Landfill leachate treatment process and treatment device of landfill leachate

A landfill leachate and treatment process technology, applied in the field of wastewater treatment, can solve problems such as increased concentration of salt and pollutants, paralysis of biochemical systems and reverse osmosis systems, and difficult treatment of reverse osmosis concentrates, achieving reasonable structure and effective treatment good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

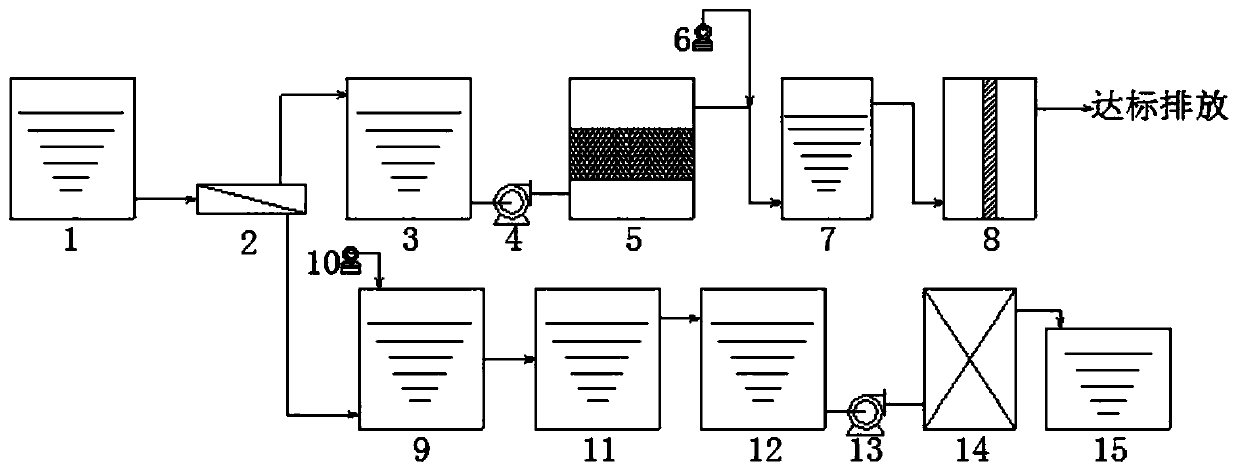

[0036] Such as figure 1 Shown, a kind of landfill leachate treatment process comprises the following steps:

[0037] 1) The wastewater is filtered by nanofiltration membrane, which can intercept most of COD;

[0038] 2) Carry out micro-electrolysis treatment to the nanofiltration product water produced in step 1), and micro-electrolysis can remove part of COD;

[0039] 3) adding hydrogen peroxide to the nanofiltration product water after the micro-electrolysis treatment in step 2) for Fenton treatment: the water after the micro-electrolysis treatment contains some iron ions, and the iron ions in the water are used as catalysts, and then hydrogen peroxide is added to carry out the Fenton reaction. Further remove COD;

[0040] 4) After step 3) the Fenton-treated nanofiltration product water is subjected to electrocatalytic oxidation treatment. The main function of electrocatalytic oxidation treatment is to remove total nitrogen, and at the same time, it can also remove part of...

Embodiment 2

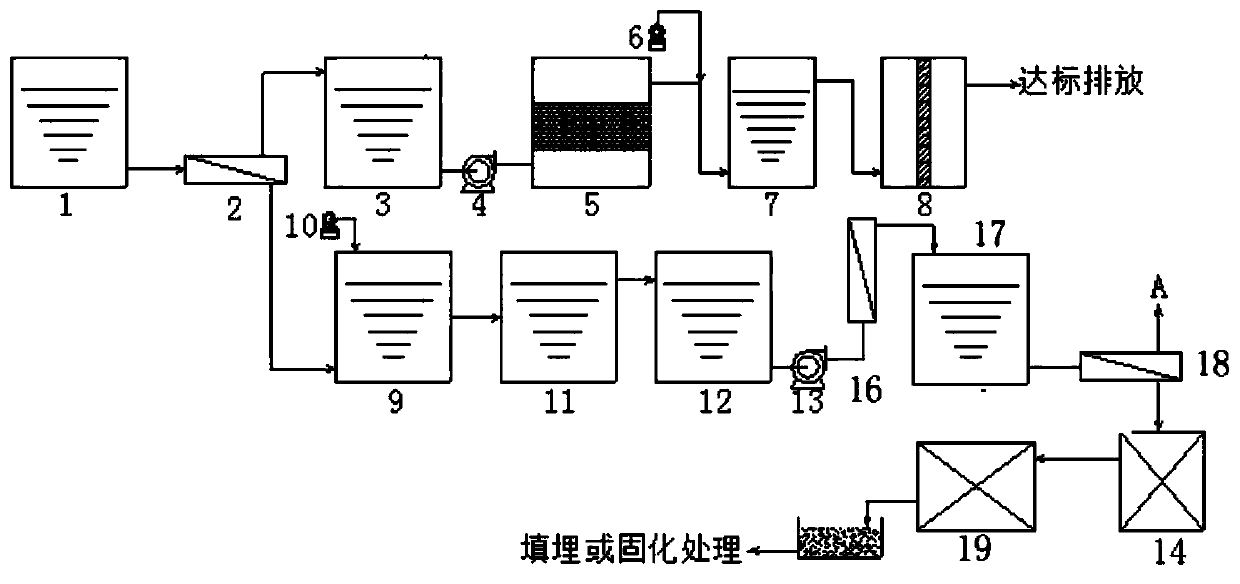

[0055] Such as figure 2 Shown, a kind of landfill leachate treatment process comprises the following steps:

[0056] 1) The wastewater is filtered by nanofiltration membrane, which can intercept most of COD;

[0057] 2) Carry out micro-electrolysis treatment to the nanofiltration product water produced in step 1), and micro-electrolysis can remove part of COD;

[0058] 3) adding hydrogen peroxide to the nanofiltration product water after the micro-electrolysis treatment in step 2) for Fenton treatment: the water after the micro-electrolysis treatment contains some iron ions, and the iron ions in the water are used as catalysts, and then hydrogen peroxide is added to carry out the Fenton reaction. Further remove COD;

[0059] 4) After step 3) the Fenton-treated nanofiltration product water is subjected to electrocatalytic oxidation treatment. The main function of electrocatalytic oxidation treatment is to remove total nitrogen, and at the same time, it can also remove part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com