Horizontal rotary food fermentation equipment

A technology of food fermentation and equipment, which is applied in the field of horizontal rotary food fermentation equipment, can solve problems such as difficult to eliminate and excessive foam, and achieve the effect of avoiding difficult to handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

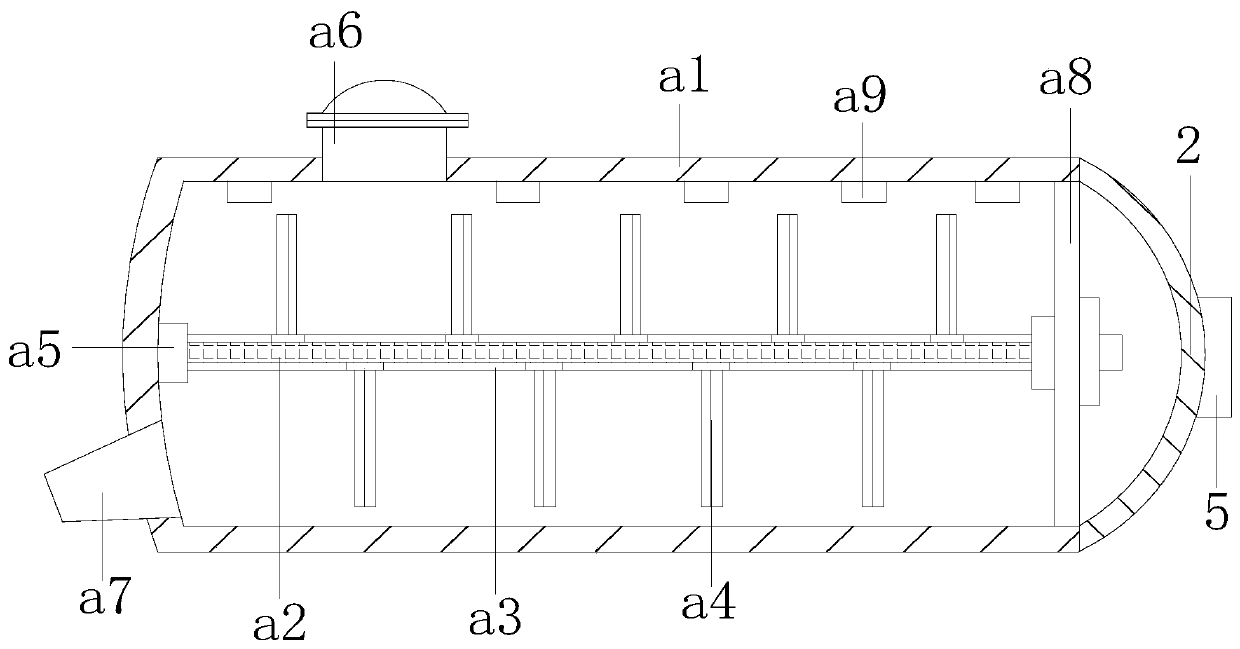

[0026] Such as Figure 1-Figure 5 Shown:

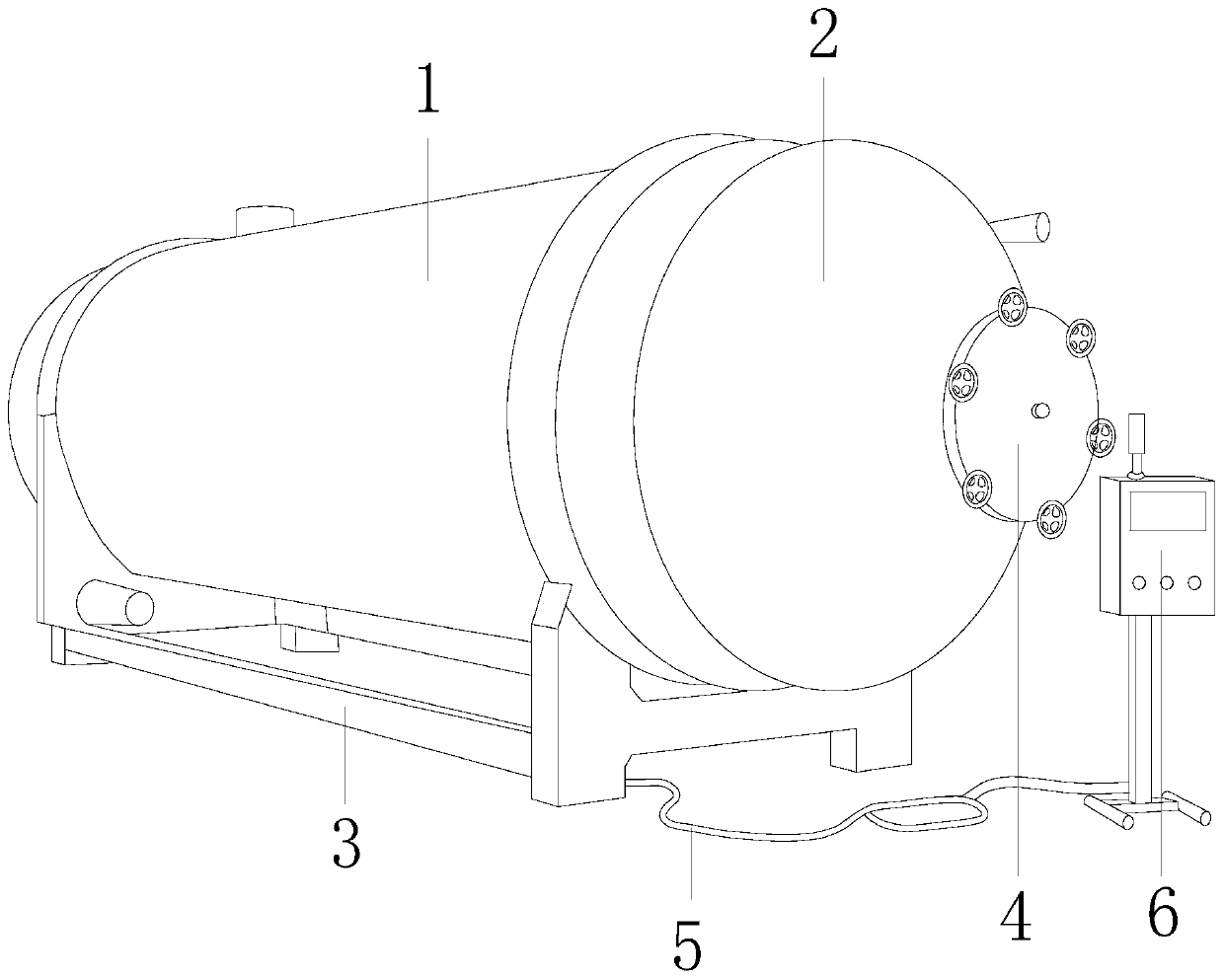

[0027] The present invention provides a horizontal rotary food fermentation equipment, the structure of which includes a fermentation tank 1, a tank cover 2, a bottom frame 3, a closed valve 4, a connecting line 5, and a console 6, and the tank cover 2 is hinged to the front end of the fermentation tank 1 , the closed valve 4 is threadedly connected to the front center of the tank cover 2, the console 6 is electrically connected to the fermenter 1 through the connection line 5, and the fermenter 1 is embedded and connected to the position directly above the bottom frame 3, and the The fermenter 1 mainly includes a tank body a1, a rotating shaft a2, a fixed sleeve a3, a defoamer paddle a4, a combination block a5, a feed door a6, a discharge port a7, an isolation plate a8, and a defoamer a9. a9 is embedded and fixedly connected to the top position of the inner wall of the tank body a1, the separation plate a8 is riveted and connected t...

Embodiment 2

[0034] Such as Figure 6-Figure 8 Shown:

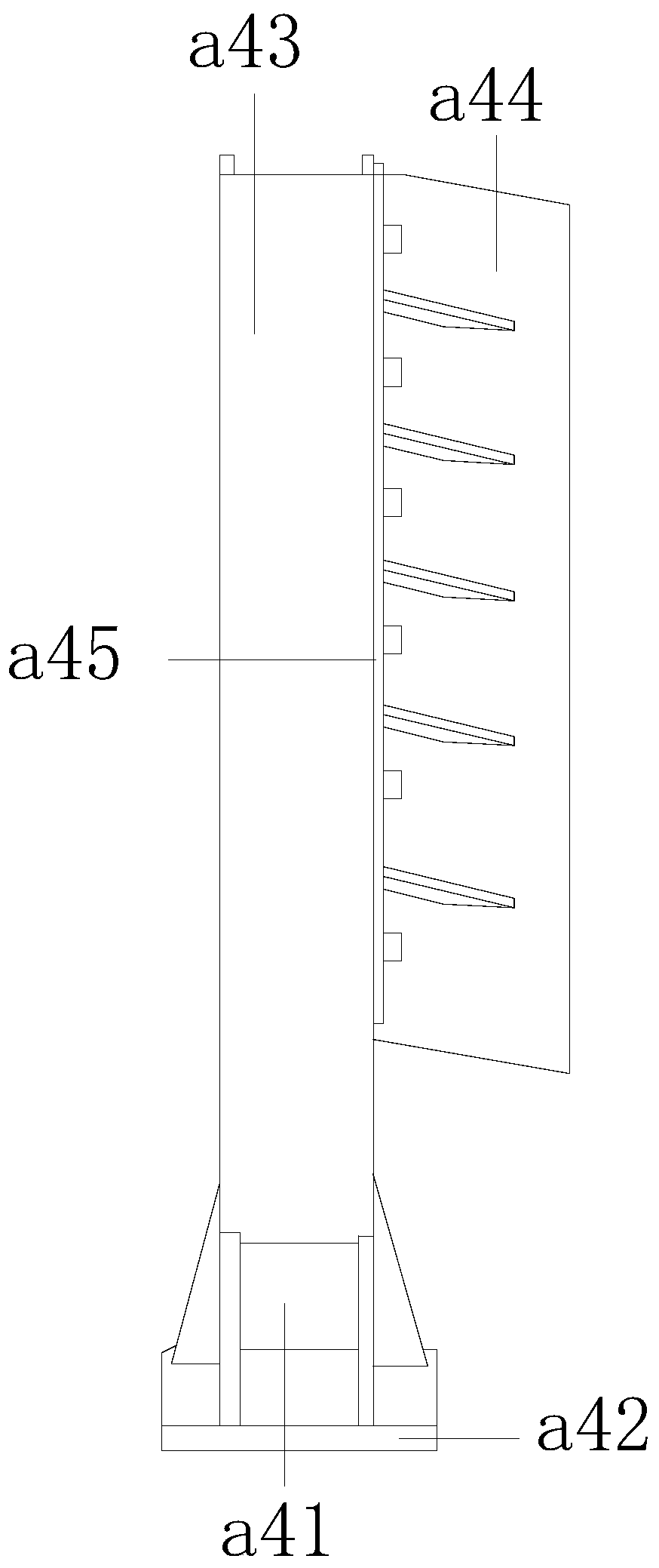

[0035] The present invention provides a horizontal rotating food fermentation equipment. The defoaming device a9 mainly includes a conduit c1, a hollow plate c2, an inclined block c3, a foam feed mechanism c4, and a foam feed channel c5. The conduit c1 passes through the hollow plate c2 In the middle position of the foam inlet channel c5, the foam inlet mechanism c4 is fixedly connected under the hollow plate c2, and the inclined block c3 is provided with two right-angled triangle structures, with the foam inlet mechanism c4 as the center line and symmetrically distributed left and right It can make it easier for the foam feeding mechanism c4 to engage between the inclined blocks c3.

[0036]Wherein, the foam feeding mechanism c4 mainly includes a blocking piece c41, a support ring c42, a chute c43, a support floating block c44, and a spacer c45. Fitted and installed inside the chute c43, the support floating block c44 is threadedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com