Hierarchy cascade short process copper smelting device and process

A copper smelting device and series technology, which is applied in the field of short-process copper smelting devices, can solve the problems of low metal recovery rate, poor operating environment and high labor cost, and achieve the effects of simple equipment structure, less equipment and avoiding transportation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

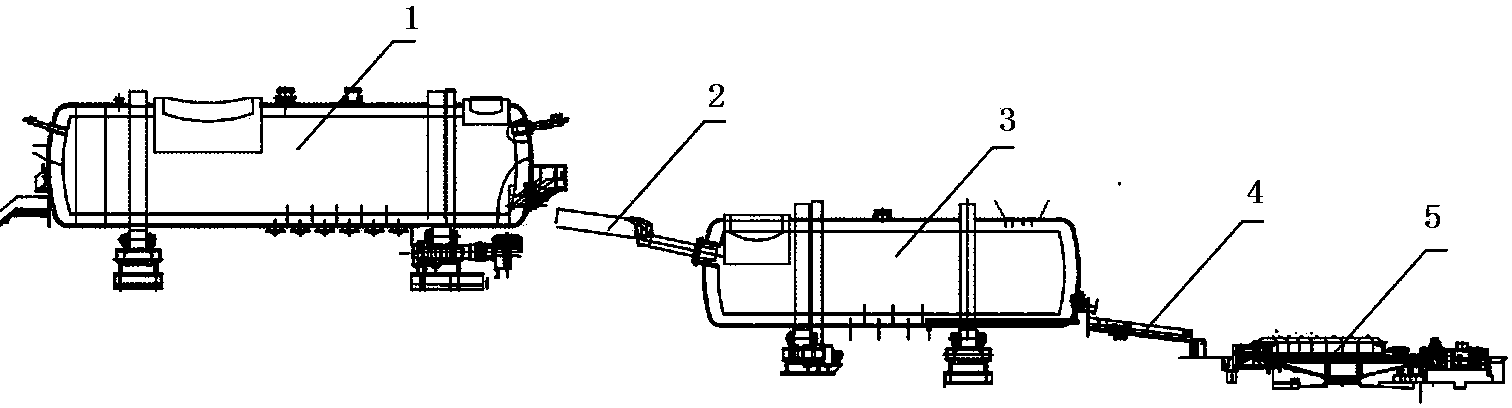

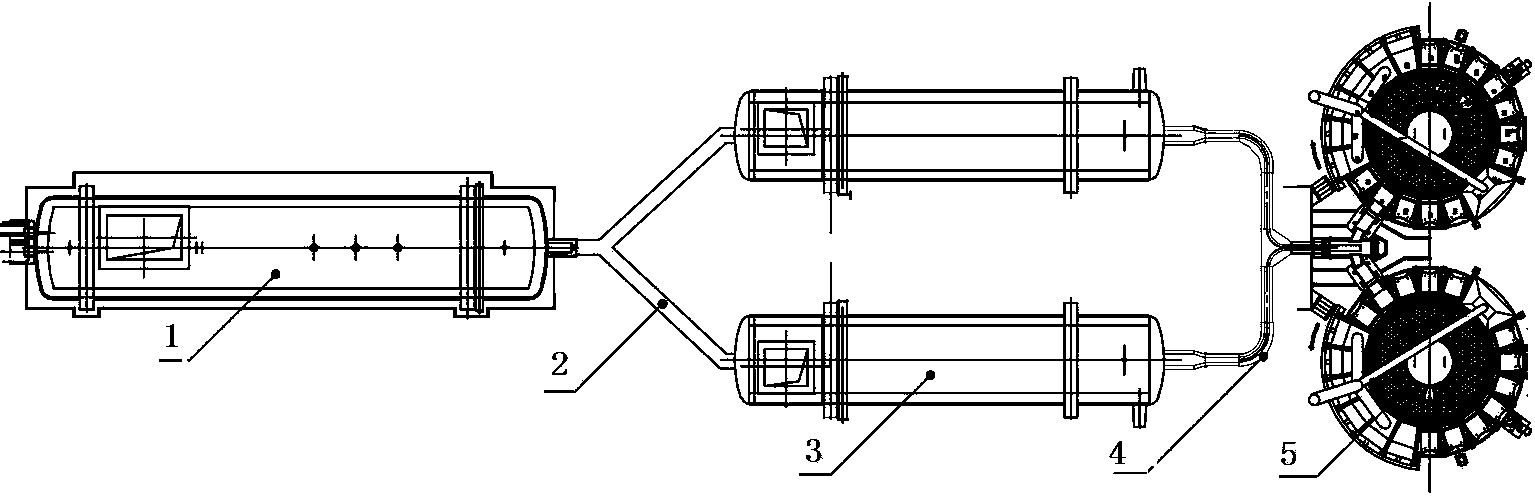

[0020] A layered series short-process copper smelting device, including a multi-element furnace 1 and a pyrofinishing furnace 3, both of which are rotatable horizontal cylindrical furnaces. The outer shell is made of steel plates, and the inner lining is refractory materials. On the basis, one end of one of the supporting rollers is equipped with a motor and gear transmission, and the furnace body can rotate along the axis; 1-40 spray guns are arranged at the bottom of the furnace, arranged in single or multiple rows; the furnace is connected by chute 2 , consists of one multi-element furnace 1 and two pyrofinishing furnaces 3, and the three furnaces are arranged in a "pin-shaped hierarchical series".

[0021] The bottom spray guns of the multi-element furnace 1 and the pyrofinishing furnace 3 are at -90°~0°~+90° to the vertical line of the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com