Rubber asphalt and preparation method thereof

A technology of rubber asphalt and rubber powder, which is applied in the field of rubber asphalt and its preparation, and can solve the problems of difficulty in meeting the requirements of various indicators of asphalt, low utilization rate, limited absorption of silicon product waste residue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a kind of preparation method of asphalt rubber, comprising the following steps:

[0023] (1) mixing activator, silicon product waste residue and waste tire rubber powder to obtain modified rubber powder;

[0024] (2) The modified rubber powder obtained in the step (1) is mixed with matrix asphalt to carry out thermal cracking reaction to obtain rubber asphalt;

[0025] The rubber asphalt is prepared from raw materials comprising the following mass percentages:

[0026] 0.1wt%-0.5wt% activator, 10wt%-15wt% silicon product waste residue, 25wt%-35wt% waste tire rubber powder and 50wt%-60wt% matrix asphalt.

[0027] Based on the weight ratio of asphalt rubber as 100%, the raw material for preparing asphalt rubber of the present invention includes 0.1wt% to 0.5wt% of activator, preferably 0.2wt% to 0.3wt%, more preferably 0.25wt% to 0.3wt% %. In the present invention, the activator is preferably a nonionic surfactant, more preferably 2,4,7,9-tetrame...

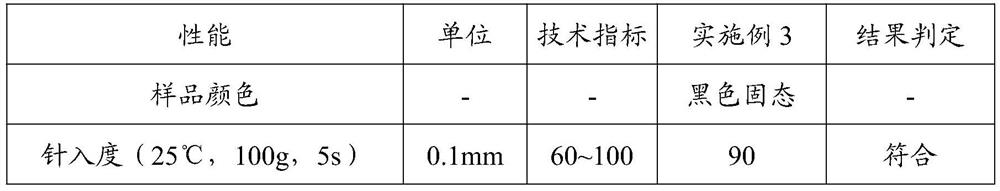

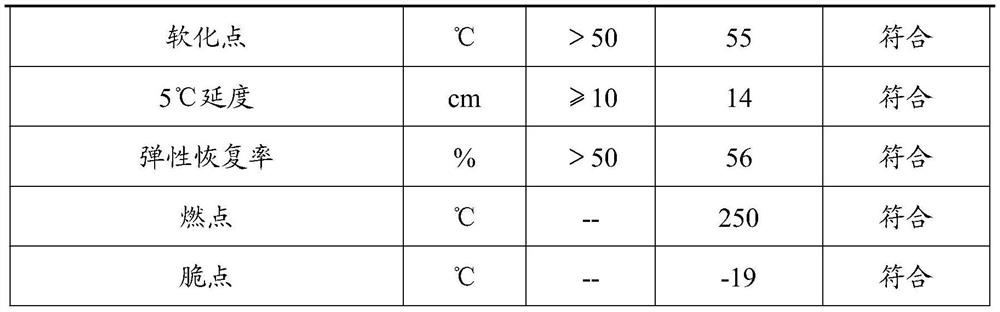

Embodiment 1

[0040] Taking the weight ratio of rubber asphalt as 100%, the raw material is 0.3wt% of 2,4,7,9-tetramethyl-5-decyne-4,7-diol, 15wt% organic silicon waste residue (with a particle size of 210 ~230 mesh), 34.7wt% waste tire rubber powder (grain size is 20~40 mesh, natural rubber hydrocarbon content greater than 30%) and 50wt% matrix asphalt.

[0041] Step (1) Fully mix 2,4,7,9-tetramethyl-5-decyne-4,7-diol, organic silicon waste residue and waste tire rubber powder at normal temperature and pressure to obtain modified rubber powder ;

[0042] Step (2) Add the modified rubber powder obtained in the step (1) to the base asphalt at 120°C and mix evenly, then react in a reactor at 200°C for 1.5min to obtain black solid rubber asphalt.

Embodiment 2

[0044] Taking the weight ratio of rubber asphalt as 100%, the raw material is 0.2wt% of 2,4,7,9-tetramethyl-5-decyne-4,7-diol, 10wt% organic silicon waste residue (with a particle size of 210 ~230 mesh), 29.8wt% waste tire rubber powder (grain size is 20~40 mesh, natural rubber hydrocarbon content is greater than 30%) and 60wt% matrix asphalt.

[0045] Step (1) Fully mix 2,4,7,9-tetramethyl-5-decyne-4,7-diol, organic silicon waste residue and waste tire rubber powder at normal temperature and pressure to obtain modified rubber powder ;

[0046] Step (2) Add the modified rubber powder obtained in the step (1) to the base asphalt at 120°C and mix evenly, then react in a reactor at 200°C for 1.5min to obtain black solid rubber asphalt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com