Tool platform with continuous dust removal function and control method

A tooling and platform technology, which is applied to the tooling platform and control field with continuous dust removal function, can solve the problems of affecting the heat dissipation of the tool, inconvenient use, poor smoke exhaust, etc., to achieve high energy utilization, maintain working environment, and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

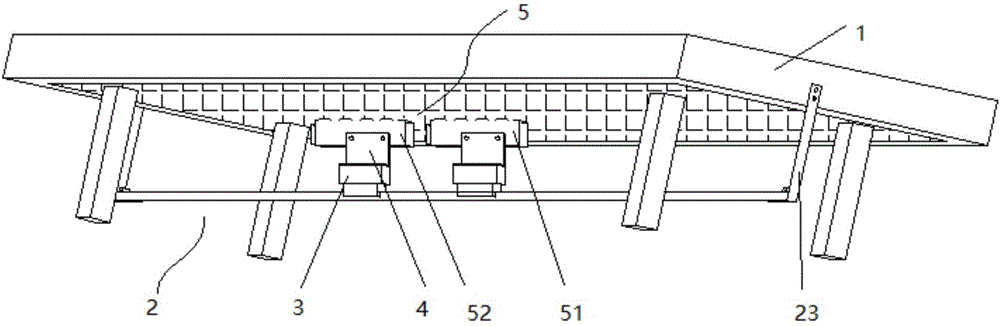

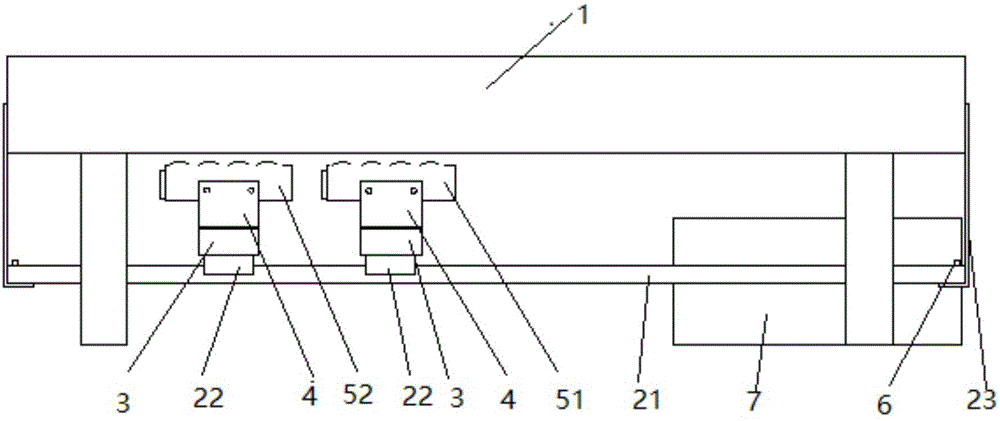

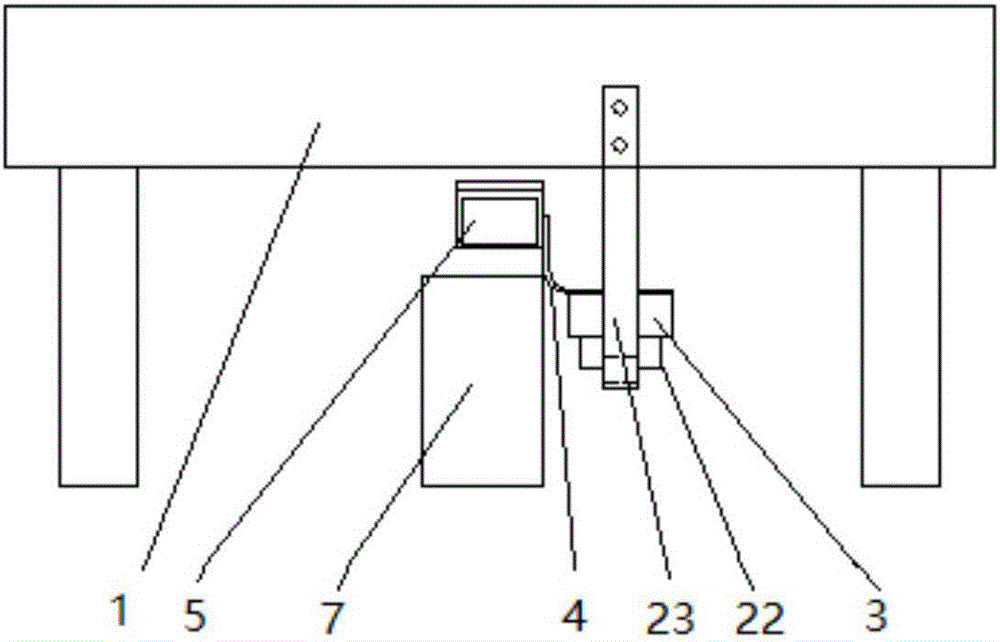

[0039] First aspect, such as Figure 1-5 As shown, this embodiment provides a tooling platform with a continuous dust removal function, including: a workbench 1, an ash collection box 7, a guide rail pair 2, two sets of power components 3, two connectors 4 and two dust collectors 5, The worktable 1 is composed of a tabletop and legs, the middle of the tabletop is hollowed out, the upper surface of the tabletop is provided with a sensor for sensing the amount of dust accumulated on the tabletop, and the guide rail pair 2 includes a guide rail 21, a guide rail bracket 23 and two The slider 22 and the guide rail 21 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com