Preparation method of high-cracking resistance rock wool board

A technology of rock wool board and high crack resistance, which is applied in the field of preparation of high crack resistance rock wool board, which can solve problems such as weak bonding of walls, endangering personal safety, loose tissue structure, etc., and achieves increased hardness and improved bonding Strength, the effect of improving the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

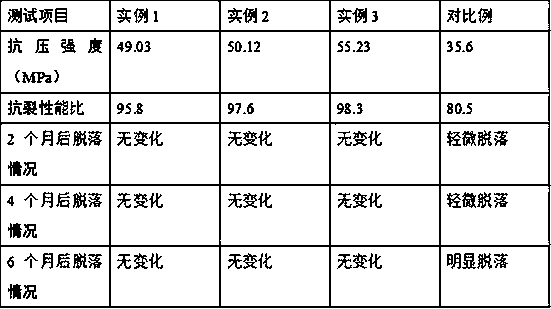

Examples

example 1

[0023]Weigh 0.4kg of basalt, grind and pulverize it for 8 minutes, pass it through a 100-mesh sieve, collect the sieved powder, put the sieved powder into a muffle furnace, melt it at a temperature of 1450°C for 16 minutes, pour it into a wire drawing bushing for wire drawing, and obtain Self-made basalt fiber, basalt fiber and silane coupling agent KH-560 were mixed and stirred for 20 minutes according to the mass ratio of 3:1 to obtain modified self-made basalt fiber; polystyrene resin and sodium silicate were mixed according to the mass ratio of 3:1 Put it in a foaming machine, foam and soften at a temperature of 160°C for 10 minutes, wait until no gas escapes, grind and discharge the material to obtain foamed polystyrene particles; weigh 10 parts of cyanoacrylate and put them in Put it into a mixer with 20 parts of deionized water and dilute it for 10 minutes, then add 20 parts of expanded polystyrene particles, 6 parts of ash calcium powder and 5 parts of silane coupling a...

example 2

[0025] Weigh 0.5kg of basalt, grind and pulverize it for 9 minutes, pass it through a 100-mesh sieve, collect the sieved powder, put the sifted powder into a muffle furnace, melt it at a temperature of 1500°C for 18 minutes, pour it into a wire drawing bushing for wire drawing, and obtain Self-made basalt fiber, basalt fiber and silane coupling agent KH-560 were mixed and stirred for 25 minutes according to the mass ratio of 3:1 to obtain modified self-made basalt fiber; according to the mass ratio of 3:1, polystyrene resin and sodium silicate were mixed Put it in a foaming machine, foam and soften at a temperature of 170°C for 11 minutes, wait until no gas escapes, grind and discharge the material to obtain foamed polystyrene particles; weigh 11 parts of cyanoacrylate and put them in Put it into a mixer with 25 parts of deionized water to dilute for 11 minutes, then add 25 parts of expanded polystyrene particles, 7 parts of ash calcium powder and 6 parts of silane coupling age...

example 3

[0027] Weigh 0.6 kg of basalt, grind and pulverize it for 10 minutes, pass through a 100-mesh sieve, collect the sieved powder, put the sieved powder into a muffle furnace, melt it at a temperature of 1550 ° C for 20 minutes, pour it into a wire drawing bushing for wire drawing, and obtain Self-made basalt fiber, basalt fiber and silane coupling agent KH-560 were mixed and stirred for 30 minutes according to the mass ratio of 3:1 to obtain modified self-made basalt fiber; according to the mass ratio of 3:1, polystyrene resin and sodium silicate were mixed Put it in a foaming machine, foam and soften at a temperature of 180°C for 12 minutes, wait until no gas escapes, grind and discharge the material to obtain foamed polystyrene particles; weigh 12 parts of cyanoacrylate and put them in Put it into a blender with 30 parts of deionized water to dilute for 12 minutes, then add 30 parts of expanded polystyrene particles, 8 parts of ash calcium powder and 7 parts of silane coupling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com