Fall resistant and antibacterial PP plastic meal box and preparation method thereof

A technology for plastics and lunch boxes, applied in the field of plastic products, can solve the problems of low impact strength and tensile strength, insufficient rigidity, easy aging, etc., and achieve the effects of strong impact resistance, improved heat resistance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

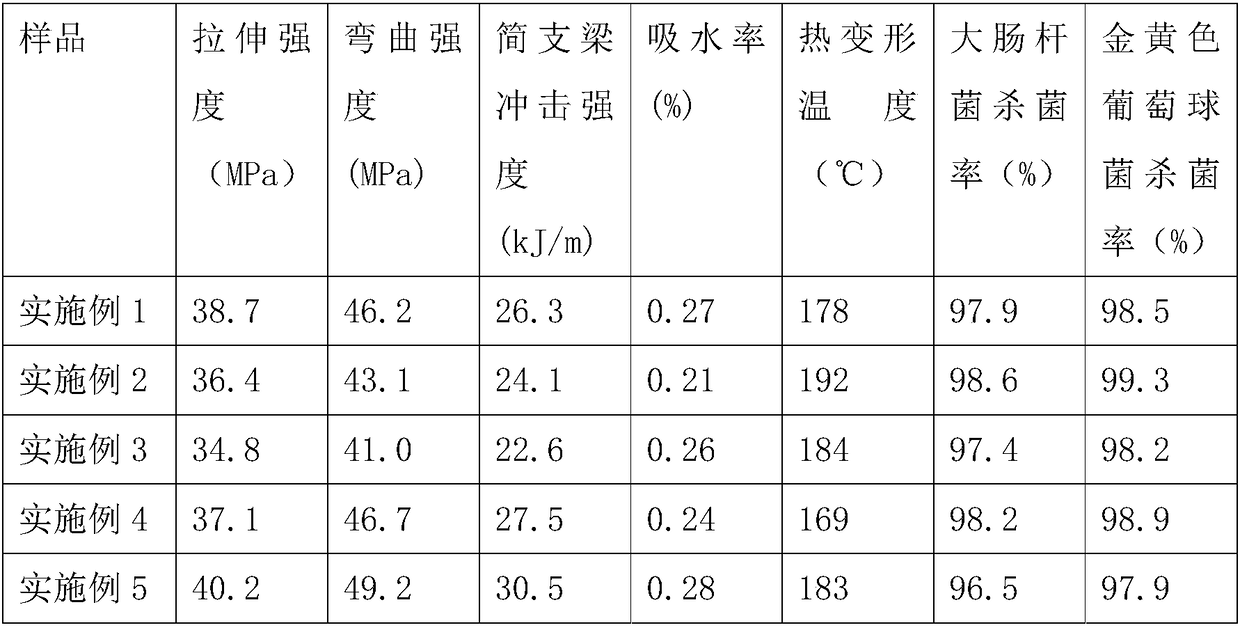

Examples

Embodiment 1

[0026] A drop-resistant and antibacterial PP plastic lunch box, comprising the following raw materials in parts by weight: 100 parts of PP resin, 80 parts of bagasse, 7 parts of chitosan, 12 parts of shell powder, 15 parts of nano-calcium carbonate, and 5 parts of sepiolite fiber 1.5 parts of phytic acid, 2 parts of modifier, 1 part of coupling agent, 1.5 parts of plasticizer, 0.5 parts of CA antioxidant, 1 part of compound antibacterial agent, 2 parts of cocamidopropyl betaine and carboxymethyl 3 parts of cellulose; the modifying agent is composed of octaaminophenyl clathrate silsesquioxane and polyethylene glycol stearate at a ratio of 1:1.

[0027] The coupling agent is composed of rapeseed fatty acid alkanolamide borate and polyglycerol-10 polyricinoleate in a mass ratio of 1:1.

[0028] The composite antibacterial agent is composed of lanthanum oxide and silver oxide with a mass ratio of 1:2.

[0029] The plasticizer is composed of coconut acid diethanolamide and polyeth...

Embodiment 2

[0036] A drop-resistant and antibacterial PP plastic lunch box, comprising the following raw materials in parts by weight: 100 parts of PP resin, 100 parts of bagasse, 8 parts of chitosan, 10 parts of shell powder, 20 parts of nano-calcium carbonate, and 4 parts of sepiolite fiber 2 parts, 2 parts of phytic acid, 2.5 parts of modifier, 1.5 parts of coupling agent, 2 parts of plasticizer, 1 part of 1010 antioxidant, 2 parts of compound antibacterial agent, 1.5 parts of cocamidopropyl betaine and carboxymethyl 5 parts of cellulose; the modifying agent is composed of octaaminophenyl clathrate silsesquioxane and polyethylene glycol stearate at a ratio of 1:1.5.

[0037] The coupling agent is composed of rapeseed fatty acid alkanolamide borate and polyglycerol-10 polyricinoleate in a mass ratio of 1:2.

[0038] The composite antibacterial agent is composed of lanthanum oxide and silver oxide with a mass ratio of 1:3.

[0039] The plasticizer is composed of coconut acid diethanolam...

Embodiment 3

[0046] A drop-resistant and antibacterial PP plastic lunch box, comprising the following raw materials in parts by weight: 100 parts of PP resin, 60 parts of bagasse, 7 parts of chitosan, 15 parts of shell powder, 12 parts of nano-calcium carbonate, and 5 parts of sepiolite fiber 1 part, 1 part of phytic acid, 1 part of modifier, 1 part of coupling agent, 1.5 parts of plasticizer, 0.5 part of 1076 antioxidant, 1 part of compound antibacterial agent, 3 parts of cocamidopropyl betaine and carboxymethyl 3 parts of cellulose; the modifying agent is composed of octaaminophenyl clathrate silsesquioxane and polyethylene glycol stearate at a ratio of 1:3.

[0047] The coupling agent is composed of rapeseed fatty acid alkanolamide borate and polyglycerol-10 polyricinoleate in a mass ratio of 1:1.

[0048] The composite antibacterial agent is composed of lanthanum oxide and silver oxide with a mass ratio of 1:2.

[0049] The plasticizer is composed of coconut acid diethanolamide and poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com