Dual membrane method brine refining technology and device in whole bittern caustic soda production

A brine purification and double-membrane technology, applied in alkali metal halide purification and other directions, can solve the problems of unavailability of high-nitrate brine, weak membrane processing capacity, and small filling area of separation membrane, so as to reduce the types of pharmaceutical dosage and improve the Membrane processing capacity, the effect of saving the cost of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

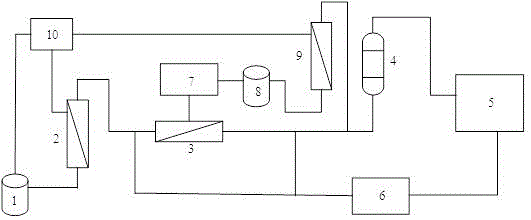

Image

Examples

Embodiment 1

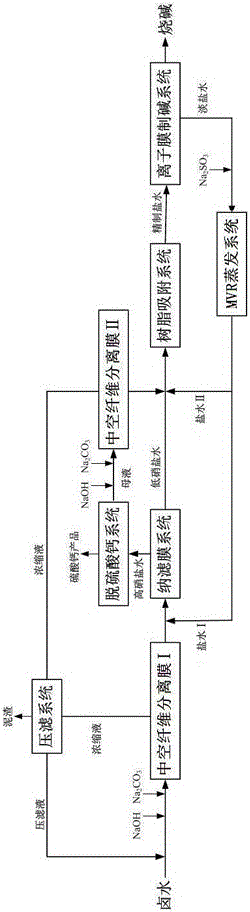

[0046] Double-membrane brine refining process in all-halogen soda production of the present invention:

[0047] S1: The raw brine extracted from the mine is directly pumped into the brine reaction tank Ⅰ, the NaCl concentration of the raw brine is 305g / L, the calcium content is 0.53g / L, the magnesium content is 0.1g / L, and the sulfate content is 17g / L 1.80g / L of sodium carbonate and 0.52g / L of sodium hydroxide are metered into the brine reaction tank Ⅰ, and Ca 2+ , Mg 2+ The reaction produces CaCO 3 Precipitate and Mg(OH) 2 Colloid, through hollow fiber separation membrane I for ultrafiltration, operating pressure 0.15MPa, membrane flux 85L / m 2 h, the total content of calcium and magnesium in permeate brine is less than 4mg / L;

[0048] S2: The permeate from the ultrafiltration enters the nanofiltration membrane module for nanofiltration after being raised by the high pressure pump, the operating pressure is 2.4MPa, and the membrane flux is 25L / m 2 h, most SO 4 2- After ...

Embodiment 2

[0051] Double-membrane brine refining process in all-halogen soda production of the present invention:

[0052] S1: The raw brine extracted from the mine is directly pumped into the brine reaction tank Ⅰ, the NaCl concentration of the raw brine is 305g / L, the calcium content is 0.53g / L, the magnesium content is 0.1g / L, and the sulfate content is 17g / L 1.80g / L of sodium carbonate and 0.52g / L of sodium hydroxide are metered into the brine reaction tank Ⅰ, and Ca 2+ , Mg 2+ The reaction produces CaCO 3 Precipitate and Mg(OH) 2 Colloid, through hollow fiber separation membrane I for ultrafiltration, operating pressure 0.15MPa, membrane flux 85L / m 2 h, the total content of calcium and magnesium in the permeated liquid brine is less than 4mg / L; the concentrated liquid intercepted by the hollow fiber separation membrane I is sent to the filter press system, and the pressed sludge is transported outside for treatment, and the filter press liquid is recycled;

[0053] S2: The perme...

Embodiment 3

[0056] Double-membrane brine refining process in all-halogen soda production of the present invention:

[0057] S1: The raw brine extracted from the mine is directly pumped into the brine reaction tank Ⅰ, the NaCl concentration of the raw brine is 305g / L, the calcium content is 0.53g / L, the magnesium content is 0.1g / L, and the sulfate content is 17g / L 1.80g / L of sodium carbonate and 0.52g / L of sodium hydroxide are metered into the brine reaction tank Ⅰ, and Ca 2+ , Mg 2+ The reaction produces CaCO 3 Precipitate and Mg(OH) 2 Colloid, through hollow fiber separation membrane I for ultrafiltration, operating pressure 0.15MPa, membrane flux 85L / m 2 h, the total content of calcium and magnesium in the permeated liquid brine is less than 4mg / L; the concentrated liquid intercepted by the hollow fiber separation membrane I is sent to the filter press system, and the pressed sludge is transported outside for treatment, and the filter press liquid is recycled;

[0058] S2: The perme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com