System and method for efficiently preparing taurine

A technology of taurine and taurine, which is applied in the field of chemical engineering, can solve problems such as the quality that cannot be sold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

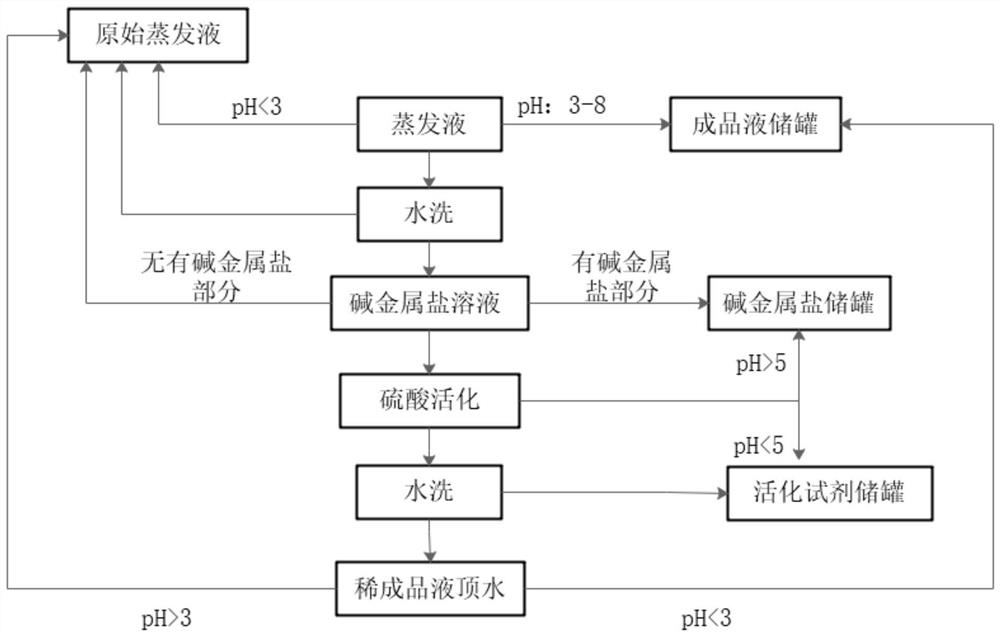

[0072] ①Resin pretreatment: Take 1L of resin and put it into a chromatographic column, keep 3-5cm of water on the top of the resin, treat the resin with 4% sulfuric acid solution 3 times the volume of the resin, and the flow rate is 2-4 times the volume of the resin per hour. Wash the resin with tap water until the outlet pH>4, then transform the resin with 1.5-2BV of 4% NaOH solution at a flow rate of 2-4 times the volume of the resin per hour, and then wash the resin with tap water until the outlet pH 4, and the resin is activated and ready for use.

[0073] ②Column passage of evaporated liquid sample: Take the original evaporated liquid and dilute it until the content of taurine alkali metal salt is about 20wt%. Various indicators. After the evaporating liquid is sampled, wash the ion-exchange column with water until the pH of the effluent is 8-9, that is, the elution is completed.

[0074] ③ Resin regeneration: The resin is activated according to the first activation mode...

Embodiment 3

[0111] ①Resin pretreatment: Take 6L resin and put it into a chromatographic column. Keep 3-5cm of water on the top of the resin. Treat the resin with 4% sulfuric acid solution 3 times the volume of the resin. The flow rate is 2-4 times the volume of the resin per hour. Wash the resin with tap water until the outlet pH>4, then transform the resin with 1.5-2BV of 4% NaOH solution at a flow rate of 2-4 times the volume of the resin per hour, and then wash the resin with tap water until the outlet pH 4, and the resin is activated and ready for use.

[0112] ② Resin column packing: Take 6L of activated resin and put them into 6 chromatographic columns in equal amounts, and keep 3-5cm of water on the top of the resin, and the numbers are A, B, C, D, E, F.

Embodiment 4

[0143] The resin column of Group C or D in Comparative Example 10 was selected for the following experiments, and the activation mode was the second activation mode.

[0144] ③Column passage of evaporating liquid sample: The evaporating liquid is fixed to a certain volume according to a certain multiple, and a certain amount of pretreated resin is transferred to the chromatography column, and the evaporating liquid with a constant volume is forwardly passed through the column according to a certain flow rate for adsorption, according to different time periods It is required to determine the end point and measure various indicators. After the evaporating liquid is sampled, the step is to wash with water until the pH of the effluent is 8-9, that is, the elution is completed.

[0145] ④ Resin regeneration: Use sulfuric acid solution to pass through the column at a certain flow rate for desorption. It is determined that the resin is fully activated when there is no sodium ion in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com