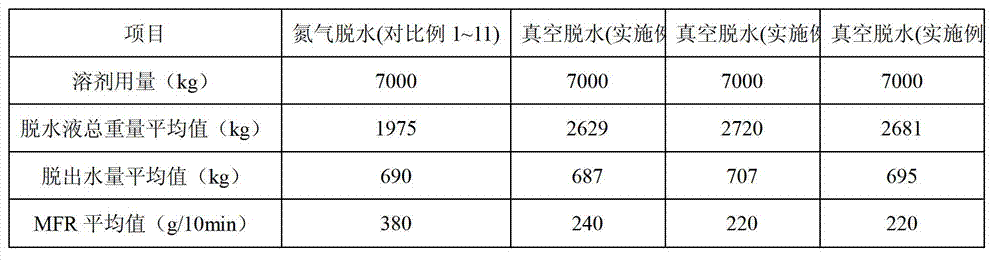

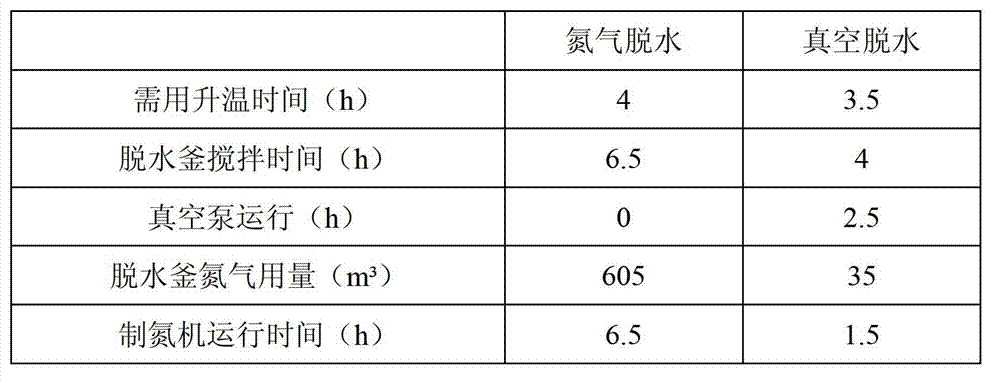

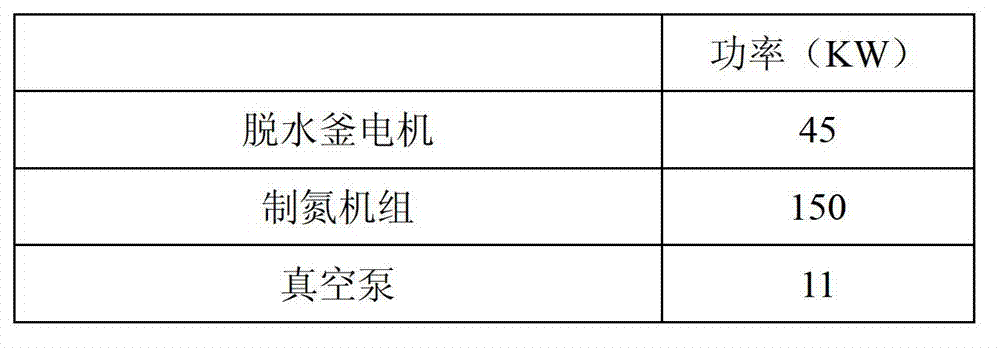

Embodiment 1~4

[0028] In the sodium sulfide dehydration treatment stage, in order to make the raw material Na in the solvent system 2 S:NMP:NaOH:H 2 The mol ratio between O is 1.0: 3.9: 0.02, is that the Na in the formula is ≥ 66.0%wt purity 2 S. 3 h 2 O solid excess 1% is added in common reactor, under the pressure is -0.9Mpa, is heated to 80 ℃, makes Na 2 After the S is fully dissolved, adjust the vacuum degree to 0.75Mpa and then raise the temperature to 150°C, keep the temperature, the pressure is -0.75Mpa, and the stirring speed is 300rpm; dehydration treatment until the water content in the sodium sulfide solution is 1.0mol / molNa 2 After S, after using a quick moisture analyzer to detect the moisture content therein, Na 2S: p-dichlorobenzene (p-DCB) molar ratio of 1:1.5 is added to p-dichlorobenzene for temperature rise polymerization to complete the polymerization reaction of polyphenylene sulfide; the amount of nitrogen and energy consumption in this dehydration process are onl...

example 5~8

[0030] In the sodium sulfide dehydration treatment stage, in order to make the raw material Na in the solvent system 2 S:NMP:NaOH:H 2 The molar ratio between O is 1.0: 3.9: 0.02: 1.5, is that the Na in the formula is ≥ 66.0%wt with purity 2 S. 3 h 2 O solid excess 1% is added in common reactor, under the pressure is -0.92Mpa, is heated to 80 ℃, makes Na 2 After S is fully dissolved, adjust the vacuum degree to -0.73Mpa and then raise the temperature to 150°C, keep the temperature, pressure at -0.73Mpa, stirring speed at 300rpm; dehydration treatment until the water content in the sodium sulfide solution is 1.0mol / molNa 2 After S, after using a quick moisture analyzer to detect the moisture content therein, Na 2 S: p-dichlorobenzene (p-DCB) molar ratio of 1:0.98 is added to p-dichlorobenzene for temperature-rising polymerization to complete the polymerization of polyphenylene sulfide; the amount of nitrogen and energy consumption in this dehydration process are only nitro...

example 8~11

[0032] In the sodium sulfide dehydration treatment stage, in order to make the raw material Na in the solvent system 2 S:NMP:NaOH:H 2 The molar ratio between O is 1.0: 3.9: 0.02: 1.5, is that the Na in the formula is ≥ 66.0%wt with purity 2 S. 3 h 2 O solid excess 1% is added in the common reactor, under pressure is 0.97Mpa, is heated to 80 ℃, makes Na 2 After S is fully dissolved, adjust the vacuum degree to -0.72Mpa and then raise the temperature to 150°C, keep the temperature, pressure at -0.72Mpa, stirring speed at 300rpm; dehydration treatment until the water content in the sodium sulfide solution is 1.0mol / molNa 2 After S, after using a quick moisture analyzer to detect the moisture content therein, Na 2 S: p-dichlorobenzene (p-DCB) with a molar ratio of 1:1.05 is added to p-dichlorobenzene for temperature-rising polymerization to complete the polymerization of polyphenylene sulfide; the amount of nitrogen and energy consumption in this dehydration process are only...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com