Patents

Literature

35results about How to "Change interface state" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mechanical equipment cleaning liquid

InactiveCN102618396AEasy to cleanImprove safety and environmental protectionNon-ionic surface-active compoundsDetergent compounding agentsHazardous substanceMechanical equipment

The invention discloses a mechanical equipment cleaning liquid, which consists of monohydric alcohol, glycol, complexing agent, anionic surfactant, nonionic surfactant, compound corrosion inhibitor, coloring agent and water. The mechanical equipment cleaning liquid is prepared by using environmental-friendly substances, is a universal cleaning fluid for mechanical equipment maintenance and repair, does not have inflammables and explosive characteristics during use, does not cause higher adverse influences on a working environment, does not contain environmentally hazardous substances such as nitrite, phenol and formaldehyde, is nonflammable, is nontoxic to operators and has a better effect of cleaning inorganic fouling such as asphalt, better safety and environmental friendliness are realized, the processing environment and sanitary conditions can be improved, the working efficiency can be improved and the cost can be reduced.

Owner:苏州安美润滑科技有限公司

Anti-water blocking agent for drilling fluid

InactiveCN103045182AReduce surface tensionReduce interfacial tensionDrilling compositionInorganic saltsRock core

The invention discloses an anti-water blocking agent for drilling fluid. The anti-water blocking agent is formed by mixing the following components: at least one main surfactant capable of reducing surface tension of a solution, at least one auxiliary surfactant capable of improving the drainage assisting capability and minimizing the water saturation of a rock core, inorganic salts, and the balance of water. The anti-water blocking agent disclosed by the invention can be used for greatly reducing the surface tension or interfacial tension of the solution, changing the interface state of a solution system, producing a wetting or anti-wetting effect, improving the relative permeability of a gas phase and enabling the injection process to overcome water blocking damages.

Owner:东营利丰化工新材料有限公司

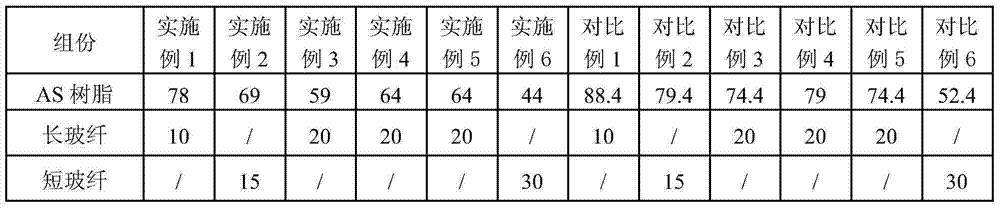

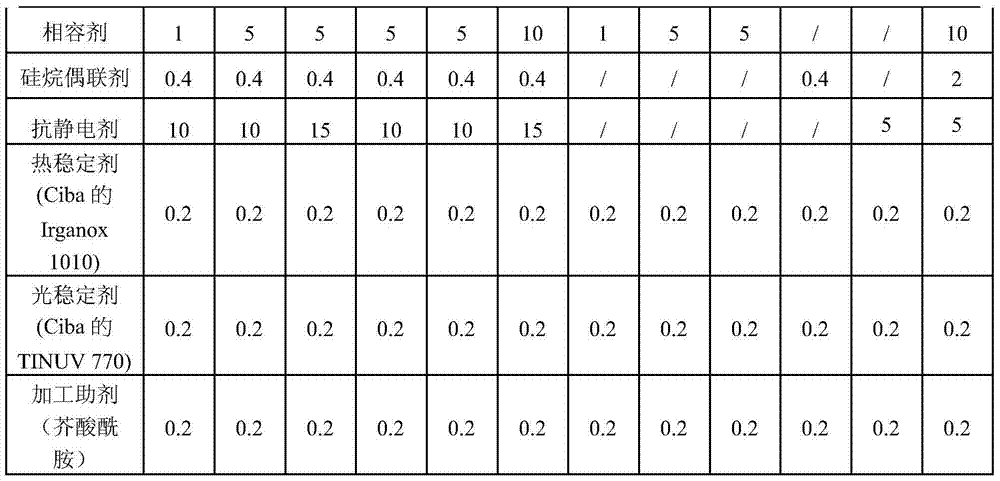

High-performance, anti-static and anti-bacterial glass fiber reinforced AS (acrylonitrile-styrene) composite material and preparation method thereof

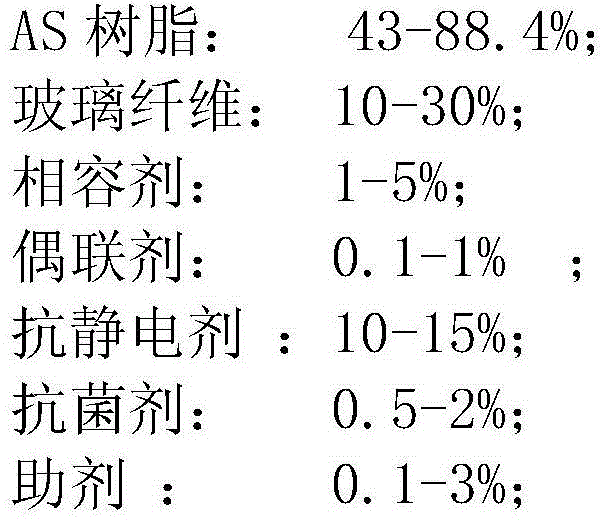

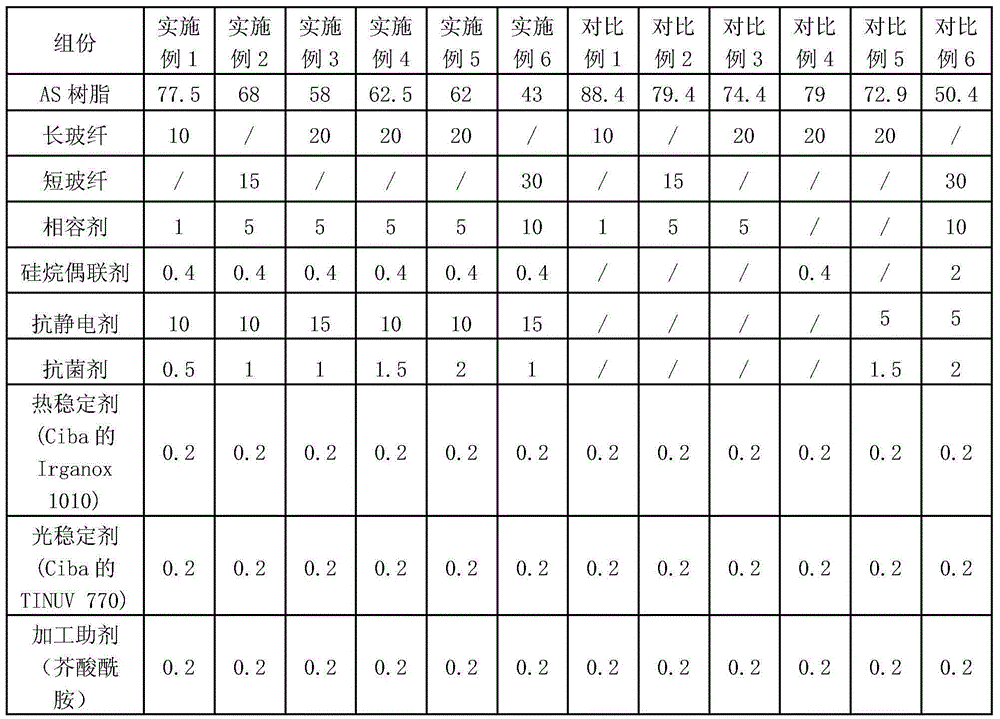

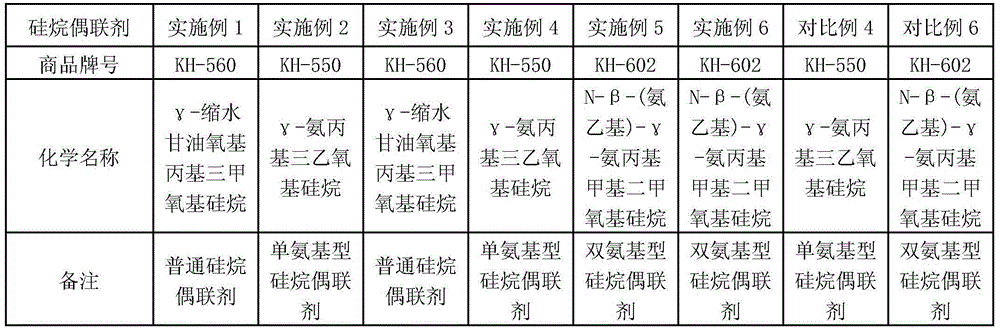

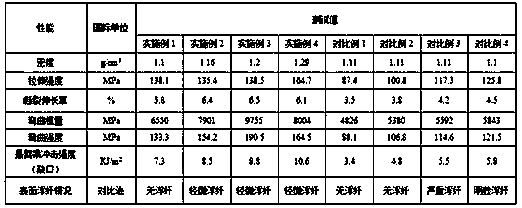

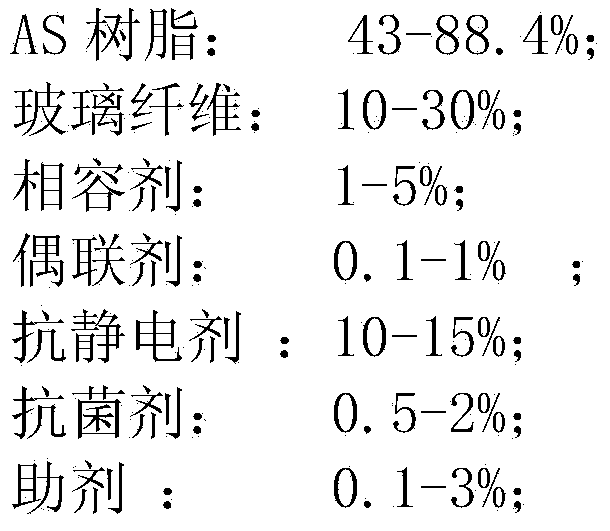

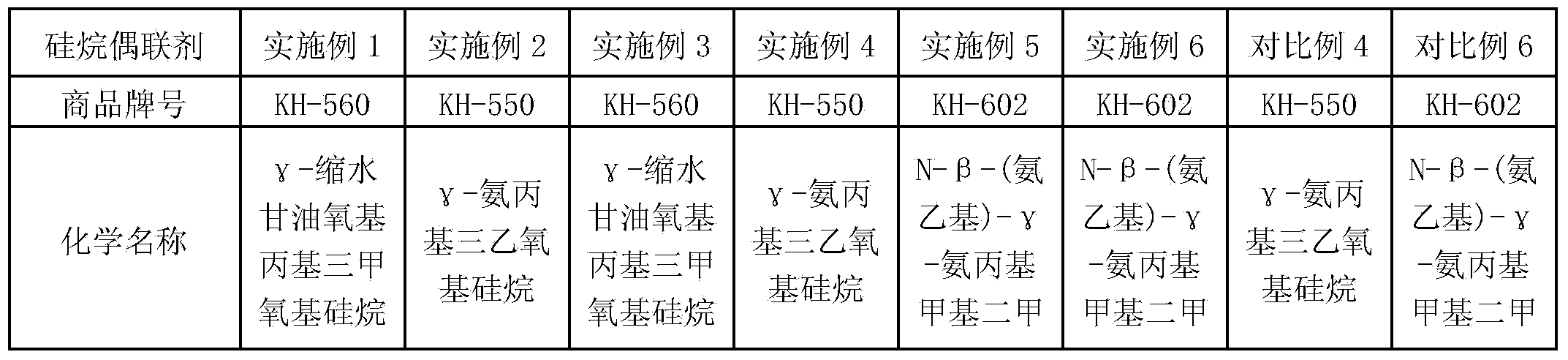

The invention provides a high-performance, anti-static and anti-bacterial glass fiber reinforced AS (acrylonitrile-styrene) composite material and a preparation method thereof. The high-performance, anti-static and anti-bacterial glass fiber reinforced AS composite material comprises components in percentage by weight as follows: 43%-88.4% of AS resin, 10%-30% of glass fiber, 1%-5% of a compatilizer, 0.1%-1% of a coupling agent, 10%-15% of an anti-static agent, 0.5%-2% of an anti-bacterial agent and 0.1%-3% of an assistant, wherein the compatilizer adopts PMMA (polymethyl methacrylate), and the coupling agent adopts a silane coupling agent. The substrate of the composite material is AS resin, and the composite material has the advantages of excellent performance, low cost, simple preparation technology and the like; and besides, PMMA is taken as the compatilizer, so that not only is bonding force between the glass fiber and the AS resin strengthened, but also the PMMA is also suitable for enhancing a fiber and resin composite material system with the similar property.

Owner:TIANJIN KINGFA NEW MATERIAL

Low-floating fiber glass fiber reinforced AS (Acrylonitrile Styrene) composition as well as preparation method and application thereof

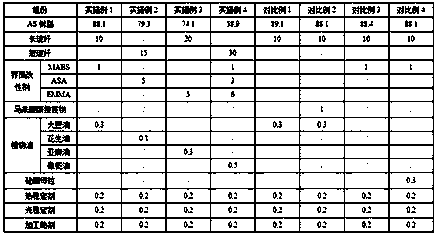

The invention relates to a low-floating fiber glass fiber reinforced AS (Acrylonitrile Styrene) composition as well as a preparation method and application thereof. The low-floating fiber glass fiberreinforced AS composition comprises the following components in percentage by mass: 57.4-88.4% of an acrylonitrile-styrene resin, 10-30% of a glass fiber, 1-10% of an interface modifier, 0.1-0.5% of plant oil and 0.1-3% of aids, wherein the interface modifier is one or more of MABS (Methyl Methacrylate Acrylonitrile Butadiene Styrene), an ASA (Acrylonitrile Styrene Acrylate Copolymer) or EMMA (Ethylene Methyl Methacrylate). With the combination of the interface modifier, the plant oil, the glass fiber, the AS resin and other components, the glass fiber reinforced AS composition is good in processing property, size stability and mechanical property, and in addition a product prepared from the AS composition as a raw material is remarkably improved in fiber floating phenomenon and can be widely applied to the field of household electric appliances.

Owner:WUHAN JINFA TECH CO LTD +1

Waterproof and moisture-permeable polyurethane and preparation method and application thereof

InactiveCN111848911AGood waterproof and moisture permeabilityChange interface statePolyurea/polyurethane coatingsLeather surface finishingPolymer scienceOrganometallic catalysis

The invention provides waterproof and moisture-permeable type polyurethane, which is prepared from the following raw materials in parts by mass: 110 to 150 parts of polyhydric alcohol, 45 to 60 partsof diisocyanate, 10 to 15 parts of fluorine-containing dihydric alcohol, 3 to 8 parts of fluorine-containing monohydric alcohol, 0.1 to 0.3 part of an organic metal catalyst, 7 to 10 parts of a hydrophilic chain extender, 5 to 8 parts of a neutralizer, 3 to 5 parts of a post-chain extender and 500 to 700 parts of water. According to the invention, polyhydric alcohol and diisocyanate are taken as main bodies, fluorine-containing dihydric alcohol is utilized to change the interface state of the material and improve the water resistance and moisture permeability, fluorine-containing monohydric alcohol is utilized to play a waterproof role in chain segments, and under the combined action of auxiliaries such as an organic metal catalyst, a hydrophilic chain extender and the like, the water resistance and moisture permeability are further improved. The embodiment shows that the polyurethane disclosed by the invention has the water pressure resistance of 78-88 KPa, the moisture permeability of 6.8-8.2 kg / m <2> / d and the air permeability of 5.7-6.3 mm / s.

Owner:QI HE LI HOU CHEM CO LTD

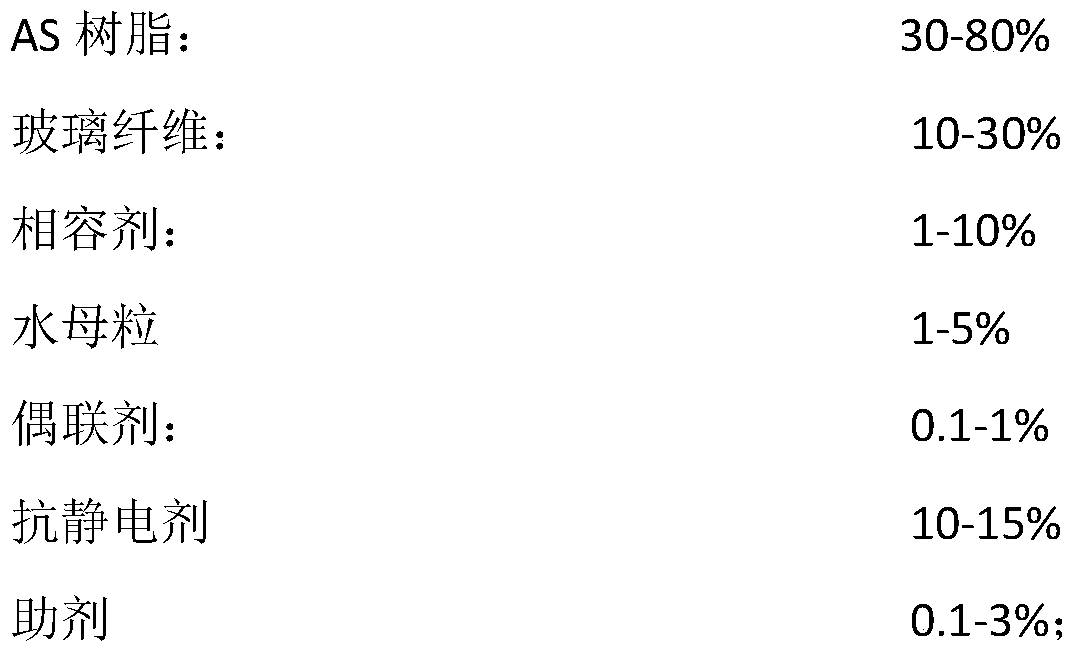

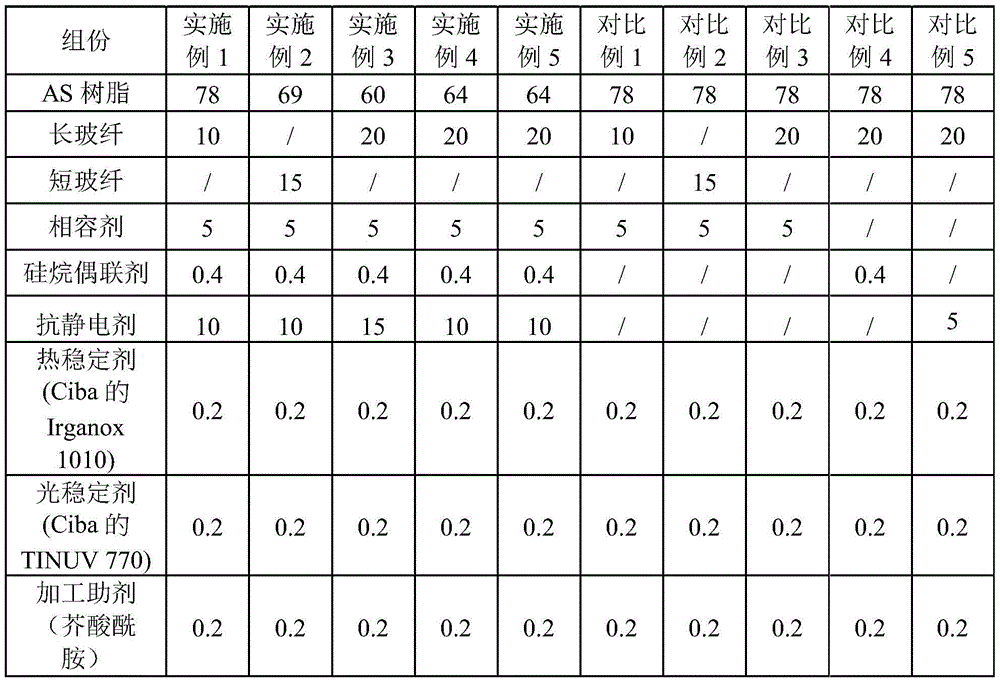

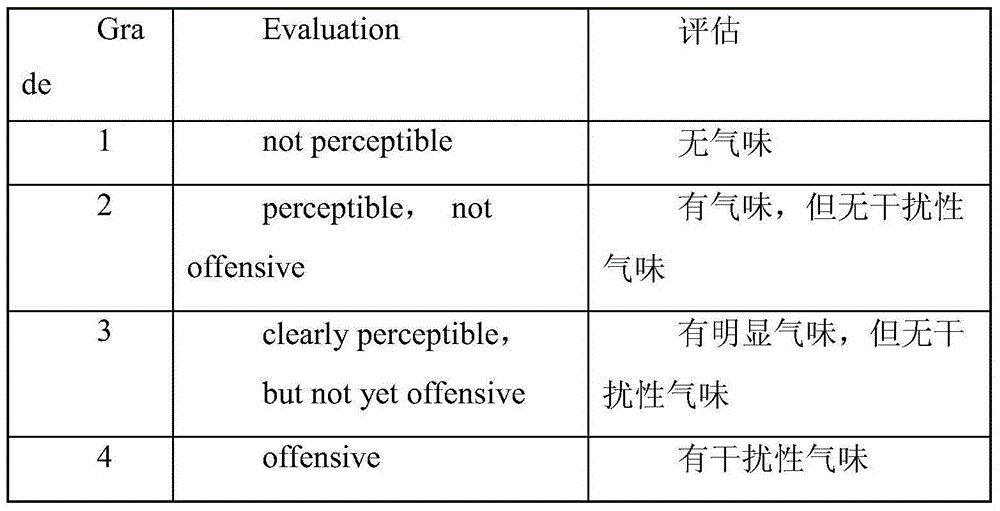

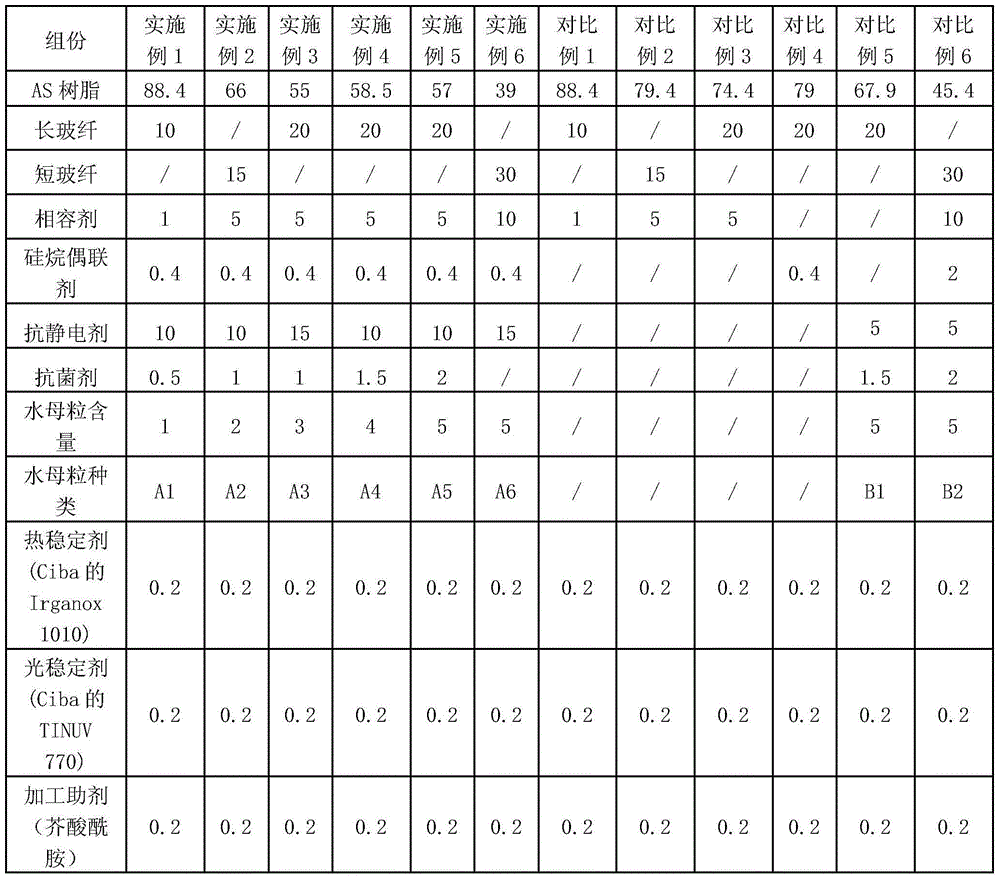

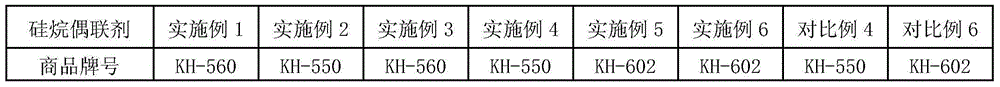

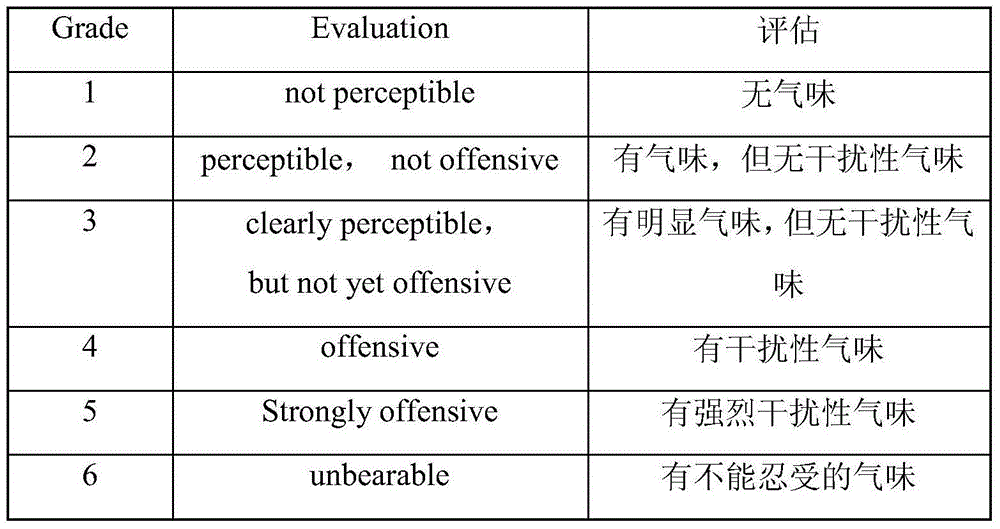

Low-odor antistatic high-performance glass fiber reinforced AS composition and preparation method thereof

InactiveCN105524367AEfficient removalDoes not affect mechanical propertiesGlass fiberAntistatic agent

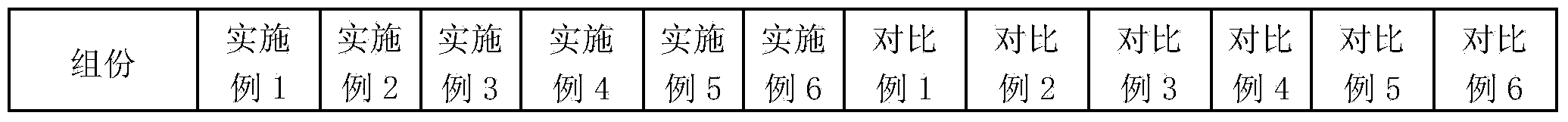

The invention relates to a low-odor antistatic high-performance glass fiber reinforced AS composition, which contains, by weight, 30-80% of AS resin, 10-30% of glass fiber, 1-10% of a compatilizer, 1-5% of jellyfish granules, 0.1-1% of a coupling agent, 10-15% of an antistatic agent and 0.1-3% of an auxiliary agent. The total percentage of the above components is 100%. The antistatic agent is a permanent antistatic agent and contains molecular distilled glycerin monostearate component, which is specifically hardened palm glyceride. The jellyfish granules used in the invention are easily available, has advantages of simple preparation technology and low cost, can effectively remove odor and will not influence mechanical property of the composition. By adding the antistatic agent, surface resistivity of the AS composition can be reduced from 1016 Omega to 109 Omega, and the antistatic effect is good.

Owner:TIANJIN KINGFA NEW MATERIAL

Anti-static glass fiber reinforced AS composition and preparation method thereof

The invention provides an anti-static glass fiber reinforced AS composition and a preparation method thereof. The anti-static glass fiber reinforced AS composition comprises, by weight parts, 44-78 parts of AS resin, 10-20 parts of glass fiber, 5-10 parts of compatilizer, 0.1-1 part of coupling agent, 10-15 parts of anti-static agent and 0.1-1 part of auxiliaries. The AS resin is a copolymer of acrylonitrile and styrene, and the glass fiber is one or two or more of long glass fiber and chopped glass fiber. According to the anti-static glass fiber reinforced AS composition, acrylate polymer or copolymer is used to serve as the compatilizer, so that the interface state between the glass fiber and the resin can be effectively changed, the interfacial binding power is improved, and thus the performance of a composite material is improved.

Owner:TIANJIN KINGFA NEW MATERIAL

Preparation method of high-cracking resistance rock wool board

InactiveCN108117364AImprove crack resistanceHigh bonding strengthCrack resistancePolyethylene glycol

The invention discloses a preparation method of a high-cracking resistance rock wool board, belonging to the technical field of preparation of rock wool boards. According to the preparation method, the rock wool board with high cracking resistance and bonding strength is prepared by taking basalt fibers as a main material and rubber powder polyphenyl particles, glass melting liquid, quartz sand and the like as reinforcing filling materials, and the main material and the reinforcing filling materials are firmly connected together, so that the bonding strength of the rock wool board is effectively improved; polystyrene is foamed by virtue of a foaming agent to form a hard hole-closed structure, and formed polystyrene particles are dually modified by virtue of a bonding agent and a silane coupling agent, so that the bonding strength of the rock wool board is improved; the glass melting liquid is modified by virtue of polyethylene glycol stearate, so that the expansion of cracks can be inhibited, the mechanical property of the rock wool board can be improved; and after glass fibers are modified, the contact areas with the basalt fibers are increased by virtue of rough surface structures, the bonding strength of an interface can be substantially enhanced, the cracking resistance and bonding strength of the rock wool board are further improved; and the preparation method has wide application prospects.

Owner:常州富思通管道有限公司

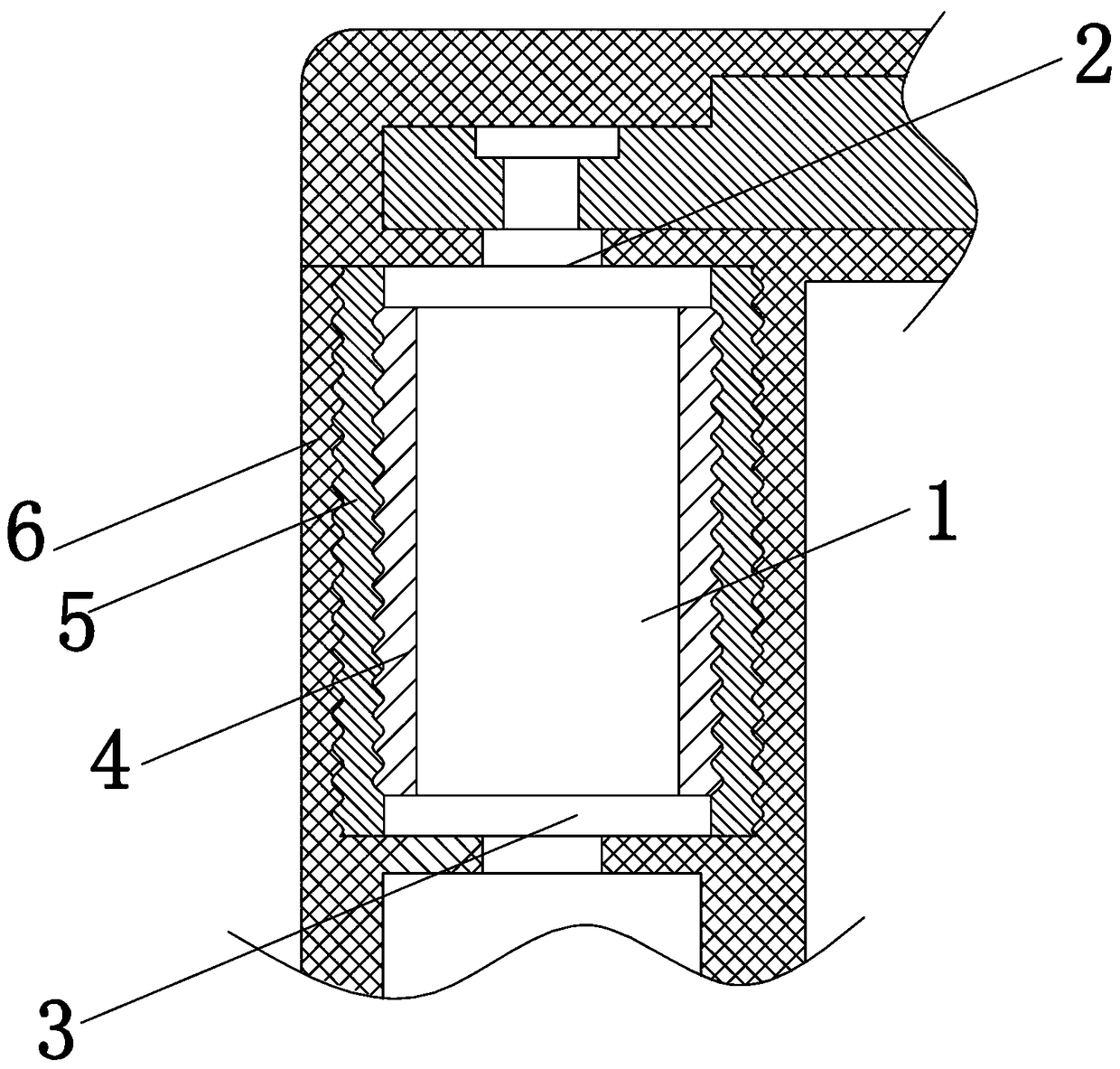

Composite insulated solid-sealed pole and production method thereof

InactiveCN108648954AImprove the level of external insulationImprove interface stateHigh-tension/heavy-dress switchesAir-break switchesEpoxySilicone Gels

The invention discloses a composite insulated solid-sealed pole, comprising a vacuum interrupter. A static end cover plate and a movable end cover plate are arranged at the two ends of the vacuum interrupter, a ceramics insulating layer is arranged on the surface of the vacuum interrupter, the outer side of the ceramic insulating layer is coated with a silica gel layer, and the outer side of the silica gel layer is coated with epoxy resin, wherein the contact interface between the ceramic insulating layer and the silica gel layer is an annular corrugated surface, and the contact interface of the silicone gel layer and the epoxy resin is also an annular corrugated surface. According to the composite insulated solid-sealed pole obtained by the invention, the buffering effect of the silica gel layer of the vacuum interrupter is improved, no air bubble is caused, and the external insulation level of the vacuum interrupter can be obviously improved, The distance between the static end coverplate and the movable end cover plate of the vacuum interrupter is increased by about 30% through the arrangement of the annular corrugated surfaces, the interface state of the two materials is changed, the surface dielectric structure is changed, and the linear breakdown is avoided.

Owner:慈溪益成电器有限公司

Environment-friendly glass fiber reinforced AS composite material and preparation method thereof

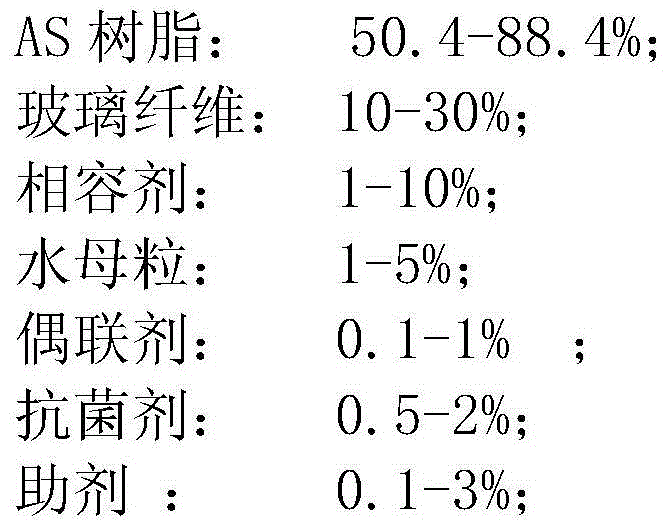

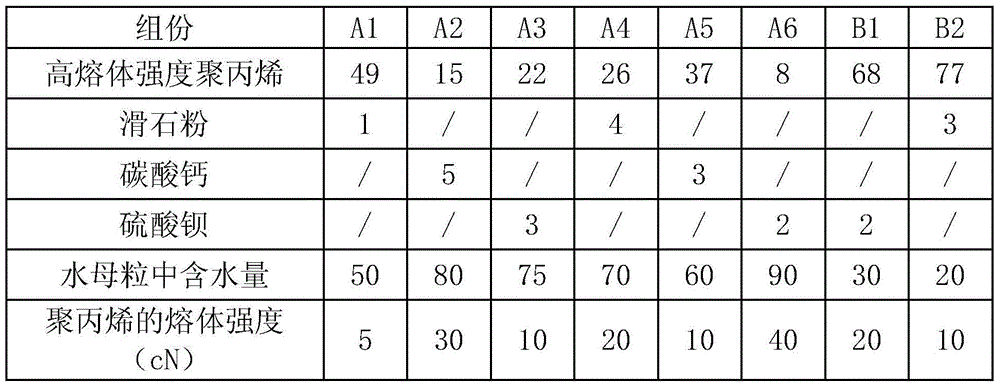

The invention provides an environment-friendly glass fiber reinforced AS composite material. The environment-friendly glass fiber reinforced AS composite material comprises, by weight percentage, AS resin, glass fiber, compatilizer, jellyfish grain, coupling agent, antibacterial agent and adjuvant, wherein the jellyfish grain comprises, by weight percentage, polypropylene, mineral filler and water. Compared with the prior art, the environment-friendly glass fiber reinforced AS composite material and the preparation method have the advantages that (1) a silane coupling agent is added, so that the adhesive strength between the glass fiber and the resin is enhanced; (2) the flavor can be removed effectively, and the mechanical property of the composite material is not affected by the utilization of the jellyfish grain; and (3) the prepared glass fiber reinforced AS composite material has excellent antibacterial effect through the addition of the antibacterial agent and can be utilized as antibacterial materials to be used in car, refrigerator and television industries.

Owner:TIANJIN KINGFA NEW MATERIAL

Novel rare earth compound type brake pad and preparation method thereof

InactiveCN103644224AReduce coefficient of frictionImproved heat decay performanceOther chemical processesBraking membersFiberRare earth

The invention discloses a novel rare earth compound type brake pad. The novel rare earth compound type brake pad comprises, by weight, 14-18% of modified phenolic resin, 25-30% of fiber materials, 25-35% of filling materials and 25-35% of rear earth materials, wherein the rear earth materials are composed of one or more kinds of lanthanum oxide, cerium oxide and praseodymium oxide, and the fiber materials are composed of one or more kinds of mineral fibers, glass fibers and paper fibers. The invention further discloses a preparation method of the novel rare earth compound type brake pad. The novel rare earth compound type brake pad is good in high-temperature resistance, excellent in abrasion resistance and large in impact resistance, and the preparation method is simple and low in cost.

Owner:NINGGUO FEIYING AUTO SPARE PARTS

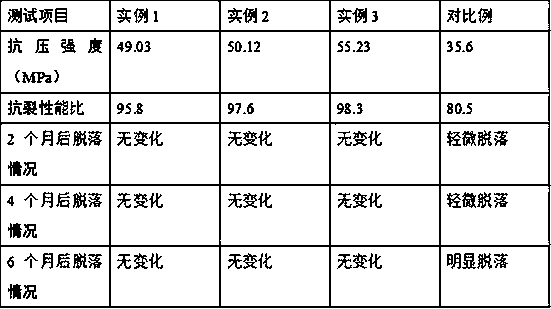

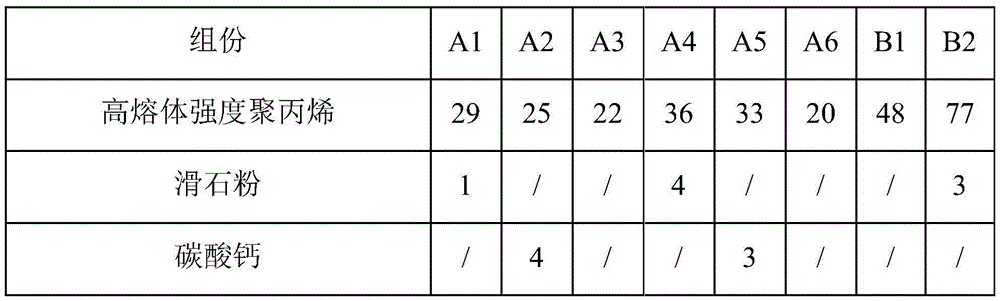

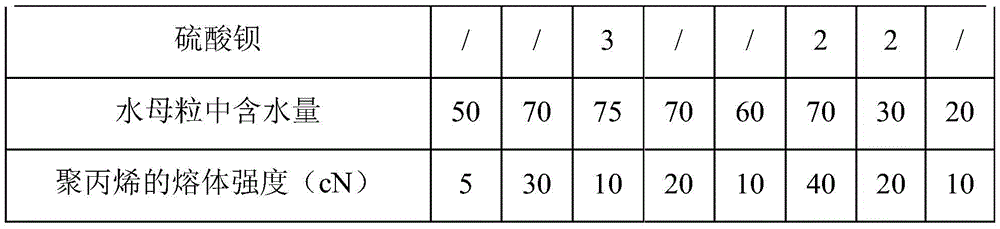

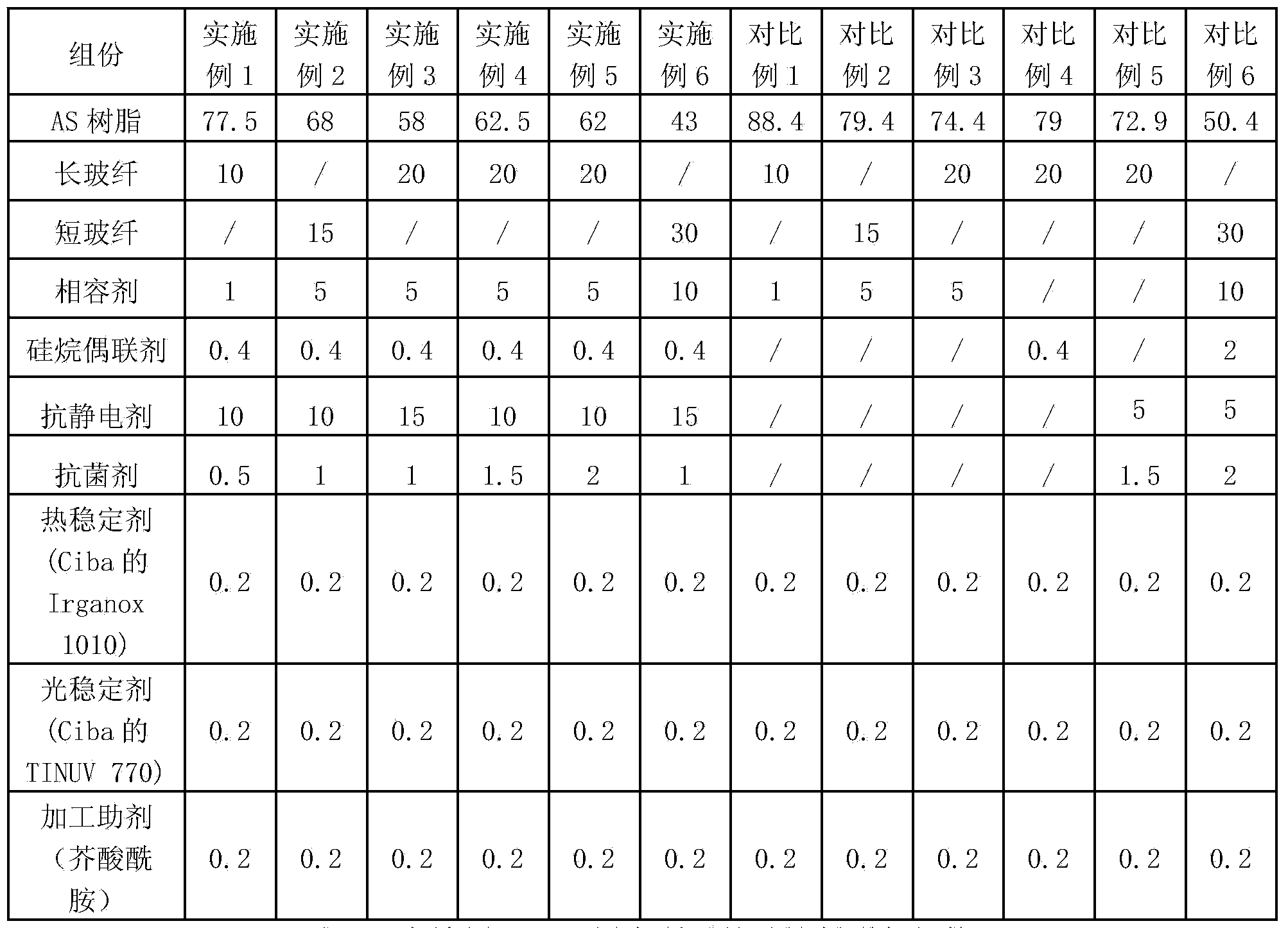

Low-odor anti-static glass-fiber-reinforced AS (acrylonitrile-styrene) composition and preparation method thereof

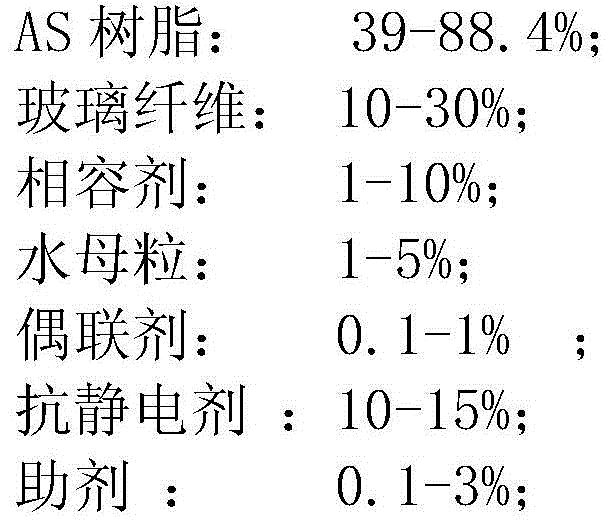

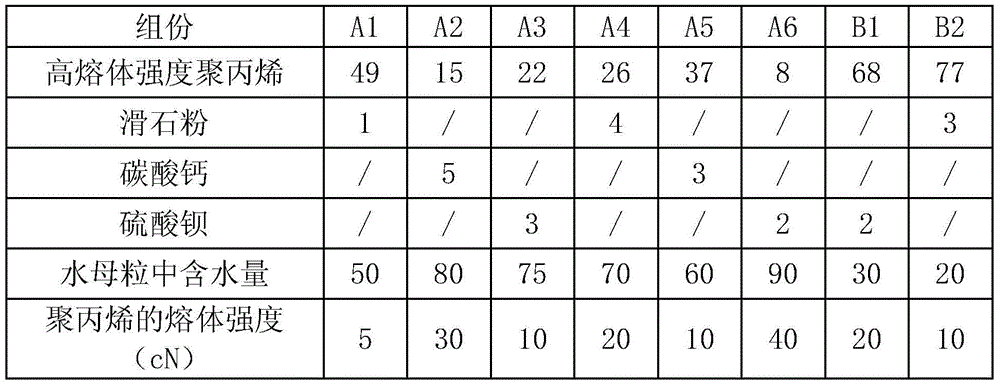

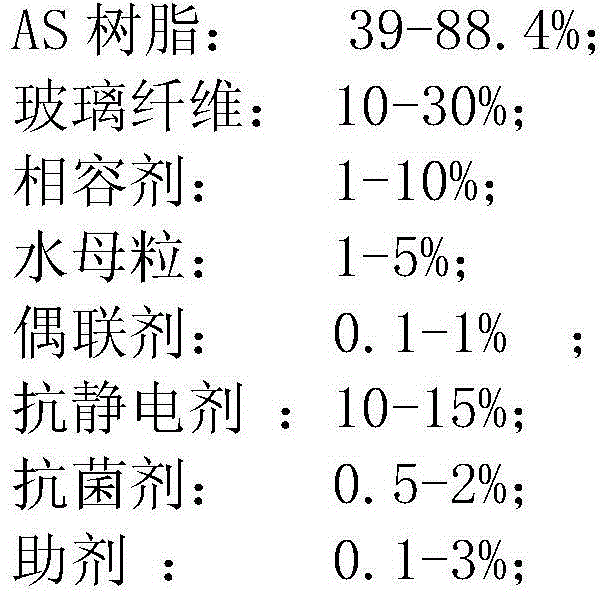

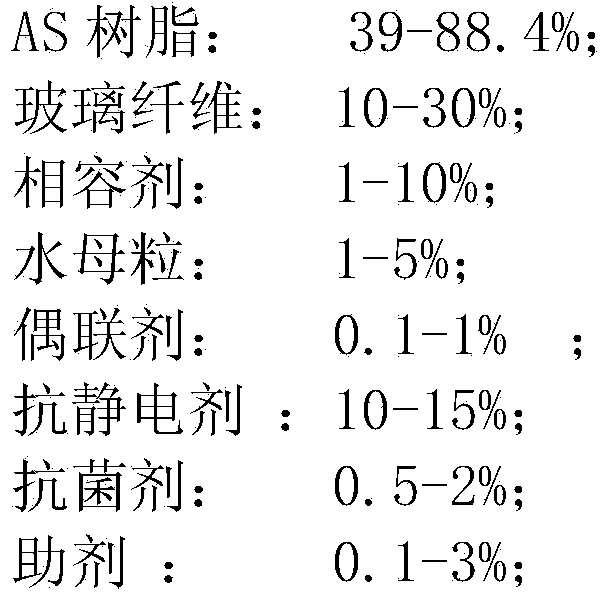

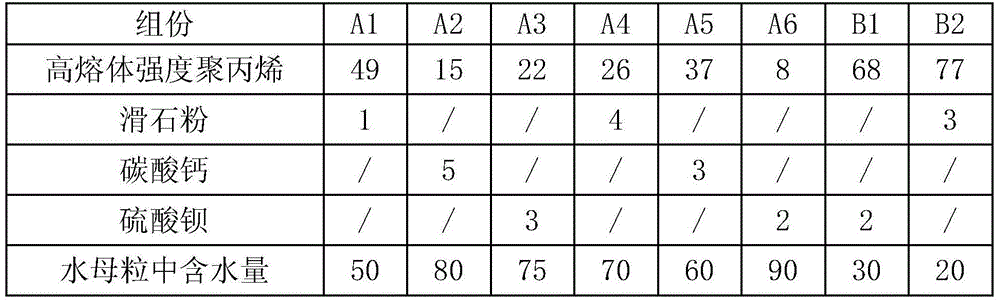

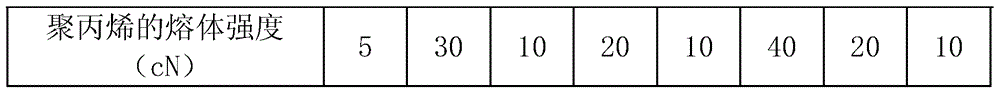

The invention provides low-odor anti-static glass-fiber-reinforced AS (acrylonitrile-styrene) composition and a preparation method thereof. The composition comprises components in percentage by weight as follows: 39-88.4% of AS resin, 10-30% of glass fibers, 1-10% of a compatilizer, 1-5% of water masterbatch, 0.1-1% of a coupling agent, 10-15% of an antistatic agent and 0.1-3% of an additive, wherein the water masterbatch comprises components in percentage by weight as follows: 1-49% of polypropylene, 50-98% of water and 0.1-5% of mineral filler; the compatilizer is PMMA (polymethyl methacrylate); the coupling agent is a silane coupling agent. A matrix of the composition is the AS resin, and the composition has advantages of excellent performance, low cost, simple preparation technology and the like; the PMMA is used as the compatilizer, the bonding force between the glass fibers and the AS resin is enhanced, and the PMMA is applicable to reinforcement of fiber and resin composite material systems with similar properties.

Owner:TIANJIN KINGFA NEW MATERIAL

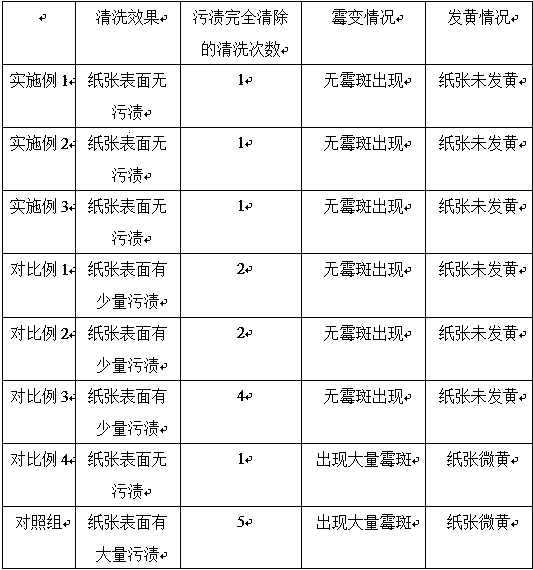

Cleaning fluid for book cleaning and preparation method thereof

InactiveCN109135947ASimple preparation processEasy to operateOrganic detergent compounding agentsNon-ionic surface-active compoundsFiberPolyvinyl alcohol

The invention discloses cleaning fluid for book cleaning and a preparation method thereof. The cleaning fluid is prepared from the following raw materials: a surfactant, chitosan grafted keratin / polyvinyl alcohol fiber powder, polyvinylpyrrolidone, carboxymethylcellulose, sodium citrate, a defoaming agent, rosemary essential oil and distilled water. The preparation method comprises the following steps: (1) treating the distilled water to prepare pretreated distilled water; (2) mixing the polyvinylpyrrolidone, the carboxymethylcellulose, the sodium citrate and the surfactant, adding the mixtureinto the pretreated distilled water, heating and stirring to dissolve the mixture, and preparing a solution A; and (3) mixing the defoaming agent, the rosemary essential oil and the chitosan graftedkeratin / polyvinyl alcohol fiber powder, adding the mixture into the solution A, heating the solution, then stirring the solution at a high speed, and cooling the product to obtain the cleaning fluid.According to the cleaning fluid prepared by the preparation method disclosed by the invention, the preparation process is simple, and the operation is convenient; the selected raw materials are pollution-free to the environment; waste fluid obtained by cleaning is convenient to treat and can meet an environmentally-friendly discharging requirement; and furthermore, the cleaning fluid is high in cleaning capacity, high in cleaning speed and long in service life.

Owner:蚌埠心里程教育科技有限公司

Low-odor, anti-static and anti-bacterial glass fiber reinforced AS (acrylonitrile-styrene) composition and preparation method thereof

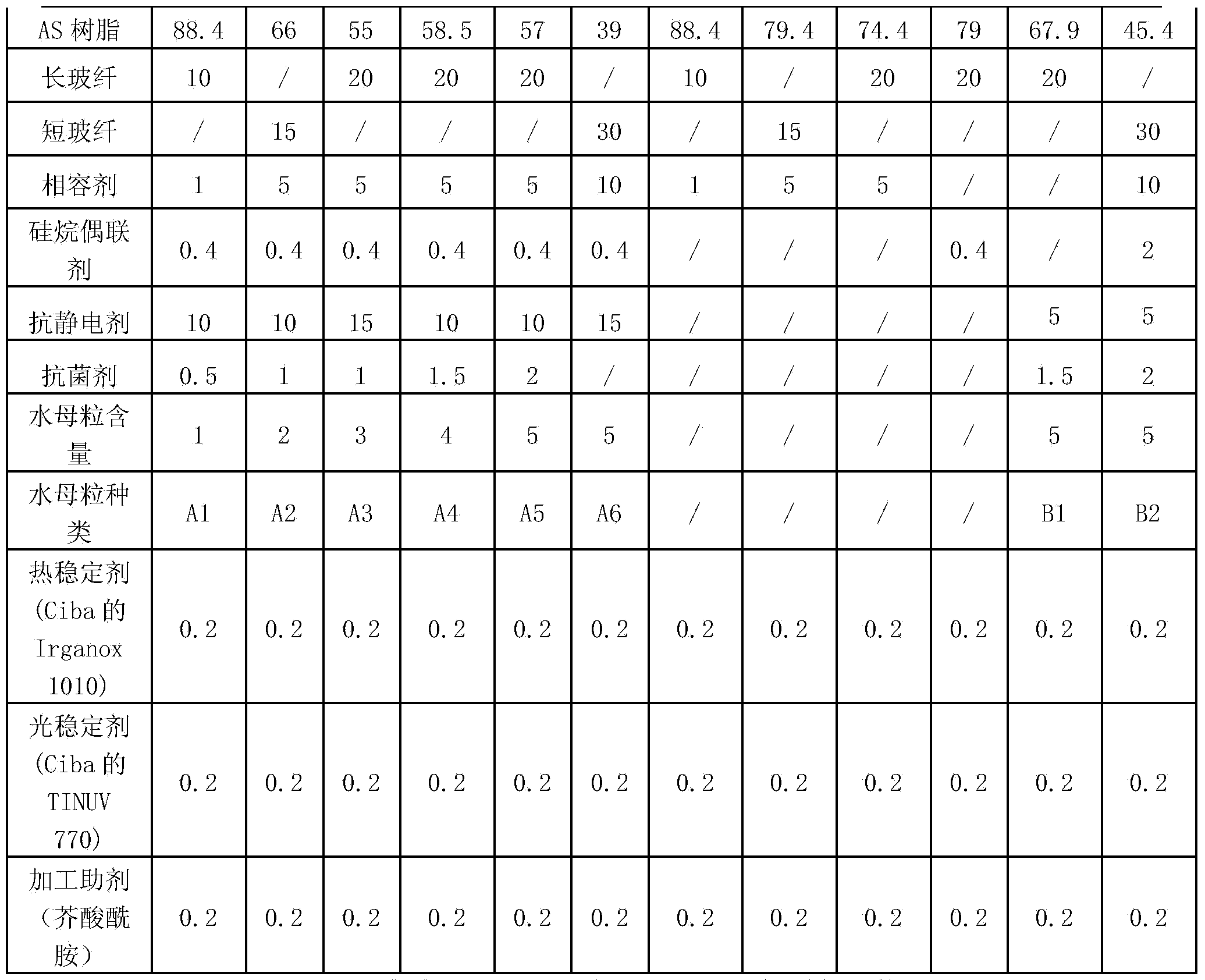

The invention provides low-odor, anti-static and anti-bacterial glass fiber reinforced AS (acrylonitrile-styrene) composition and a preparation method thereof. The low-odor, anti-static and anti-bacterial glass fiber reinforced AS composition comprises components in percentage by weight as follows: 39%-88.4% of AS resin, 10%-30% of glass fiber, 1%-10% of a compatilizer, 1%-5% of water master batch, 0.1%-1% of a coupling agent, 10%-15% of an antistatic agent, 0.5%-2% of an anti-bacterial agent and 0.1%-3% of an auxiliary, wherein the water master batch comprises components in percentage by weight as follows: 1%-49% of polypropylene, 50%-98% of water and 0.1%-5% of mineral filler; the compatilizer is PMMA (polymethyl methacrylate); and the coupling agent is a silane coupling agent. The matrix of the composition is AS resin, and the composition has the advantages of good performance, low cost, simple preparation process and the like; and besides, PMMA is taken as the compatilizer, so that bonding force between the glass fiber and the AS resin is strengthened, and the fiber and resin composite material system with the similar performance is enhanced.

Owner:TIANJIN KINGFA NEW MATERIAL

Low-odor antistatic antibacterial glass fiber reinforced AS (acrylonitrile-styrene) composition and preparation method thereof

The invention provides a low-odor antistatic antibacterial glass fiber reinforced AS (acrylonitrile-styrene) composition and a preparation method thereof. The low-odor antistatic antibacterial glass fiber reinforced AS composition comprises the following components in percentage by weight: 39 to 88.4 percent of AS resin, 10 to 30 percent of glass fibers, 1 to 10 percent of a compatilizer, 1 to 5 percent of a hydrophilic master batch , 0.1 to 1 percent of a coupling agent, 10 to 15 percent of an antistatic agent, 0.5 to 2 percent of an antibacterial agent and 0.1 to 3 percent of an additive, wherein the hydrophilic master batch comprises the following components in percentage by weight: 1 percent to 49 percent of polypropylene, 50 percent to 98 percent of water and 0.1 to 5 percent of mineral filler; the compatilizer is PMMA (polymethyl methacrylate); the coupling agent is a silane coupling agent. The low-odor antistatic antibacterial glass fiber reinforced AS composition uses the AS resin as a matrix and has the advantages of excellent performance, low cost, simple preparation process and the like; the PMMA is used as the compatilizer, so that the low-odor antistatic antibacterial glass fiber reinforced AS composition not only is limited to reinforcement on a bonding force between the glass fibers and the AS resin, but also is suitable for reinforcing a composite material system of fibers and resin similar properties.

Owner:TIANJIN KINGFA NEW MATERIAL

Efficient cleaning agent

The invention discloses an efficient cleaning agent. The efficient cleaning agent is prepared from the following raw materials in parts by weight: 1.5-2.8 parts of triethylene glycol methylpropyl ether, 0.8-2.3 parts of hydroxyl ethylidene bisphosphoric acid, 1.2-3.4 parts of alcohol amine, 1.2-1.5 parts of deionized water, 1.5-2.8 parts of cis-1,2-dimethyl cyclohexane, 3.1-6.4 parts of a stabilizer, 3.5-6.7 parts of lauryl dimethylamine betaine and 4.5-5.8 parts of sodium chloride. The efficient cleaning agent has the beneficial effects that the surface tension of water can be remarkably lowered, so that the surface of a workpiece can be easily wetted and is strong in seepage force; the interface condition between oil stains and the workpiece can be more effectively changed, so that oil-in-water type granules are formed by the oil stains through emulsifying, dispersing, rolling and solubilization and are cleaned; the formula is scientific and reasonable, the foam is little during cleaning, the cleaning capability is strong, the continuity is good, the speed is high, and the service life is long.

Owner:QINGDAO KERUN PLASTIC MACHINERY

High-performance anti-static antibacterial glass-fiber reinforced AS composite material and preparation method thereof

The invention provides a high-performance anti-static antibacterial glass-fiber reinforced AS (acrylonitrile-styrene) composite material and a preparation method thereof. The high-performance anti-static antibacterial glass-fiber reinforced AS composite material comprises the following components in percentage by weight: 43-88.4 percent of AS resin, 10-30 percent of glass fiber, 1-5 percent of a compatilizer, 0.1-1 percent of a coupling agent, 10-15 percent of an antistatic agent, 0.5-2 percent of an antibacterial agent and 0.1-3 percent of an additive, wherein the compatilizer is made of PMMA (polymethyl methacrylate); the coupling agent adopts a silane coupling agent. The AS resin is used as a matrix, and has the advantages of excellent performance, low cost, simple preparation process and the like; made of PMMA, the compatilizer is not only used for enhancing the binding force between the glass fiber and the AS resin, but also suitable for enhancing a composite material system of fiber and resin with similarity properties.

Owner:TIANJIN KINGFA NEW MATERIAL

Low-odor antibacterial glass-fiber-reinforced AS (acrylonitrile-styrene) composition and preparation method thereof

The invention provides low-odor antibacterial glass-fiber-reinforced AS (acrylonitrile-styrene) composition and a preparation method thereof. The composition comprises components in percentage by weight as follows: 50.4-88.4% of AS resin, 10-30% of glass fibers, 1-10% of a compatilizer, 1-5% of water masterbatch, 0.1-1% of a coupling agent, 0.5-2% of an antibacterial agent and 0.1-3% of an additive, wherein the water masterbatch comprises components in percentage by weight as follows: 1-49% of polypropylene, 50-98% of water and 0.1-5% of mineral filler; the compatilizer is PMMA (polymethyl methacrylate); the coupling agent is a silane coupling agent. A matrix of the composition is the AS resin, and the composition has advantages of excellent performance, low cost, simple preparation technology and the like; the PMMA is used as the compatilizer, the bonding force between the glass fibers and the AS resin is enhanced, and the PMMA is applicable to reinforcement of fiber and resin composite material systems with similar properties.

Owner:TIANJIN KINGFA NEW MATERIAL

Antibacterial glass fiber reinforced AS (acrylonitrile-styrene copolymer) composite material and preparation method thereof

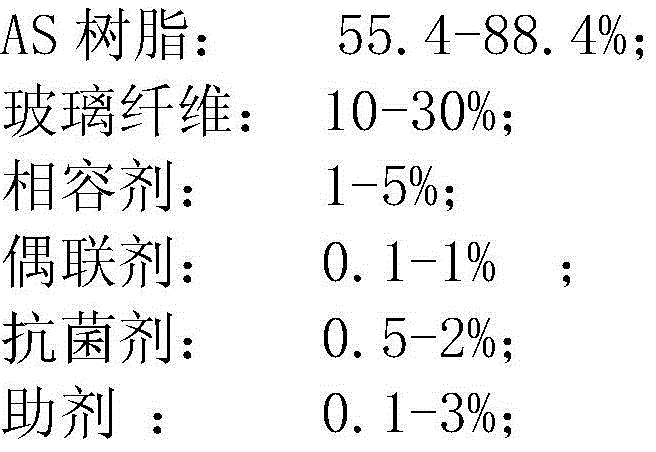

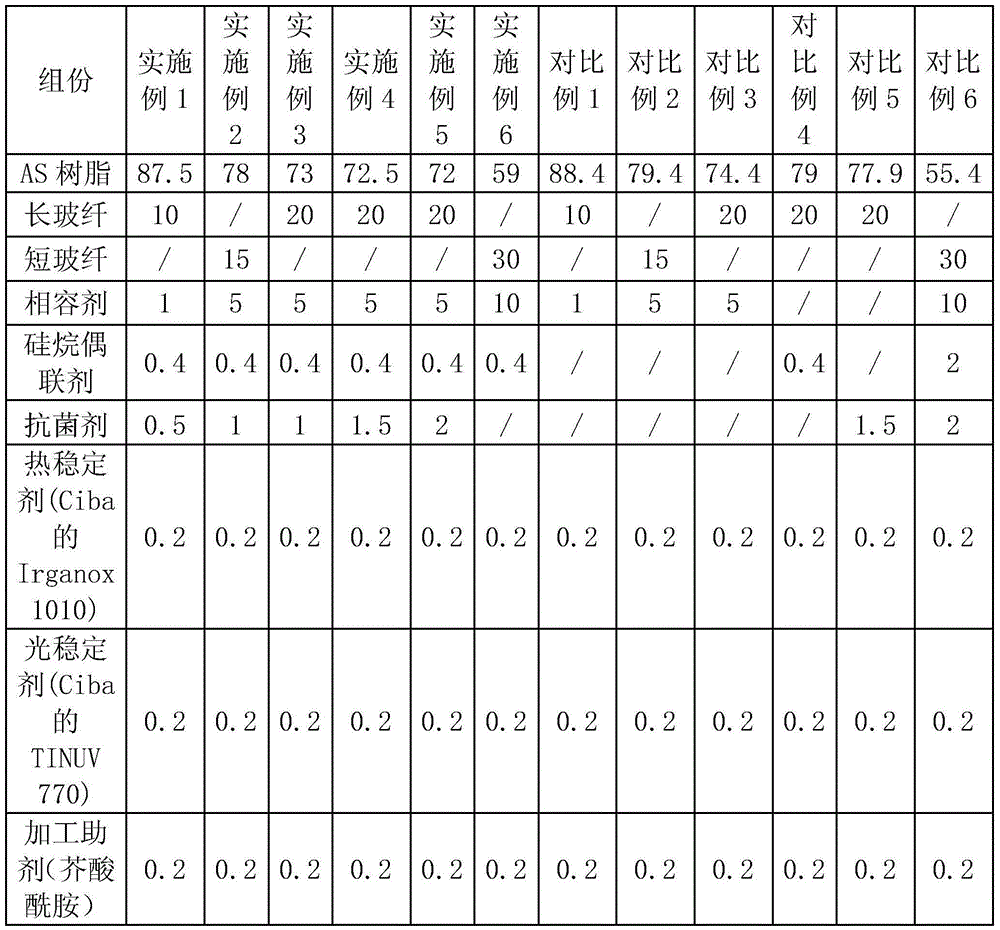

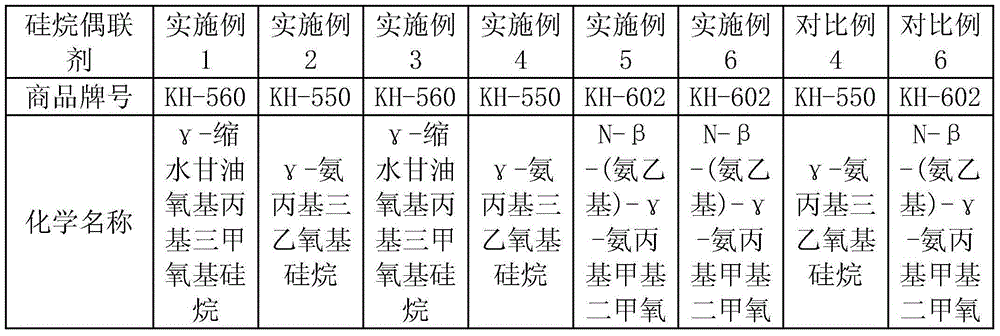

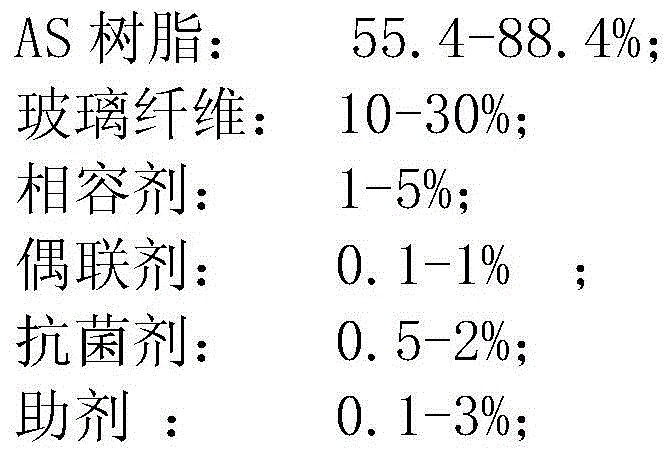

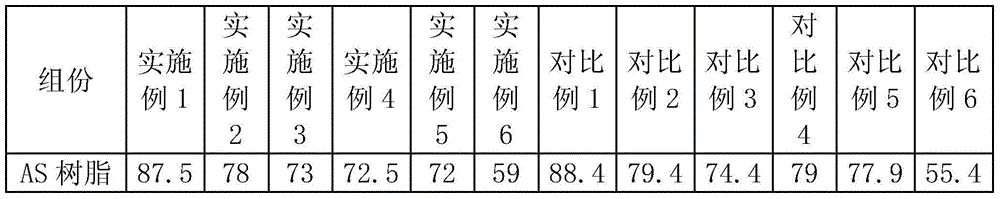

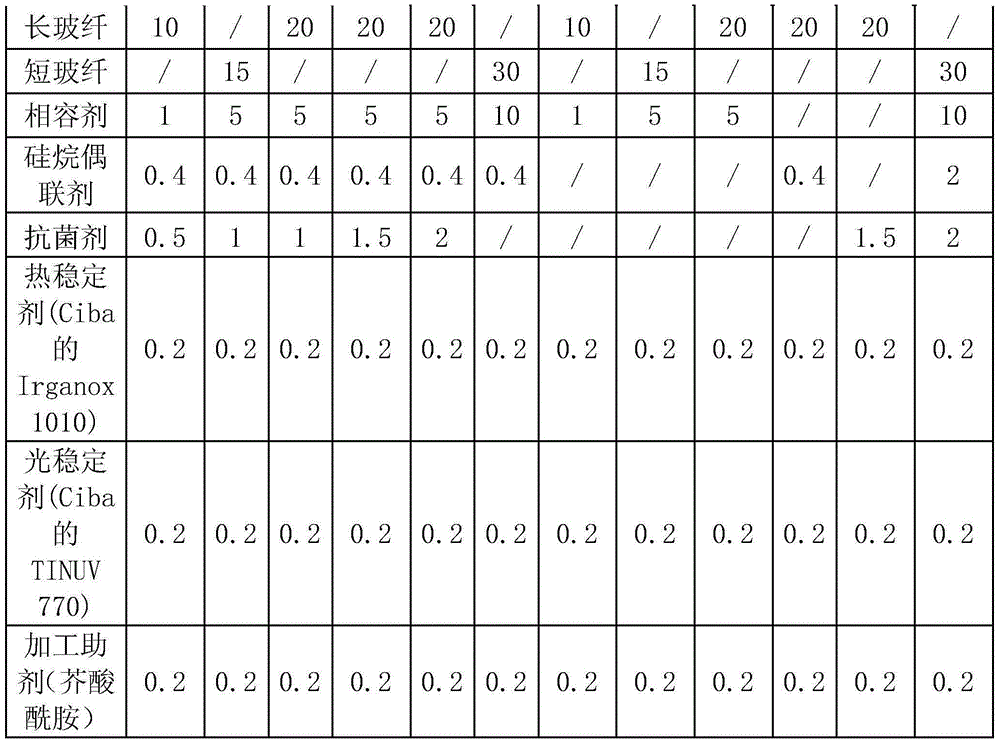

The invention provides an antibacterial glass fiber reinforced AS (acrylonitrile-styrene copolymer) composite material and a preparation method thereof. The composite material comprises the following components by weight percent: 55.4-88.4% of AS resin, 10-30% of glass fibers, 1-5% of compatilizer, 0.1-1% of coupling agent, 0.5-2% of antibacterial agent and 0.1-3% of auxiliaries, wherein the compatilizer is PMMA (polymethyl methacrylate); the coupling agent is a silane coupling agent. The composite material has the advantages and positive effects that with the AS resin as the matrix, the composite material has the advantages of excellent properties, low cost, simple preparation process, and the like; used as the compatilizer, PMMA is not only limited to reinforcing the binding forces between the glass fibers and the AS resin but is also suitable for reinforcing fiber and resin composite material systems with similar properties.

Owner:TIANJIN KINGFA NEW MATERIAL

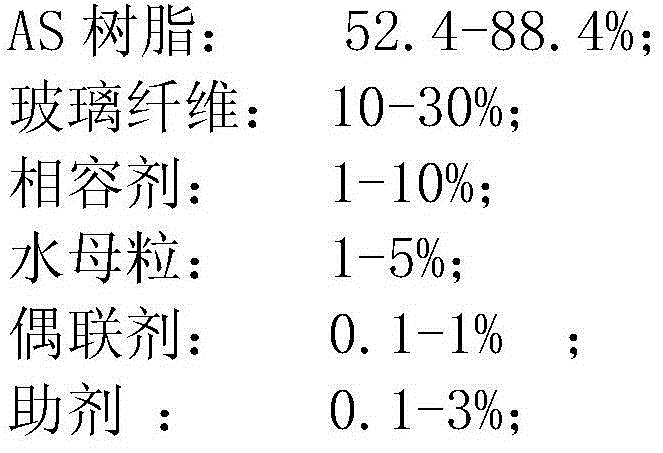

Low-odor glass-fiber-reinforced AS (acrylonitrile-styrene) composition and preparation method thereof

The invention provides low-odor glass-fiber-reinforced AS (acrylonitrile-styrene) composition and a preparation method thereof. The composition comprises components in percentage by weight as follows: 52.4-88.4% of AS resin, 10-30% of glass fibers, 1-10% of a compatilizer, 1-5% of water masterbatch, 0.1-1% of a coupling agent and 0.1-3% of an additive, wherein the water masterbatch comprises components in percentage by weight as follows: 1-49% of polypropylene, 50-98% of water and 0.1-5% of mineral filler; the compatilizer is PMMA (polymethyl methacrylate); the coupling agent is a silane coupling agent. A matrix of the composition is the AS resin, and the composition has advantages of excellent performance, low cost, simple preparation technology and the like; the PMMA is used as the compatilizer, the bonding force between the glass fibers and the AS resin is enhanced, and the PMMA is applicable to reinforcement of fiber and resin composite material systems with similar properties.

Owner:TIANJIN KINGFA NEW MATERIAL

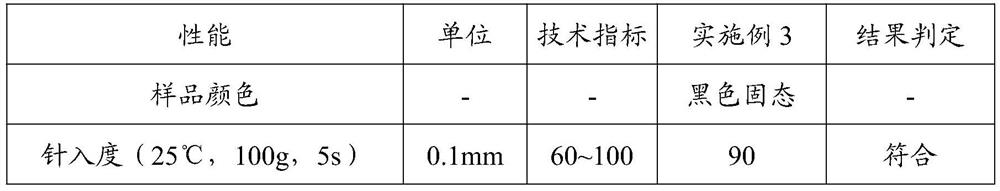

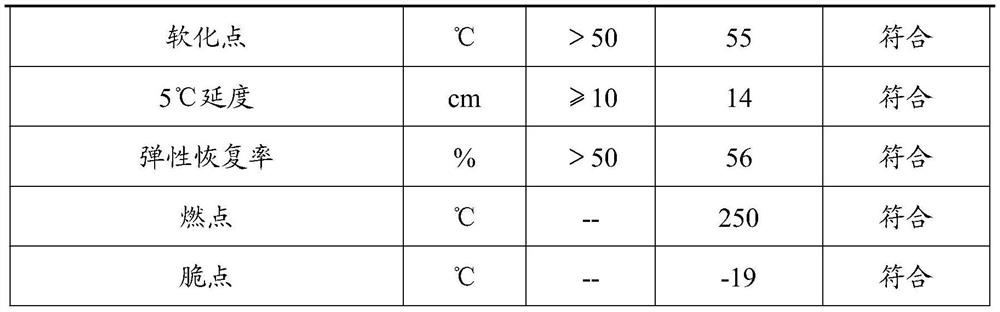

Rubber asphalt and preparation method thereof

InactiveCN111675914AGuaranteed Performance RequirementsIncrease profitBuilding insulationsCracking reactionWaste tires

The invention provides a preparation method of rubber asphalt. The preparation method comprises the following steps: mixing an activator, silicon product waste residues and waste tire rubber powder toobtain modified rubber powder; and mixing the modified rubber powder with matrix asphalt, and performing a thermal cracking reaction to obtain the rubber asphalt. The rubber asphalt is prepared from0.1-0.5 wt% of the activator, 10-15 wt% of the silicon product waste residues, 25-35 wt% of the waste tire rubber powder and 50-60 wt% of the matrix asphalt. Physical and chemical methods are combined, the waste tire rubber powder is modified with the activator and the silicon product waste residues, physical mixing is matched, under the shearing action, the interface state of the waste tire rubber powder is changed, the compatibility of the waste tire rubber powder and the matrix asphalt is improved, the utilization rate of the silicon product waste residues is increased, and the rubber powder and the asphalt are promoted to form a stable system and are not separated, so the performance of the rubber asphalt is guaranteed.

Owner:甘禄祥

Antibacterial glass fiber reinforced AS (acrylonitrile-styrene copolymer) composite material and preparation method thereof

The invention provides an antibacterial glass fiber reinforced AS (acrylonitrile-styrene copolymer) composite material and a preparation method thereof. The composite material comprises the following components by weight percent: 55.4-88.4% of AS resin, 10-30% of glass fibers, 1-5% of compatilizer, 0.1-1% of coupling agent, 0.5-2% of antibacterial agent and 0.1-3% of auxiliaries, wherein the compatilizer is PMMA (polymethyl methacrylate); the coupling agent is a silane coupling agent. The composite material has the advantages and positive effects that with the AS resin as the matrix, the composite material has the advantages of excellent properties, low cost, simple preparation process, and the like; used as the compatilizer, PMMA is not only limited to reinforcing the binding forces between the glass fibers and the AS resin but is also suitable for reinforcing fiber and resin composite material systems with similar properties.

Owner:TIANJIN KINGFA NEW MATERIAL

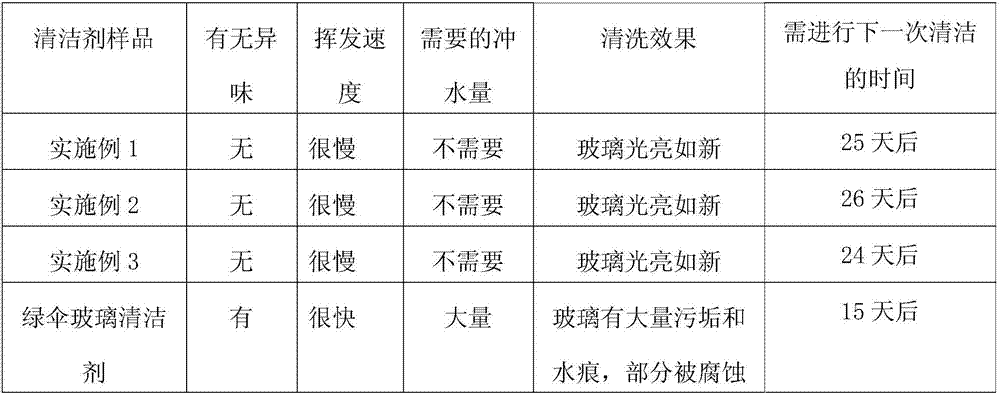

High-efficiency glass cleaning agent and preparation method thereof

InactiveCN108865494AGood effectEasy to prepareInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsChemistrySodium carboxymethylcellulose

The invention provides a high-efficiency glass cleaning agent and a preparation method thereof. The high-efficiency glass cleaning agent is prepared from the following components: modified zeolite powder, sodium dodecyl benzene sulfonate, sodium carboxymethyl cellulose, modified bentonite, fatty alcohol polyoxyethylene ether, sodium alginate, sodium citrate, a polyethylene glycol solution, a detergent, propylene glycol, a chelating agent, a preservative and deionized water. The glass cleaning agent prepard by the method is remarkable in cleaning effect, simple in preparation method and wide inapplication scope, is free from undesirable odor, has no harm to a human body, does not need to be washed with a great deal of clean water, and saves a great deal of manpower and material resources,thus being worth popularizing and producing.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

Vehicle window glass detergent and production technology thereof

InactiveCN107043659AReduce surface tensionExcellent decontaminationInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsAlkanePolyethylene glycol

The invention provides a vehicle window glass detergent and a production technology thereof, and relates to the technical field of detergents. The vehicle window glass detergent comprises sodium alkyl benzene sulfonate, secondary alkane sulfonate, alkylphenol polyoxyethylene ether, lauroyl diethanolamide, glucosyl dimethyl ester, sodium alginate, ethylenediamine tetraacetic acid, diethylenetriamine pentacarboxylic acid, carboxymethylcellulose sodium, polyethylene glycol, aminobenzoic acid, modified kaolin, a detergent and deionized water. The c vehicle window glass detergent has the advantages of remarkable effect, simplicity in preparation, wide application range, no peculiar smell, harmlessness to human bodies, and saving of a lot of manpower and material resources due to realization of bright glass only through uniformly coat the surface of glass with the detergent in use and wipe-drying with a clean cotton cloth without clear water flushing, and is worth promoting production.

Owner:岑健

Anti-static glass fiber reinforced AS composition and preparation method thereof

The invention provides an anti-static glass fiber reinforced AS composition and a preparation method thereof. The composition is prepared from the following components in percentage by weight: 59-88% of AS resin, 10-30% of glass fibers, 0.8-10% of a compatilizer, 0.1-1% of a coupling agent, 10-15% of an anti-static agent and 0.1-3% of auxiliaries, wherein the compatilizer is polymethylmethacrylate and the coupling agent is a silane coupling agent. As the matrix is the AS resin, the composition has the advantages of excellent performance, low cost, simple preparation process and the like. By using PMMA as the compatilizer, not only is the binding force between the glass fibers and the AS resin enhanced, but also the composition is suitable for enhancing a fiber and resin composite material system with similar properties.

Owner:TIANJIN KINGFA NEW MATERIAL

Capsule type oil-spill dispersant and preparation method thereof

InactiveCN107760269AGood storage stabilityExtended storage timeFatty/oily/floating substances removal devicesOther chemical processesNaturally occurring surfactantsGlycerol

The invention relates to a capsule type oil dispersant and a preparation method thereof, belonging to the technical field of petrochemical environmental protection treatment agents. The invention mainly includes a capsule shell and a degreasing agent capsule core. Firstly, tea saponin, nonionic surfactant, emulsifier, dispersant, etc. are mixed to obtain a degreasing agent capsule core, and then sodium alginate solution and tea extract are extracted. Konjac powder, glycerin, etc. are stirred and mixed to obtain a film-forming solution. The film-forming solution is vacuum degassed, and the defoamed film-forming solution is dipped in glue, calcified and formed, and then dried, demoulded, and cut to obtain capsules. shell, and finally inject the oil dispersant capsule core into the capsule shell and seal it. After the present invention is put into use, the capsule shell will be slowly hydrolyzed, and substances such as glycerin and tea extract can not only weaken the force between oil molecules, but also substances such as sodium alginate can increase the stability of the emulsion during the dispersion process. Thus, the emulsification efficiency is greatly improved, and the natural surfactant is used at the same time, which reduces the pollution to seawater.

Owner:常州市雄图纺织有限公司

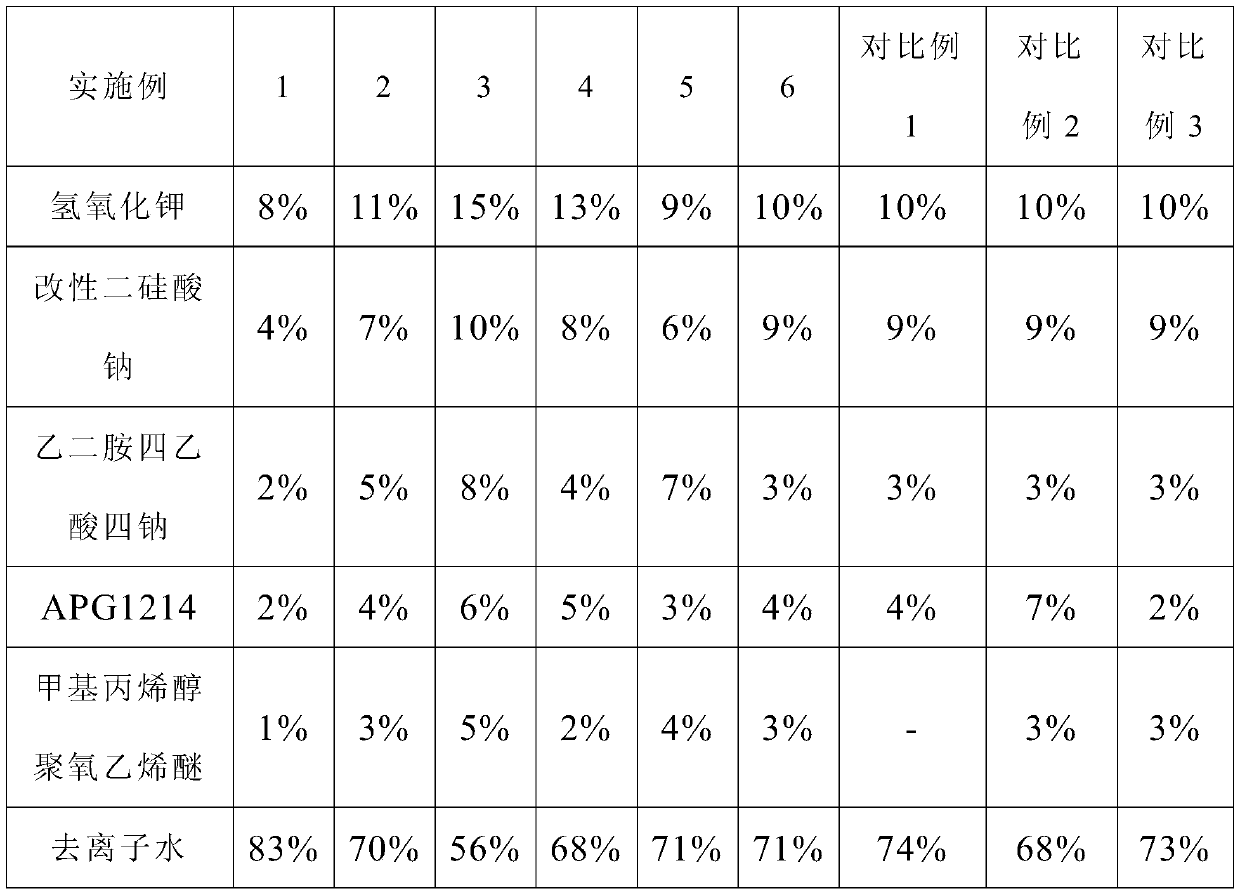

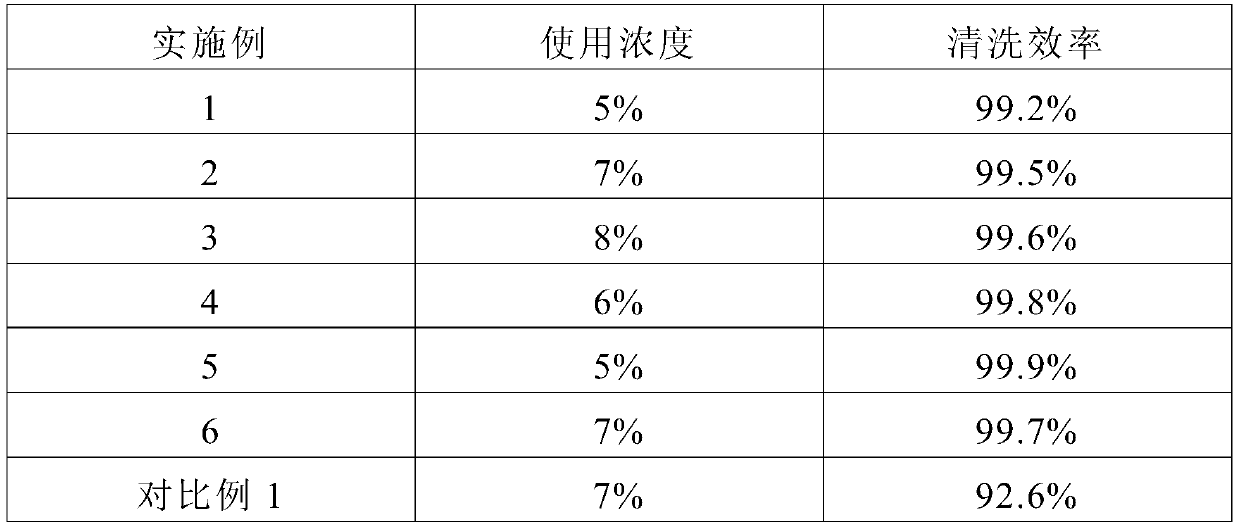

Degreasing agent for cleaning steel plate surface

The invention relates to the field of detergent compounds, in particular to a degreasing agent for a cleaning steel plate surface. The degreasing agent is characterized by comprises, by weight percentage, 8-15% of potassium hydroxide, 4-10% of modified sodium disilicate, 2-8% of ethylenediaminetetraacetic acid tetrasodium salt, 2-6% of lauryl glycoside, 1-5% of methyl propylene alcohol polyoxyethylene ether and the balanced deionized water. The degreasing agent has the advantage that the steel plate surface cleaning efficiency can be significantly improved.

Owner:武汉钢铁有限公司

A kind of electrolytic solution and the method for preparing the black film layer on the surface of magnesium alloy by using the electrolytic solution

The invention discloses an electrolyte and a method for preparing a black membrane on an aluminum alloy surface by using same. The electrolyte comprises 8-15 g / L of hydroxide, 10-15 g / L of fluoride, 20-30 g / L of phosphate, 4-14 g / L of ferrate, 1-5 g / L of fluorotitanate, 10-20 g / L of organic alcohol and 80-300 g / L of an ablation inhibitor, and the solvent is deionized water. The method has the advantages that higher black level can be achieved on a thinner membrane to effectively avoid the problem of the discarding of a complicated precision product caused by local ablation when the complicatedprecision product is processed.

Owner:西安强微电气设备有限公司

Cleaning liquid for book cover of dermatoglyph paper book, and use method thereof

InactiveCN109694779ANo smellReduce surface tensionOrganic detergent compounding agentsAnionic surface-active compoundsDaily operationPhosphate

The invention discloses a cleaning liquid for the book cover of a dermatoglyph paper book, wherein the cleaning liquid is formed by uniformly mixing the following components by mass: 8-10 parts of ananionic surfactant, 8-10 parts of potassium dihydrogen phosphate, 1-3 parts of citric acid, 1-2 parts of tartaric acid, 6-8 parts of triethanolamine, 4-8 parts of sodium dodecyl benzenesulfonate, 8-10parts of trichloroethylene, and 25-27 parts of ethanol. According to the present invention, the cleaning liquid can significantly reduce the surface tension of water so as to easily wet the surface of the book cover of the dermatoglyph paper book, can effectively change the condition of the interface between the oil stain and the book cover, can emulsify, disperse, detach and solubilize oil stains, has characteristics of safe and reliable use, no odor, health and environmental protection, and does not affect the daily operation of the library after the cleaning.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Degumming cleaning fluid for NdFeB magnetic material processing

ActiveCN103600080BEfficient, fast and thorough cleaningImprove safety and environmental protectionInductances/transformers/magnets manufactureMagnetic materialsHazardous substanceMaterials processing

The invention discloses a degumming cleaning fluid for processing neodymium iron boron magnetic materials. Raw materials of the cleaning fluid include ethylene glycol, complexing agent, anionic surfactant, nonionic surfactant, compound corrosion inhibitor, alkaline agent, and balance of water. The cleaning fluid is prepared and formed through environment-friendly materials, is used for processing the neodymium iron boron magnetic materials and has no flammable and combustible features during use; large adverse impact on the work environment occurs rarely, nitrite, phenol, and formaldehyde and other environmentally hazardous substances are eliminated; the cleaning fluid is anti-flaming, is not toxic to operators and has good safe environmental protection, and processing environment and sanitary conditions are optimized; meanwhile, good cleaning effect on processing oil and fixing glue is achieved, working efficiency can be improved, and cost is reduced.

Owner:AMER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com