Patents

Literature

54results about How to "Avoid intractable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dual membrane method brine refining technology and device in whole bittern caustic soda production

ActiveCN105731495AReduce pollutionEasy to handleAlkali metal halide purificationHollow fibreSocial benefits

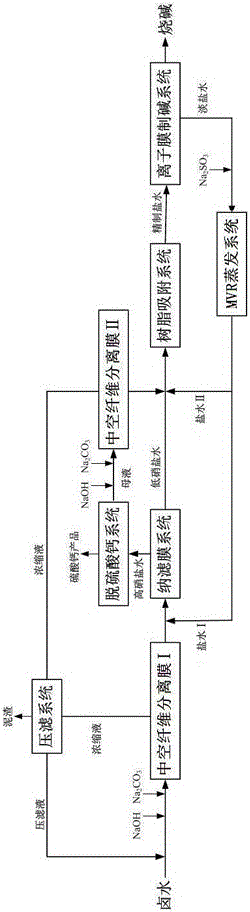

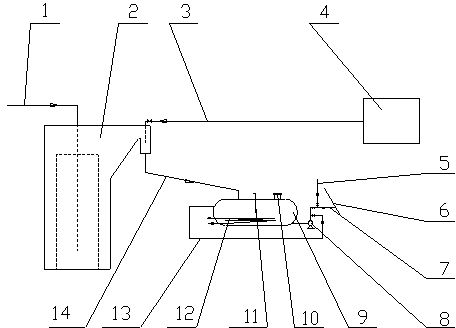

The invention relates to a dual membrane method brine refining technology and device in whole bittern caustic soda production, and belongs to the technical field of brine refining. The technology comprises the following steps: step one, refining bittern, and then introducing refined bittern into a hollow fiber separating membrane (I); step two, mixing the filtrate and brine (I), introducing the mixture into a nano filtration membrane system, wherein the nano filtration membrane divides the brine into two parts namely low nitrite brine and high nitrite brine, adding Ca<2+> into high nitrite brine to generate calcium sulfate, and carrying out solid-liquid separation to obtain calcium sulfate solids; step three, after nano filtration, adsorbing the filtrate by resin to obtain refined brine, and finally delivering the refined brine to an ionic membrane caustic soda production system. The adopted technology can reduce membrane pollution and improve the membrane processing ability. The technology is more advanced, moreover, the technology process is simple, the resource utilization rate is high, the investment and production cost is low, the operation is safe and convenient, and great economic benefits and social benefits are generated.

Owner:JIANGSU NINE HEAVEN HIGH TECH

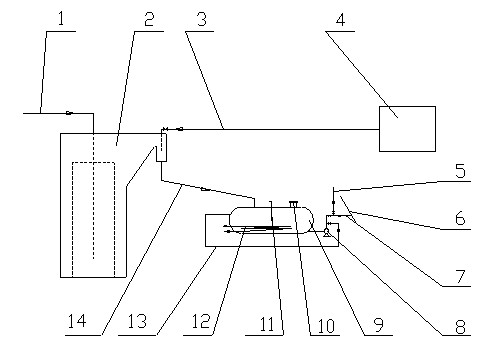

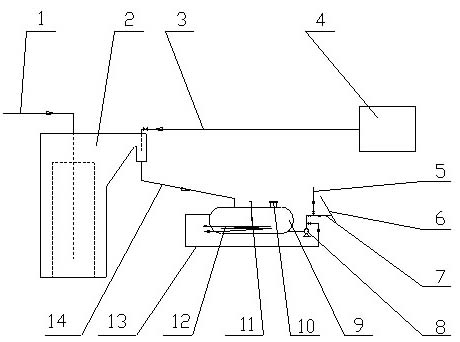

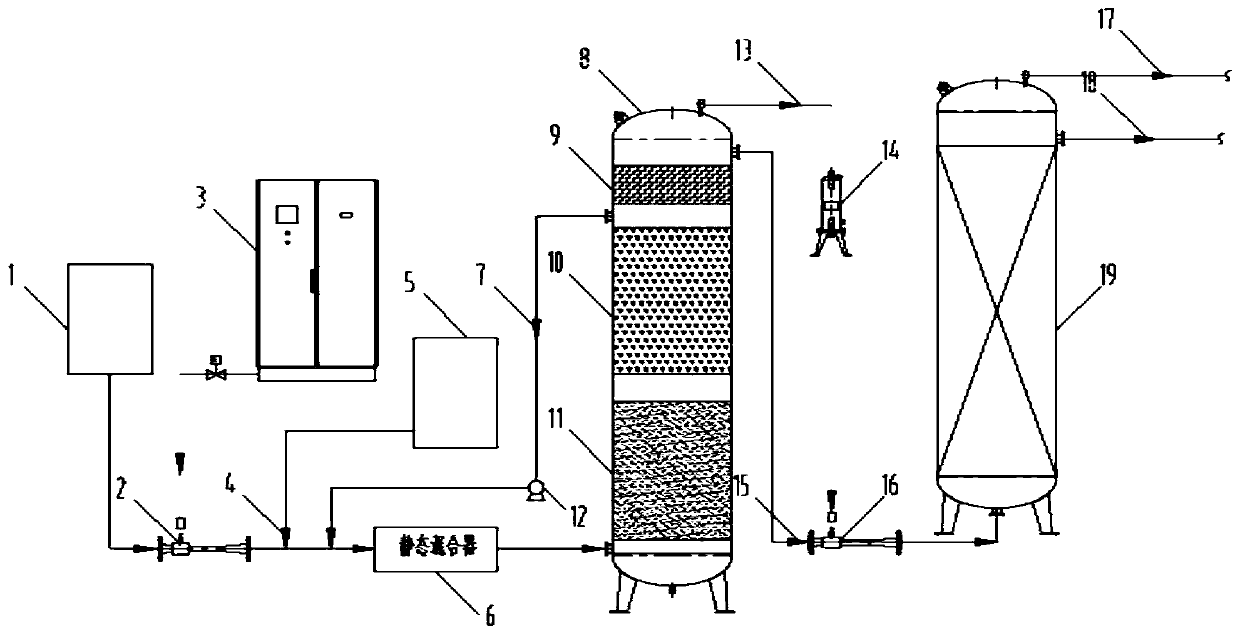

Method and device for treating leachate MBR effluent through combination of ozone-catalyzed oxidation and aeration biological filter towers

ActiveCN107759026ARealize full processingRealize comprehensive utilizationMultistage water/sewage treatmentBiological filterMunicipal solid waste landfill

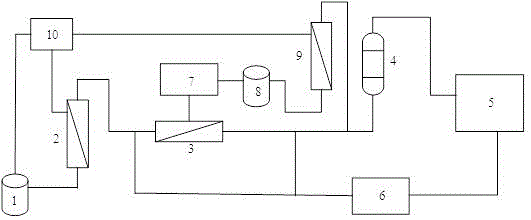

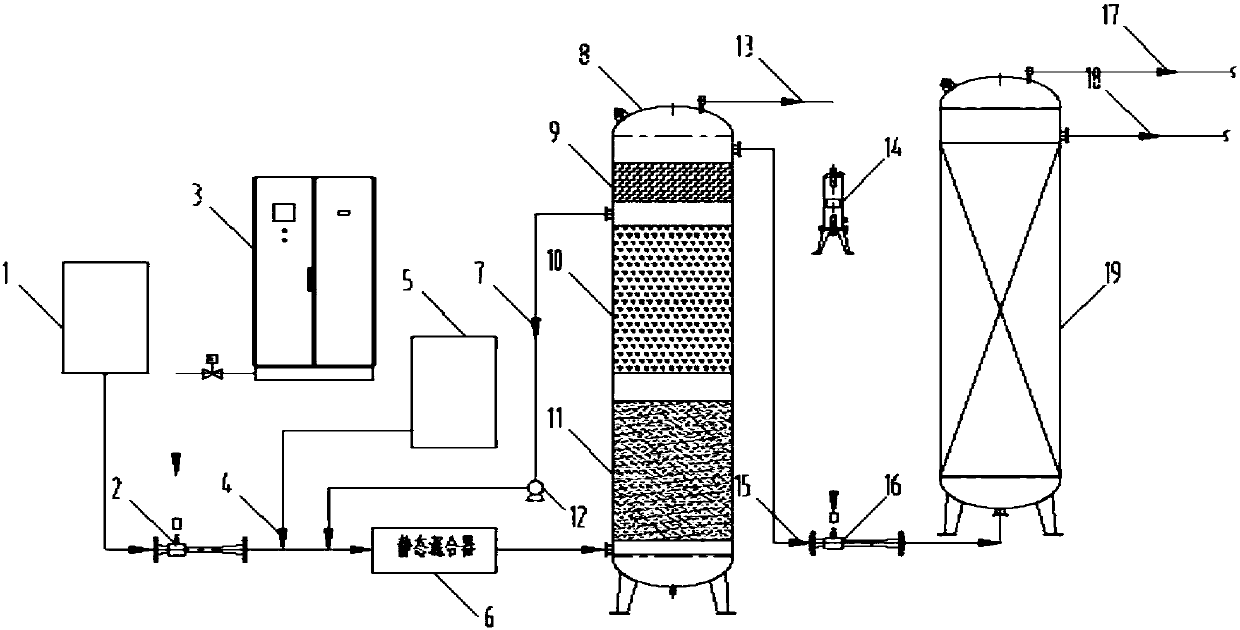

The invention provides a method for treating leachate MBR effluent through combination of ozone-catalyzed oxidation and aeration biological filter towers. The method comprises carrying out gas-liquidmixing on leachate MBR effluent and ozone according to a reaction ratio through an injector, mixing the gas-liquid mixture and a circulation fluid, mixing the mixture and hydrogen peroxide according to a reaction ratio through a static mixer, feeding the final mixed liquid into an ozone-catalyzed oxidation tower through a lower water inlet, feeding the tail gas discharged through a top tail gas outlet into an ozone decomposing device, carrying out treatment, carrying out gas-liquid mixing through the injector, feeding the gas-liquid mixture into a biological filter tower through a low water inlet, and carrying out treatment through the biological filter tower so that the product water can stably satisfy the municipal solid waste landfill pollution control standard (GB 16889-2008) in the fig 2. The method realizes full treatment on leachate MBR, solves the problem that the prior art is difficult to treat a thick membrane liquid and realizes the efficient and comprehensive utilization ofozone.

Owner:NANJING WONDUX ENVIRONMENTAL PROTECTION TECH CO LTD

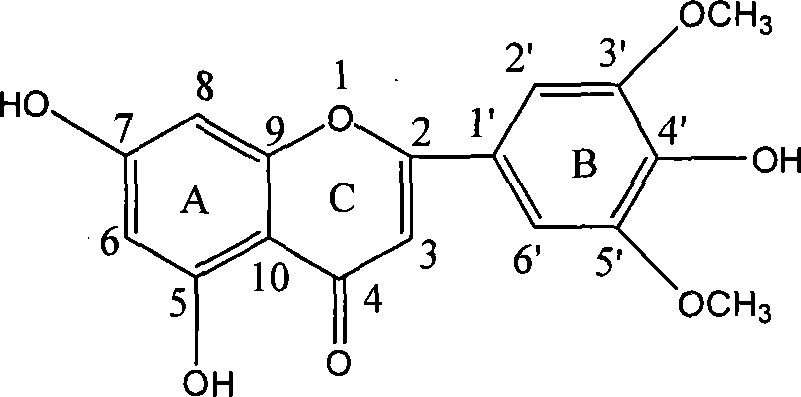

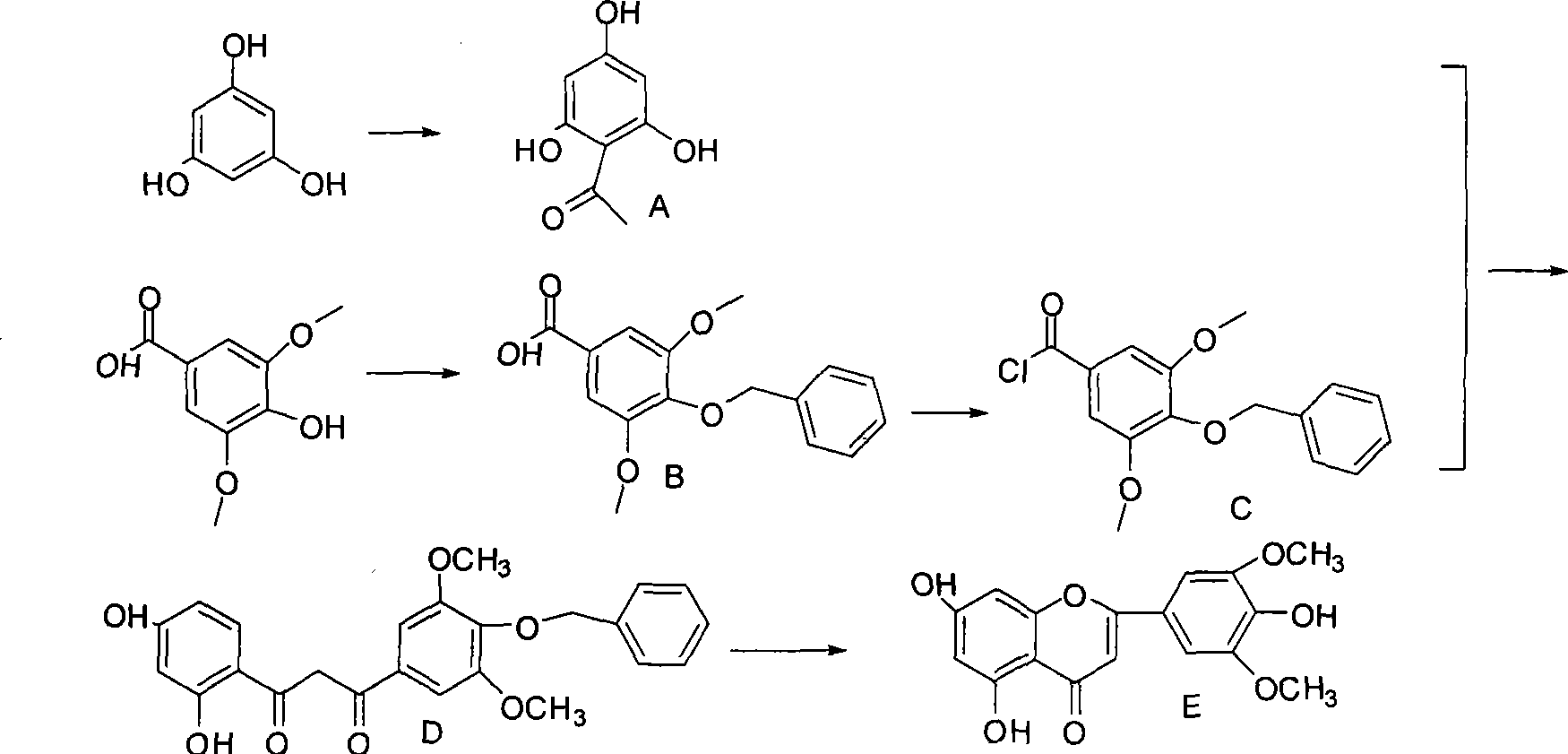

Synthesis method and application of 5,7,4'-trihydroxy-3',5'-dimethoxyflavone

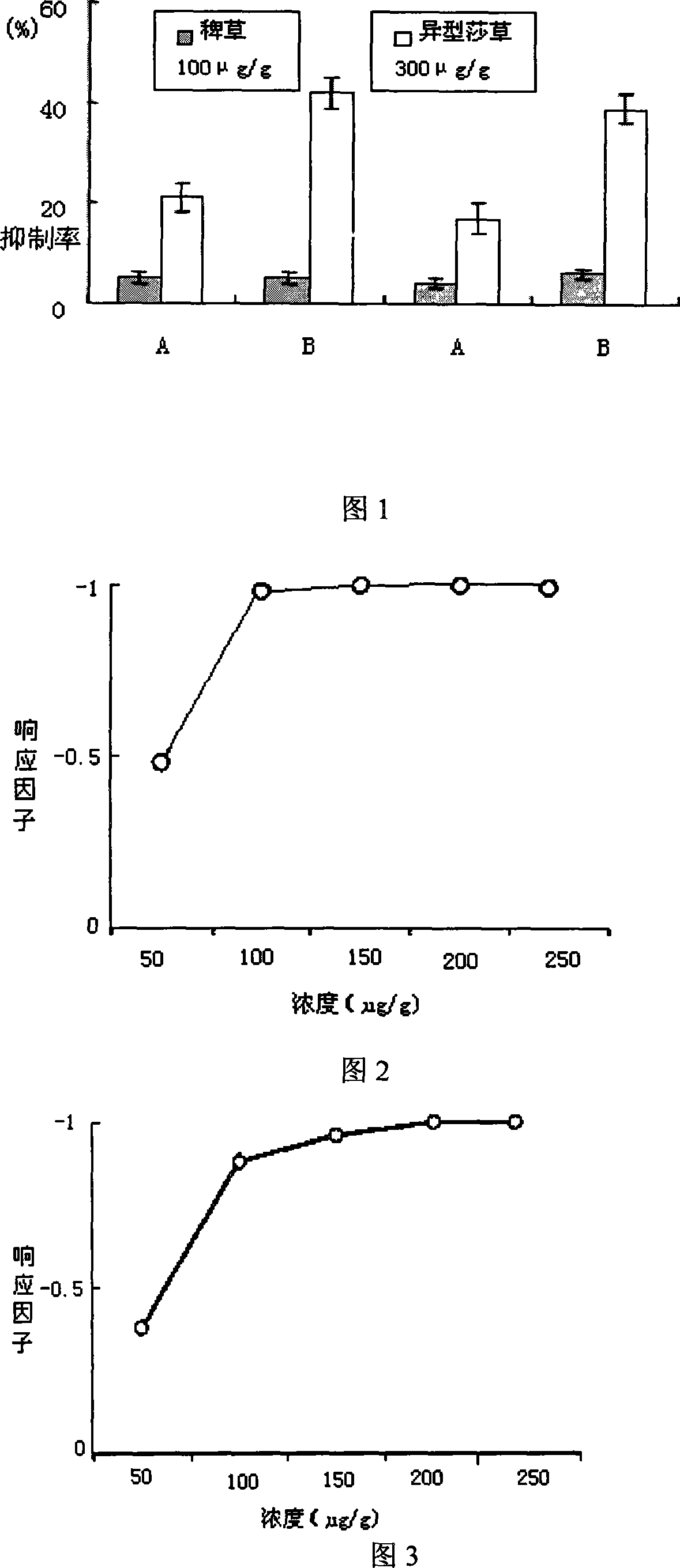

InactiveCN101239960AInhibit growthInhibition of germinationBiocideOrganic chemistryChemical synthesisSpore germination

The invention relates to a synthesis method of 5, 7, 4'-trihydroxy-3', 5'-dimethoxyflavone and application thereof, particularly to a chemical synthesis method of allelochemicals, 5, 7, 4'-trihydroxy-3', 5'-dimethoxyflavone, by separating from allelochemical rice, Oryza sativa L.(PI312777). Syringic acid and phloroglucinol are used as the raw materials, the object products are synthesized by four steps. The products are protected by benzyl, and benzyl is synchronously removed with glacial acetic acid heating and ring closing in the final reaction step, thereby reducing the reaction steps. Compared with the method of removing benzyl by Pd / C charging hydrogen, the method of the invention is more simple, economical, and safe. The invention is capable of effectively stopping growth of garnyardgrass, cyperus iria linn and cyperus difformis linn seeds in rice, restraining paddyfield weed, improving rice yield, stopping spore germination of pyricularia oryzae and rhizoctonia solan so as to avoid the problems due to pesticide application and promote sustainable development of agriculture.

Owner:NANKAI UNIV

Process and device for recycling coked ammonium sulfate acid tar

The invention belongs to the technical field of purification of coke-oven gas, in particular to a process and device for recycling coked ammonium sulfate acid tar. The process comprises the following steps of: spraying acid tar extracted from a full launder in an ammonium sulfate procedure with hot ammonia water which is subjected to heat exchange by using an ammonia steaming ammonia water heat exchanger at the temperature of 92-98 DEG C; mixing and introducing a mixture into an acid tar neutralizing tank; performing acid-alkali neutralization in the neutralizing tank; extracting mixed liquorof tar and ammonia water from the bottom of the front end of the neutralizing tank by taking a pump as power; introducing acid tar from the upper part of the back end of the tank into the neutralizing tank through the outlet of the pump to fully neutralize the acid tar; circulating for 30 minutes; pumping the mixed liquor into a coal gas sucking pipeline of a coke oven by using the pump; and introducing the mixed liquor into a mechanical ammonia water settling tank along with an ammonia water system to fulfill the aim of recycling the acid tar. The process and device are easy to operate and have low investment and running costs. By adopting the process and device, a heat source of ammonium steaming waste water is fully used for heating the acid tar, a large amount of steam is saved, and the acid tar can be directly taken as a product.

Owner:NANJING IRON & STEEL CO LTD

Environment-friendly exterior wall tile strengthening process

ActiveCN108071238AAvoid the risk of falling outAvoid pollutionBuilding repairsArchitectural engineeringUltimate tensile strength

An environment-friendly exterior wall tile strengthening process includes the steps of tile cleaning, investigation and restoration, preparation of stainless steel meshes, reinforcement, reinforcementmethod for special positions and inspection. The environment-friendly exterior wall tile strengthening process has the advantages of simple process, less construction difficulty, short construction period, low labor intensity of workers and less construction risks, the risk that the tiles are divorced from the wall space to drop out from high altitude can be completely solved, the problem that anouter wall is smashed to be installed again can be avoided, the discharge of construction waste can be reduced from the root, the environment is protected, and the construction cost is saved. The noise pollution caused by smashing the tiles with a traditional process and the environmental pollution caused by generated dust can be avoided, the generation of haze can be reduced, thereby contributing to building a better city.

Owner:李彬杰

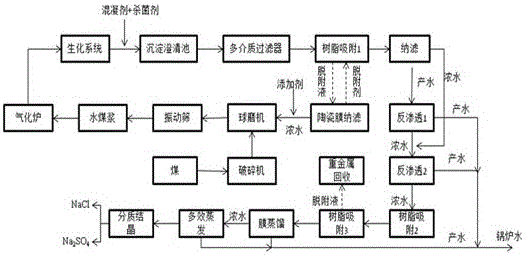

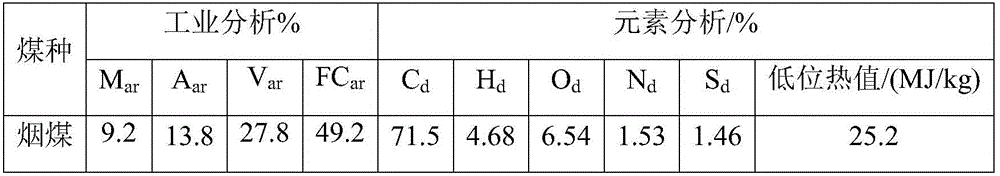

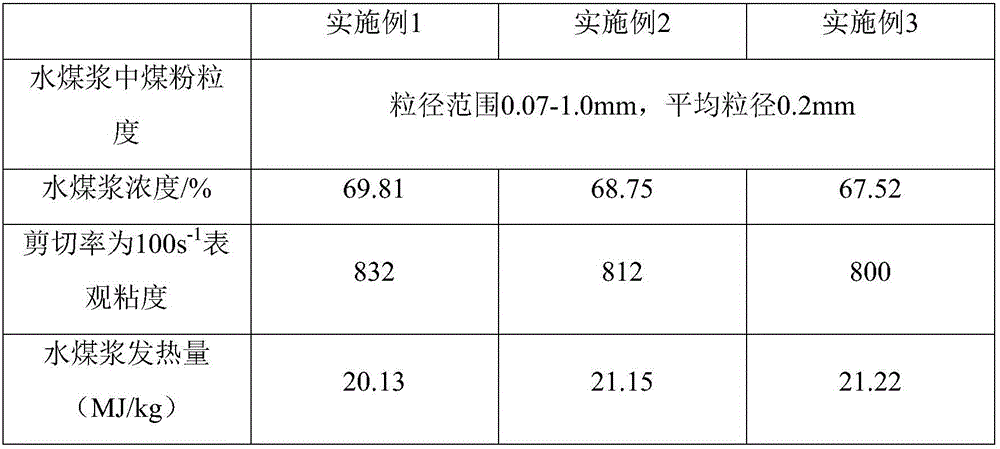

Zero-drainage technology of biochemical effluent water deep treatment and resource recycling of coal chemical industry wastewater

InactiveCN106630350AReduce salt contentOvercome the problems introducedWater treatment parameter controlFatty/oily/floating substances removal devicesDesorptionWater filter

The invention relates to a zero-drainage technology of biochemical effluent water deep treatment and resource recycling of coal chemical industry wastewater. The zero-drainage technology comprises the following steps of adding a coagulant and a sterilizing agent into biochemical effluent water, sending into a settling and clarifying tank and a multi-medium filter, and removing small-particle suspension and oil; sending into a resin adsorbing tank 1 and a nanofiltration membrane module; sending resin adsorbing liquid into a ceramic membrane nanofiltration membrane module, thickening, and mixing with an additive, so as to obtain a water-coal-slurry finished product, wherein the water filtered by the ceramic membrane nanofiltration membrane module is used as a desorbing agent for the next resin desorption; enabling the water produced by the nanofiltration membrane module to pass through a reverse osmosis membrane module 1, a reverse osmosis membrane module 2, a resin adsorbing tank 2, a resin adsorbing tank 3 and a membrane distiller, sending the produced water as boiler water into a boiler, and sending the concentrated water to perform multi-efficiency evaporation treatment and quality-divided crystallization, so as to obtain NaCl (sodium chloride) and Na2SO4 (sodium sulfate) industrial salts. The zero-drainage technology has the advantages that the secondary pollution is avoided, the cost is low, the energy consumption is low, and the long-term running is realized.

Owner:SEDIN ENG

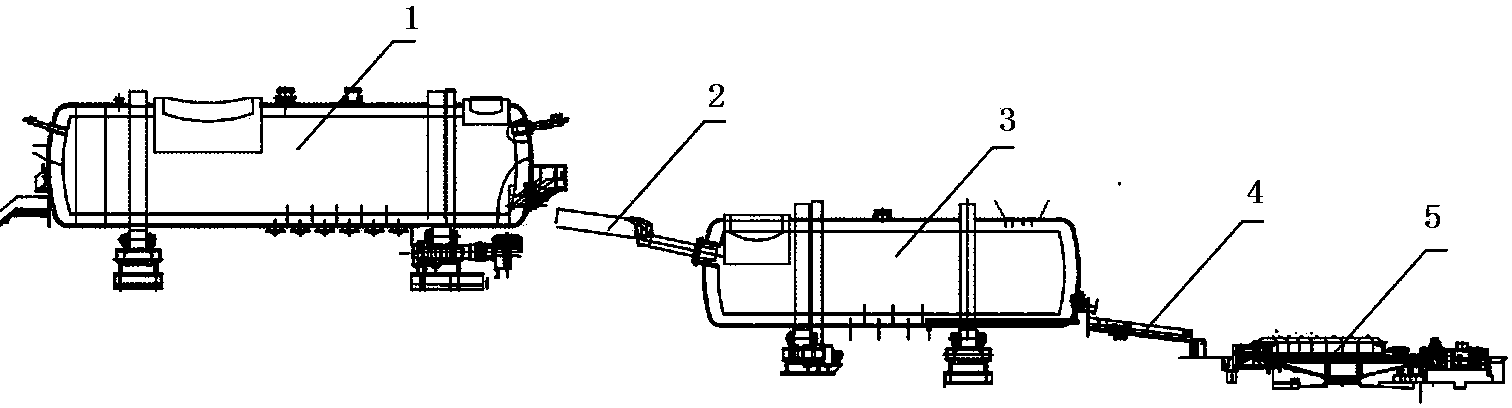

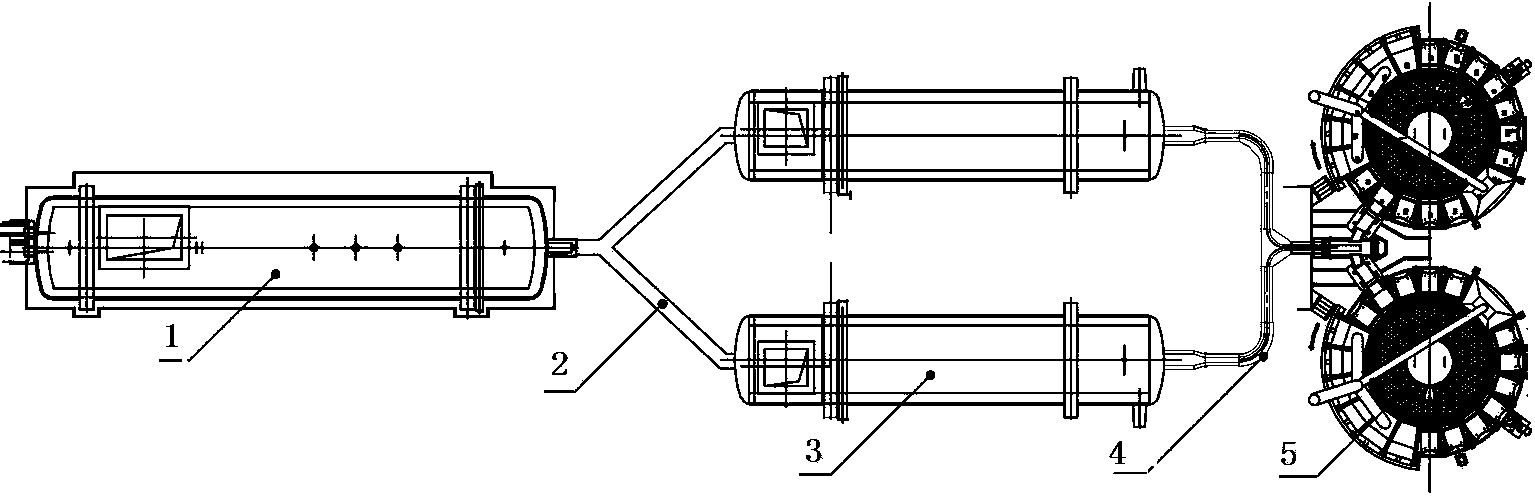

Hierarchy cascade short process copper smelting device and process

InactiveCN104004922ARealize switchingAvoid intractableRotary drum furnacesCrucible furnacesGear driveChinese characters

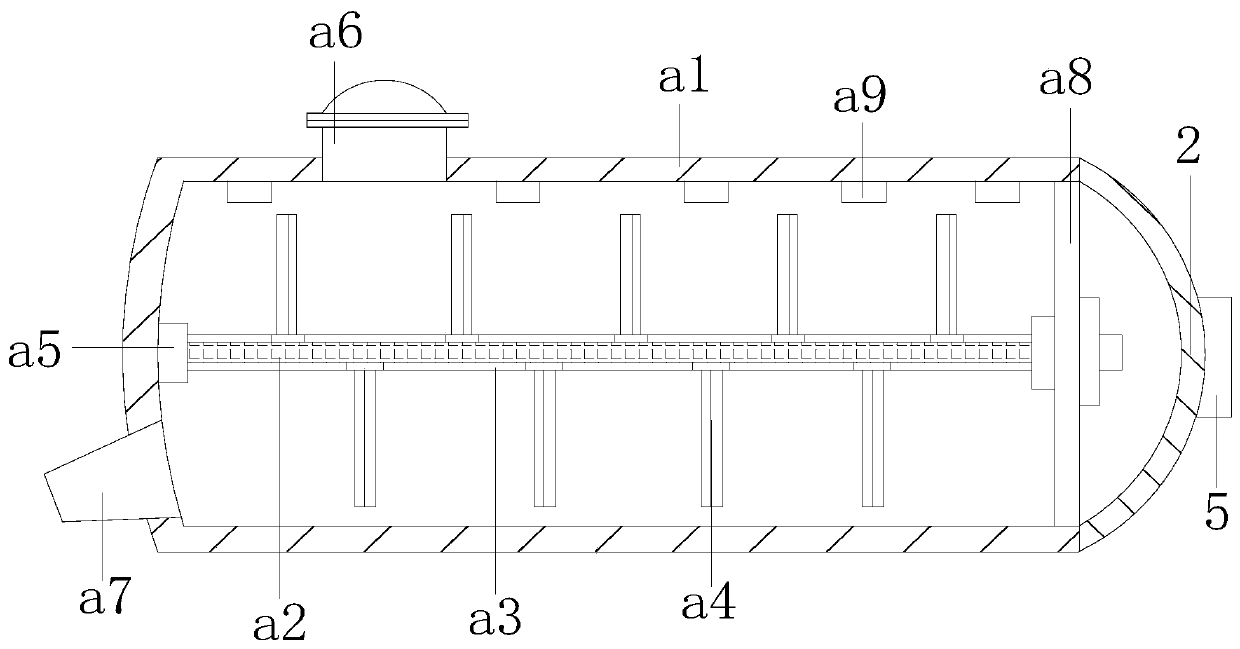

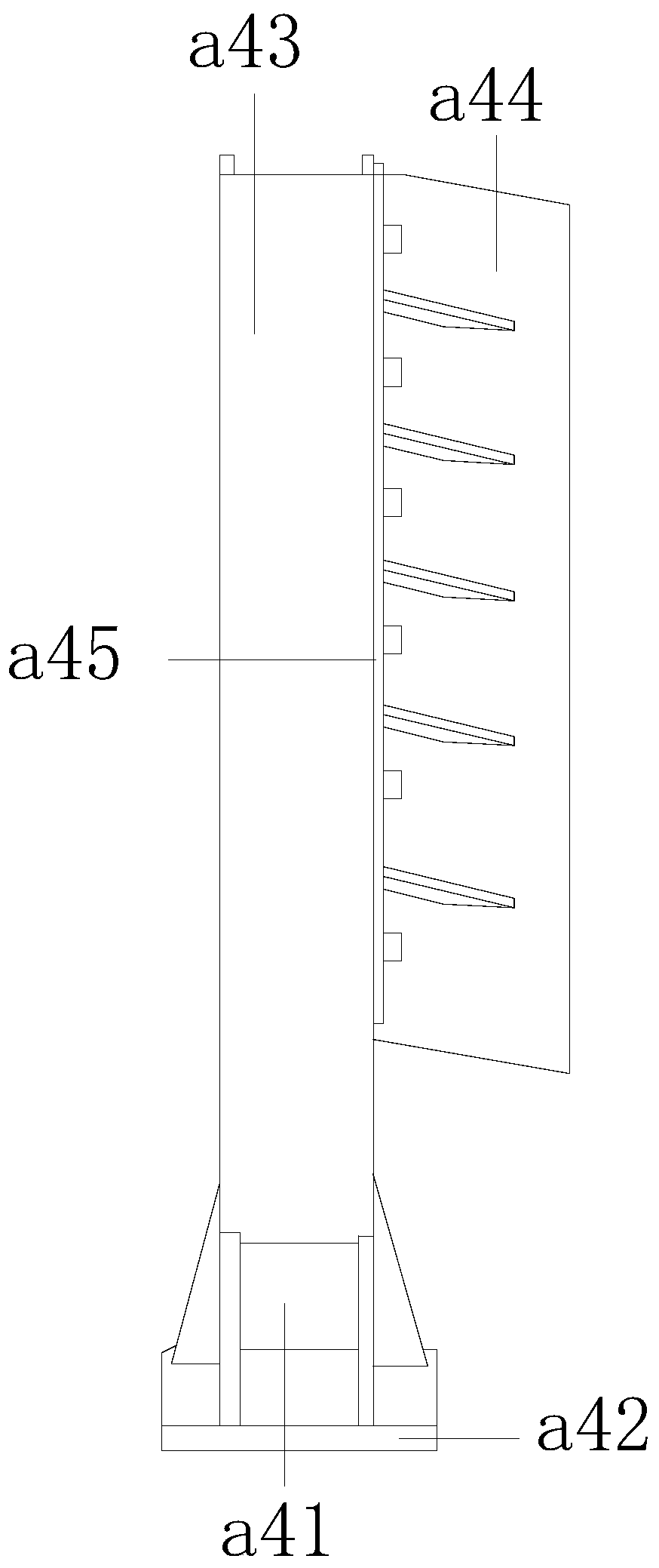

The invention discloses a hierarchy cascade short process copper smelting device and process. The device comprises one multi-component furnace and two elemental furnace which are rotary horizontal cylindrical furnaces, wherein a shell is a steel plate; a lining is a refractory material; the furnace body is supported on a base through two carrier rollers; a motor is arranged at one end of one carrier roller; the furnace body can rotate along the axis through gear drive; 1-40 spray guns are arranged at the bottom of the furnace and are arranged in a single row or multiple rows; the furnaces are connected by adopting a chute and the one multi-component furnace and two elemental furnaces are arranged in a hierarchy cascade mode in the shape like a Chinese character pin. The hierarchy cascade short process copper smelting device has the advantages of simple structure, reasonable design, energy conservation and environment friendliness and has high popularization and application values.

Owner:SHANDONG FANGYUAN NON FERROUS METAL TECH SERVICE +3

Feed additive premix for preventing and controlling snakehead deformity

The invention relates to a feed additive premix for preventing and controlling the snakehead deformity, and belongs to the technical field of feed. The feed additive premix comprises compound vitamins and compound trace elements; raw materials are stable in source, the nutrition is comprehensive, and the requirements on the vitamins and the mineral nutrition for high-density cultivation of raw fish (snakehead) in the areas of Jiangsu and Zhejiang can be met; the feed additive premix is safe and efficient after being used for a long time, has no toxic and side effects, can reduce the cultivation death rate of the raw fish (snakehead) in the areas of Jiangsu and Zhejiang remarkably, and reduces the deformity greatly, the cultivated snakeheads are high in survival rate, high in growth speed and low in deformity, and the economic benefits are remarkable.

Owner:珠海海为饲料有限公司

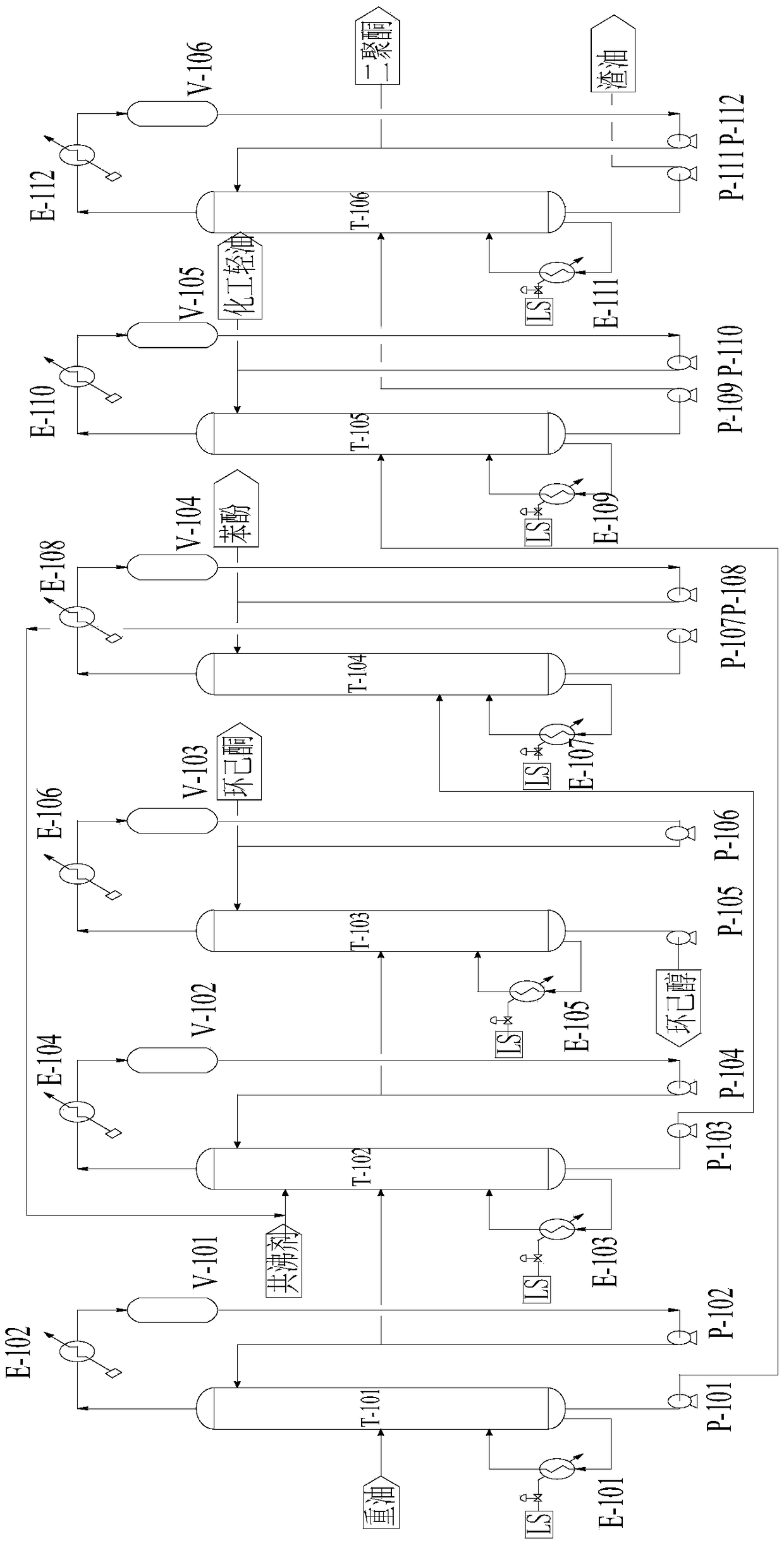

Technology for comprehensively treating heavy oil produced in hydration-method cyclohexanone production process

ActiveCN108863722AEfficient use ofLow running costOrganic compound preparationHydroxy compound preparationChemistryBoiling point

The invention provides a technology for comprehensively treating heavy oil produced in a hydration-method cyclohexanone production process. The technology comprises the following steps: conveying a byproduct heavy oil of a hydration-method cyclohexanone device into the middle part of a primary separation tower; separating by a tower kettle of the primary separation tower to obtain a component witha boiling point greater than that of phenol and conveying the component into a middle component tower; separating at a tower top of the primary separation tower to obtain the phenol and a light component with the boiling point smaller than that of the phenol; conveying the phenol and the light component into the middle part of a co-boiling rectifying tower; obtaining a mixture of cyclohexanone and cyclohexanol at the tower top of the co-boiling rectifying tower, and conveying the mixture into the middle part of a cyclohexanone tower; separating by the tower kettle to obtain a highest-boiling-point azeotrope formed by the phenol and an azeotrope agent; conveying the highest-boiling-point azeotrope into the middle part of a phenol recycling tower; separating at the tower top of the cyclohexanone tower to obtain cyclohexanone and extracting the cyclohexanone; separating by the tower kettle to obtain the cyclohexanol and extracting the cyclohexanol as a product. According to the technology provided by the invention, cyclohexanone, cyclohexanol, phenol and dipolyketone products are obtained respectively by carrying out comprehensive recycling and utilization on the heavy oil; meanwhile, byproducts including chemical light oil and dreg oil are produced, the utilization rate of the byproduct heavy oil is improved, the operation cost of the device is reduced and the environment pollution is reduced.

Owner:CHINA TIANCHEN ENG

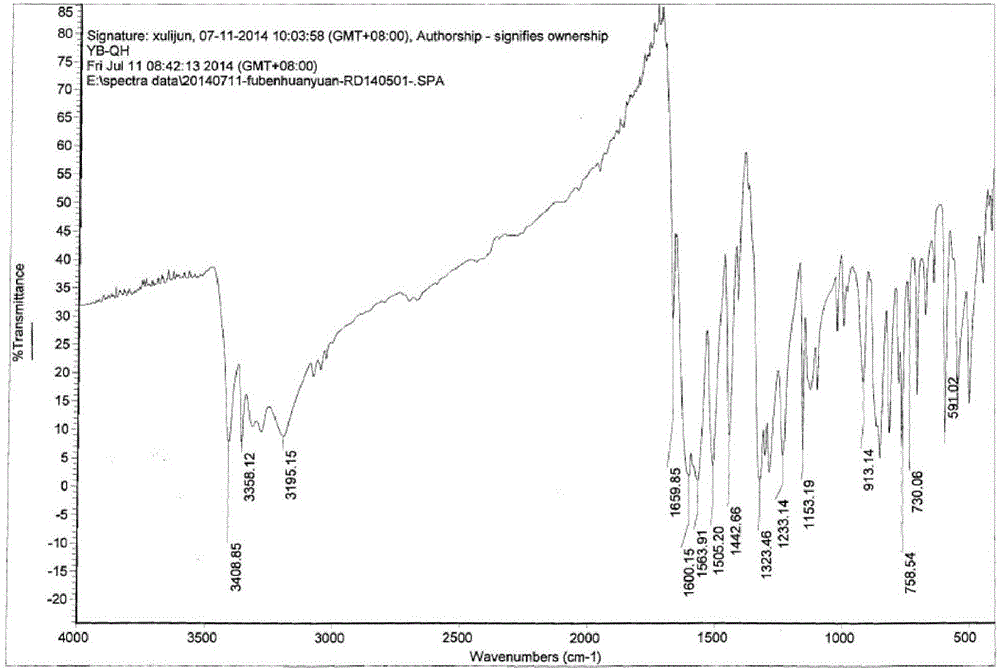

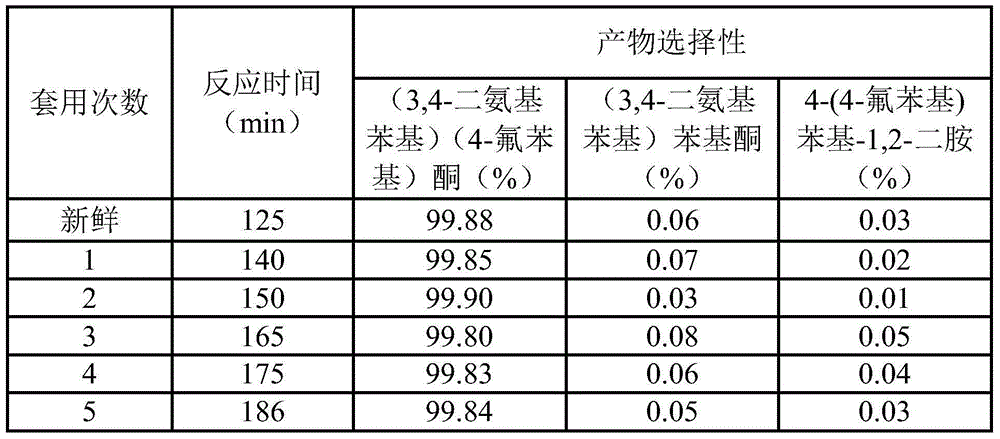

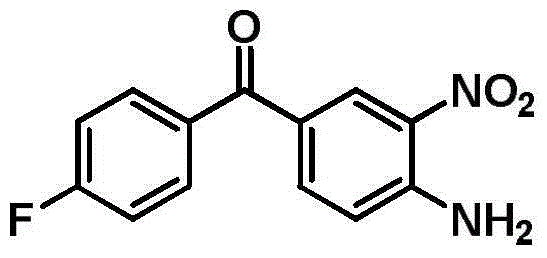

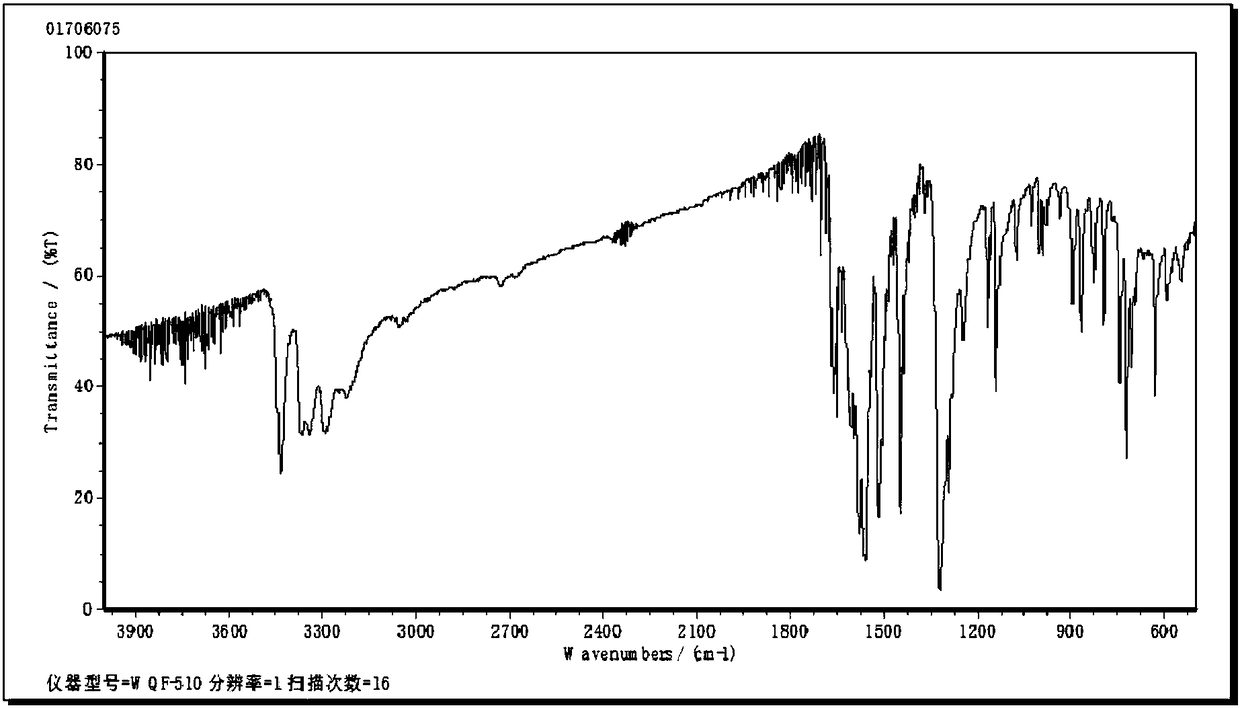

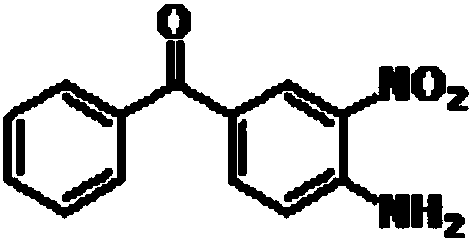

Method for preparing high-purity (3,4-diaminophenyl)(4-fluorophenyl) ketone by virtue of catalytic hydrogenation

ActiveCN104086452AEasy to prepareHigh reactivityOrganic chemistryOrganic compound preparationOrganic solventSodium hydrosulfide

The invention relates to a method for preparing high-purity (3,4-diaminophenyl)(4-fluorophenyl) ketone by virtue of catalytic hydrogenation, belonging to the technical field of pharmaceutical and chemical engineering. The method comprises the following steps: adding (4-amino-3-nitrophenyl)(4-fluorophenyl) ketone (I) and a catalyst into an organic solvent, introducing hydrogen, and performing hydrogenation reduction reaction to obtain a flubendazole intermediate namely (3,4-diaminophenyl)(4-fluorophenyl) ketone (II). The method disclosed by the invention has the advantages that compared with a reduction method using sodium hydrosulfide, the method is simple in process, small in solvent dosage and short in reaction time, can be used for solving the problem that a large amount of sulfide-containing wastewater is difficult to be treated, and is beneficial for industrial production; meanwhile, a novel catalyst preparation method is simple, and has the characteristics of high reaction activity, good selectivity and recycled catalyst; compared with a pure Pt / C catalyst, the novel catalyst can be used for effectively inhibiting the phenomenon that carbanyl groups are reduced into methylene and inhibiting the occurrence of the defluorination phenomenon, and is relatively high in product yield and purity.

Owner:CHANGZHOU YABANG QH PHARMACHEM

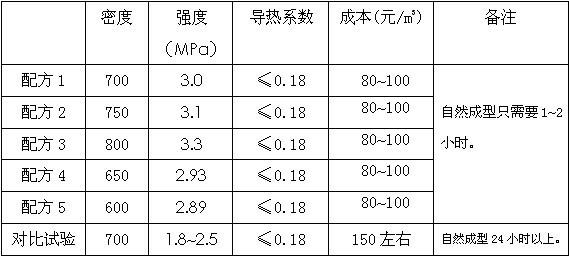

Shale sintering foam building block and preparation method thereof

InactiveCN102617181AAvoiding the Difficult Problems of Development SpoilsAvoid intractableCeramicwareClaywaresLand resourcesMetallurgy

The invention discloses a shale sintering foam building block, which is dosed by the following materials by weight: 70 to 80 parts of shale, 20 to 30 parts of rubbish material, 10 to 15 parts of water and 1 part to 1.5 parts of additive. The building block is formed by conducting mixed material, foaming, mold natural molding, cutting and sintering on the raw materials. The specific preparation method includes respectively grinding the raw materials into powder of 80-100 powder, adding water into the raw materials to prepare slurry in stirring mode according to the prescription and the raw materials, adding calcium aluminate powder and sodium hydroxide into the slurry, stirring the mixture for 3 to 5 minutes, heating the mixture, adding hydrogen peroxide into the mixture, quickly stirring the mixture for 1 to 2 minutes, injecting evenly mixed materials into a mold, conducting natural foaming molding for 1 to 2 hours, conducting cutting molding through a cutting machine, finally conducting sintering under the temperature of 1000 DEG C to 1050 DEG C for 40 to 60 minutes and conducting cooling to obtain the building block. The building block avoids utilizing clay as a raw material, is capable of saving a large amount of land resources and has the advantages of being low in density, good in heat preservation performance, good in size stability, good in durability and the like. The method is simple in process, short in molding time and greatly reduces preparation cost.

Owner:重庆市旌弘建材有限公司

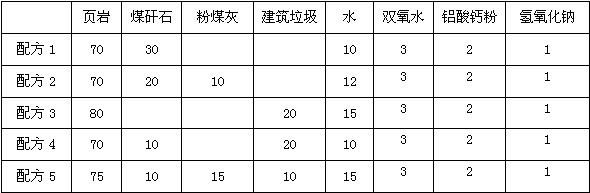

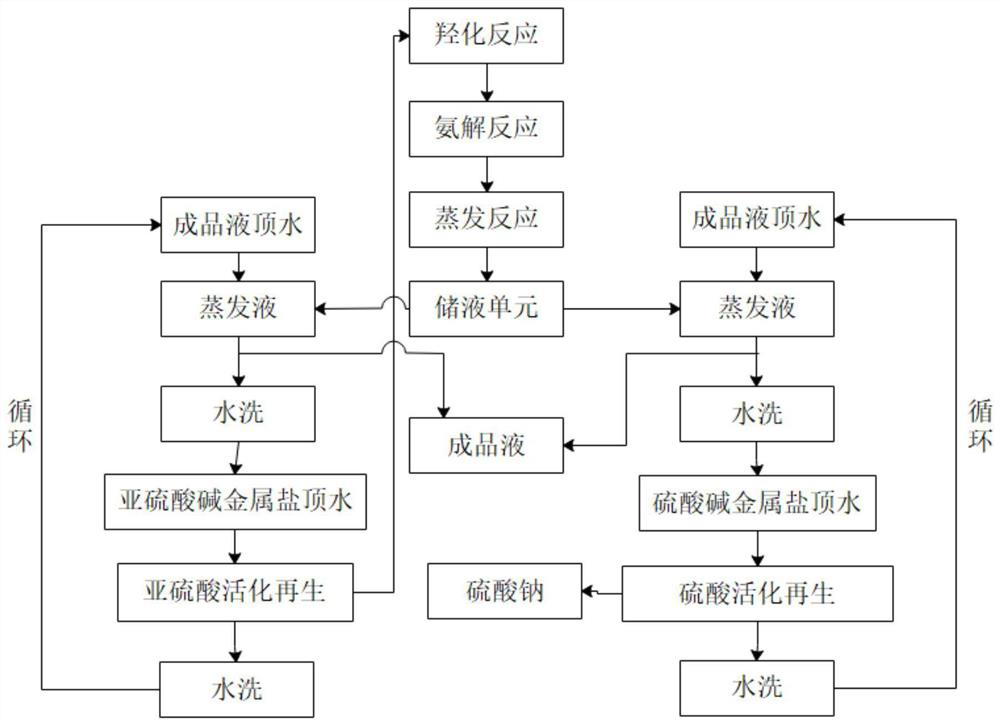

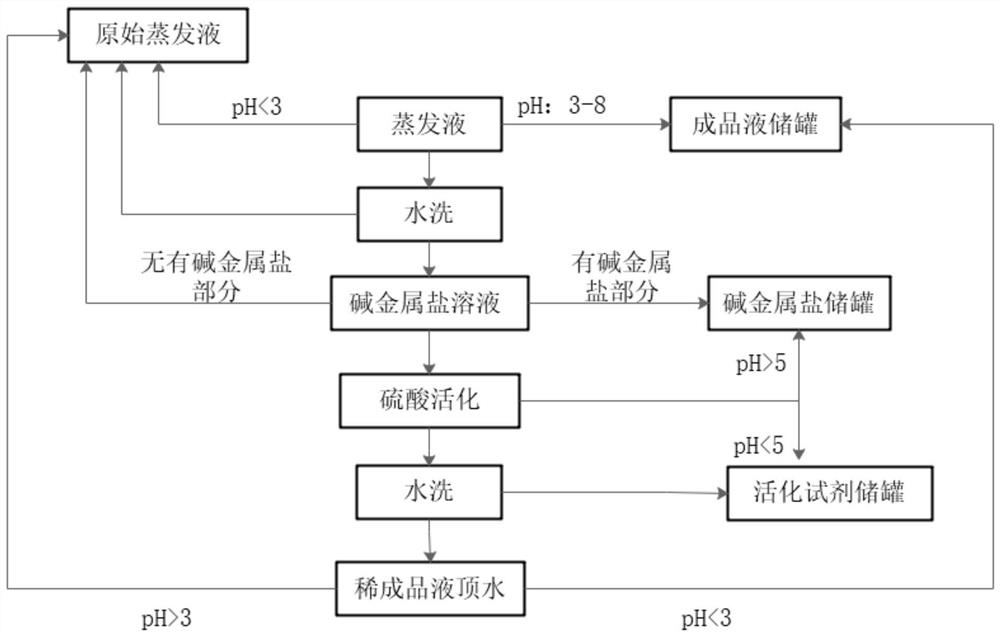

System and method for efficiently preparing taurine

ActiveCN113072468AAvoid intractableLow efficiencyOrganic compound preparationSolid sorbent liquid separationIon exchangeSulfuric acid

The present invention provides a system for efficiently preparing taurine. The system comprises a liquid storage unit, an ion exchange unit and a distribution unit. The liquid storage unit is used for storing a solution containing taurine alkali metal salt prepared by an ethylene oxide method. The ion exchange unit comprises a plurality of ion exchange resin columns, a single ion exchange column is independently activated in a first activation mode or a second activation mode, the first activation mode adopts sulfurous acid for activation so as to obtain acidic sulfurous acid alkali metal salt and taurine, and the second activation mode adopts sulfuric acid for activation so as to obtain alkali metal sulfate and taurine. The distribution unit is respectively connected with the liquid storage unit and the ion exchange unit, and the distribution unit is configured to adjust the amount of the solution conveyed from the liquid storage unit to the ion exchange resin columns in the ion exchange unit.

Owner:HUBEI GRAND LIFE SCI & TECH CO LTD

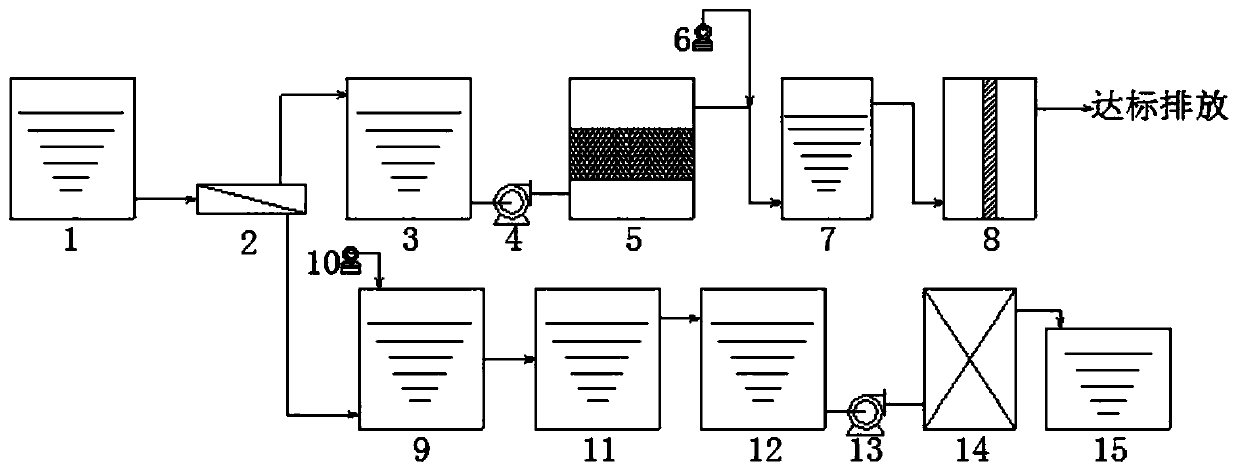

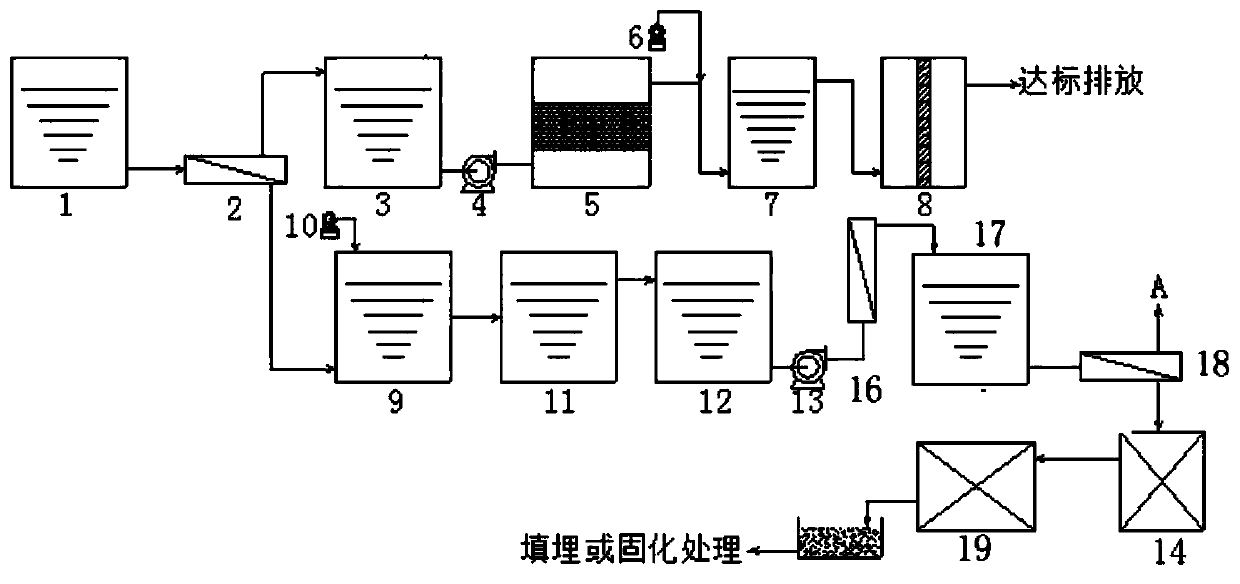

Landfill leachate treatment process and treatment device of landfill leachate

PendingCN109761416AAppropriate treatmentAvoid intractableMultistage water/sewage treatmentContaminated groundwater/leachate treatmentChemical oxygen demandElectrolysis

The invention belongs to the field of wastewater treatment, in particular to a landfill leachate treatment process and a treatment device of landfill leachate. The treatment process comprises the following steps: 1) filtering wastewater with a nanofiltration membrane; 2) performing micro-electrolysis treatment on water produced by nanofiltration in step 1); 3) adding hydrogen peroxide into the water produced by nanofiltration subjected to micro-electrolysis treatment in step 2) and performing Fenton treatment; 4) performing electrocatalytic oxidation treatment on the water produced by nanofiltration undergoing Fenton treatment in step 3), and discharging the wastewater up to standard; 5) purifying concentrated water produced by nanofiltration in step 1). A treatment method combining nanofiltration and advanced oxidization is adopted instead of a reverse osmosis treatment process, so that salts and COD (Chemical Oxygen Demand) in percolate can be treated properly to form a positive cycle, up-to-standard discharge can be achieved, and the problem of difficulty in treating a reverse osmosis concentrated solution when the reverse osmosis treatment process is adopted is solved.

Owner:山东泰禾环保科技股份有限公司

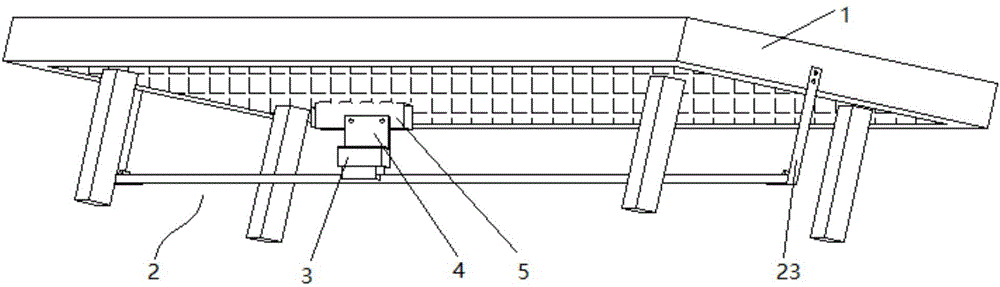

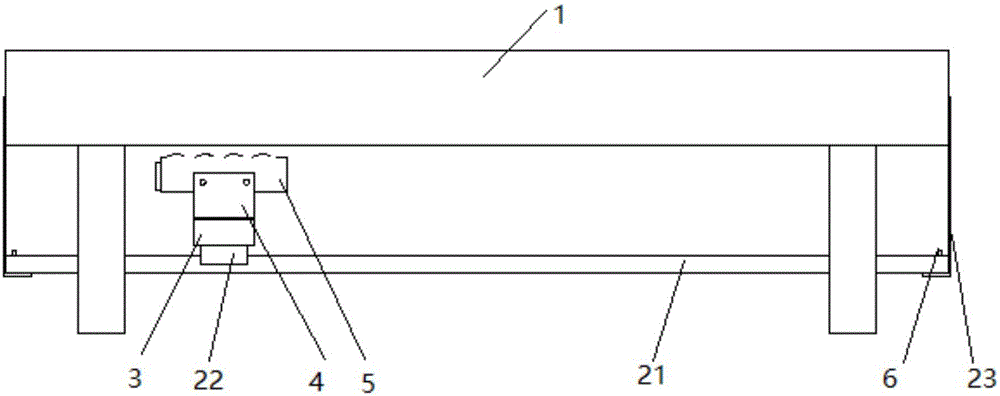

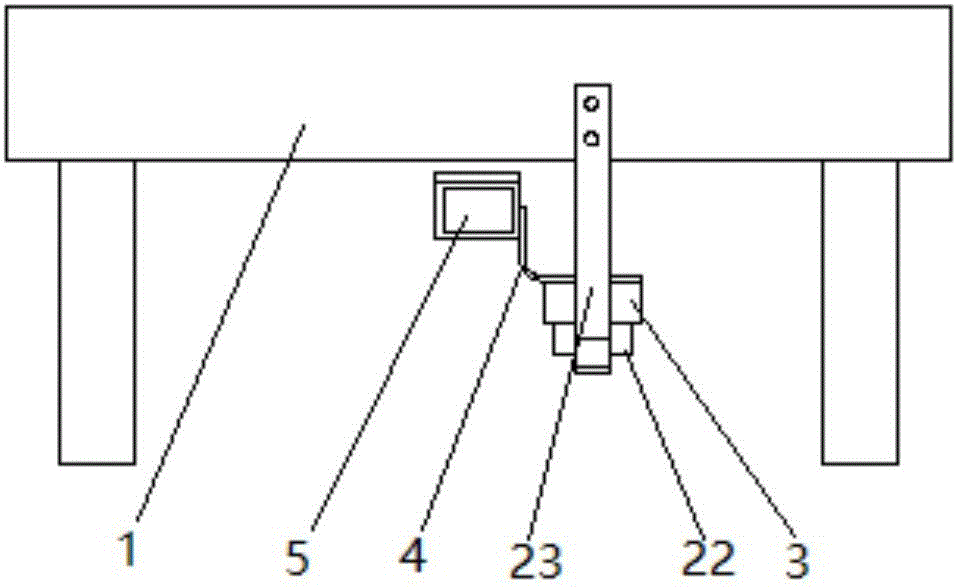

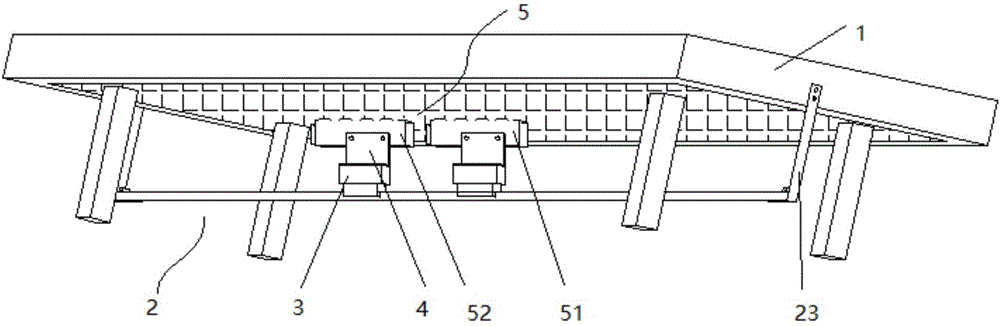

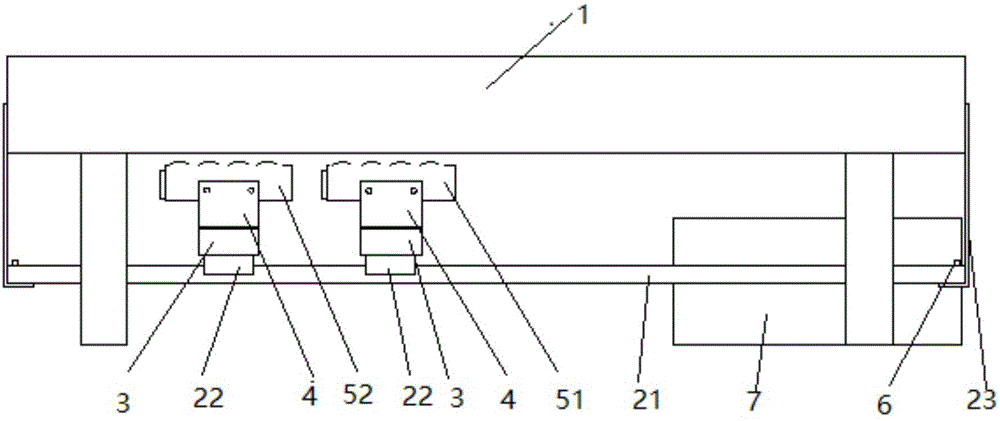

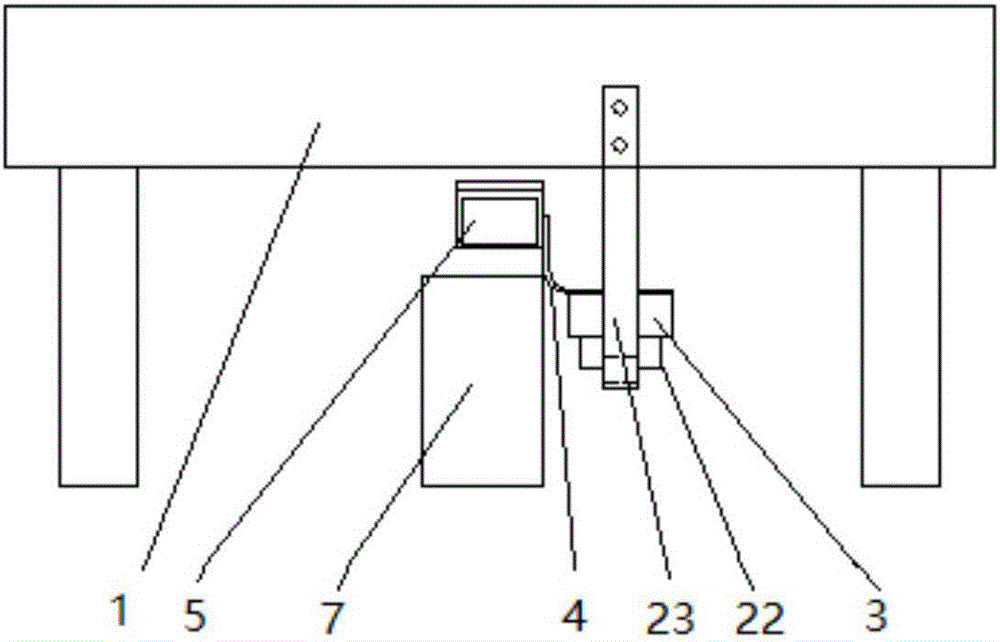

Machining table with dedusting function and working method

The invention provides a machining table with a dedusting function and a working method. The machining table with the dedusting function comprises a workbench, a guide rail pair, a power component, a connecting piece and a dust collector. The workbench is composed of a table board and supporting legs. The guide rail pair comprises a guide rail, a sliding block and a guide rail support. The dust collector and the sliding block can be driven by the power component to reciprocate linearly on the guide rail. The machining table with the dedusting function is used for controlling dust generated in the cutting process, dedusting can be effectively conducted for a dust source, air flow is hardly affected, and a good working environment can be kept easily; and an automatic dedusting function is also achieved, and the machining table can return automatically after operation is completed.

Owner:徐州大自然食品有限公司

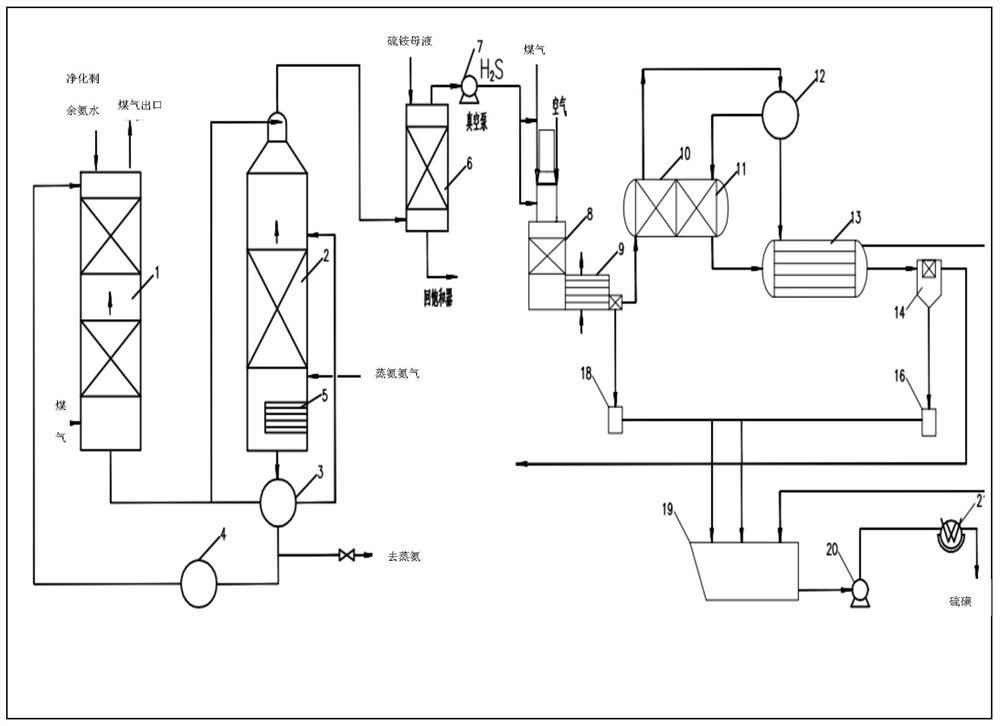

Coke oven gas desulfurization process

ActiveCN113150837AChange weaknessSave energySulfur preparation/purificationGas contaminants removalThermodynamicsWastewater

The invention discloses a coke oven gas desulfurization process, which adopts a stronger ammonia water desulfurization process, separates a coal gas desulfurization process from a deamination process, utilizes an ammonia resource of coal gas as an alkali source for desulfurization, utilizes high-temperature concentrated ammonia gas at the top of an ammonia still to be introduced into a negative-pressure deacidification tower as a heat source for deacidification, and has the advantages of low energy consumption and good desulfurization effect. After being cooled, the waste gas of the process is sent to the coal gas negative pressure system, so that secondary pollution is avoided. The purified acid gas is used for producing sulfur by using a Claus furnace, the product quality is high, and the environment is clean. The whole system has no wastewater difficult to treat.

Owner:JINAN METALLURGICAL CHEM EQUIP CO LTD

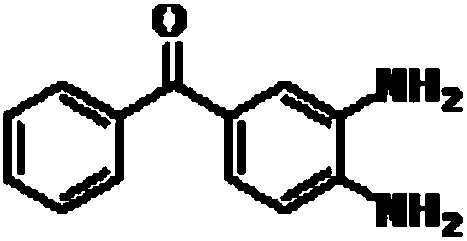

A kind of preparation method of mebendazole intermediate 3,4-diaminobenzophenone

ActiveCN106083622BMild reaction conditionsEasy to operateOrganic chemistryOrganic compound preparationReduction rateOrganic solvent

A preparing method of a mebendazole intermediate (3,4-diaminophenyl)phenyl methanone is disclosed. The method includes adding 4-amino-3-nitro diphenylmethanone and a catalyst into an organic solvent, adding a hydrogen donor, and performing transfer hydrogenation reduction to obtain the (3,4-diaminophenyl)phenyl methanone, wherein the catalyst is a Pd-X / C catalyst, and the X is one of Ni, Ru, La, Ce, Co, Li, K, Mg, Ti, Cu or Mo. The method has advantages of mild conditions, simple operation, a high reduction rate, a low cost, high environment protection performance, easy industrial production, and the like.

Owner:CHANGZHOU YABANG QH PHARMACHEM +1

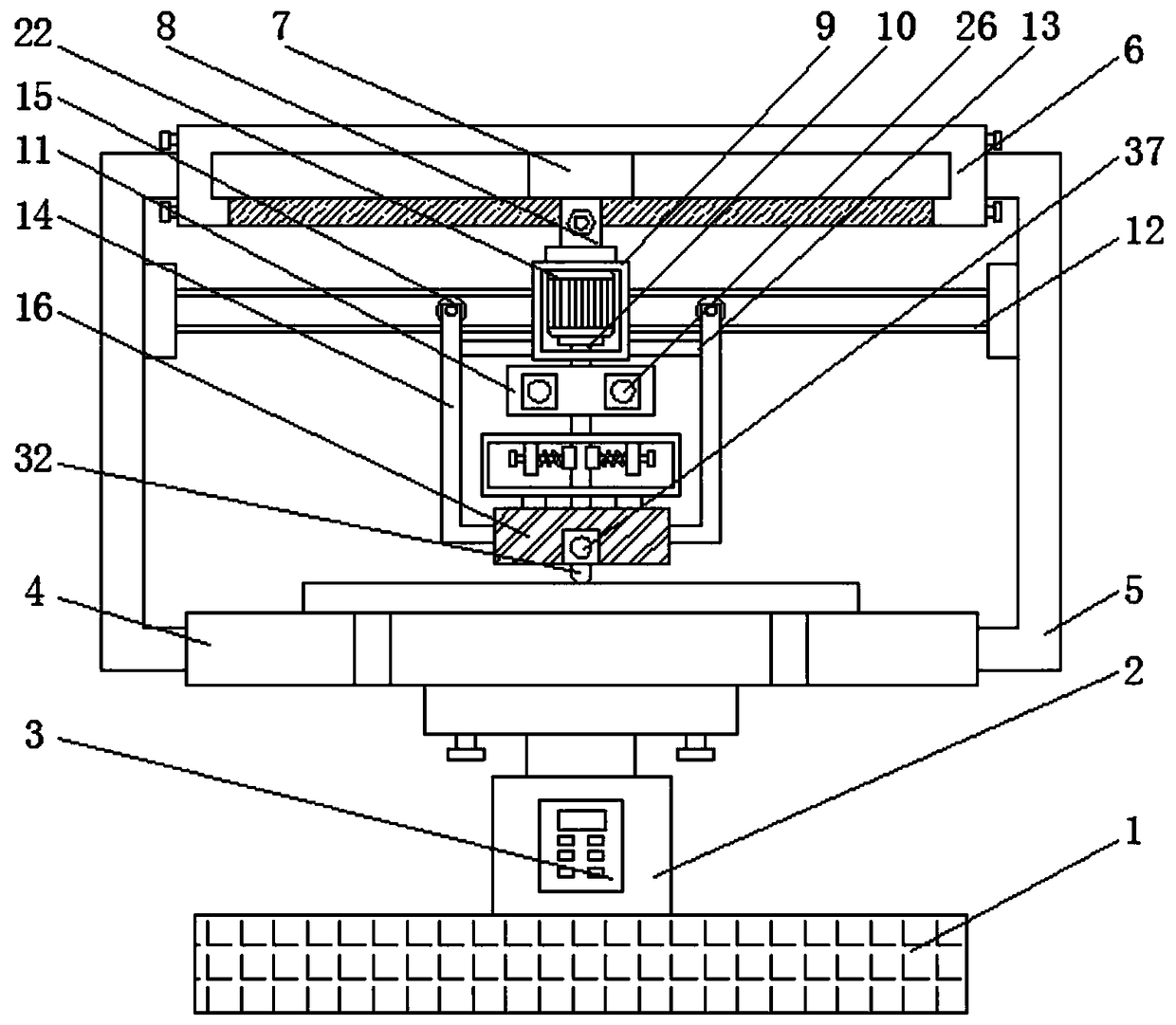

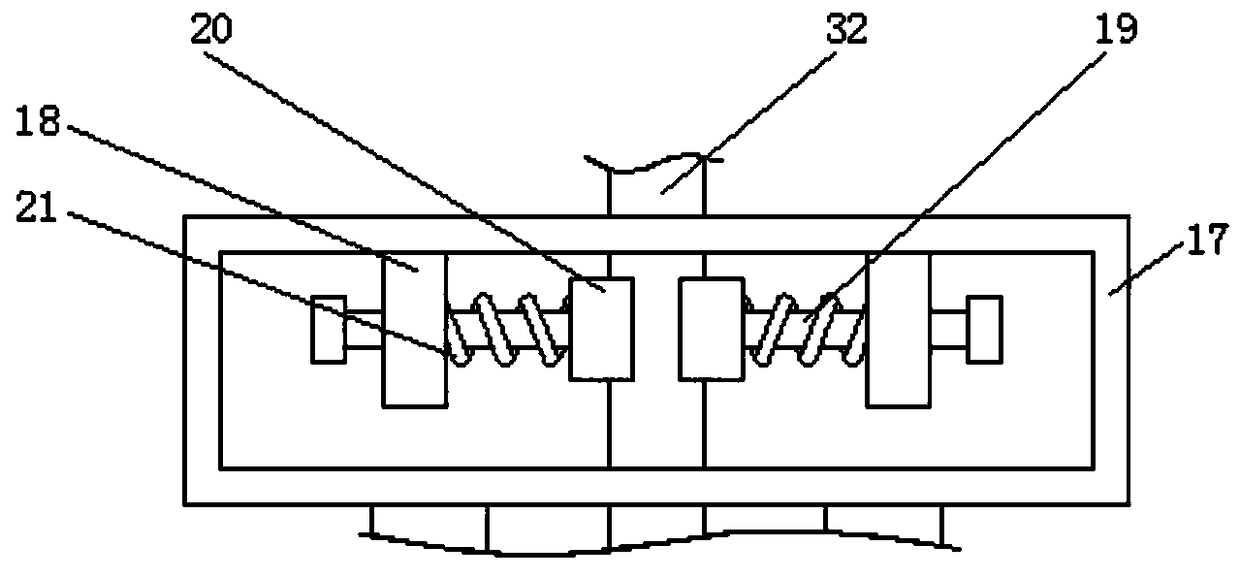

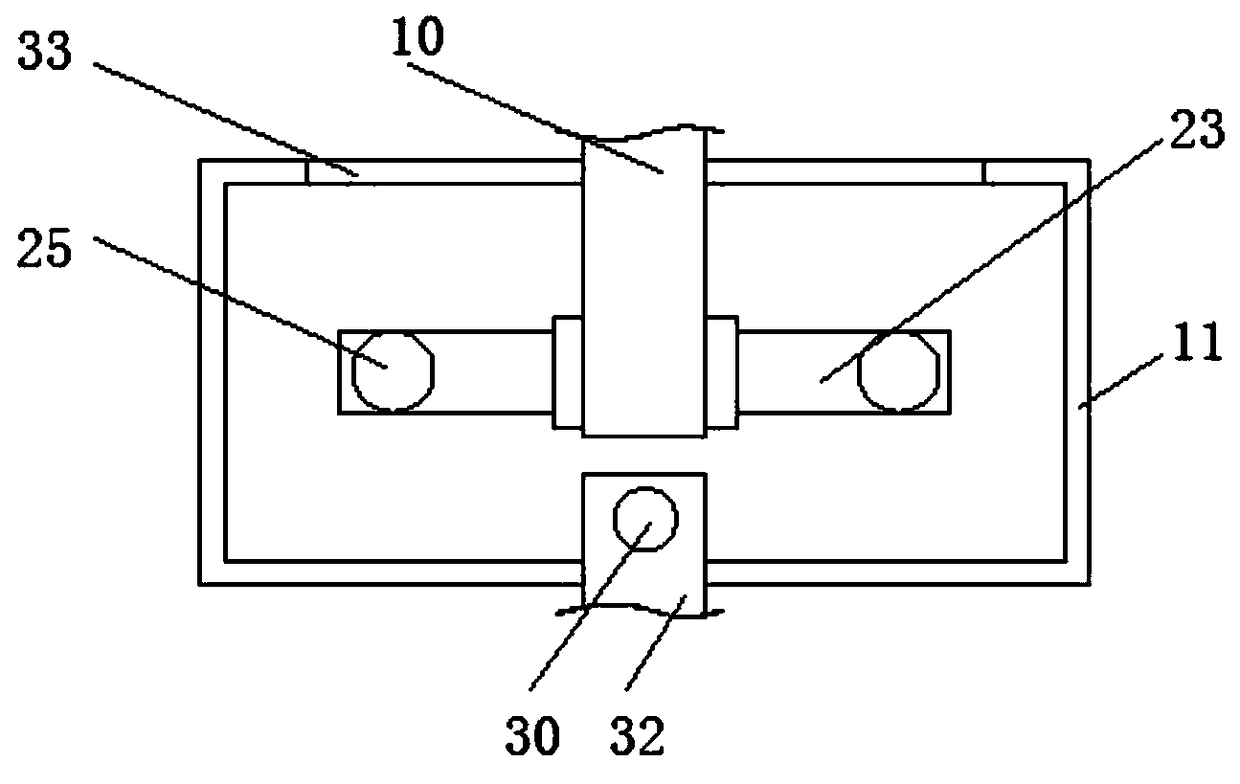

Tool platform with continuous dust removal function and control method

InactiveCN106563966AWith continuous dust removal functionDoes not affect flowWork benchesMaintainance and safety accessoriesWorking environmentPower component

The present invention provides a tool platform with a continuous dust removal function and a control method. The tool platform with the continuous dust removal function comprises a worktable, a dust collecting box, a guide rail pair, two sets of power components, two connecting components and two dust removers; the worktable is composed of a table surface and supporting legs; the guide rail pair comprises a guide rail, a rail bracket and two sliders; the dust removers and the sliders can reciprocate linearly on the guide rail under the driving of the power components; and the dust collecting box is arranged at the right end of ground below the worktable. The tool platform with the continuous dust removal function and the control method of the invention are used for controlling dust produced in a cutting process, can effectively remove dust according to a dust source, almost has no influence on air flow, is conducive to maintaining a good working environment, realizes an automatic dust removal function, and can be automatically reset after operation is completed. According to the tool platform with the continuous dust removal function and the control method of the invention, when one dust remover fails, the dust remover is shut down automatically and waits for maintenance, and the other dust remover is started, and therefore, a guarantee can be provided for the continuous work of machinery.

Owner:重庆泰奥豪骋科技有限公司

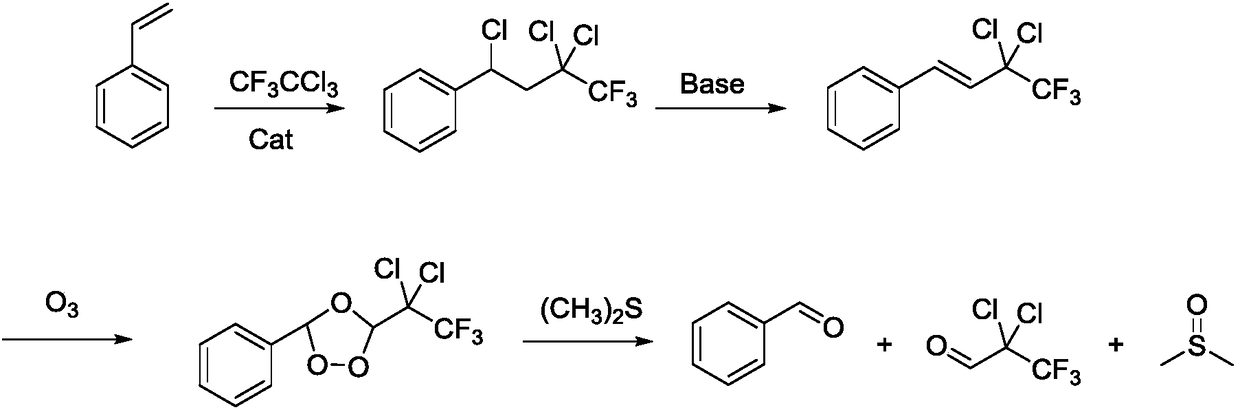

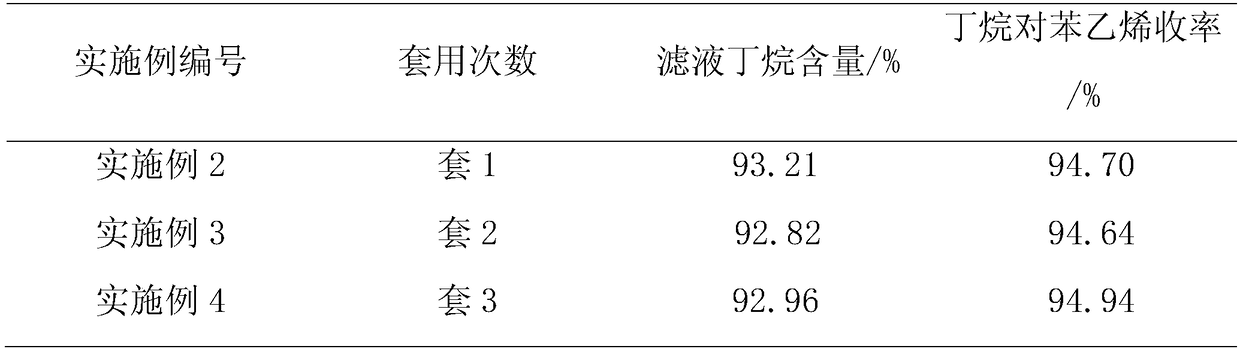

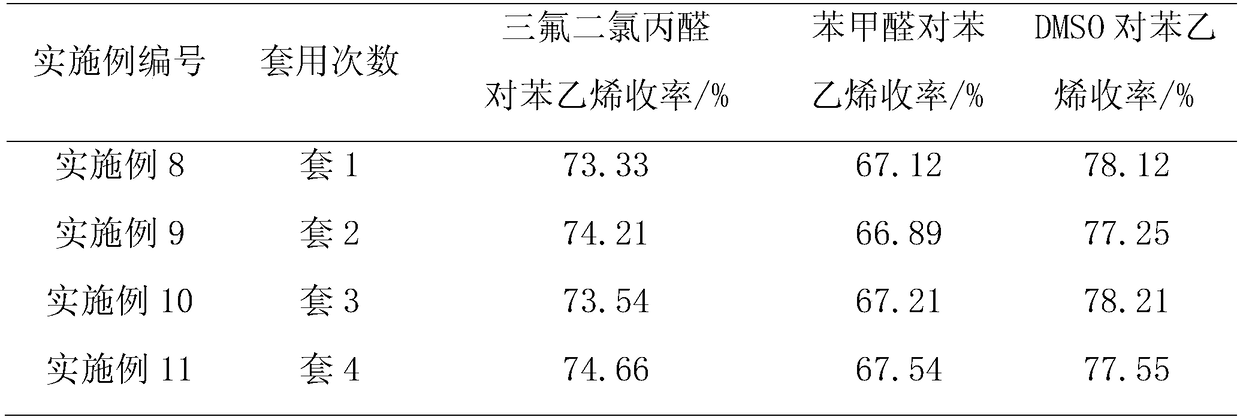

Method for synthesizing pesticide intermediate 3,3,3-trifluoro-2,2-dichloropropylaldehyde

InactiveCN108929210ALow costHigh yieldPreparation by hydrogen halide split-offPreparation by ozonolysisSimple Organic CompoundsHalogen

The invention belongs to the technical field of organic chemical engineering and relates to a method for preparing an important intermediate, i.e., 3,3,3-trifluoro-2,2-dichloropropylaldehyde of a halogen-containing pyridine organic compound. More specifically, the method disclosed by the invention comprises the step of subjecting 1,1,1-trifluorotrichloroethane and styrene, which serve as raw materials, to addition, dehalogenation, ozonation and reduction reactions, thereby synthesizing the important intermediate, i.e., 3,3,3-trifluoro-2,2-dichloropropylaldehyde of chlorfluazuron, fluazuron, Haloxyfop and Fluazinam. The total yield is stabilized to 70% or more, and the product purity is 99% or more. According to the method, the process is clean, the raw material cost is low, the product purity is high, and the industrial production is easy to achieve.

Owner:JIANGSU YANGNONG CHEM GROUP +2

Friction stir welding equipment for stationary shaft shoulder

ActiveCN108788445AImprove practicalityAvoid intractableNon-electric welding apparatusFriction weldingWaste material

The invention relates to the technical field of friction stir welding, and discloses friction stir welding equipment for a stationary shaft shoulder. The friction stir welding equipment comprises a base and a rectangular box; and a jacking block is fixedly mounted in the middle of the top end of the base, a transverse plate is fixedly mounted on the top of the jacking block, and a control unit isfixedly mounted on the obverse side of the jacking block. According to the friction stir welding equipment for the stationary shaft shoulder, by forming a square opening and a collecting box, when thebottom of a stirring needle body conducts friction welding on a workpiece, waste materials generated at the time penetrate through a gap between a stationary shaft shoulder body and the stirring needle body to enter the collecting box, the cross sectional area of the side face of the square opening is equal to the cross sectional area of the side face of the collecting box, thus the collecting box can be taken out of the stationary shaft shoulder body, the problem that the waste materials in the stationary shaft shoulder body are difficult to dispose is prevented, meanwhile, the situation that rotating of the stirring needle body is affected by the excessive waste materials in the stationary shaft shoulder body is also avoided, and the practicality of the friction stir welding equipment is improved.

Owner:HUNAN UNIV OF ARTS & SCI

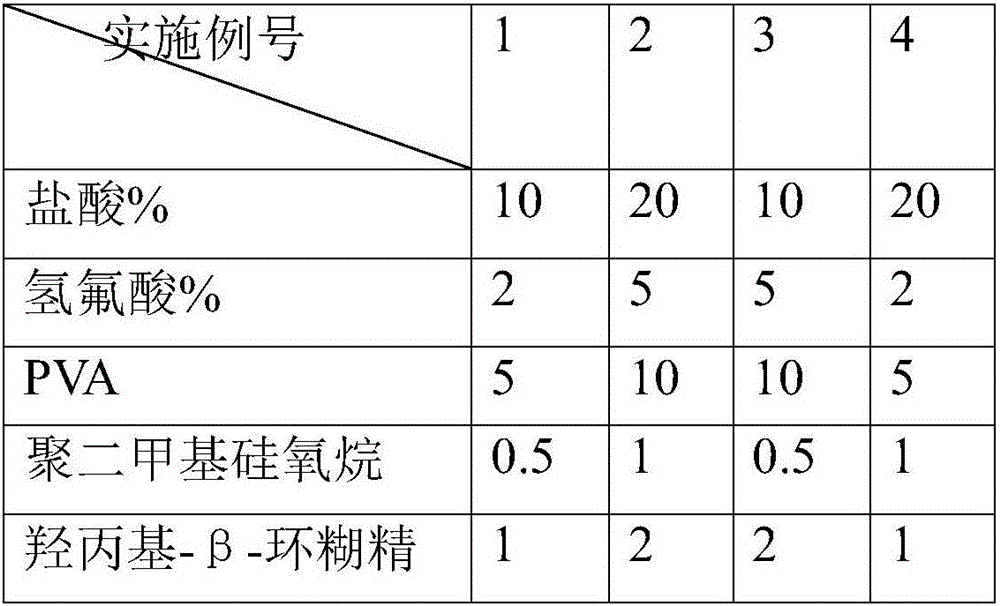

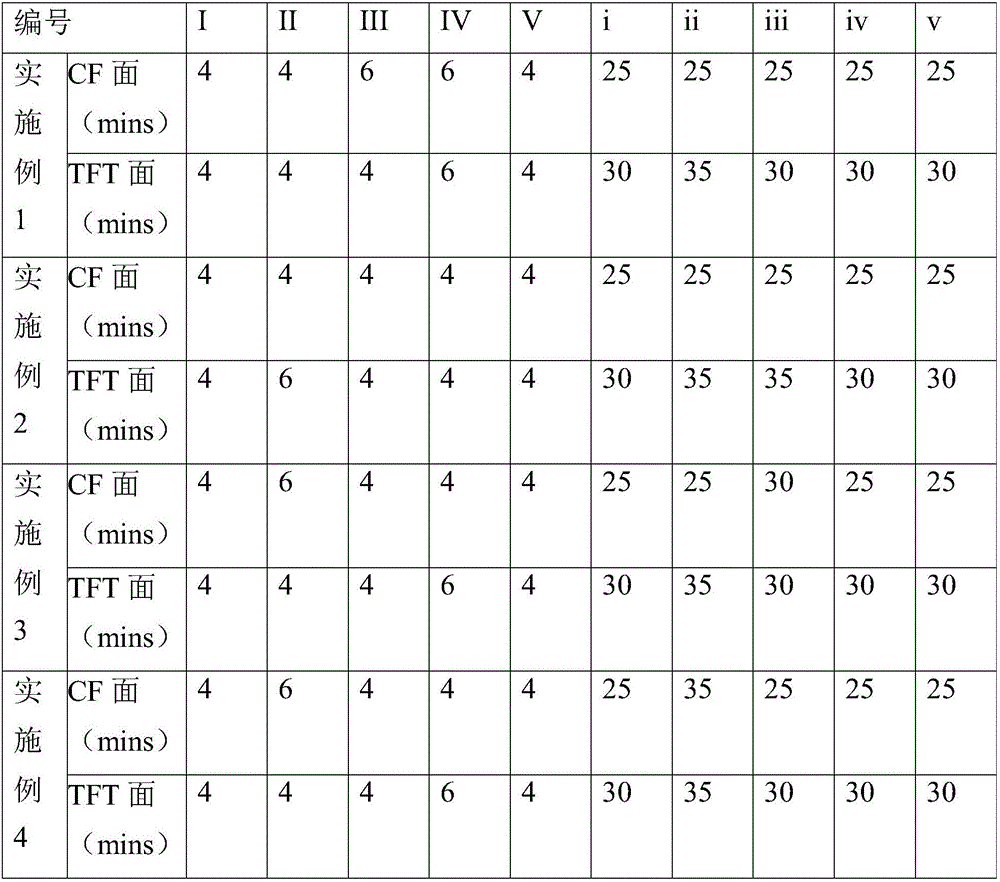

Pretreatment fluid for TFT glass substrate thinning process

A pretreatment fluid for a TFT glass substrate thinning process is characterized by being prepared from, by mass, 10-20% of hydrochloric acid (HCl), 2%-5% of hydrofluoric acid (HF), 5-10% of polyvinyl alcohol (PVA), 0.5-1% of polydimethylsiloxane, 1-2% of hydroxypropyl-beta-cyclodextrin and the balance water.

Owner:天津美泰真空技术有限公司

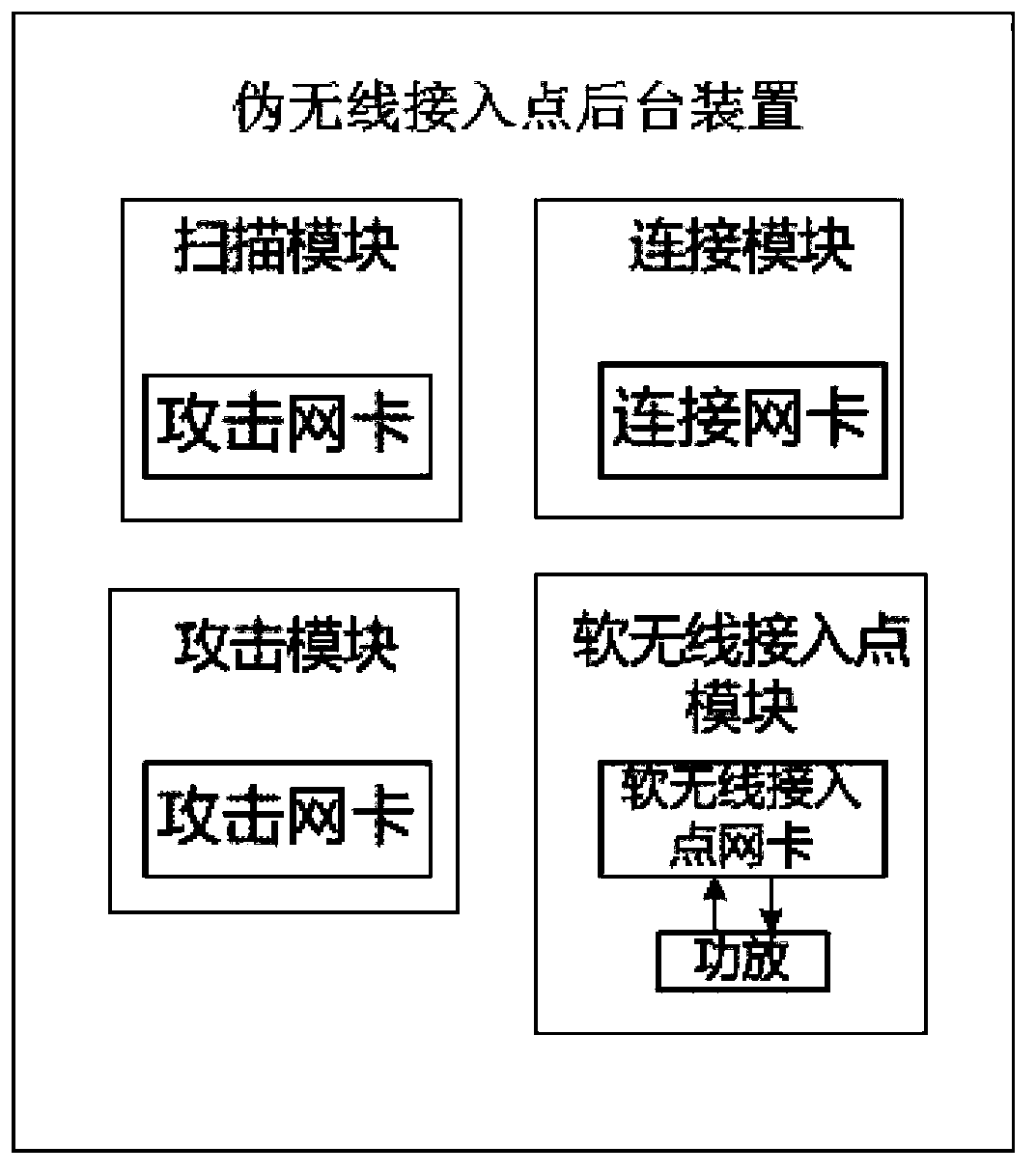

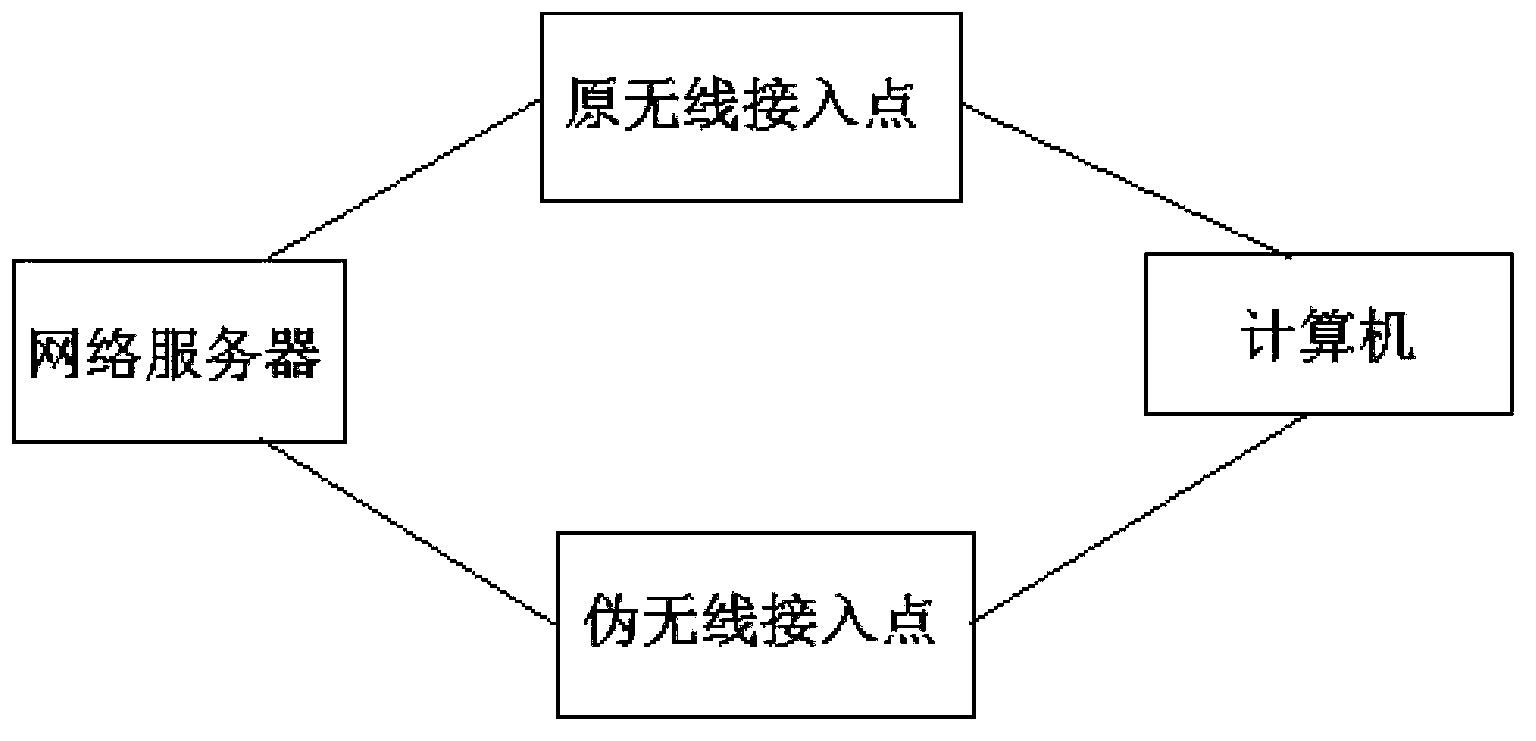

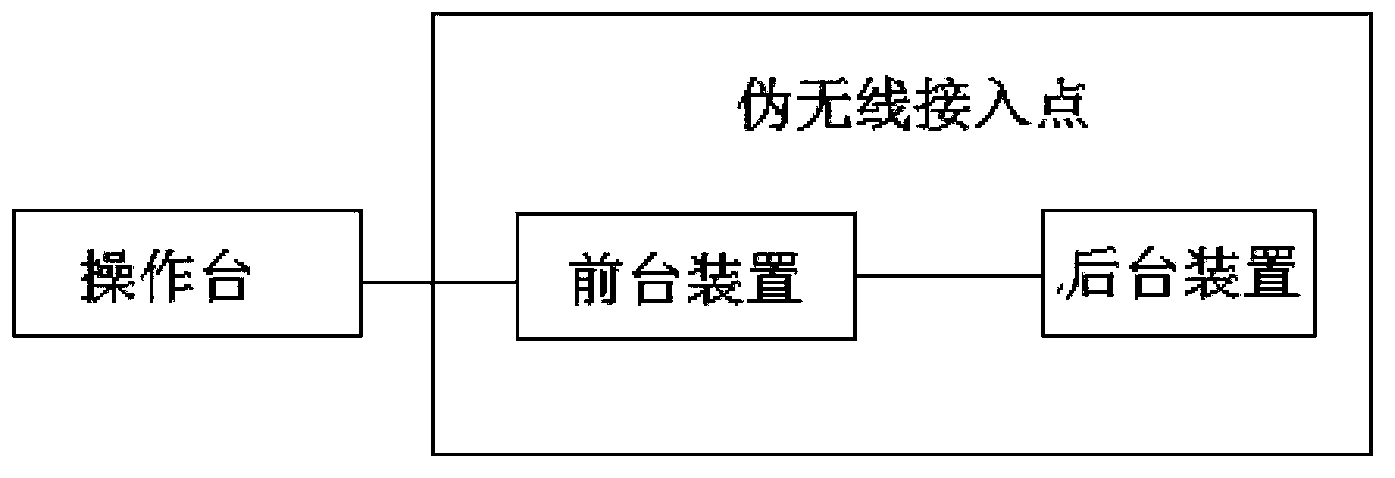

Pseudo wireless access point data analysis system and method thereof

InactiveCN103401732APrevent detectionGuaranteed connectivityData switching networksPacket lossData analysis system

The invention discloses a pseudo wireless access point data analysis system and a method thereof. The system comprises a foreground device and a background device, wherein the background device comprises a scanning module, a connection module, an attack module, and a soft wireless access point module; the scanning module and the attack module are connected; the foreground device is connected with the scanning module, the connection module, the attack module, and the soft wireless access point module; the scanning module is provided with an attack network card, the connection module is provided with a connection network card, the attack module is provided with an attack network card, the wireless access point module is provided with a soft wireless access point network card and a power amplifier, and the wireless access point network card is connected with the power amplifier. The system conducts falsification for an access point connected by a user in the wireless network environment, overcomes the problem of mass packet loss of packet catching of a conventional wireless network monitoring mode, overcomes packet loss in the air, and therefore greatly improves the integrity and the reliability of intercepted data.

Owner:SOUTHEAST UNIV

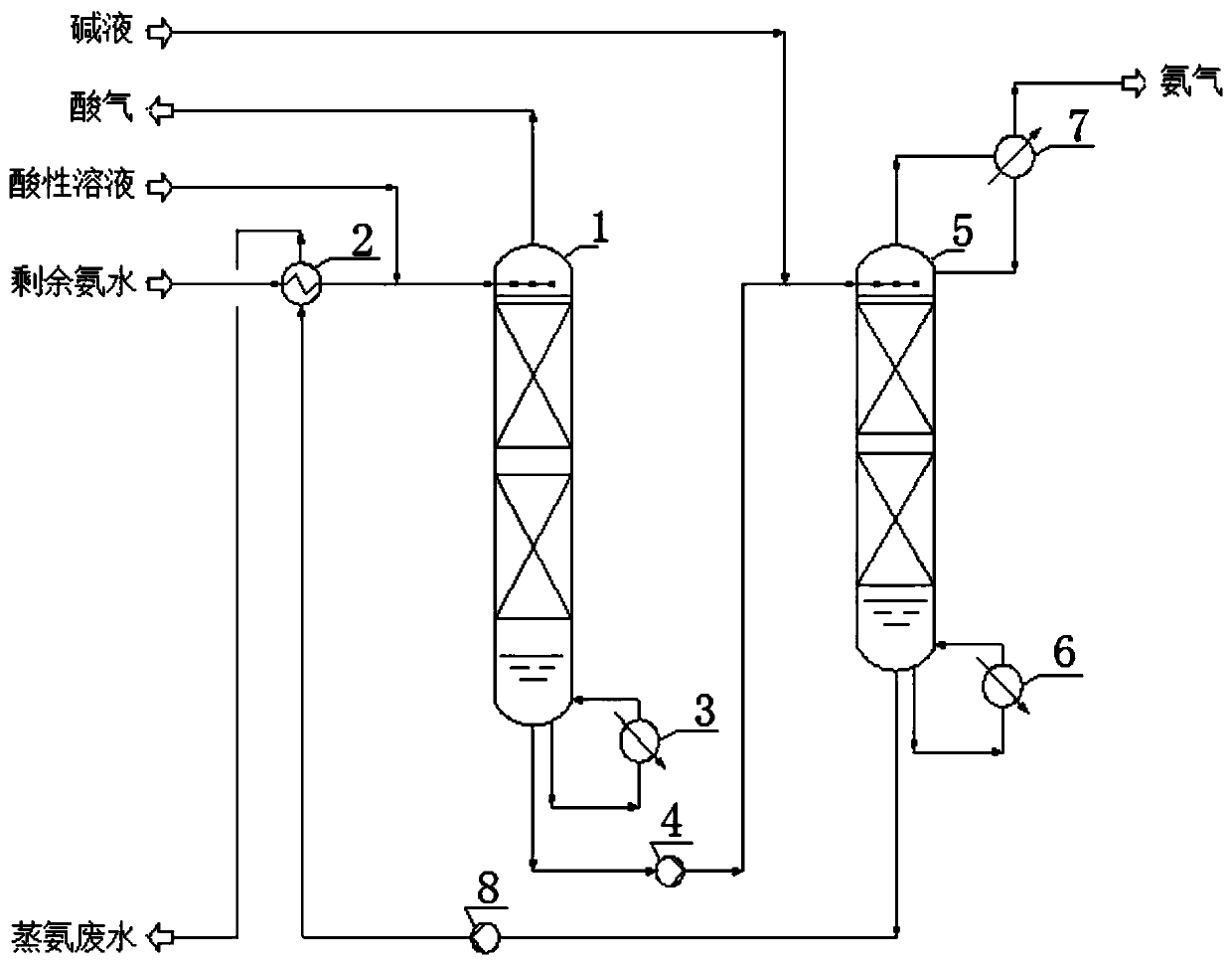

Process for producing refined ammonium hydroxide through deacidification of residual ammonium hydroxide

ActiveCN110054202APrevent escapeEfficient recyclingEnergy inputAmmonia preparation/separationDistillationEconomic benefits

The invention relates to a process for producing refined ammonium hydroxide through deacidification of residual ammonium hydroxide. The residual ammonium hydroxide exchanges heat with ammonia distilling wastewater at the bottom of an ammonia distilling tower and is then mixed with acid solution into the top of a deacidification tower, then free ammonia in the residual ammonium hydroxide can be converted into fixed ammonia so that escape of ammonia can be inhibited, and then acid gas escapes via the top of the deacidification tower; the ammonium hydroxide with the acid gas removed is mixed withalkali liquor and then fed in via the top of the ammonia distilling tower for ammonia distillation; under the action of the alkali liquor, the fixed ammonia in the ammonium hydroxide can be convertedinto free ammonia, which then escapes via the top of the ammonia distillation tower and is then condensed by a condenser into ammonia products. According to the process for producing the refined ammonium hydroxide through deacidification of the residual ammonium hydroxide, by reasonably and orderly adding in the acid solution and the alkali liquor, acid components and alkali components in the residual ammonium hydroxide can be desorbed step by step, so that ammonium hydroxide distillation can be completed and meanwhile the ammonia products can be effectively recovered, the product applicationrange can be expanded, and the economic benefits can be increased for enterprises.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

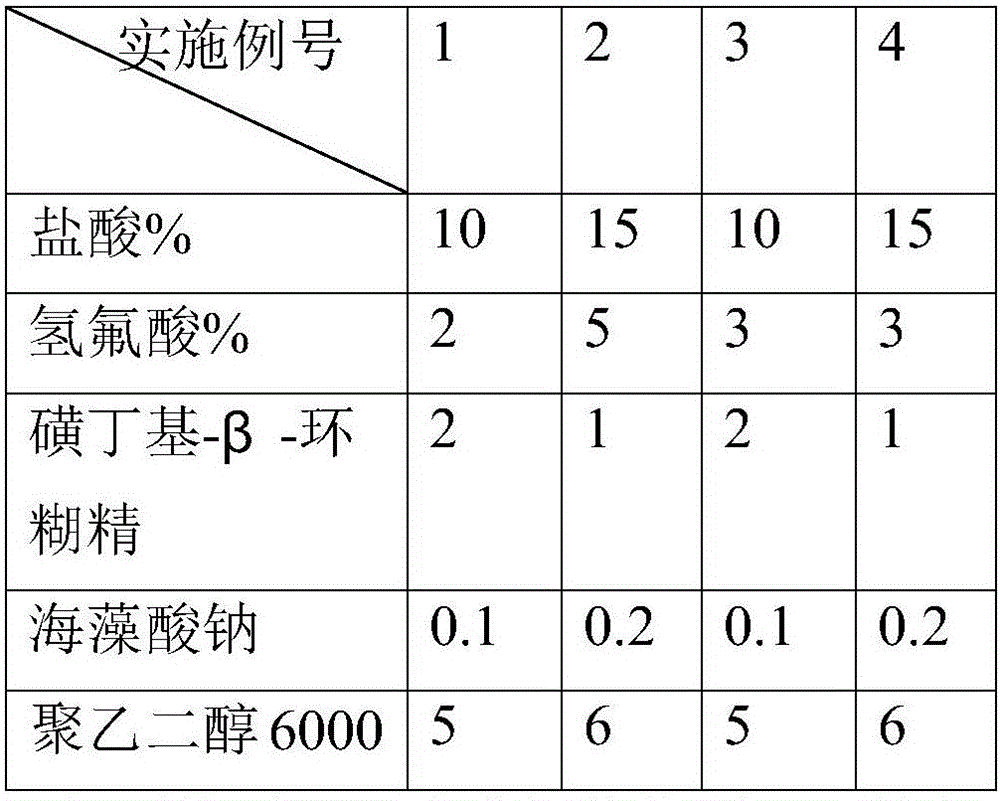

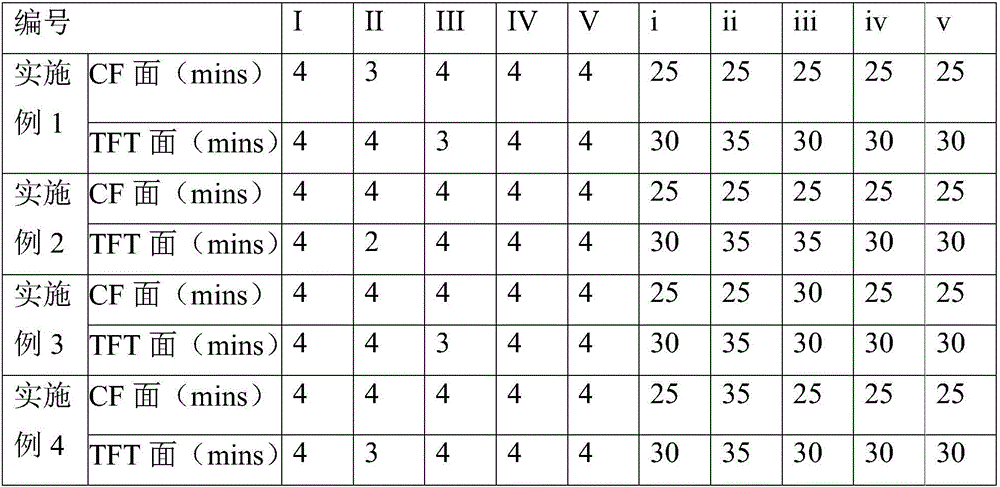

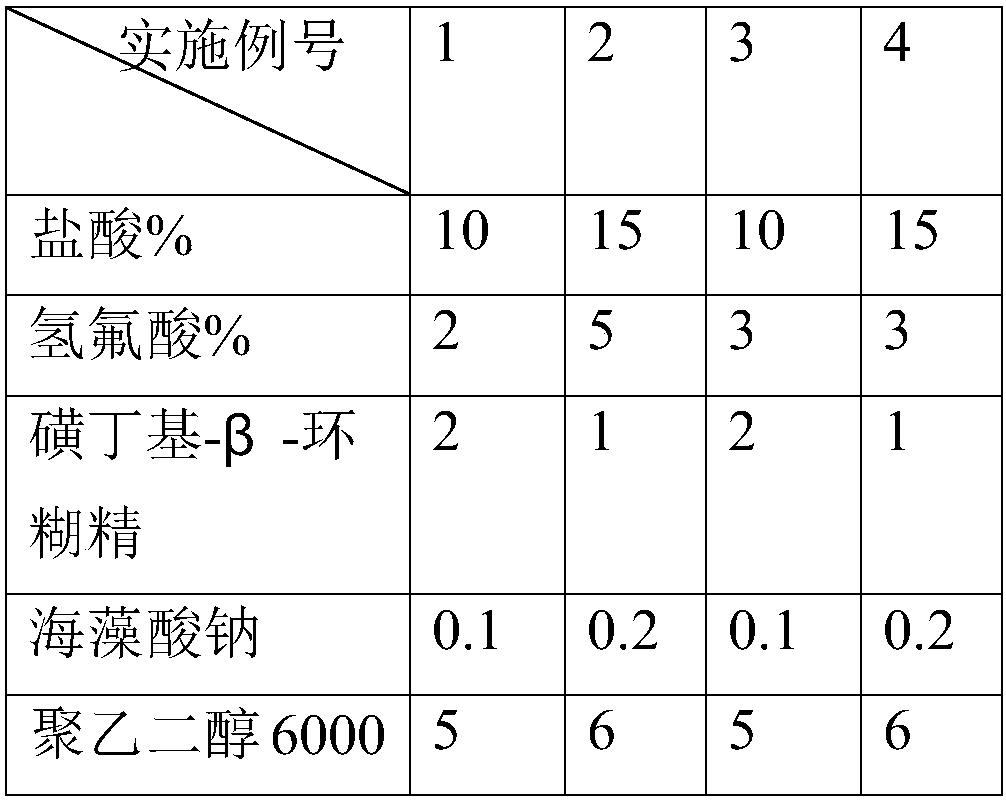

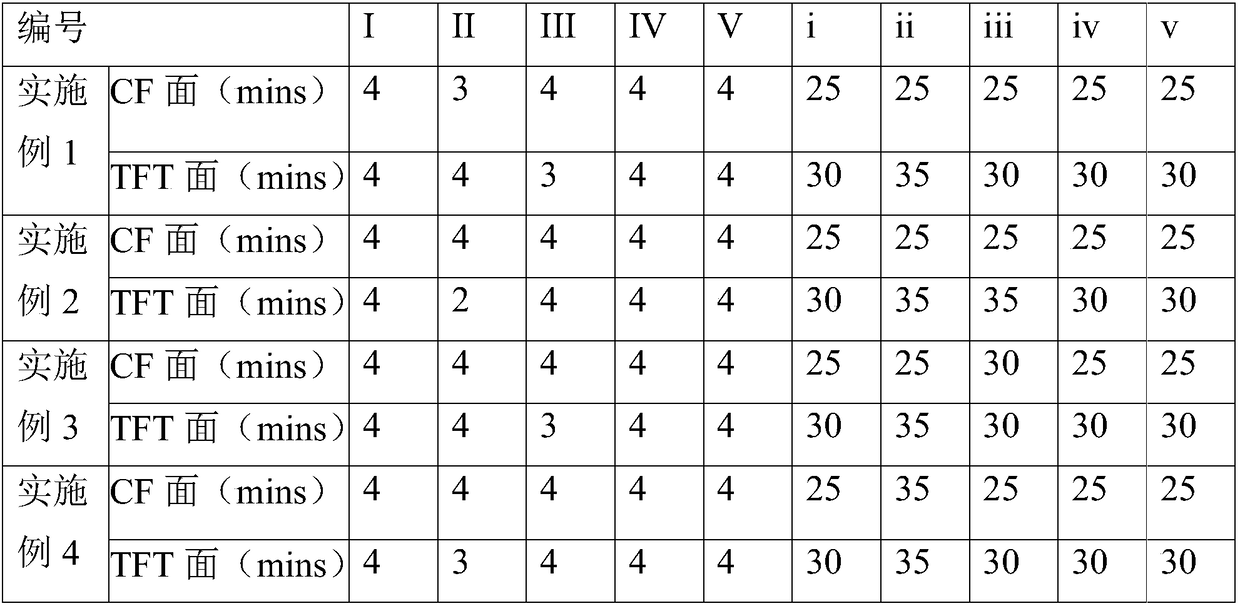

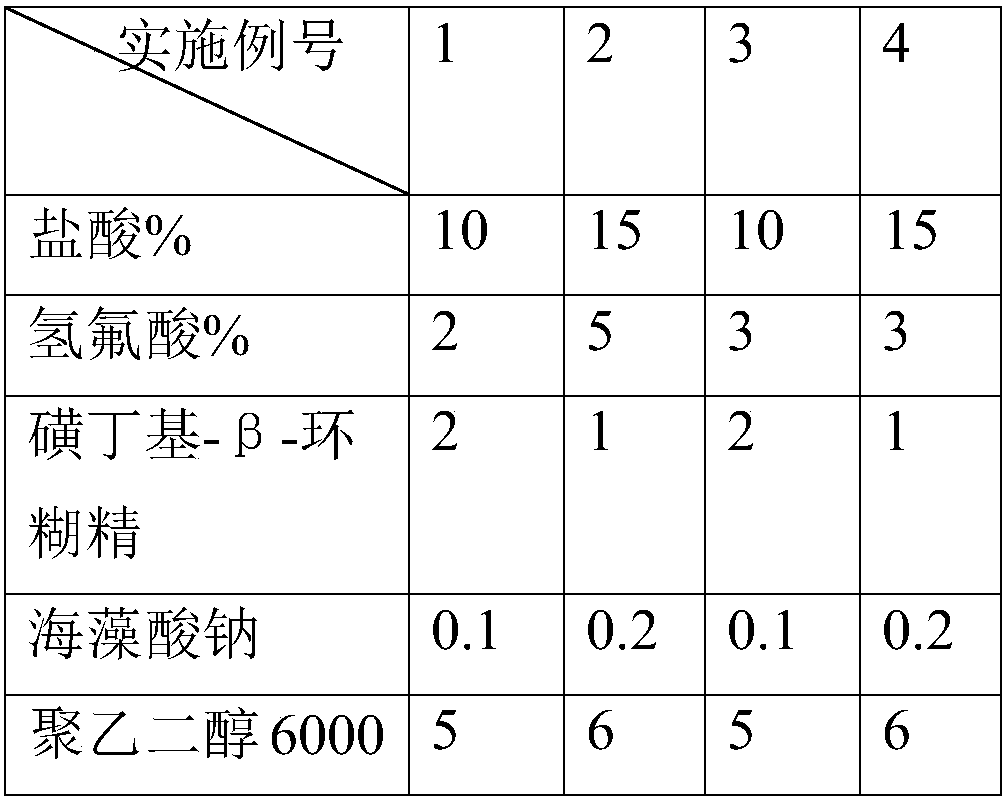

Pretreatment liquid for TFT glass thinning process

The invention provides pretreatment liquid for a thin film transistor (TFT) glass thinning process. The pretreatment liquid is characterized in that the pretreatment liquid comprises the following components in percentages by mass: 10-15% of HCl, 2-5% of HF, 1-2% of sulfobutyl ether-beta-cyclodextrin, 0.1-0.2% of sodium alginate, 5-6% of polyethylene glycol 6000, and the balance being water.

Owner:JIANGSU JIANDAEN ELECTRONICS SCI & TECH

Ozone catalytic oxidation-biological aerated filter tower co-processing device and method for leachate mbr effluent

ActiveCN107759026BRealize full processingRealize comprehensive utilizationMultistage water/sewage treatmentBiological filterCatalytic oxidation

The invention provides a method for treating leachate MBR effluent through combination of ozone-catalyzed oxidation and aeration biological filter towers. The method comprises carrying out gas-liquidmixing on leachate MBR effluent and ozone according to a reaction ratio through an injector, mixing the gas-liquid mixture and a circulation fluid, mixing the mixture and hydrogen peroxide according to a reaction ratio through a static mixer, feeding the final mixed liquid into an ozone-catalyzed oxidation tower through a lower water inlet, feeding the tail gas discharged through a top tail gas outlet into an ozone decomposing device, carrying out treatment, carrying out gas-liquid mixing through the injector, feeding the gas-liquid mixture into a biological filter tower through a low water inlet, and carrying out treatment through the biological filter tower so that the product water can stably satisfy the municipal solid waste landfill pollution control standard (GB 16889-2008) in the fig 2. The method realizes full treatment on leachate MBR, solves the problem that the prior art is difficult to treat a thick membrane liquid and realizes the efficient and comprehensive utilization ofozone.

Owner:NANJING WONDUX ENVIRONMENTAL PROTECTION TECH CO LTD

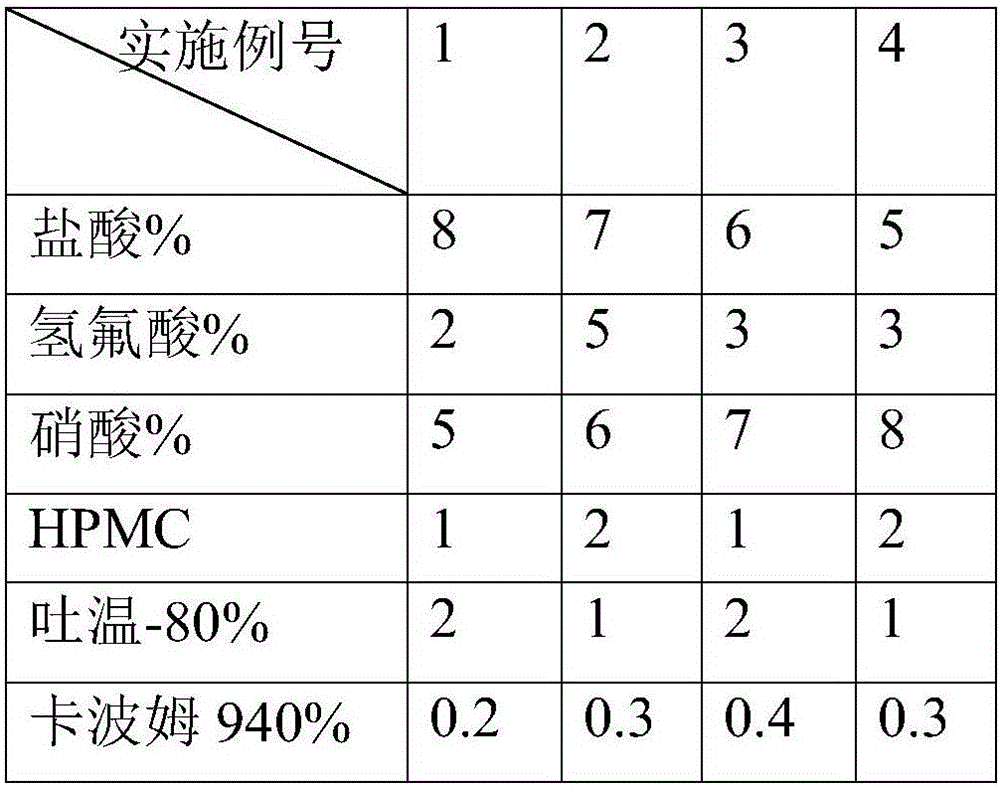

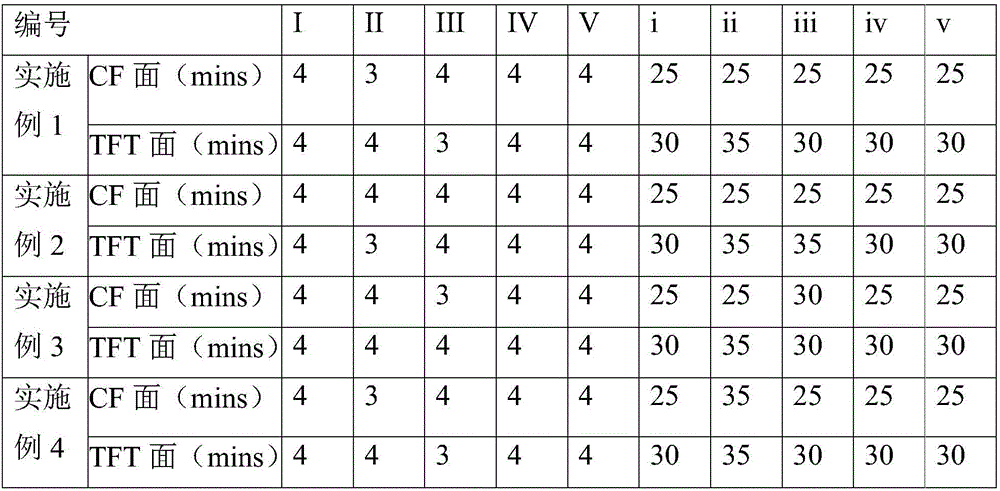

Liquid crystal display screen glass base plate thinning process pretreatment composition

The invention relates to a liquid crystal display screen glass base plate thinning process pretreatment composition, which is prepared from the following ingredients in percentage by mass: 5 to 8 percent by mass of HCl (hydrochloric acid), 5 to 8 percent by mass of HNO3 (nitric acid), 2 to 5 percent by mass of HF (hydrofluoric acid), 1 to 2 percent by mass of Tween-80, 0.2 to 0.4 percent by mass of carbomer 940, 1 to 2 percent by mass of HPMC (hydroxypropyl methylcellulose) and the balance of water.

Owner:江苏智光创业投资有限公司

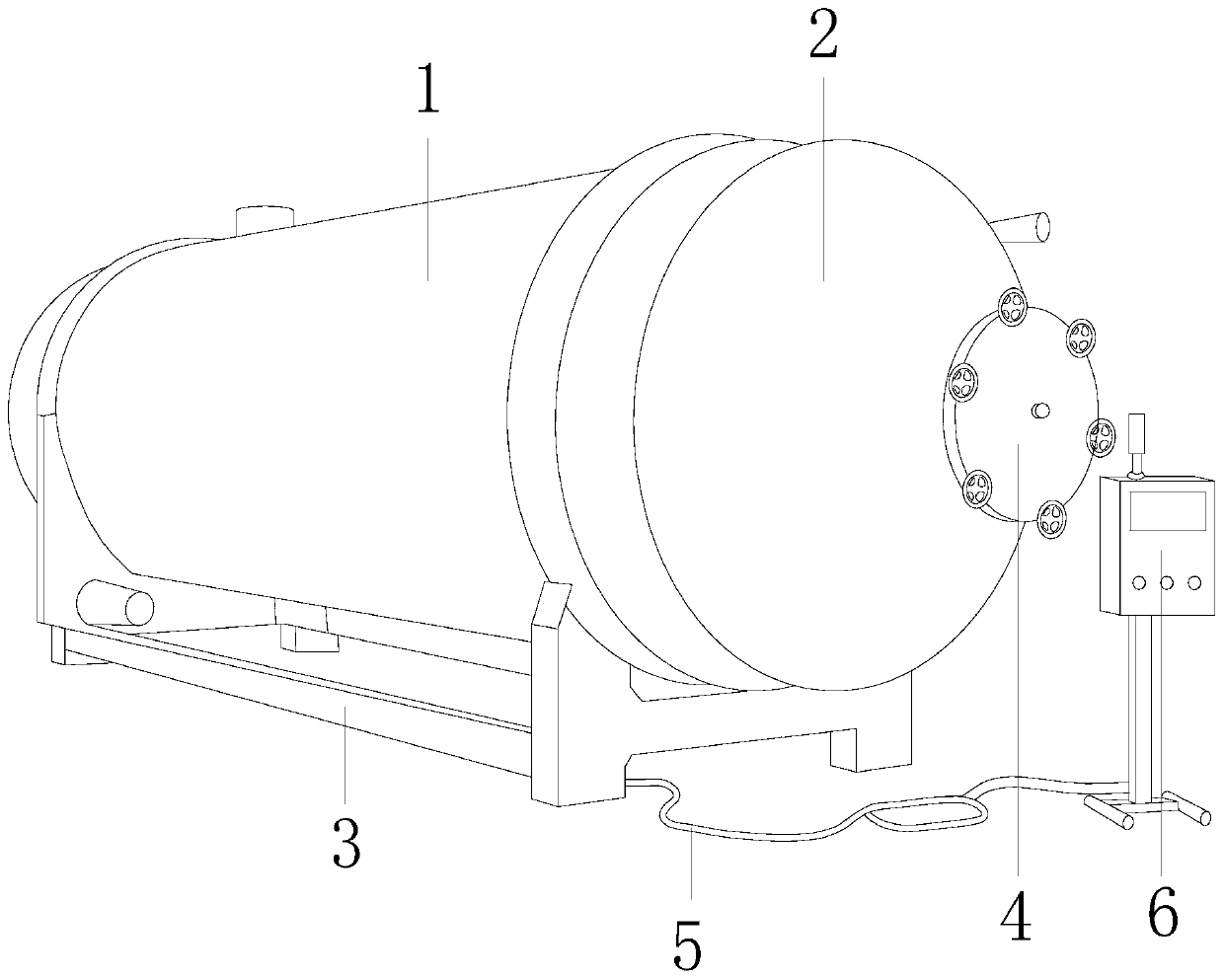

Horizontal rotary food fermentation equipment

The invention discloses horizontal rotary food fermentation equipment. The equipment structurally comprises a fermentation tank, a tank cover, a bottom frame, a sealing valve and a console; the fermentation tank is embedded and fixedly connected to a position right above the bottom frame; the fermentation tank comprises a tank body, a rotating shaft, a fixing sleeve, a defoaming paddle, a combining block, a feeding door, a discharging opening, an isolation plate and a defoaming device; the defoaming device is embedded and fixedly connected to the top end of the inner wall of the tank body; andthe defoaming paddle is in bolted connection with the periphery of the rotating shaft. The rotating shaft drives the defoaming paddle to rotate, and the auxiliary plate is in clearance fit in a movable groove. When a supporting plate drives the auxiliary plate to make contact with the grape wine liquid level, an inclined angle can be formed by the auxiliary plate, and the liquid surface is pushedto two sides, so that generation of foam is effectively reduced. When foam is generated, the foam can be in contact with the defoaming device, a supporting floating block pushes an isolation piece upwards in cooperation, and then the foam enters a foam inlet channel and is sucked away by a guide pipe, so that the problem that foam is difficult to treat is solved.

Owner:廖俊根

tft glass thinning process pretreatment liquid

Owner:JIANGSU JIANDAEN ELECTRONICS SCI & TECH

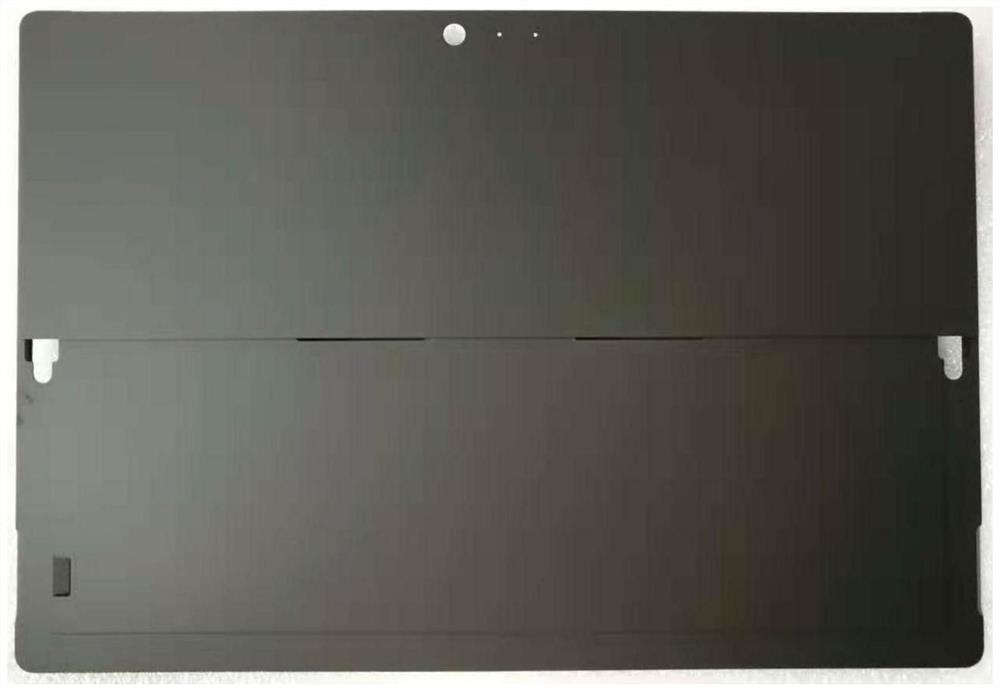

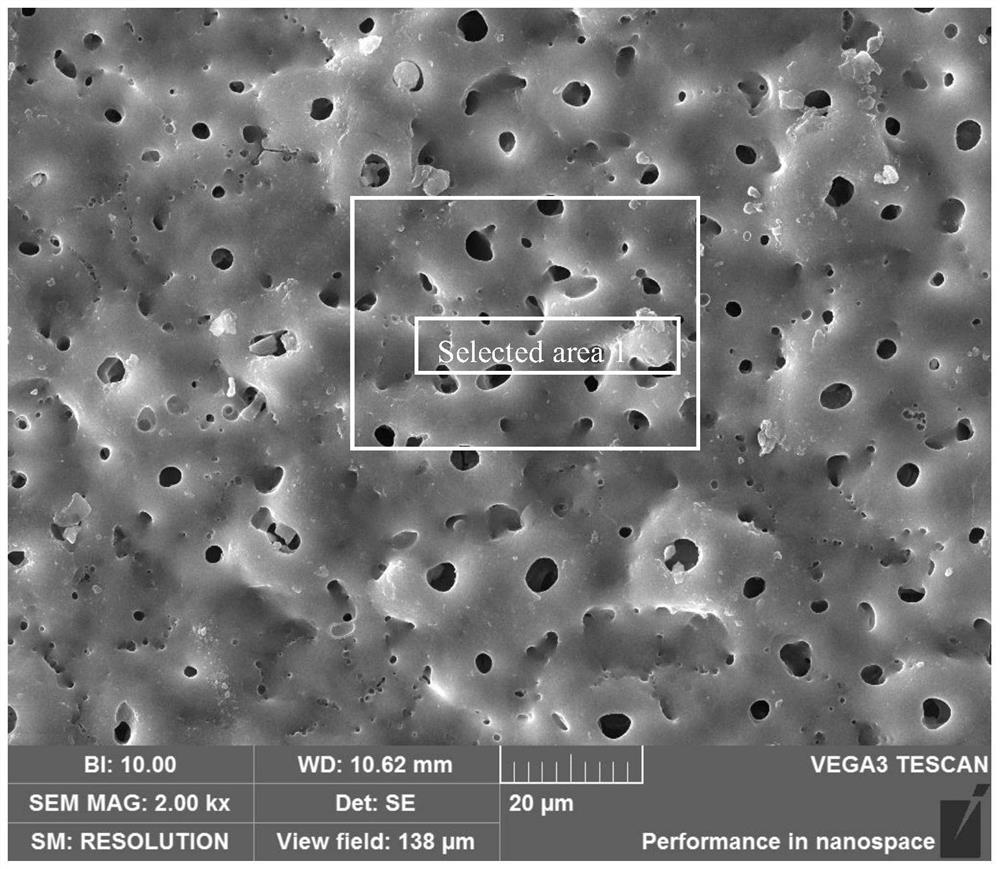

A kind of electrolytic solution and the method for preparing the black film layer on the surface of magnesium alloy by using the electrolytic solution

The invention discloses an electrolyte and a method for preparing a black membrane on an aluminum alloy surface by using same. The electrolyte comprises 8-15 g / L of hydroxide, 10-15 g / L of fluoride, 20-30 g / L of phosphate, 4-14 g / L of ferrate, 1-5 g / L of fluorotitanate, 10-20 g / L of organic alcohol and 80-300 g / L of an ablation inhibitor, and the solvent is deionized water. The method has the advantages that higher black level can be achieved on a thinner membrane to effectively avoid the problem of the discarding of a complicated precision product caused by local ablation when the complicatedprecision product is processed.

Owner:西安强微电气设备有限公司

Process and device for recycling coked ammonium sulfate acid tar

The invention belongs to the technical field of purification of coke-oven gas, in particular to a process and device for recycling coked ammonium sulfate acid tar. The process comprises the following steps of: spraying acid tar extracted from a full launder in an ammonium sulfate procedure with hot ammonia water which is subjected to heat exchange by using an ammonia steaming ammonia water heat exchanger at the temperature of 92-98 DEG C; mixing and introducing a mixture into an acid tar neutralizing tank; performing acid-alkali neutralization in the neutralizing tank; extracting mixed liquorof tar and ammonia water from the bottom of the front end of the neutralizing tank by taking a pump as power; introducing acid tar from the upper part of the back end of the tank into the neutralizing tank through the outlet of the pump to fully neutralize the acid tar; circulating for 30 minutes; pumping the mixed liquor into a coal gas sucking pipeline of a coke oven by using the pump; and introducing the mixed liquor into a mechanical ammonia water settling tank along with an ammonia water system to fulfill the aim of recycling the acid tar. The process and device are easy to operate and have low investment and running costs. By adopting the process and device, a heat source of ammonium steaming waste water is fully used for heating the acid tar, a large amount of steam is saved, and the acid tar can be directly taken as a product.

Owner:NANJING IRON & STEEL CO LTD

A Reinforcement Process for Environmentally Friendly Exterior Wall Ceramic Tile

ActiveCN108071238BAvoid the risk of falling outAvoid pollutionBuilding repairsArchitectural engineeringExternal cladding

An environment-friendly exterior wall tile strengthening process includes the steps of tile cleaning, investigation and restoration, preparation of stainless steel meshes, reinforcement, reinforcementmethod for special positions and inspection. The environment-friendly exterior wall tile strengthening process has the advantages of simple process, less construction difficulty, short construction period, low labor intensity of workers and less construction risks, the risk that the tiles are divorced from the wall space to drop out from high altitude can be completely solved, the problem that anouter wall is smashed to be installed again can be avoided, the discharge of construction waste can be reduced from the root, the environment is protected, and the construction cost is saved. The noise pollution caused by smashing the tiles with a traditional process and the environmental pollution caused by generated dust can be avoided, the generation of haze can be reduced, thereby contributing to building a better city.

Owner:李彬杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com