Zero-drainage technology of biochemical effluent water deep treatment and resource recycling of coal chemical industry wastewater

A technology for coal chemical wastewater and biochemical effluent, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve equipment and pipeline corrosion, and does not consider the life of organic matter on the membrane system Influence, no consideration of membrane fouling and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

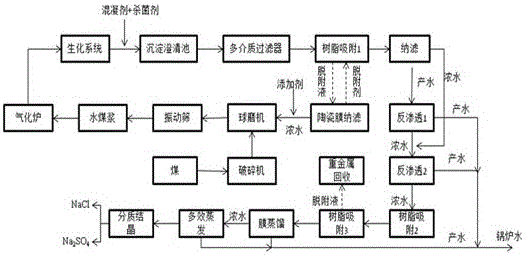

Method used

Image

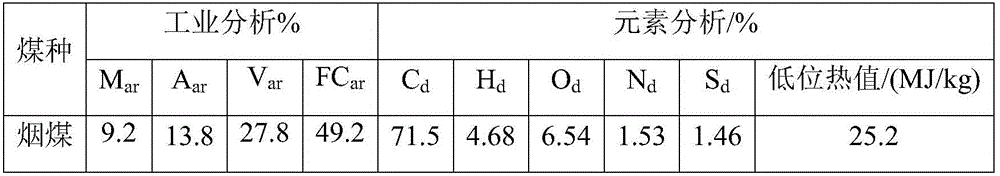

Examples

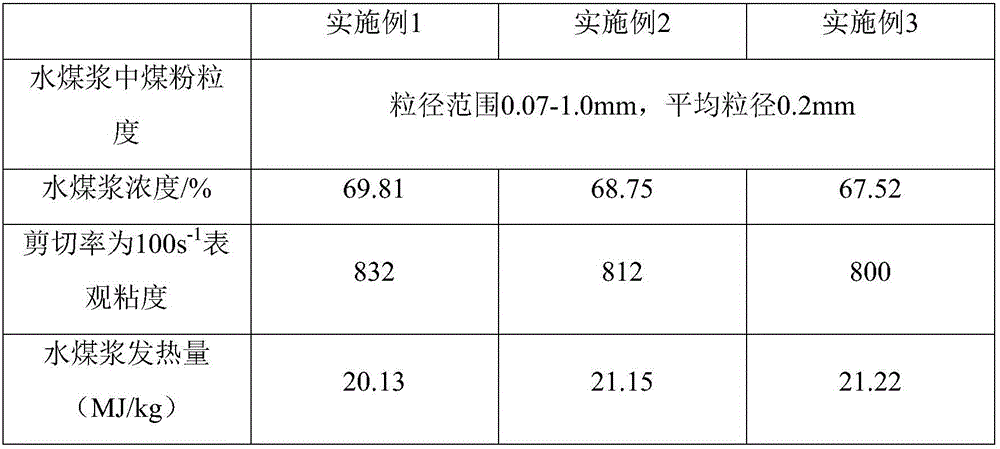

Embodiment 1

[0051] (1) Precipitation and clarification

[0052] The main water quality characteristics of biochemical tail water are: pH 7.34, COD: 100mg / L, TDS: 1000mg / L, suspended solids 160mg / L, chromaticity 50 times, turbidity: 10.8NTU. Enter the sedimentation clarifier, add PAC coagulant and NaClO fungicide, the dosage of coagulant is 20ppm, the bactericide is 2ppm, the hydraulic retention time of the sedimentation clarifier is 2h, so that the suspended solids such as sludge in the biochemical effluent can be precipitated , Removed after clarification. The effluent from the sedimentation clarifier enters the multi-media filter.

[0053] (2) Multi-media filtration

[0054] The operating pressure of the multi-media filter is 0.2MPa. The multi-media packing is divided into upper, middle and lower layers. The upper layer is a core shell with a relative density of 1.1 and a particle size of 1.5mm; the middle layer is anthracite with a relative density of 1.4 and a particle size of 1.2mm. The l...

Embodiment 2

[0076] (1) Precipitation and clarification

[0077] The main water quality characteristics of biochemical tail water are: pH 7.58, COD: 200 mg / L, TDS: 1500 mg / L, suspended solids 250 mg / L, chroma 55 times, turbidity: 20.4 NTU. Enter the sedimentation clarification tank, add polyferric sulfate (PFS) coagulant and liquid chlorine bactericide, the dosage of coagulant is 40ppm, the bactericide is 3ppm, the hydraulic retention time of the sedimentation clarifier is 3h, so that the biochemical effluent The sludge settles and is removed after clarification. The effluent from the sedimentation clarifier enters the multi-media filter.

[0078] (2) Multi-media filtration

[0079] The operating pressure of the multi-media filter is 0.4MPa. The multi-media packing is divided into upper, middle and lower layers. The upper layer is a core-shell with a relative density of 1.1 and a particle size of 1.5mm; the middle layer is anthracite with a relative density of 1.4 and a particle size of 1.2mm. ...

Embodiment 3

[0101] (1) Precipitation and clarification

[0102] The main water quality characteristics of biochemical tail water are: pH 7.86, COD: 300mg / L, TDS: 2000mg / L, suspended solids 350mg / L, color 60 times, turbidity: 30.7 NTU. Enter the sedimentation clarifier, add PAC and PAM coagulant and chlorine dioxide bactericide, the dosage of PAC is 100ppm, the dosage of PAM is 1ppm, the bactericide is 5ppm, the hydraulic retention time of the sedimentation clarifier is 4h, and the biochemical The sludge in the effluent is deposited and removed after clarification. The effluent from the sedimentation clarifier enters the multi-media filter.

[0103] (2) Multi-media filtration

[0104] The operating pressure of the multi-media filter is 0.6MPa. The multi-media packing is divided into upper, middle and lower layers. The upper layer is a core-shell with a relative density of 1.1 and a particle size of 1.5mm; the middle layer is anthracite with a relative density of 1.4 and a particle size of 1.2mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com