Patents

Literature

263results about How to "Improve the processing environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mechanical equipment cleaning liquid

InactiveCN102618396AEasy to cleanImprove safety and environmental protectionNon-ionic surface-active compoundsDetergent compounding agentsHazardous substanceMechanical equipment

The invention discloses a mechanical equipment cleaning liquid, which consists of monohydric alcohol, glycol, complexing agent, anionic surfactant, nonionic surfactant, compound corrosion inhibitor, coloring agent and water. The mechanical equipment cleaning liquid is prepared by using environmental-friendly substances, is a universal cleaning fluid for mechanical equipment maintenance and repair, does not have inflammables and explosive characteristics during use, does not cause higher adverse influences on a working environment, does not contain environmentally hazardous substances such as nitrite, phenol and formaldehyde, is nonflammable, is nontoxic to operators and has a better effect of cleaning inorganic fouling such as asphalt, better safety and environmental friendliness are realized, the processing environment and sanitary conditions can be improved, the working efficiency can be improved and the cost can be reduced.

Owner:苏州安美润滑科技有限公司

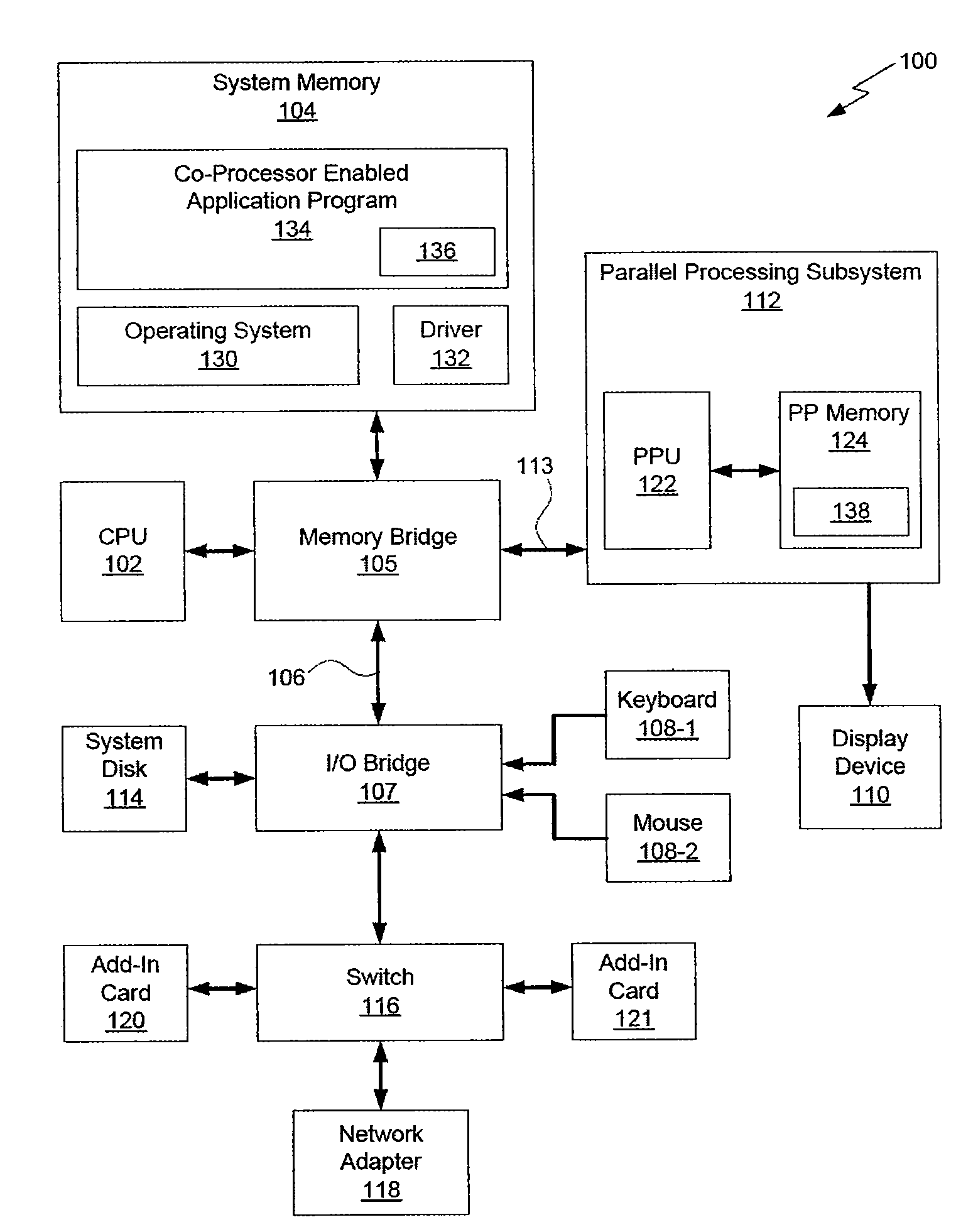

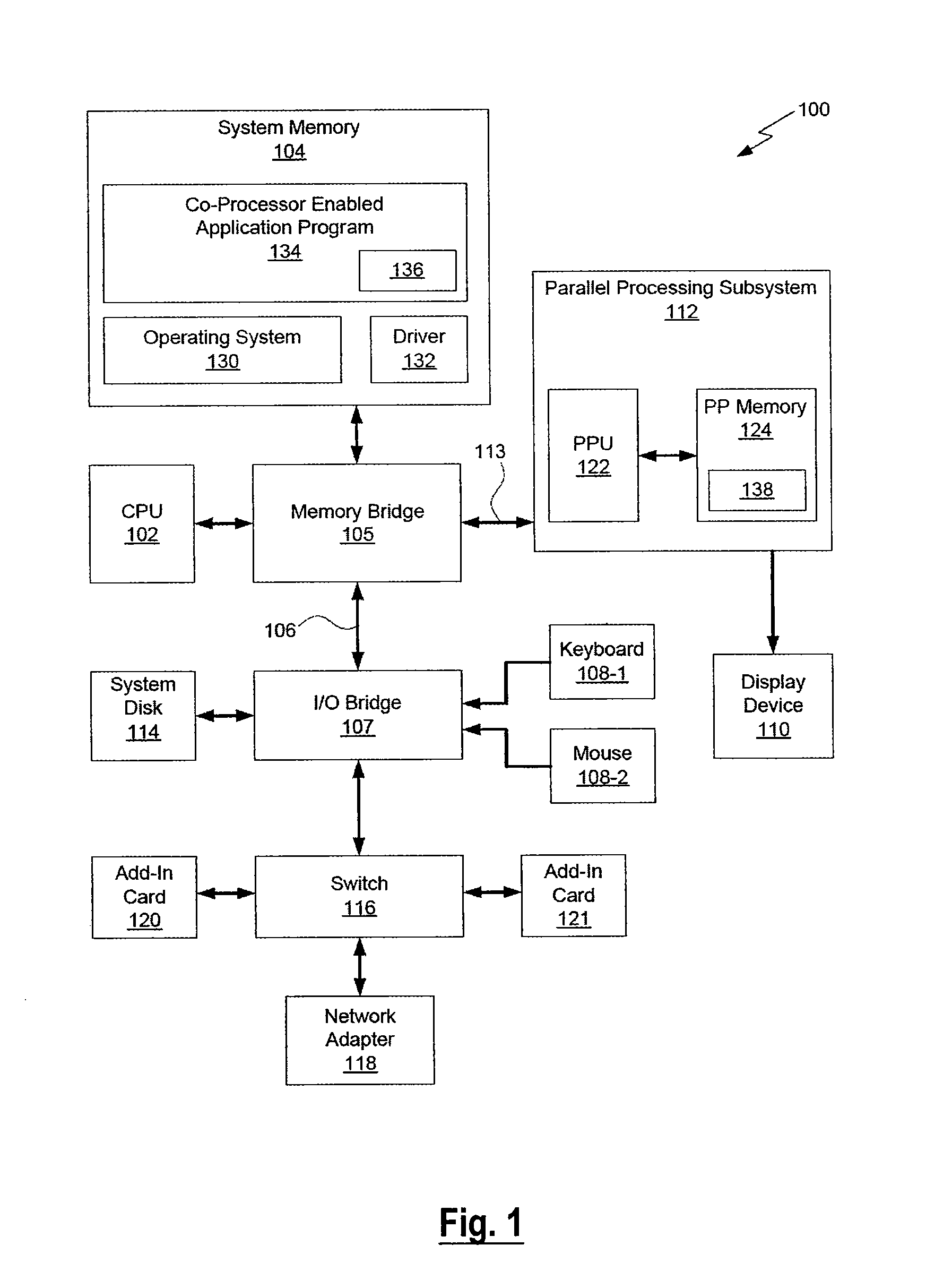

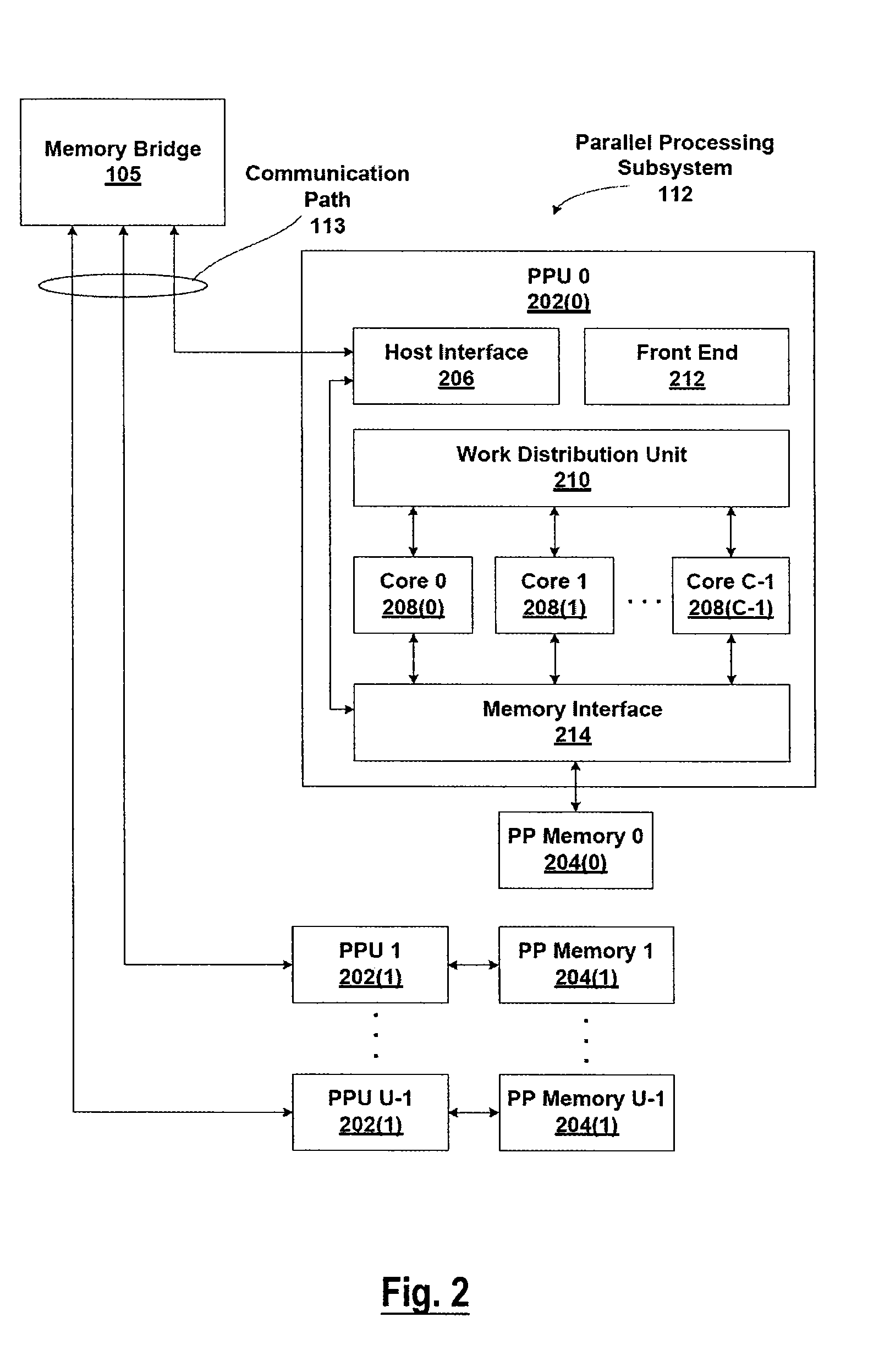

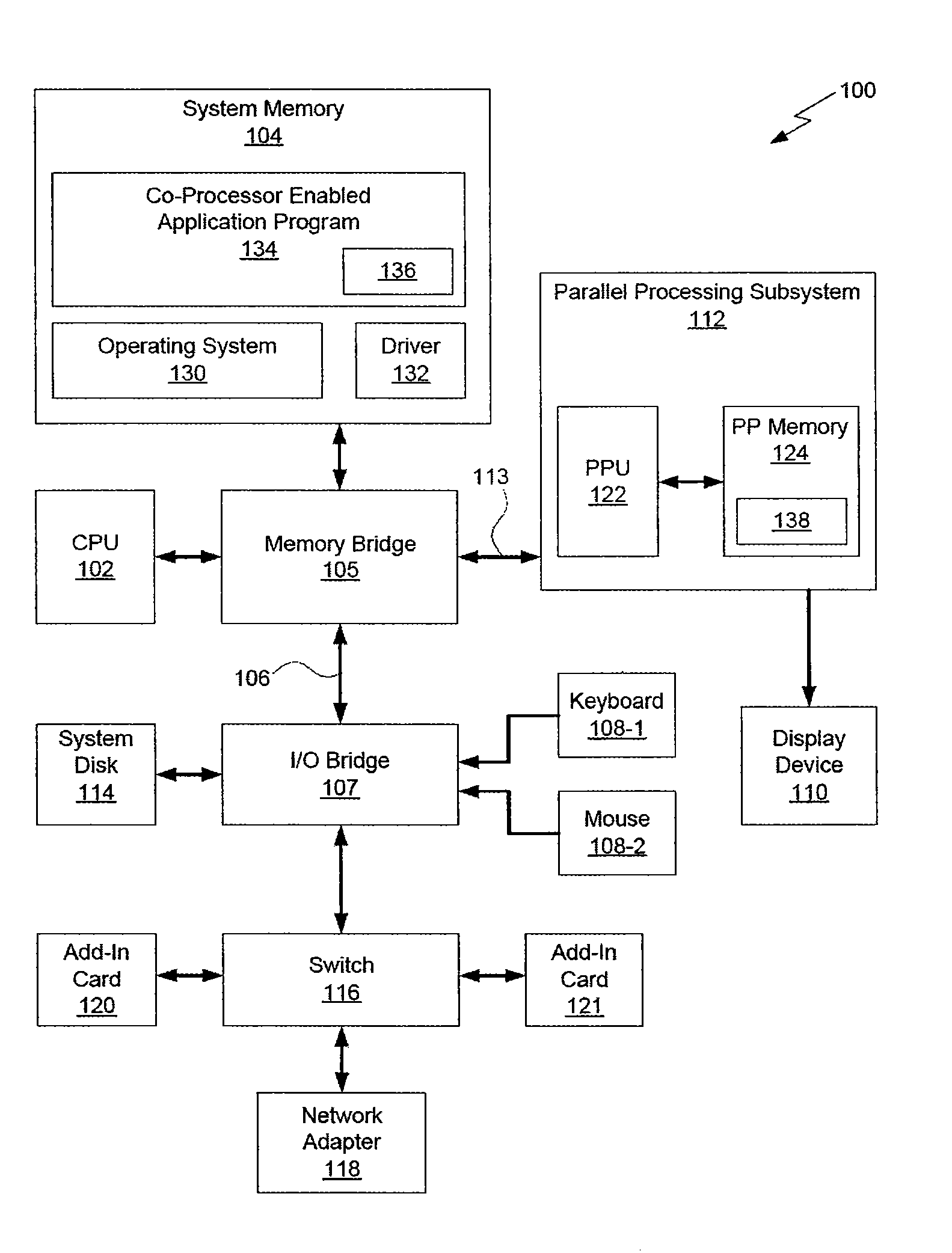

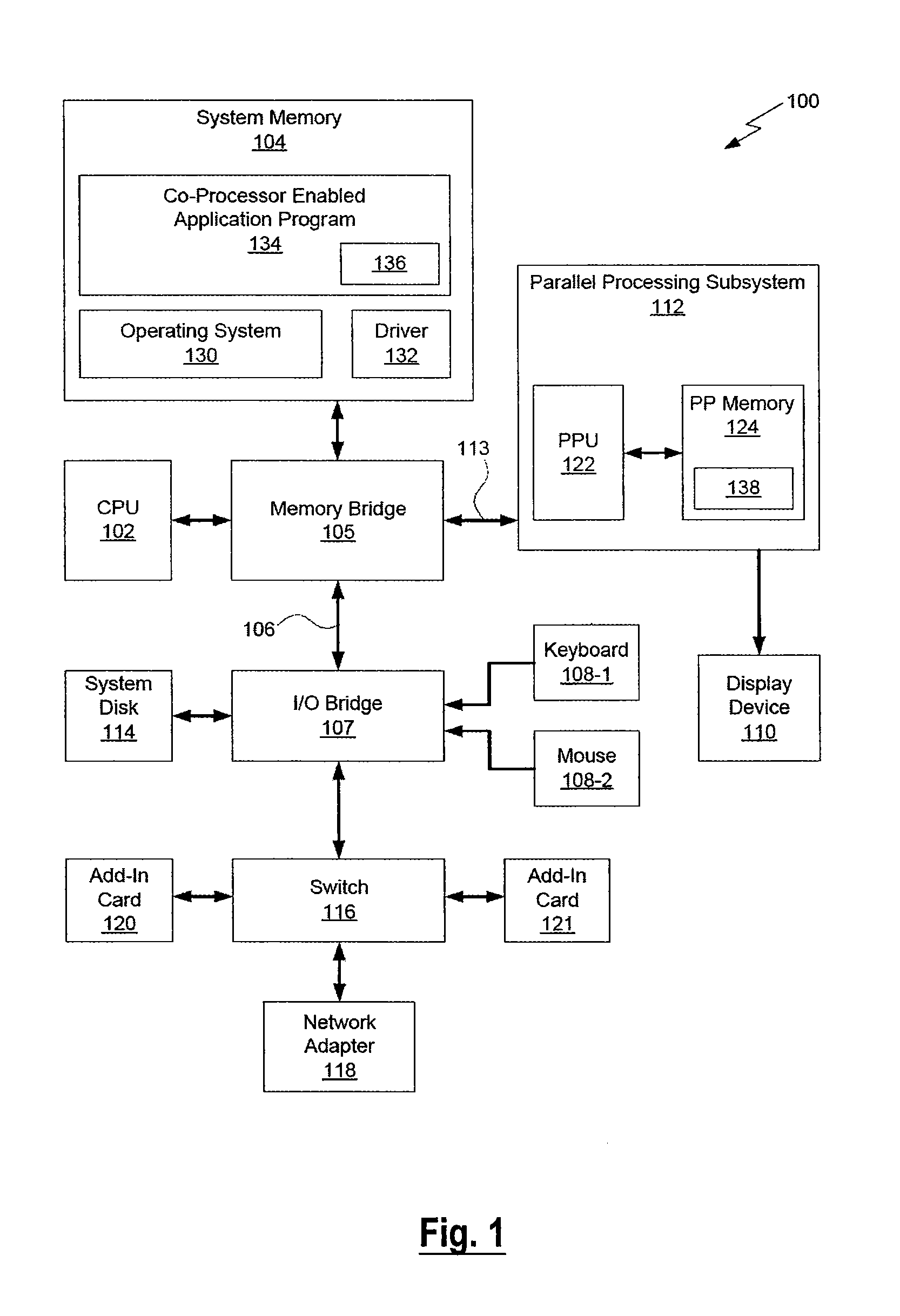

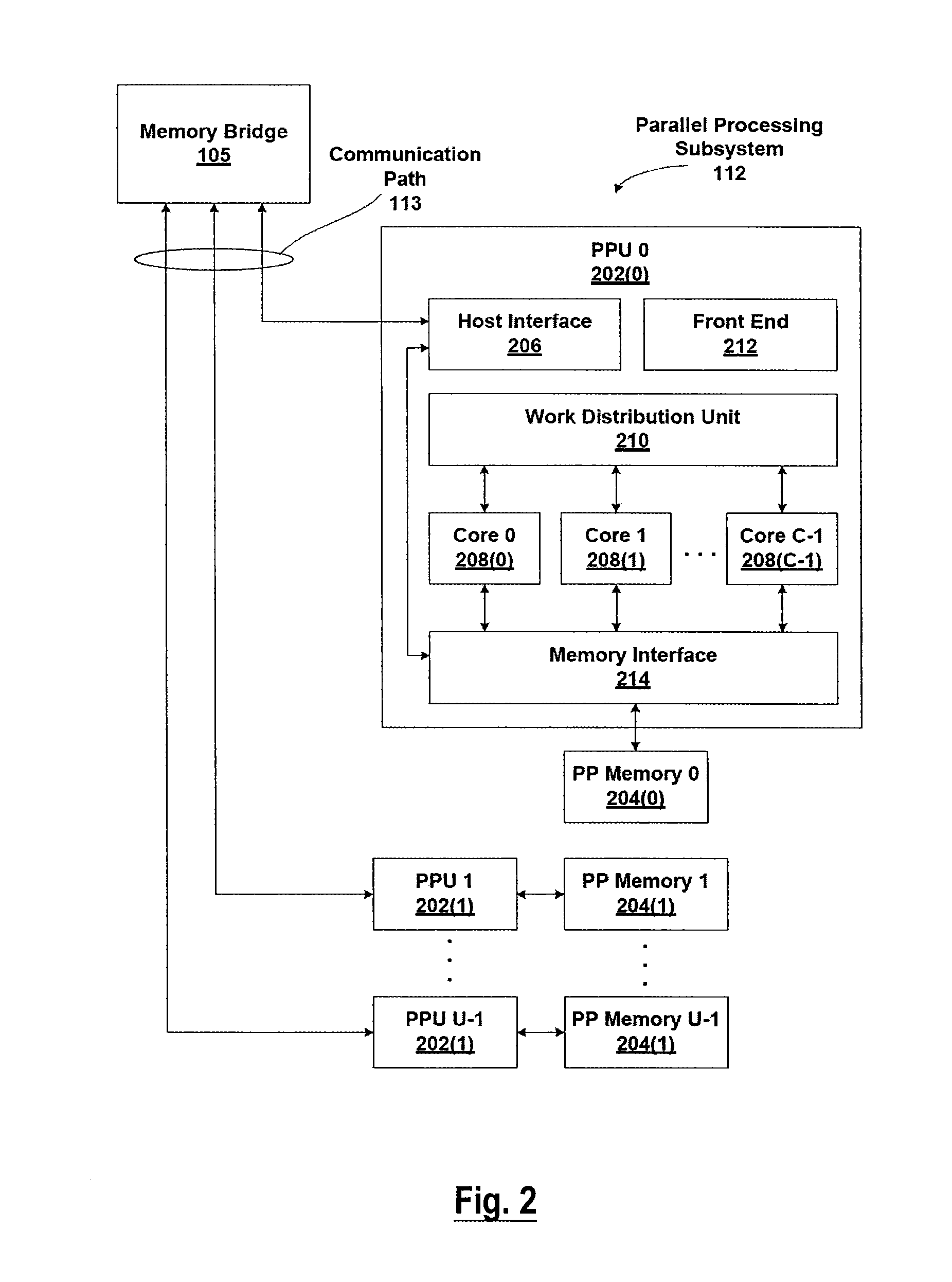

Method And System For Enabling Managed Code-Based Application Program To Access Graphics Processing Unit

ActiveUS20100149193A1Enhanced CUDA parallel processing environmentImprove the processing environmentProcessor architectures/configurationProgram controlInstruction codeCode Translation

One embodiment of the present invention sets forth a method for enabling an intermediate code-based application program to access a target graphics processing unit (GPU) in a parallel processing environment. The method includes the steps of compiling a source code of the intermediate code-based application program to an intermediate code, translating the intermediate code to a PTX instruction code, and translating the PTX instruction code to a machine code executable by the target graphics processing unit before delivering the machine code to the target GPU.

Owner:NVIDIA CORP

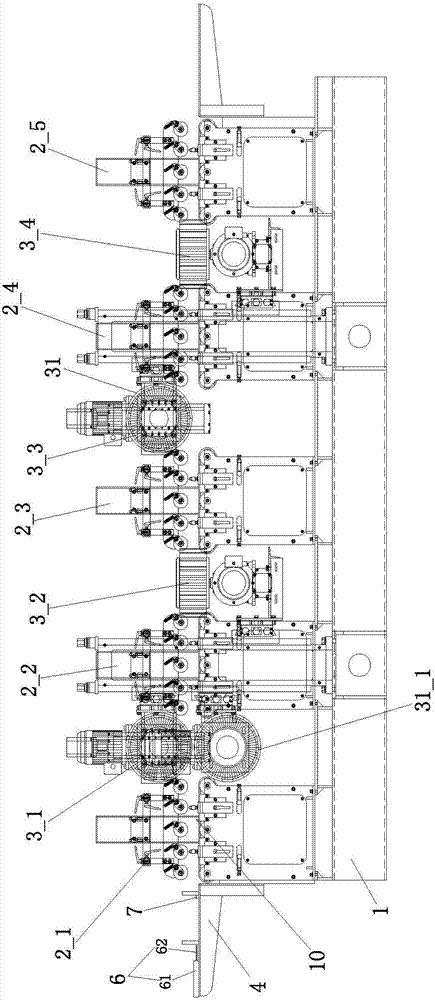

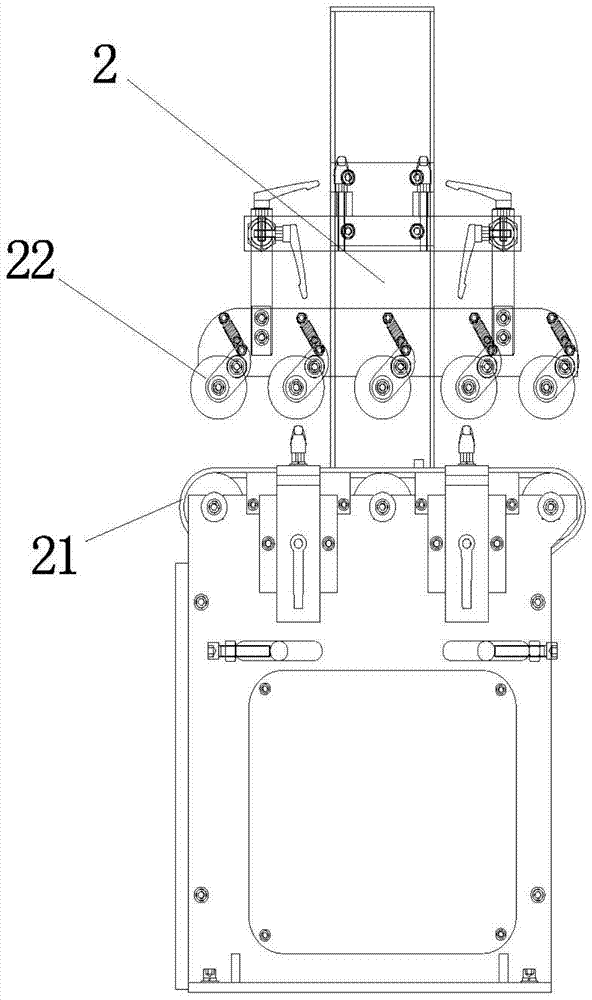

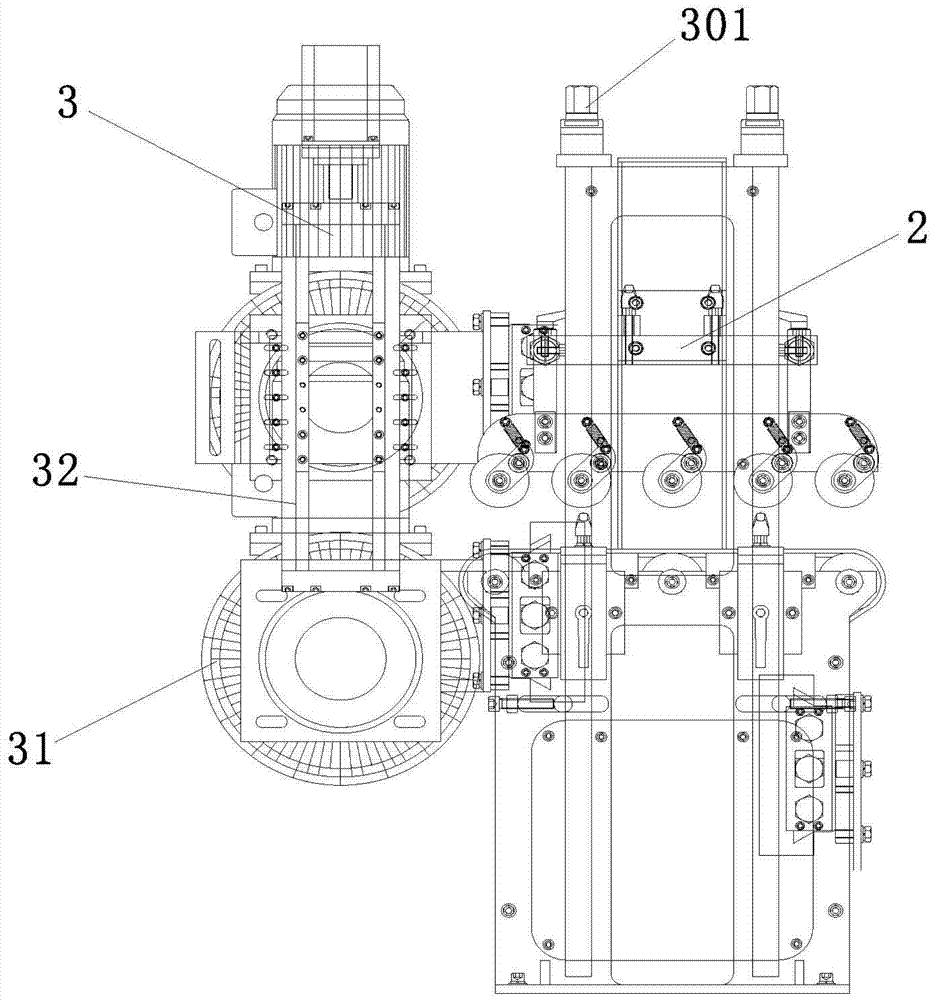

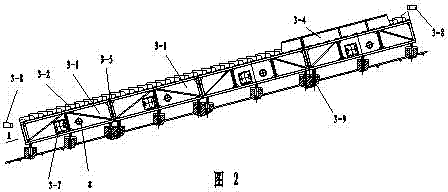

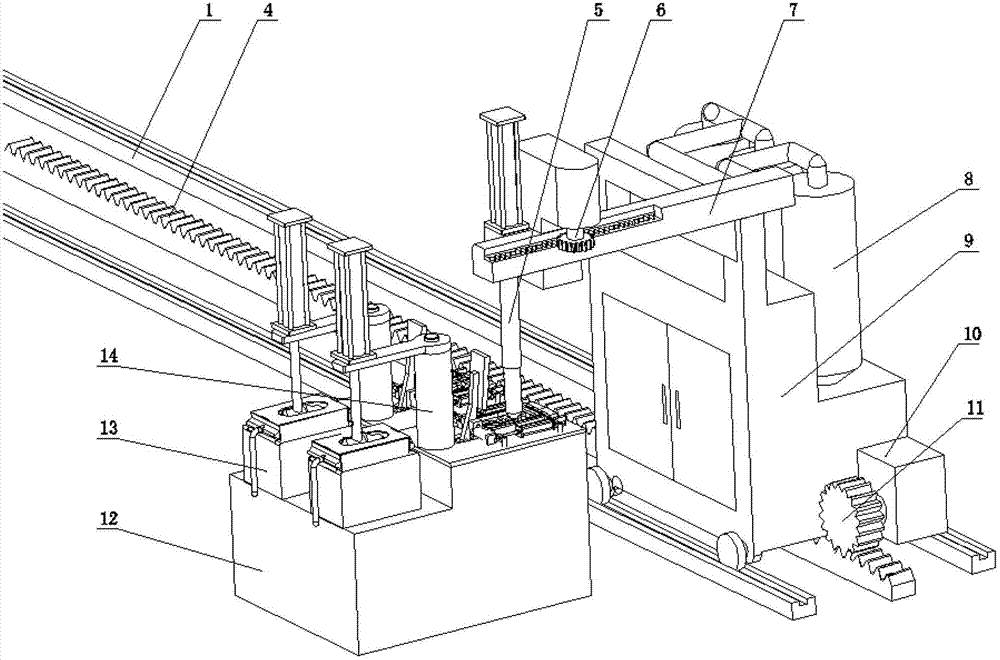

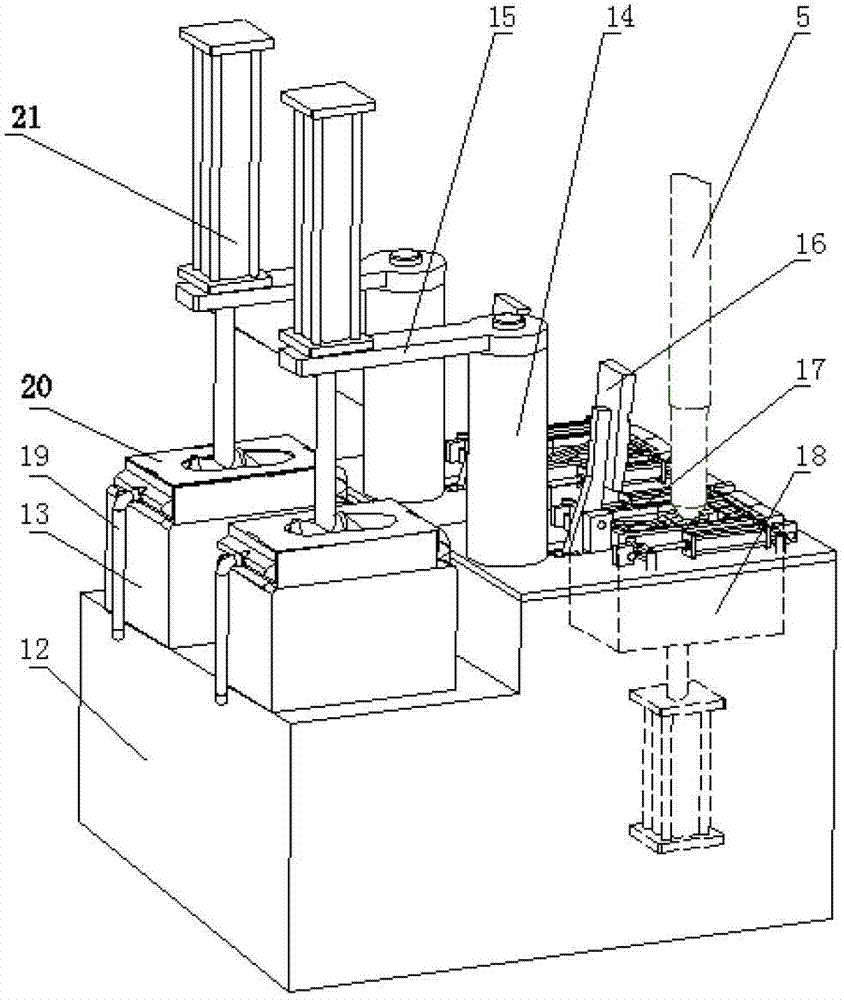

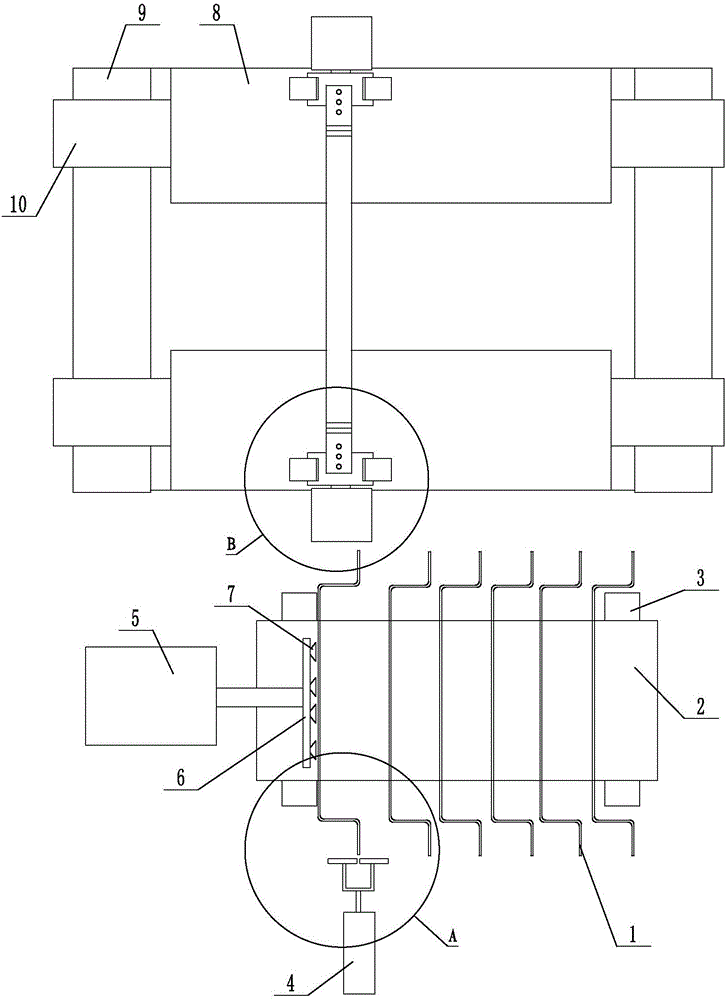

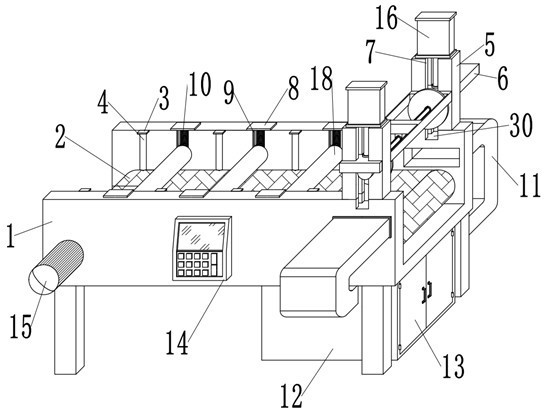

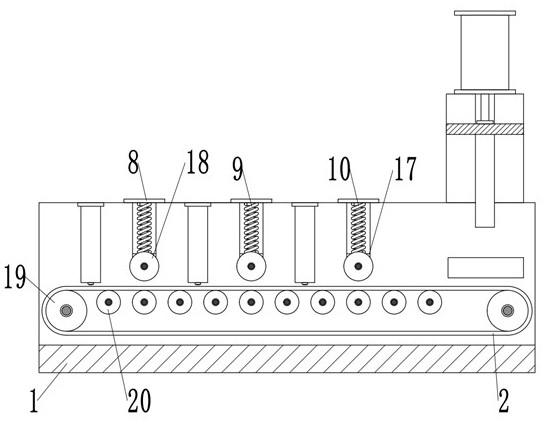

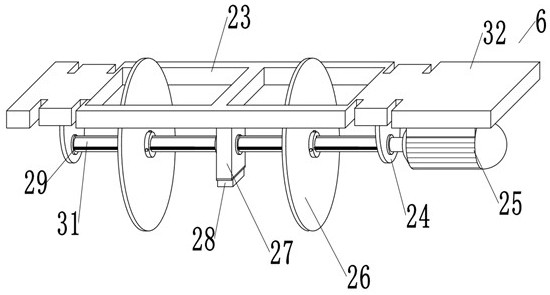

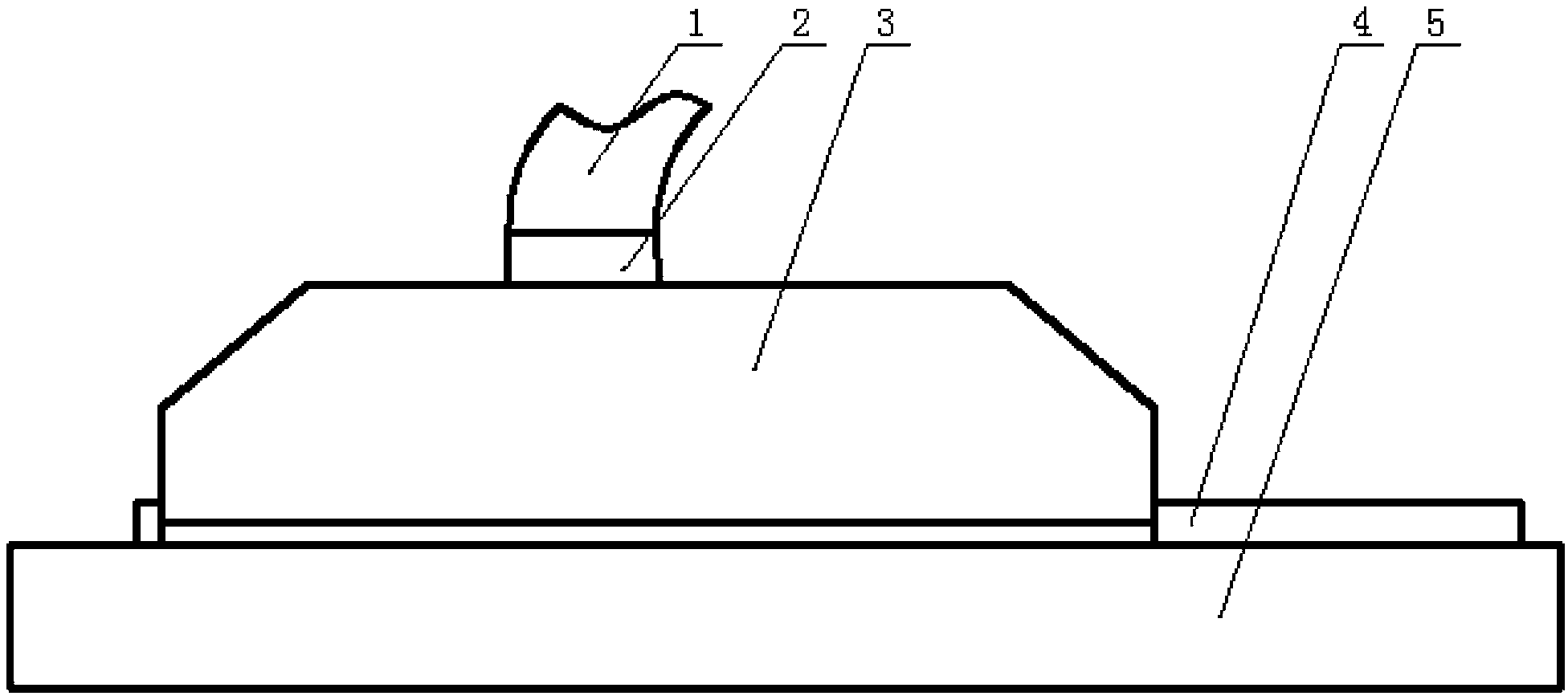

Sanding equipment for furniture part

InactiveCN103692316AImprove processing efficiencyLow technical requirementsGrinding machinesGrinding/polishing safety devicesEngineeringMachining

The invention provides sanding equipment for a furniture part, which has the advantages of flexible machining way, high accuracy and the like. The sanding equipment comprises conveying devices, sanding devices, a feeding platform and a control device, which are arranged on a base. The sanding equipment is characterized in that each conveying device comprises a conveying belt and conveying pressure rollers arranged above the conveying belt; each sanding device comprises a sand grinder and a moving mechanism which is arranged in parallel or vertical to a conveying device; each sand grinder is fixedly arranged on each moving mechanism, and can move forwards and backwards along a conveying direction or ascends and descends vertical to the conveying direction along with the moving mechanism; the sanding equipment at least comprises two conveying devices and one sanding device; any sanding device is positioned between the two conveying devices; the size information of the furniture part is at least stored or can be acquired from the control device, and the size information is translated to generate the running parameters of the conveying devices and the sanding devices; the sanding equipment comprises at least one sensing switch for acquiring the origin information of the furniture part.

Owner:中山市锋凡机械设备有限公司

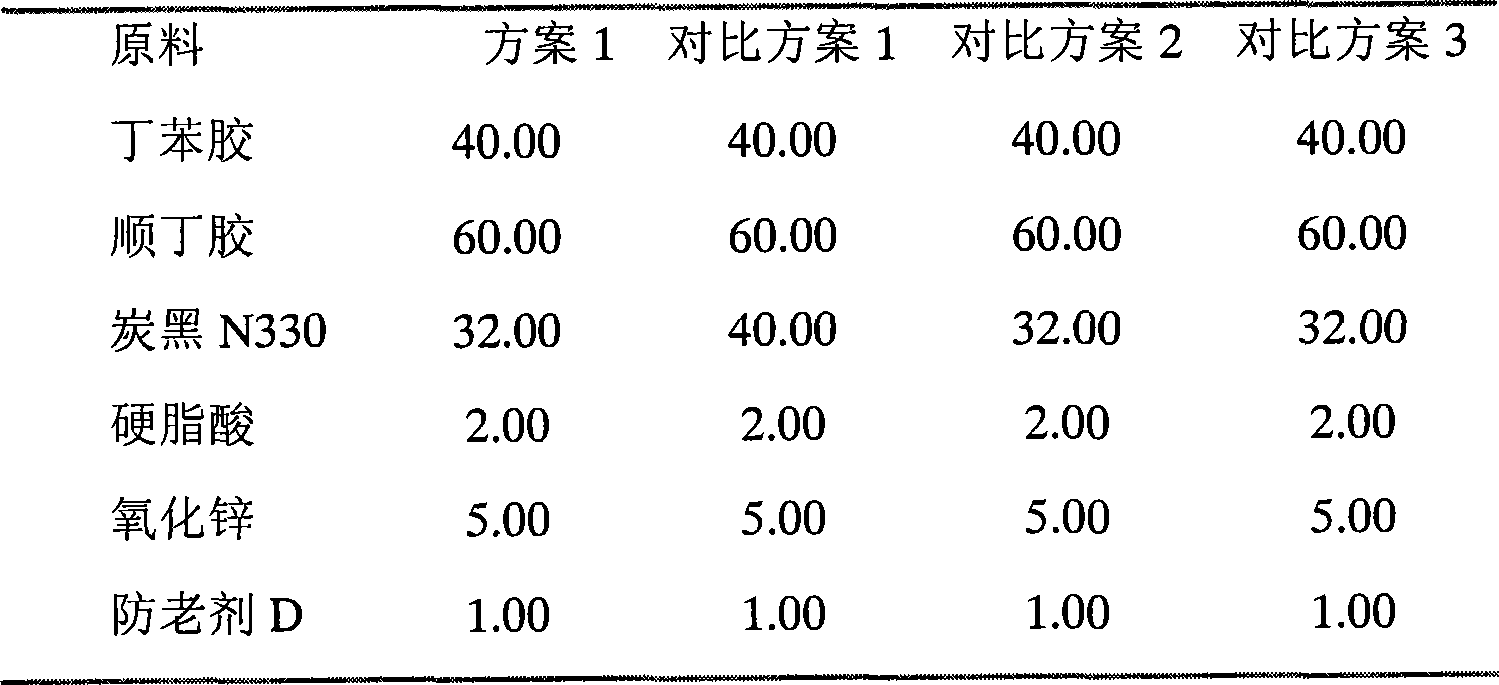

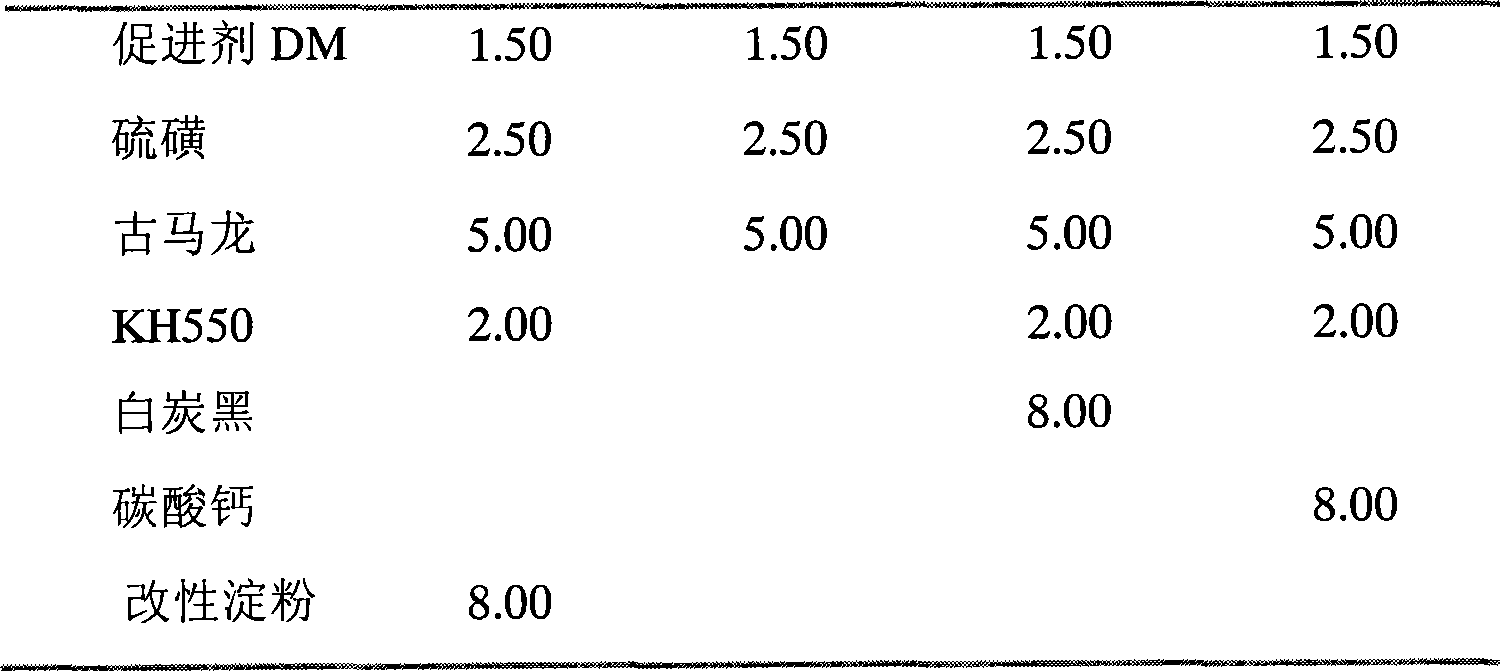

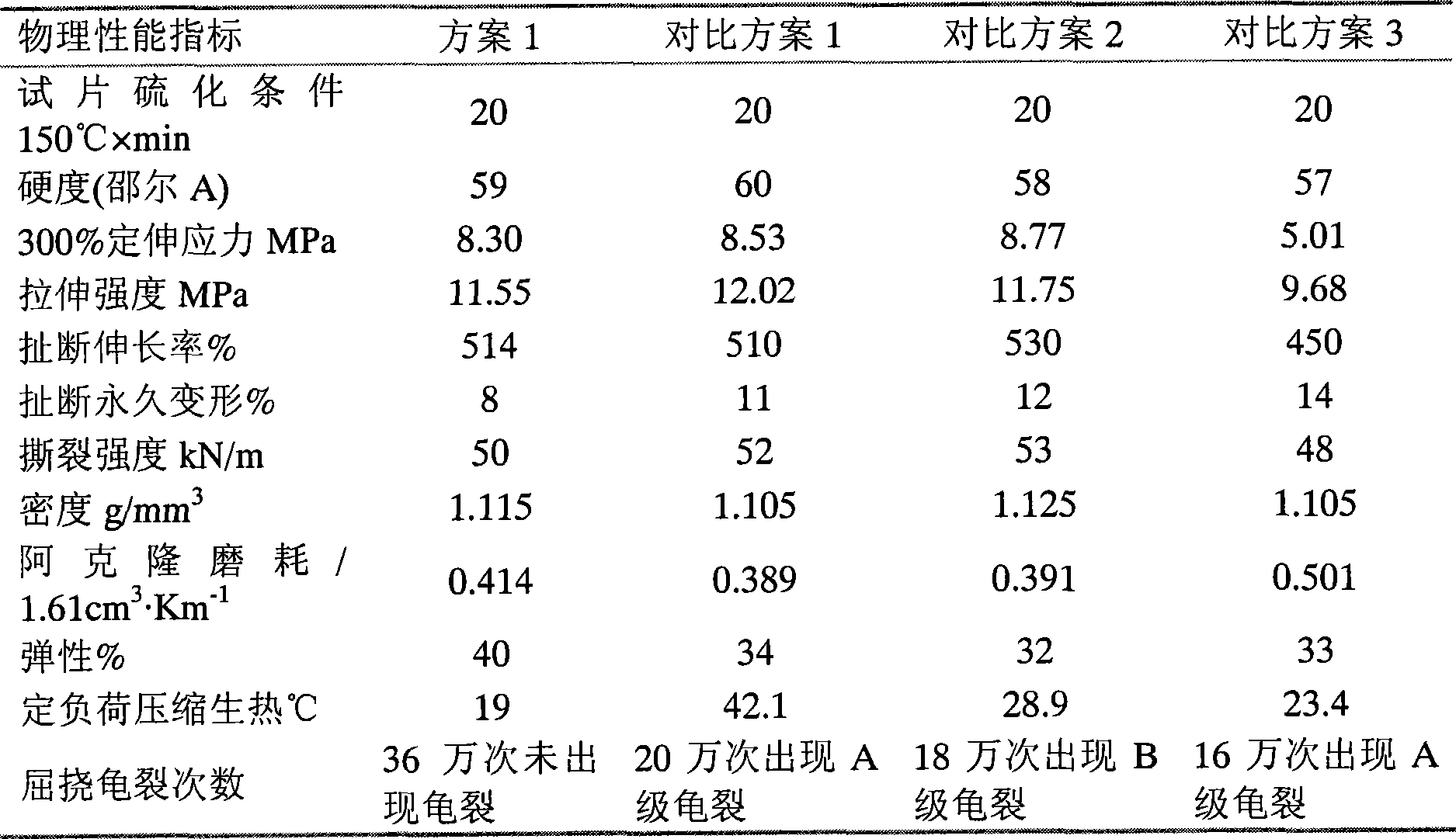

Method for preparing low-heat-generation fatigue-resistant vulcanized rubber

InactiveCN101519510AImprove fatigue lifeImprove the processing environmentButadiene-styrene rubberStearic acid

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

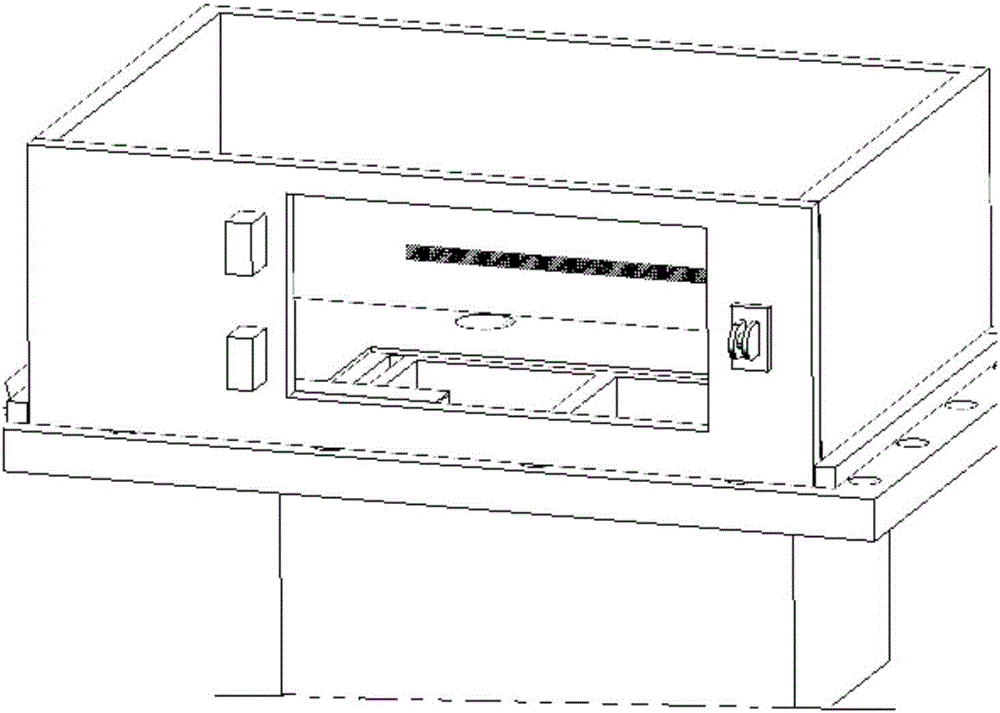

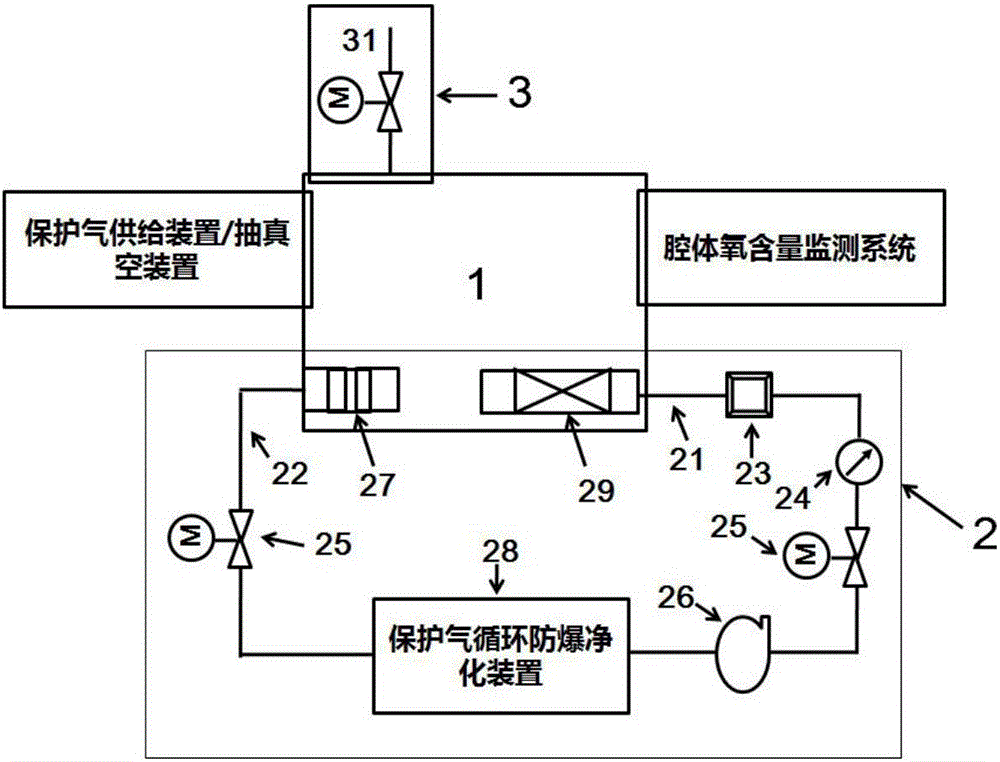

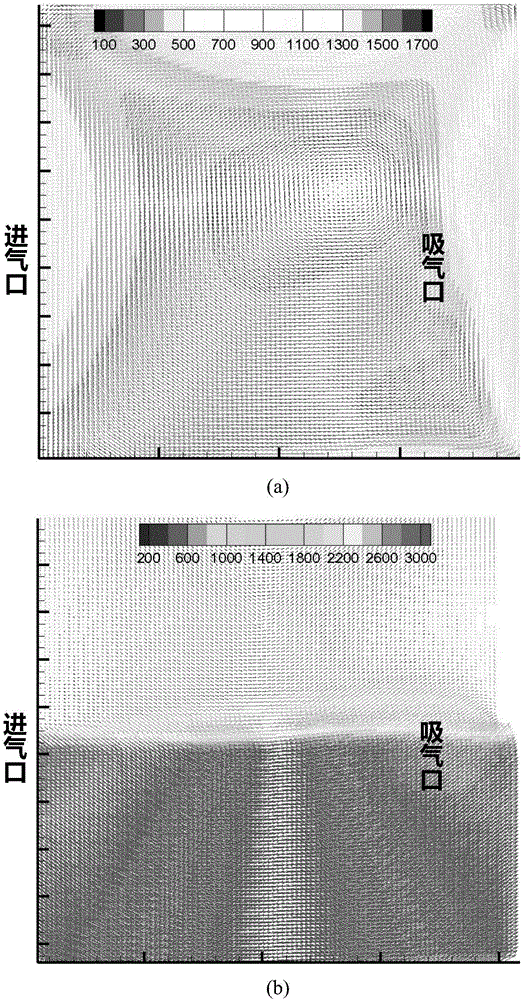

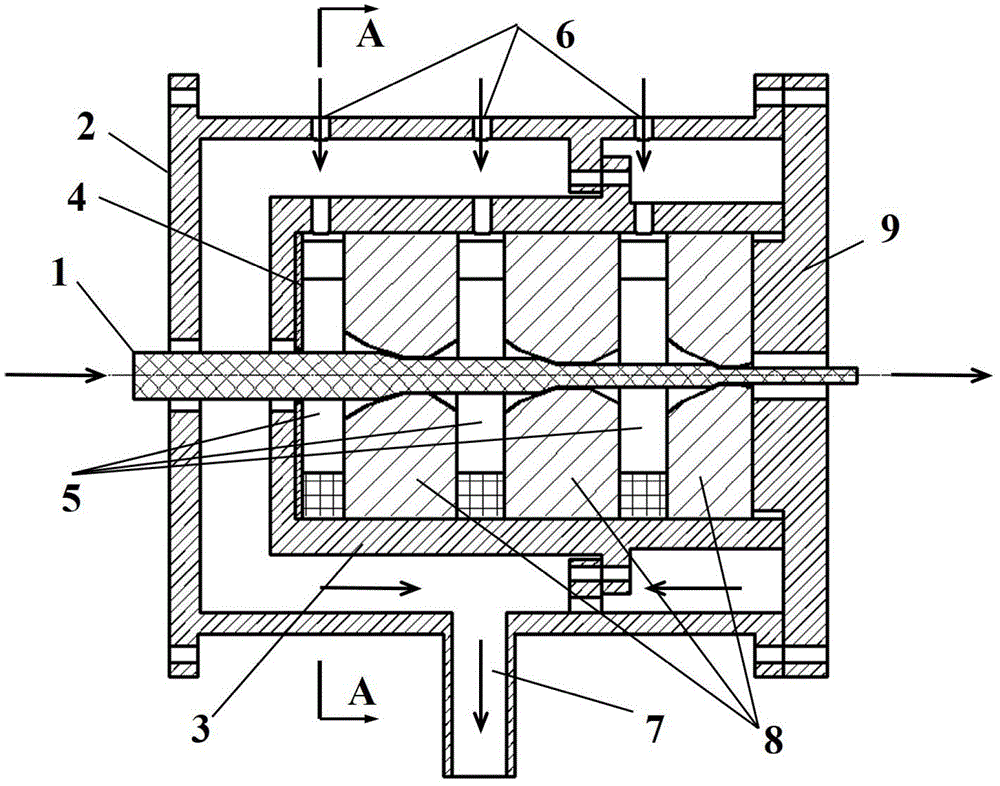

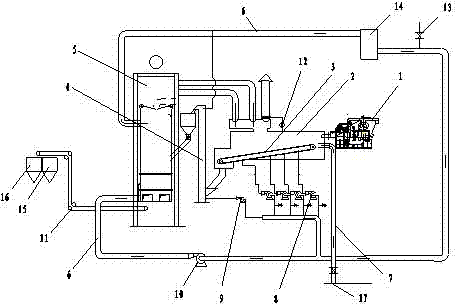

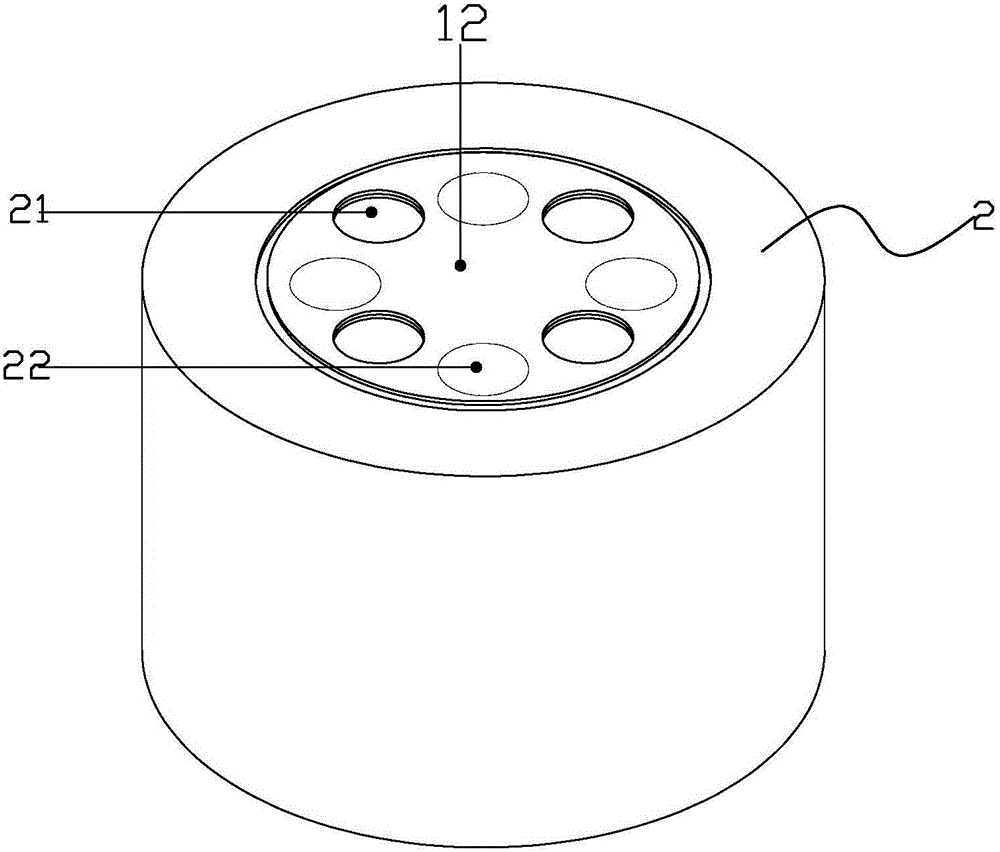

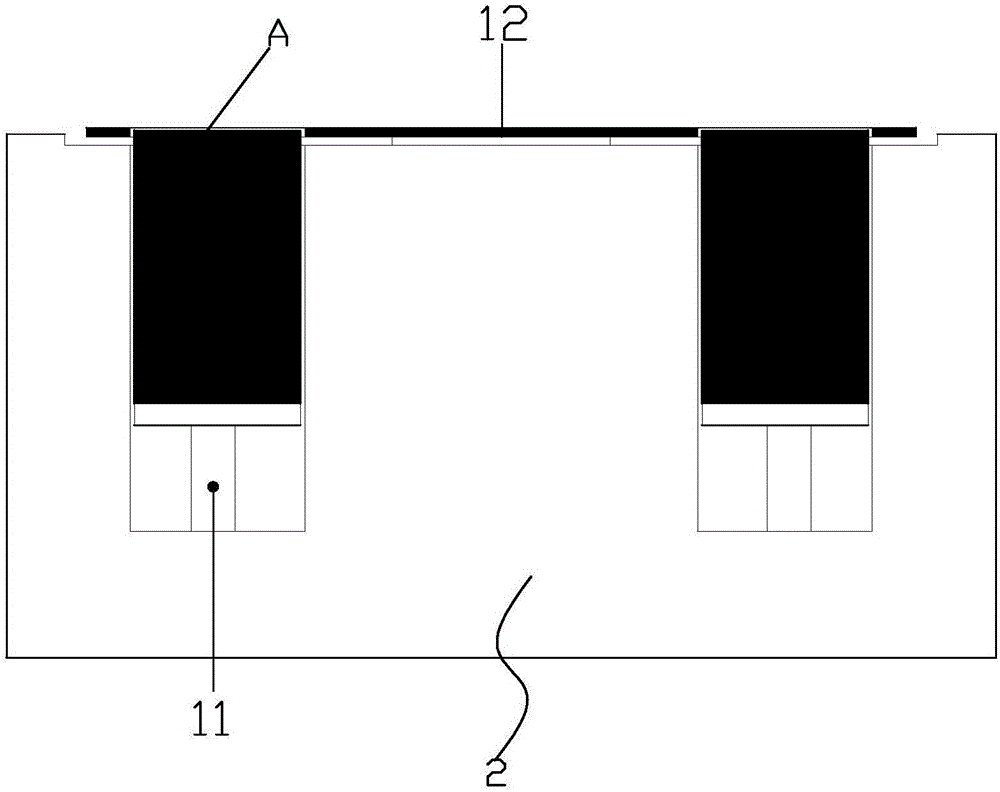

Shielding gas circulating filtration device for 3D printing metal powder bed forming cavity and optimization method of shielding gas circulating filtration device

ActiveCN106513674AEasy accessImprove cleanlinessAdditive manufacturing apparatusIncreasing energy efficiencyFiltrationCarbon Dioxide / Helium

The invention discloses a shielding gas circulating filtration device for a 3D printing metal powder bed forming cavity and an optimization method of the shielding gas circulating filtration device. According to the optimization method, the vertical movement distance z of processed smoke is adjusted and is not larger than the height h of an air suction flow guiding channel, and accordingly the purposes that the processed smoke is completely captured by the air suction flow guiding channel, and the pressure from an air inlet flow dividing port to an air suction flow guiding port in the forming cavity is gradually reduced are achieved; and a machined metal part has the beneficial effects of being good in surface quality, high in density, good in mechanical performance and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Polishing disk for polishing crystal glass

InactiveCN102120315AExtended service lifeHydrophilicAbrasion apparatusWater solubleHigh wear resistance

The invention relates to a polishing disk for polishing crystal glass. In the polishing disk for polishing crystal glass, a polishing layer comprises the following components in percentage by mass: 5 to 60 percent of grinding material, 10 to 60 percent of unsaturated resin with water swelling property, 0.5 to 5 percent of curing agent, 0.1 to 30 percent of water soluble additive and 0.05 to 8 percent of functional regulating additive, wherein the total mass percentage of the components is 100 percent. The grinding material may be diamond, carborundum and aluminum oxide. The polishing disk solves the problem that the diamond, carborundum, aluminum oxide and the like, which are harder than workpieces, cannot be used as a grinding material on the polishing disk, and has the advantages of high processing efficiency, high wear resistance and long service life.

Owner:ZHEJIANG PUJIANG MINRUI PRECISION MACHINERY TECH

Method And System For Enabling Managed Code-Based Application Program To Access Graphics Processing Unit

ActiveUS20100149194A1Enhanced CUDA parallel processing environmentImprove the processing environmentImage data processing detailsArchitecture with multiple processing unitsGraphicsCode Translation

One embodiment of the present invention sets forth a method for enabling an intermediate code-based application program to access a target graphics processing unit (GPU) in a parallel processing environment. The method includes the steps of compiling a source code of the intermediate code-based application program to an intermediate code, translating the intermediate code to a PTX instruction code, and translating the PTX instruction code to a machine code executable by the target graphics processing unit before delivering the machine code to the target GPU.

Owner:NVIDIA CORP

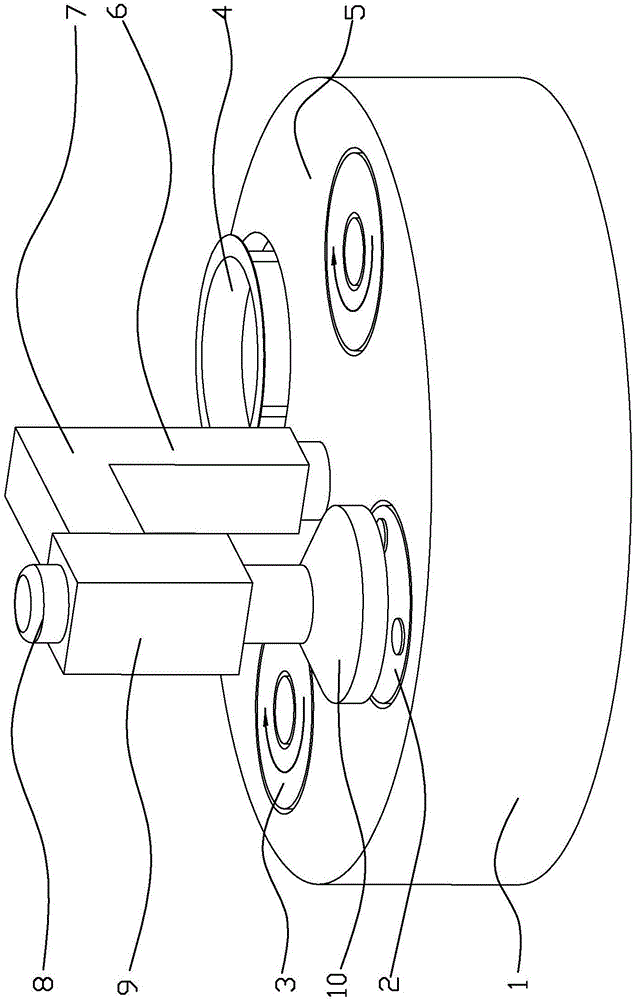

Multi-pass metal drawing device based on water lubrication drawing

The invention discloses a multi-pass metal drawing device based on water lubrication drawing. The multi-pass metal drawing device comprises a support, a drawing cavity which is fixed in the support, a sealing ring, a mold group and a lubrication chamber group which are arranged in the drawing cavity, and a cover plate which is fixed on the support, wherein the mold group is an ultra-smooth nano diamond composite coating mold; a drawing cavity lubricant inlet is aligned with the center line of a support lubricant inlet; the sealing ring, the lubrication chamber group and the mold group are sequentially placed in the drawing cavity along the drawing direction of a pipeline material; and the opening direction of a lubrication chamber is aligned with the drawing cavity lubricant inlet and outlet. The multi-pass metal drawing device can ensure that the contact area between the pipeline material and the mold group is completely immersed in a lubricant during drawing, then the excellent water lubrication property of a diamond film is brought into play, and a drawing area is effectively lubricated and cooled, so that the service life of the mold is prolonged, and the processing surface quality and the surface smooth finish and cleanliness are improved; and meanwhile, the characteristics of safety and non-pollution of a water base lubricant also ensure that a processing environment is greatly improved.

Owner:SHANGHAI JIAO TONG UNIV +2

Preparation method for anti-radiation ethylene-vinyl acetate copolymer composite material

The invention relates to a preparation method for an anti-radiation ethylene-vinyl acetate copolymer composite material. The steps comprises: weighing 100 parts of lead salt, 1-5 parts of coupling agent and 15-50 parts of solvent by weight, wherein the solvent is one or more of water and ester organic solvents, dissolving the coupling agent into the solvent, then adding the solution into the lead salt, stirring and evenly mixing the solution, activating the solution at constant temperature to obtain surface modified lead salt; and weighing 100 parts of ethylene-vinyl acetate copolymer, 50-250 parts of surface modified lead salt, 0-10 parts of polar monomer, 0-1 parts of initiator, 0.1-2 parts of antioxygen and 0-15 parts of lubricating agent, stirring and evenly mixing the mixture, fusing and compositing the mixture to obtain the composite material. The anti-radiation ethylene-vinyl acetate copolymer composite material prepared through the method of fusing forming processing can serve as an anti-radiation coating or gel film to be used in textile and to be formed into clothes and cord fabric and the like with the anti-radiation function, and has wide application prospects.

Owner:嘉兴高正新材料科技股份有限公司

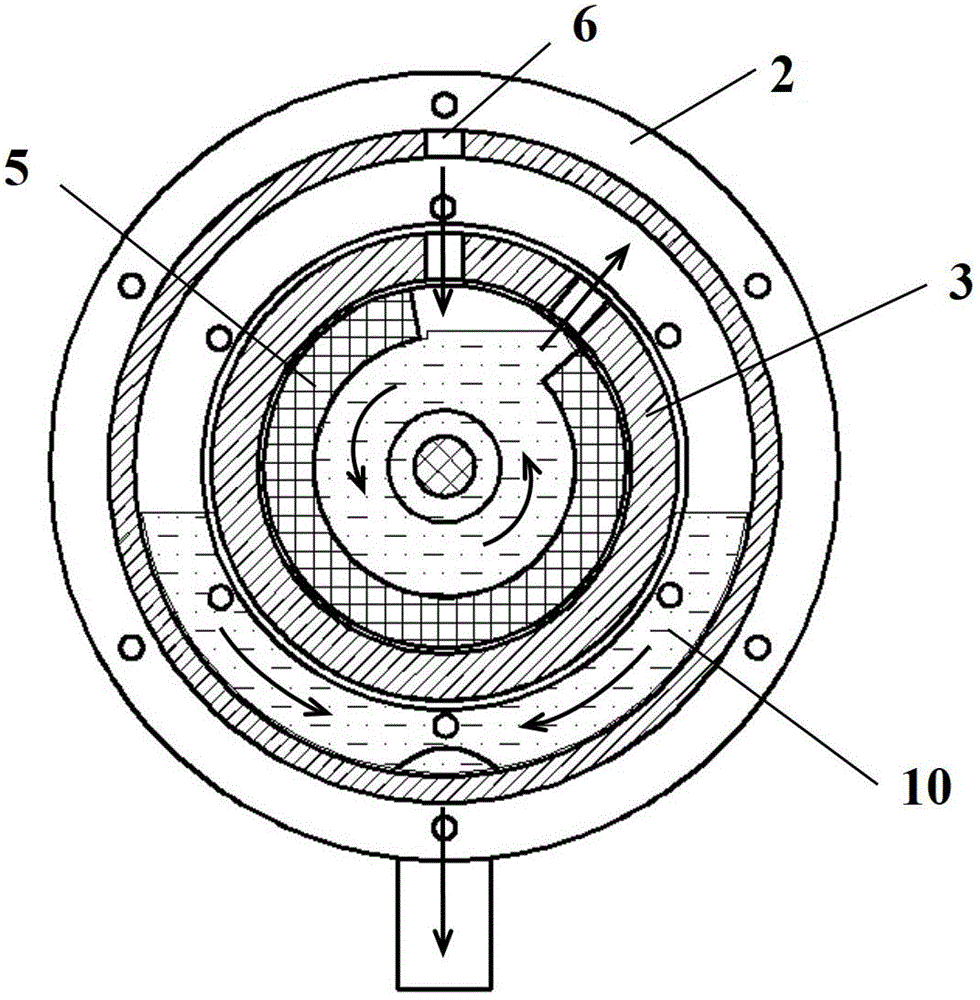

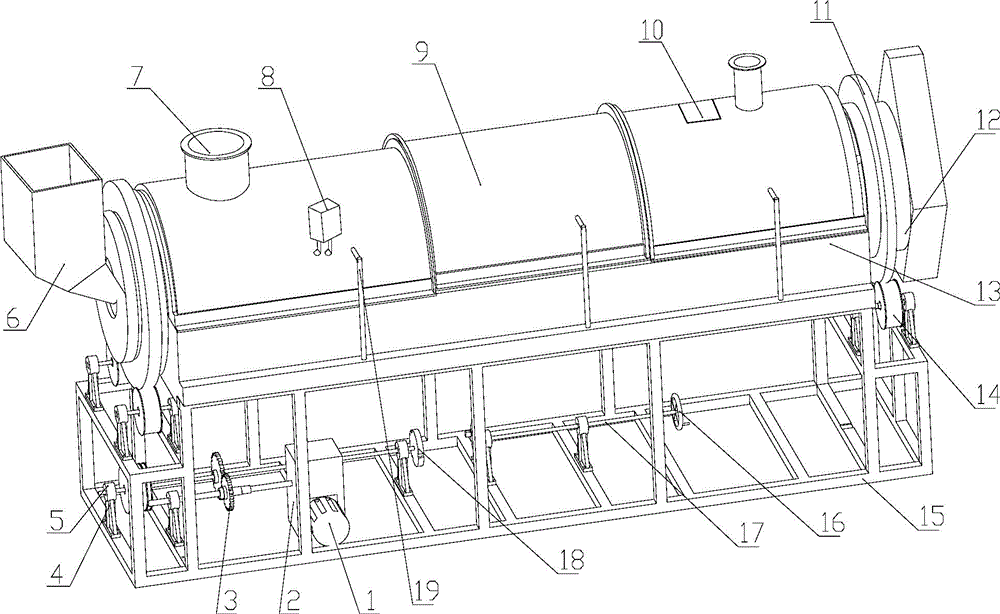

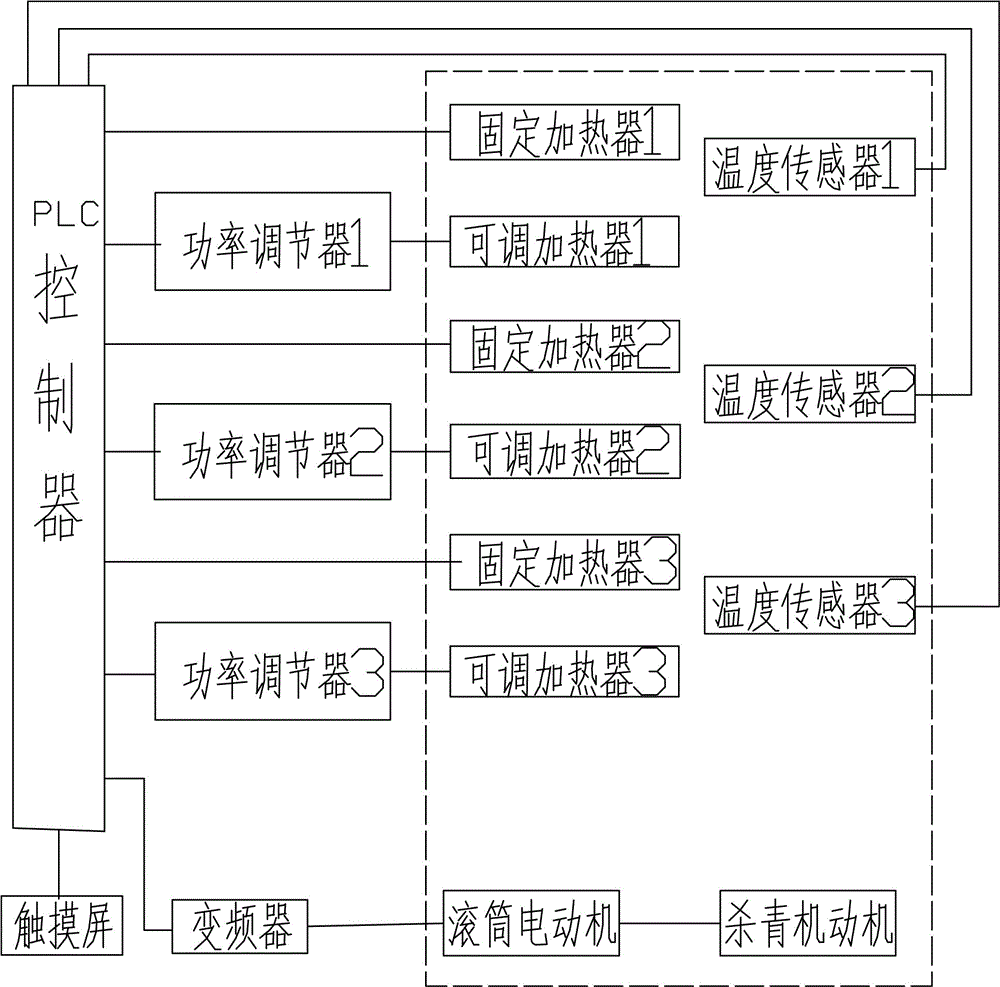

Segmented constant-temperature modular electrothermal tea leaf fixation machine

InactiveCN104904887AImprove thermal efficiencyImprove efficiencyPre-extraction tea treatmentChange controlEngineering

The invention relates to a segmented constant-temperature modular electrothermal tea leaf fixation machine. A motor is mounted on a stander; a roller base is mounted on the stander; a roller is mounted on the roller base; a speed reduction box is mounted on an output shaft of the motor; a gear is mounted on an output shaft of the speed reduction box and drives a belt wheel mounted on a supporting seat; the belt wheel drives a friction wheel meshed with the roller so as to enable the roller to rotate; an inlet funnel is arranged at the left end of the roller; a ventilating hole and a box cover are arranged at the top of the roller; a temperature control system is arranged on the box cover; an electric heating plate is mounted on the outer surface of the roller and is connected with the temperature control system. According to the fixation machine, the conventional heating mode is changed, and a PLC control technology, a modern control theory and a frequency change control technology are combined; the temperature control system of an electric heating roller fixation machine based on PLC control is designed, so that the temperature control precision, the automation degree and the interference resistance of the fixation machine are improved, and influence caused by manmade factors in actual production is reduced.

Owner:CHINA THREE GORGES UNIV

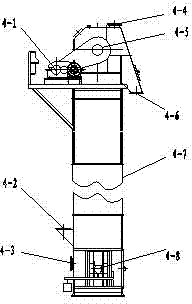

Equipment for steel slag air quenching and waste heat recycling

ActiveCN102952908AExpand the scope of processingImprove mobilityIncreasing energy efficiencyManufacturing convertersQuenchingSlag

Equipment for steel slag air quenching and waste heat recycling belongs to the technical field of the steel slag processing equipment and method. Steel slag air quenching and waste heat recycling processes are utilized to treat high-temperature steel slags and recovering heat; and the technical scheme is as follows: in the equipment, an air quenching slag pot is connected with a pelletization air tunnel which is connected with a grate cooling conveyor; the grate cooling conveyor is connected with a high-temperature-resistant bucket elevator; the high-temperature-resistant bucket elevator is connected with a circulating fluidized bed heat recovery boiler; an external nitrogen pipeline is connected with the pelletization air tunnel and the grate cooling conveyor, respectively; and a nitrogen circulating pipeline is connected with the high-temperature-resistant bucket elevator and the circulating fluidized bed heat recovery boiler, respectively. The process flow comprises hardening and cracking liquid-state steel slags into even particles by using low-temperature nitrogen, and then feeding the steel slag particles to the circulating fluidized bed heat recovery boiler through pneumatic transmission so as to collect waste heat and zero-valent iron. The integrated steel slag air quenching process provided by the invention is in a world leading level and is innovation of liquid-state steel slag treatment and heat recovery, thereby having wide prospect.

Owner:唐钢国际工程技术有限公司

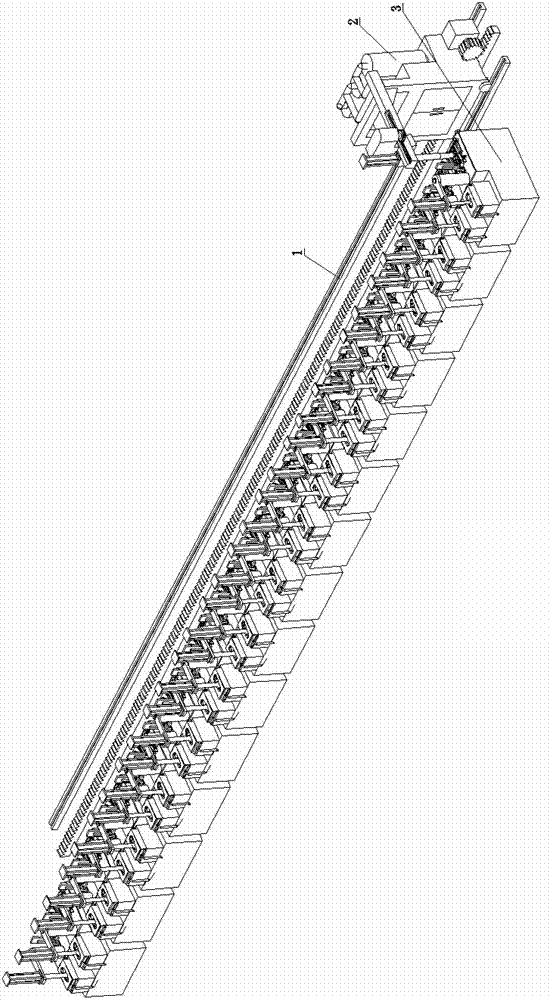

System for making shoes automatically from polyurethane

The invention relates to a system for making shoes automatically from polyurethane, comprising casting machines and a plurality of automatic shoe making machines. The casting machines are coaxially and movably arranged on two parallel guide rails in a guiding way; the juxtaposed automatic shoe making machines are arranged in parallel on one side of the two parallel guide rails in the moving direction of the casting machines; a conveying gear belt is coaxially arranged between the two parallel guide rails; and a transmitting gear which is driven by a motor and engaged with the conveying gear belt is arranged on the lower part of the casting machine. The system is scientific in structure and reasonable in design, consumes least energy and is environmentally friendly. Due to the adoption of the system, the production efficiency can be increased significantly, the product quality can be guaranteed, and the production environment can be improved.

Owner:马士通安全设备(天津)有限公司

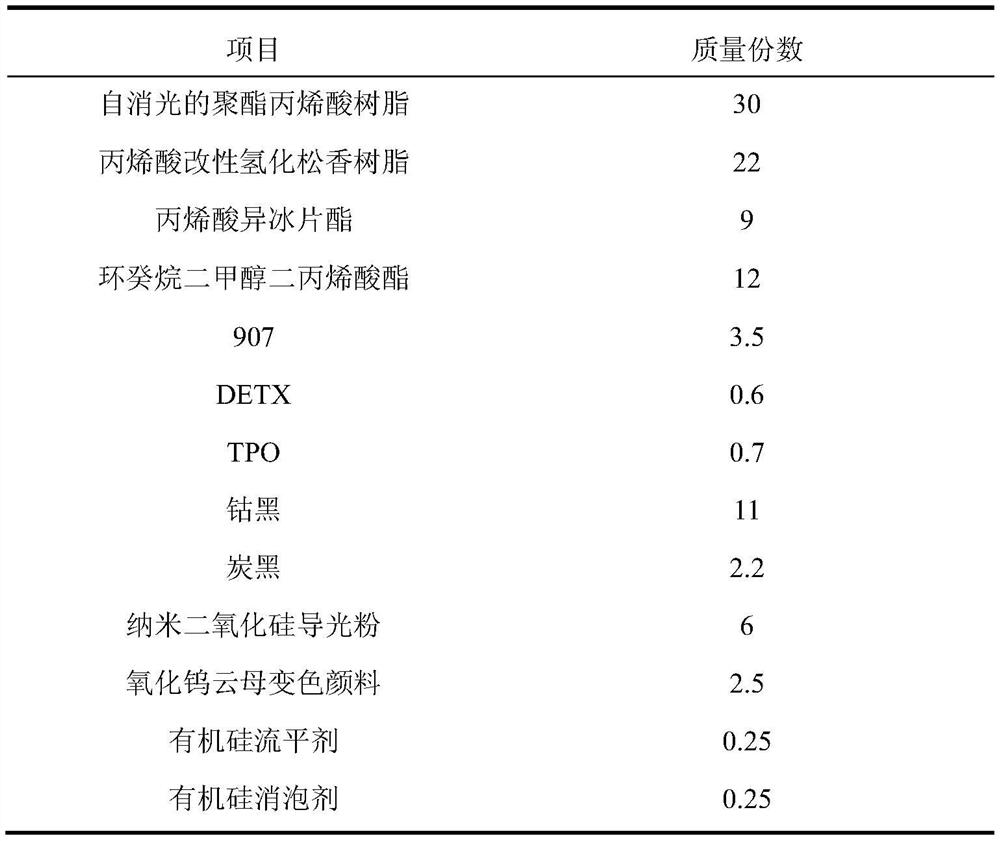

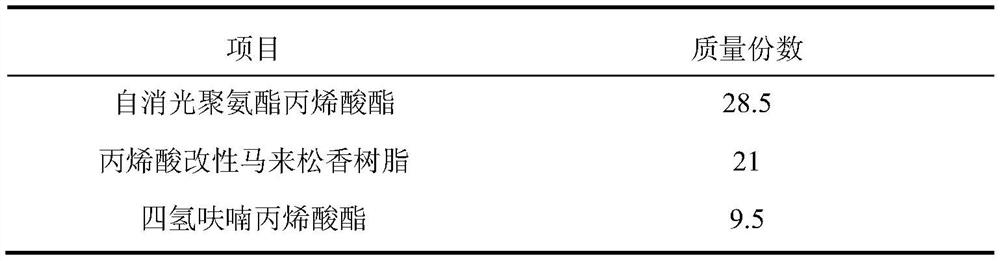

LED UV-cured black ink, preparation method and application thereof

The invention discloses LED UV-cured black ink, which comprises, by weight, 20 to 40 parts of self-extinction light-cured resin, 15 to 35 parts of acrylic acid modified rosin resin, 5 to 15 parts of UV monofunctional monomer, 5 to 20 parts of UV multifunctional monomer, 1 to 10 parts of photoinitiator, 0.5 to 8 parts of photochromic pigment, 5 to 20 parts of inorganic black pigment, 3 to 15 partsof light guide powder, 0.5 to 5 parts of carbon black, 0.05 to 0.5 part of leveling agent and 0.05 to 0.5 part of defoamer. According to the LED UV-cured black ink, an LED UV curing technology is creatively adopted, photochromism and light guide technologies are combined, a wet film is formed after a base material is coated with the black ink with high covering power, the same curing efficiency ofthe wet film from the surface to the bottom is achieved through LED UV light curing, and a coating formed after curing meets the performance requirement of thermocuring ink.

Owner:HUNAN SOKAN NEW MATERIAL

Construction steel bar machining equipment

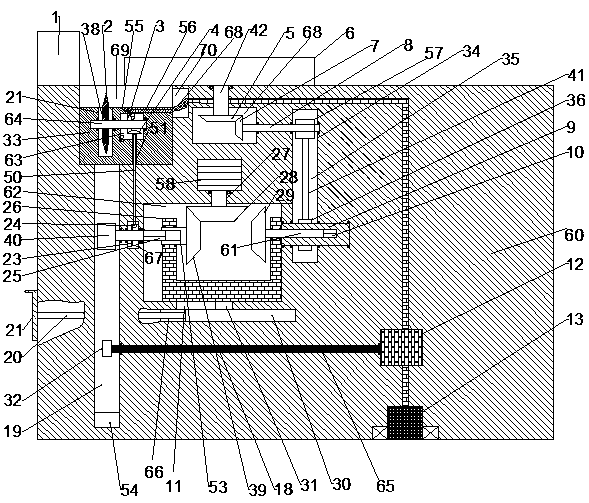

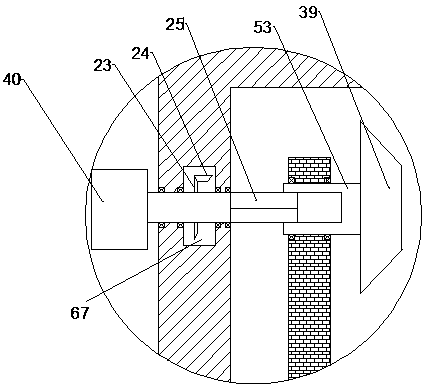

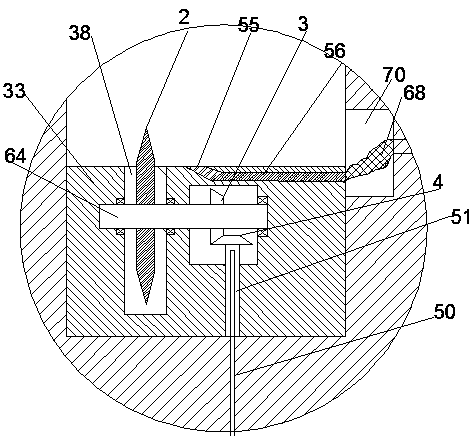

ActiveCN110961548AExtended service lifeImprove the processing environmentMaintainance and safety accessoriesElectric machineryEngineering

The invention discloses construction steel bar machining equipment. The equipment comprises a box body. The equipment is characterized in that a movable cavity is formed in the box body; a motor for providing power is fixedly mounted in the top wall of the movable cavity; a concave block is mounted in the movable cavity in a sliding manner; a first spline sleeve and a first spline shaft are rotationally mounted on the left bracket and right bracket of the concave block respectively; a first spline groove with a leftward opening is formed in the first spline sleeve; a first bevel gear is fixedly mounted at the right end of the first spline sleeve; a second bevel gear is fixedly installed at the left end of the first spline shaft; a first rotating shaft is in power connection with the lowerend of the motor; a third bevel gear capable of being engaged with the first bevel gear and the second bevel gear is fixedly installed at the lower end of the first rotating shaft; and a belt cavity extending upwards is formed in the right side of the movable cavity.

Owner:CHINA XINXING BAOXIN CONSTR CORP

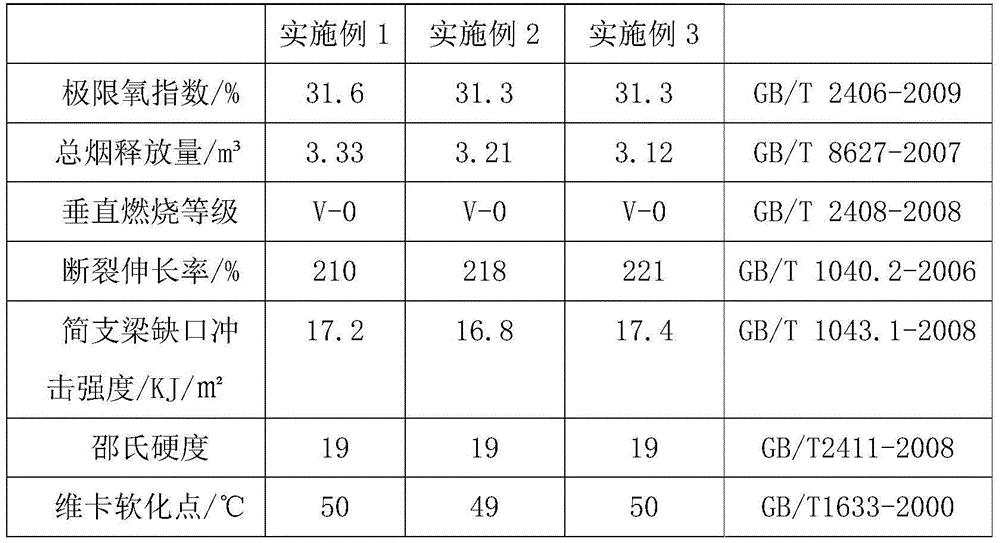

Antimony oxide compound flame-retardant PVC soft composite material and preparation method thereof

The present invention discloses an antimony oxide compound flame-retardant PVC soft composite material and a preparation method thereof. The composite material includes the following materials: PVC (SG-3), a plasticizer, antimony trioxide, ammonium molybdate, montmorillonite, a calcium zinc stabilizer, EVA, epoxy soybean oil, a coupling agent and a dispersing agent. The preparation process of the product is as below: modifying antimony trioxide; mixing the modified antimony trioxide with ammonium molybdate, montmorillonite and EVA; screening the mixture by a vibrating centrifugal screening machine; and drying the screened powder and conducting waterproof packaging. The product of the invention has efficient flame retardant and smoke suppression performance, limiting oxygen index up to 31.6%, elongation at break of 210% and Shore hardness as low as 17, can be used as a direct added raw material for PVC product, or be added as a modification additive, and can also be used as soft fireproof materials, such as PVC leather and protective decoration materials.

Owner:广西华锑科技有限公司

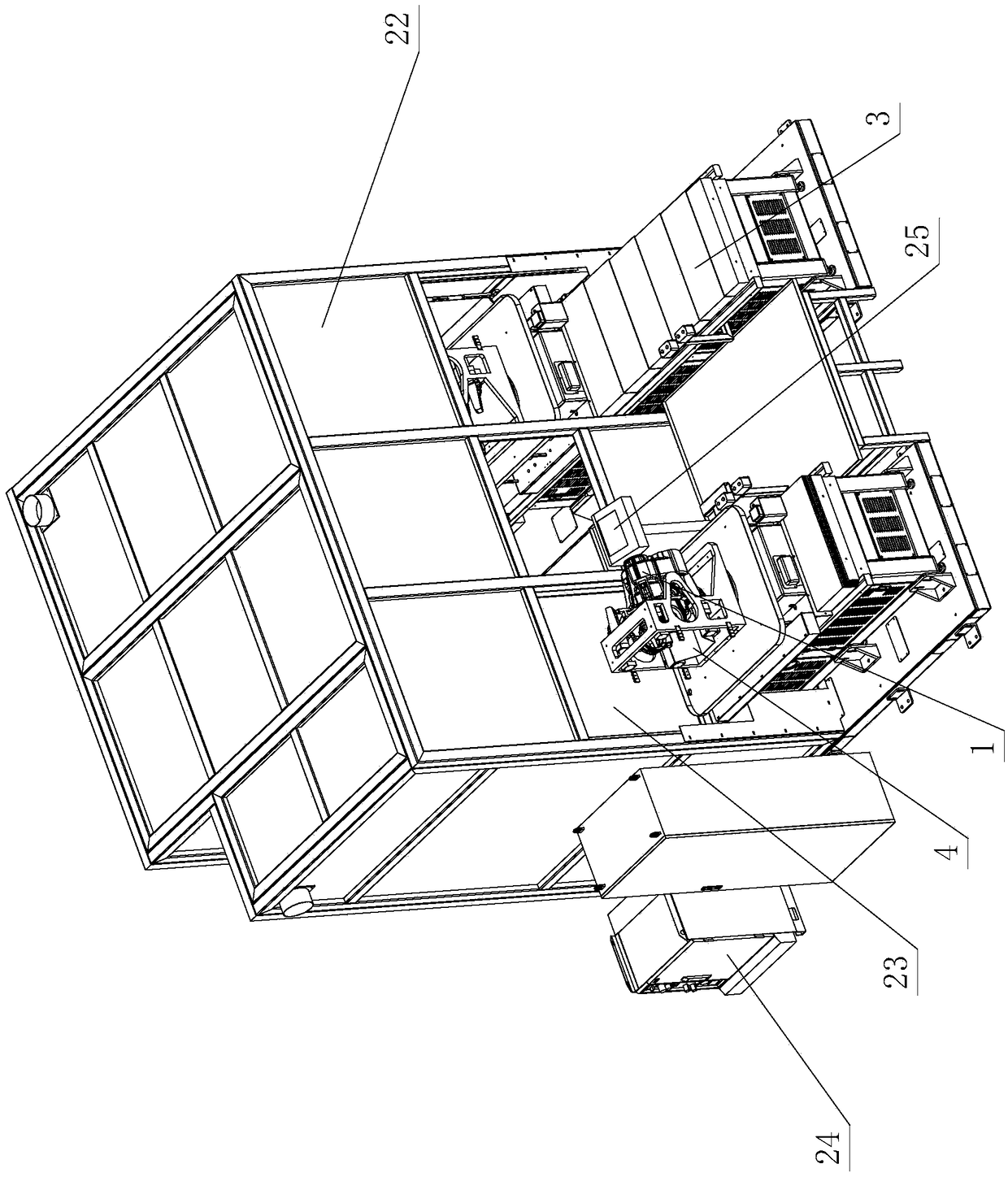

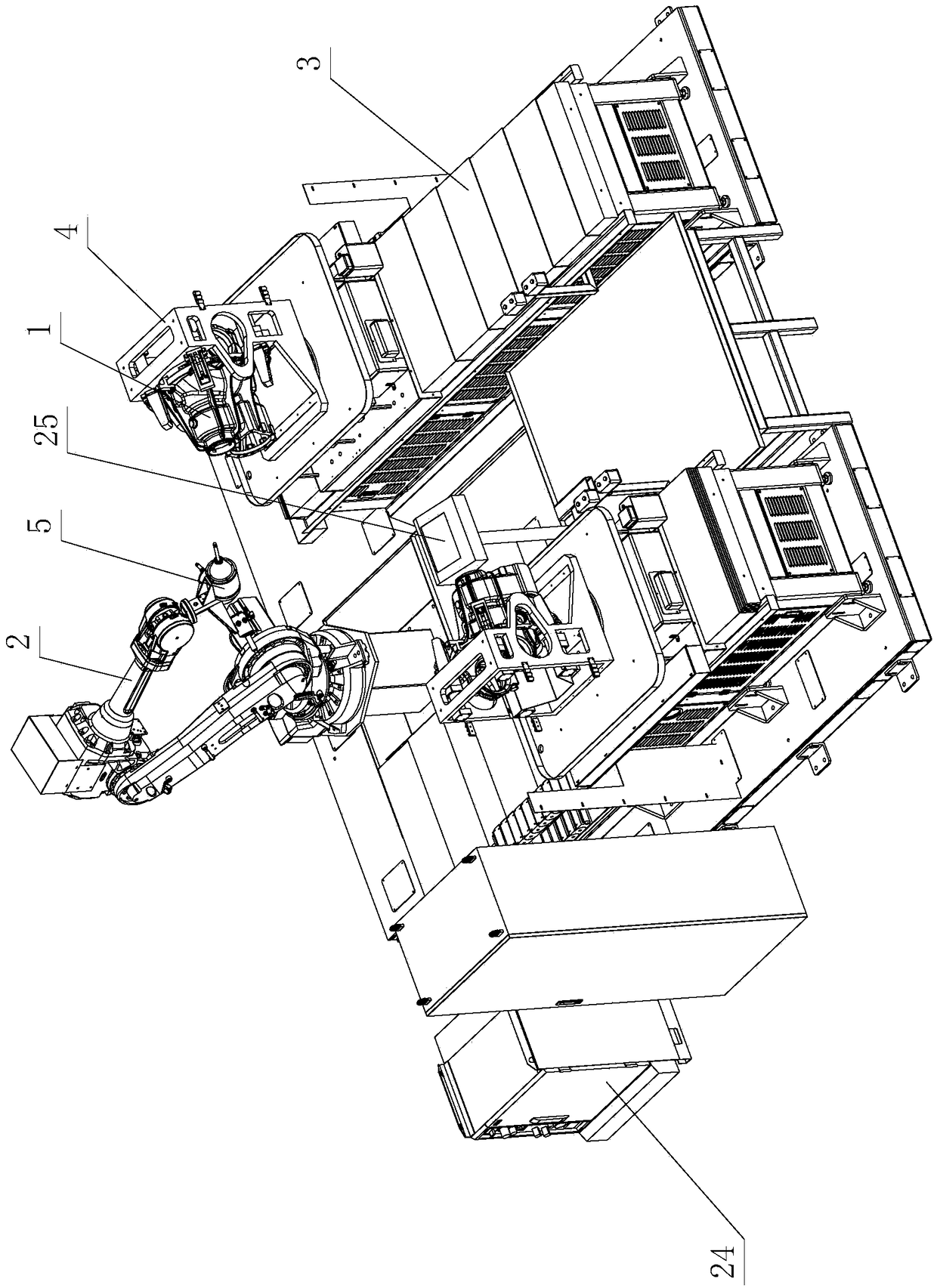

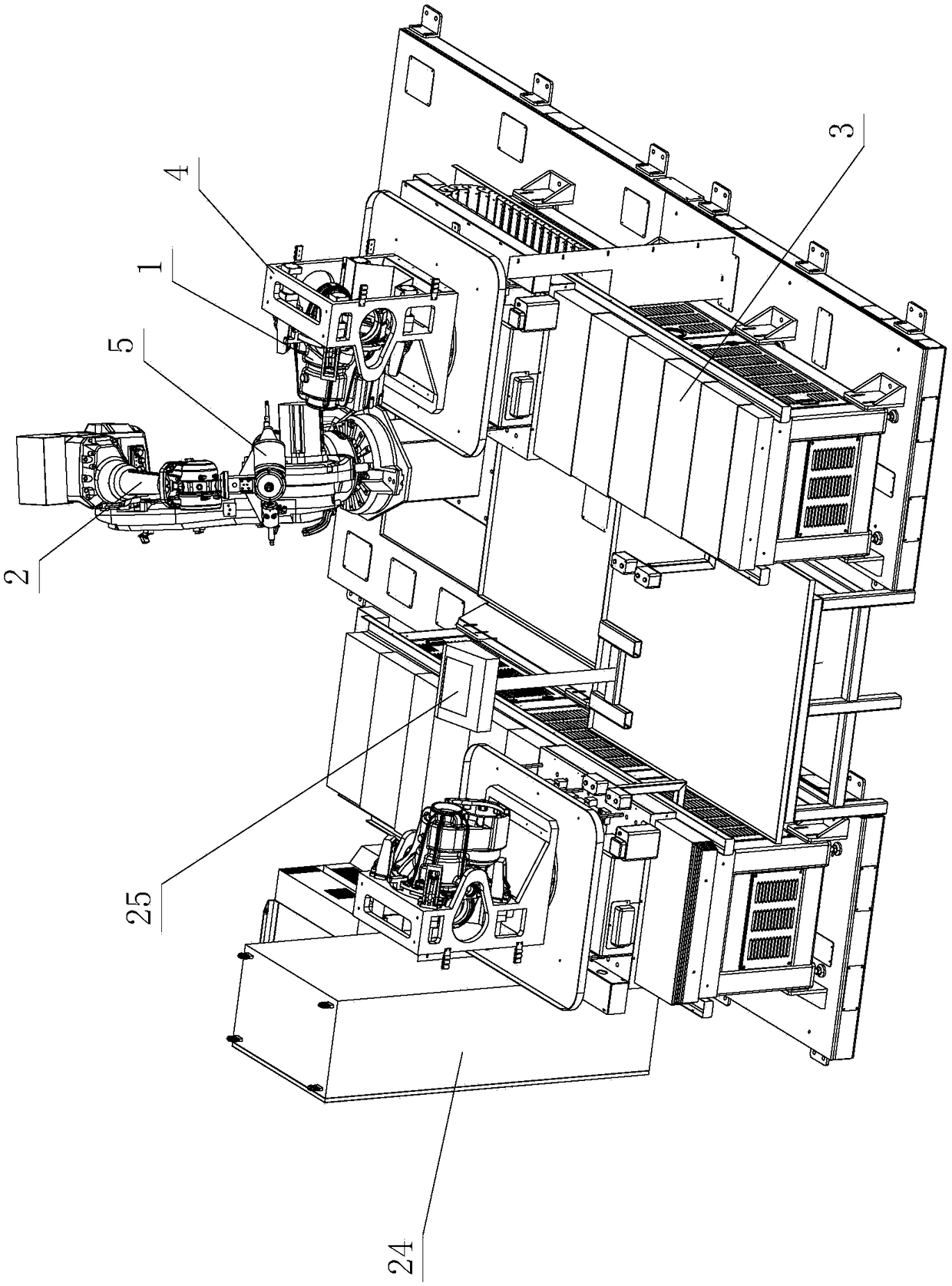

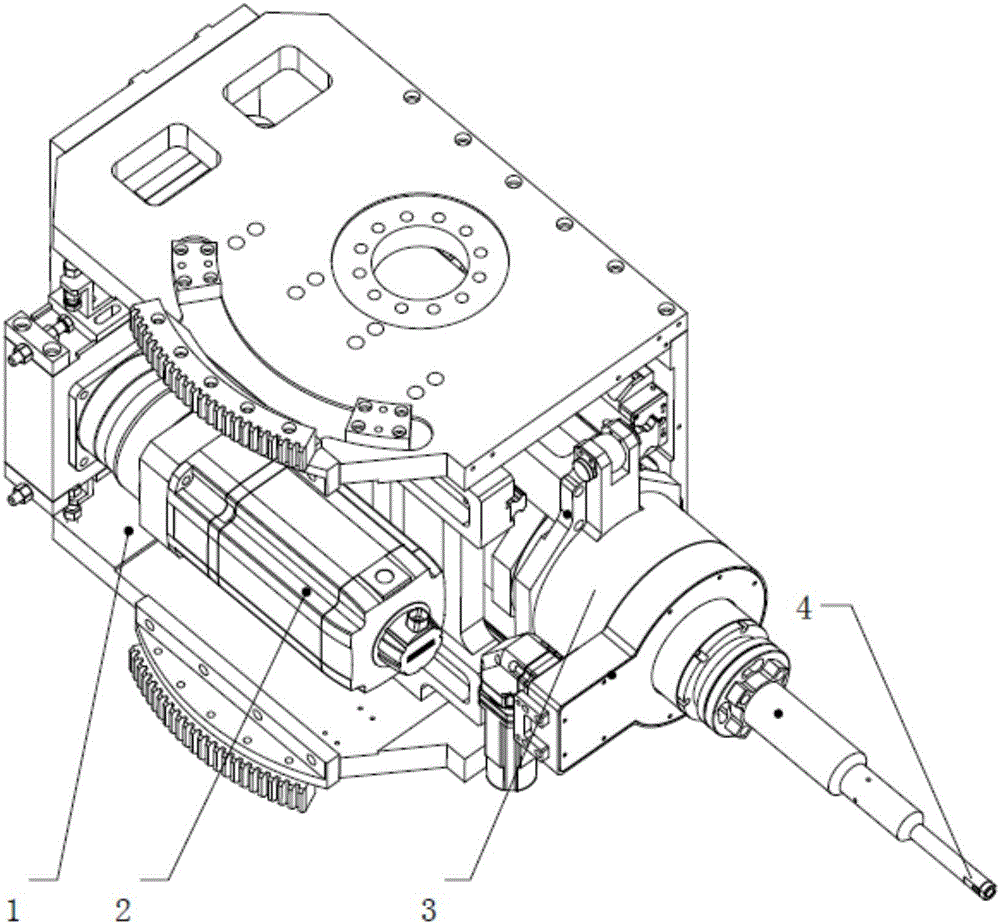

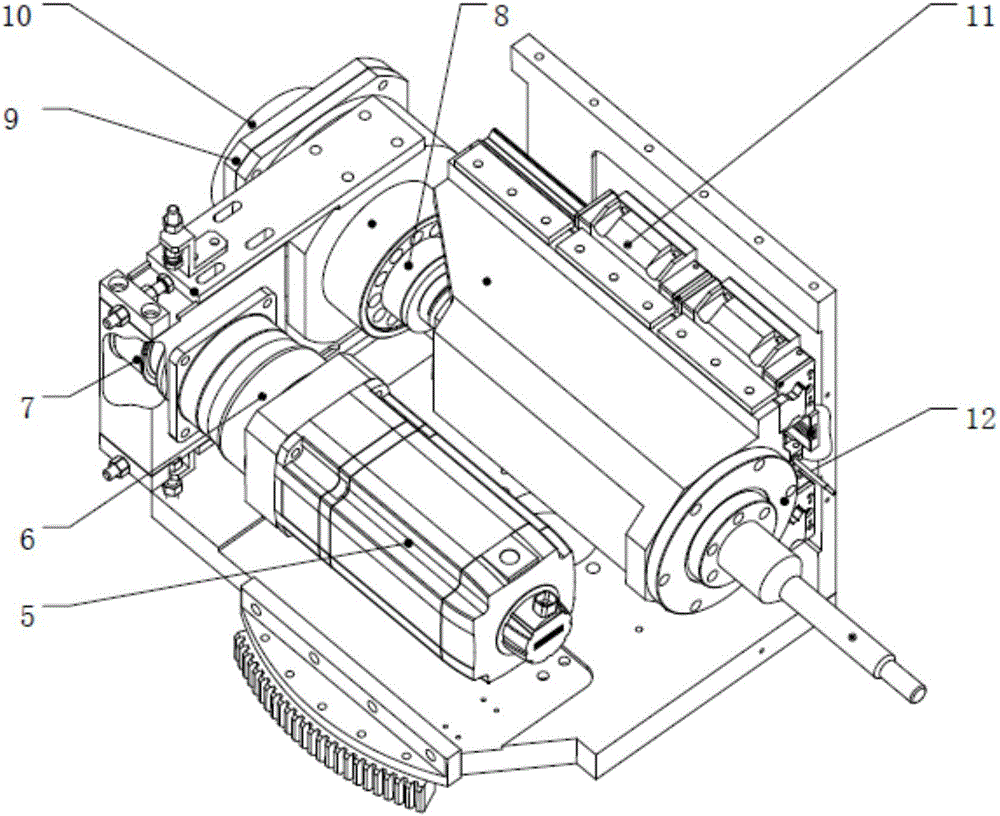

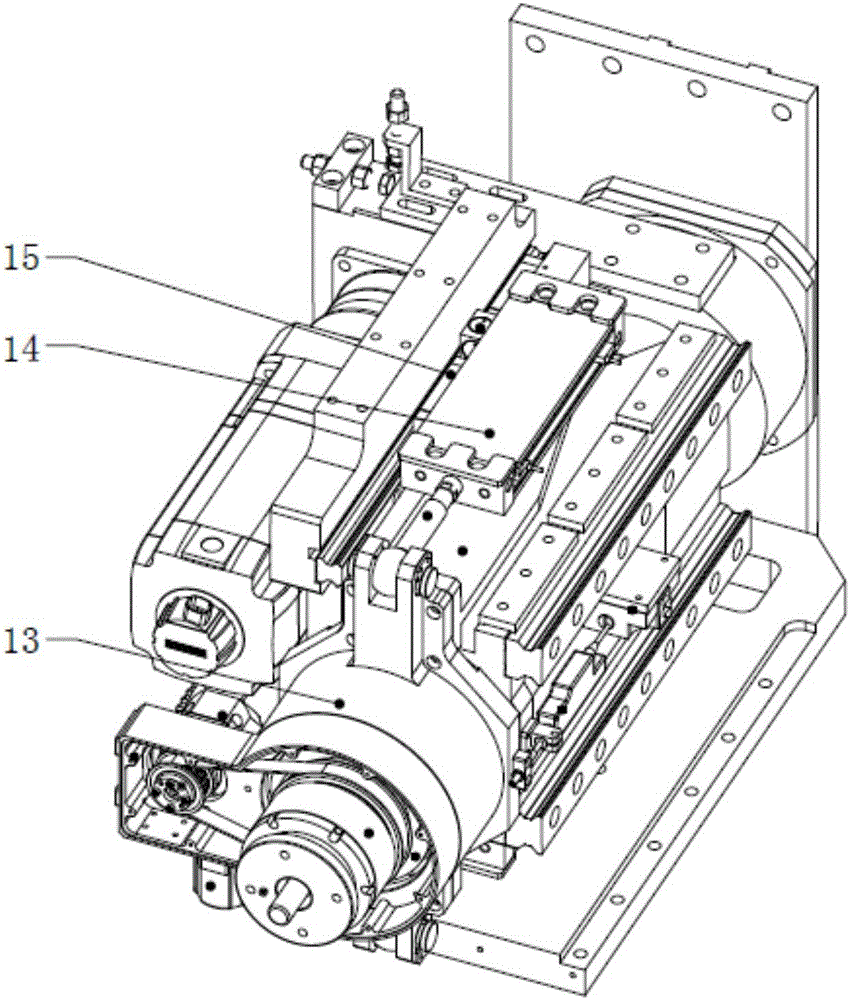

Reducer shell polishing equipment with robot

PendingCN109202615AImprove grinding efficiencyImprove grinding accuracyGrinding machinesGrinding feedersReduction driveReducer

Reducer shell polishing equipment with a robot comprises a piece to be polished, the six-axis robot and two feeding and discharging conveying platforms. The two feeding and discharging conveying platforms are provided with fixture assemblies. The fixture assemblies slide back and forth on the feeding and discharging conveying platforms, and a feeding and discharging station and a polishing stationare formed. The six-axis robot is arranged between the two feeding and discharging conveying platforms and is provided with three rotary floating polishing assemblies. The piece to be polished is fedto the fixture assemblies through the feeding and discharging station and slides to the polishing station through the fixture assemblies. The six-axis robot carries out polishing machining on the piece to be polished through the three rotary floating polishing assemblies, and the polished and machined piece to be polished slides to the feeding and discharging station through the fixture assemblies and is discharged. By means of the improvement of the structure, the reducer shell polishing equipment with the robot has the advantages of being simple and reasonable in structure, stable in quality, safe, reliable, capable of achieving full-automatic production, high in production efficiency and the like and is high in practicality.

Owner:GUANGDONG LXD ROBOTICS CO LTD

Sapphire crystal etching and polishing compound machine tool

ActiveCN106041706AImprove processing efficiencyThe machine is compactPolishing machinesLapping machinesCantileverMachine tool

The invention discloses a sapphire crystal etching and polishing compound machine tool. The machine tool comprises a stand, a vertical rotating arm, a main shaft system, a motor, a carrying disc and a negative pressure mechanism; a loading / unloading station, a rough polishing station, an etching station and a finish polishing station are peripherally arranged on the top surface of the stand at intervals; a cantilever is fixed at the upper part of the vertical rotating arm; the main shaft system can move up and down corresponding to the cantilever; the motor and the carrying disc are both connected to the main shaft system, and the motor is in transmission connection with the carrying disc to drive the carrying disc to rotate; a sucking hole is formed in the carrying disc; the negative pressure mechanism is communicated with the sucking hole; the vertical rotating arm is arranged on the axis in the peripheral direction, and can rotate around the axis; and the vertical rotating arm rotates to respectively shift the carrying disc to the loading / unloading station, the rough polishing station, the etching station and the finish polishing station for corresponding processing. The machine tool has the following advantages: the machine tool can perform the loading, etching, polishing and unloading compound processing for sapphire crystals, can quickly obtain ultrasmooth crystal surfaces without damage, and greatly improves the processing efficiency of the sapphire crystals.

Owner:HUAQIAO UNIVERSITY +1

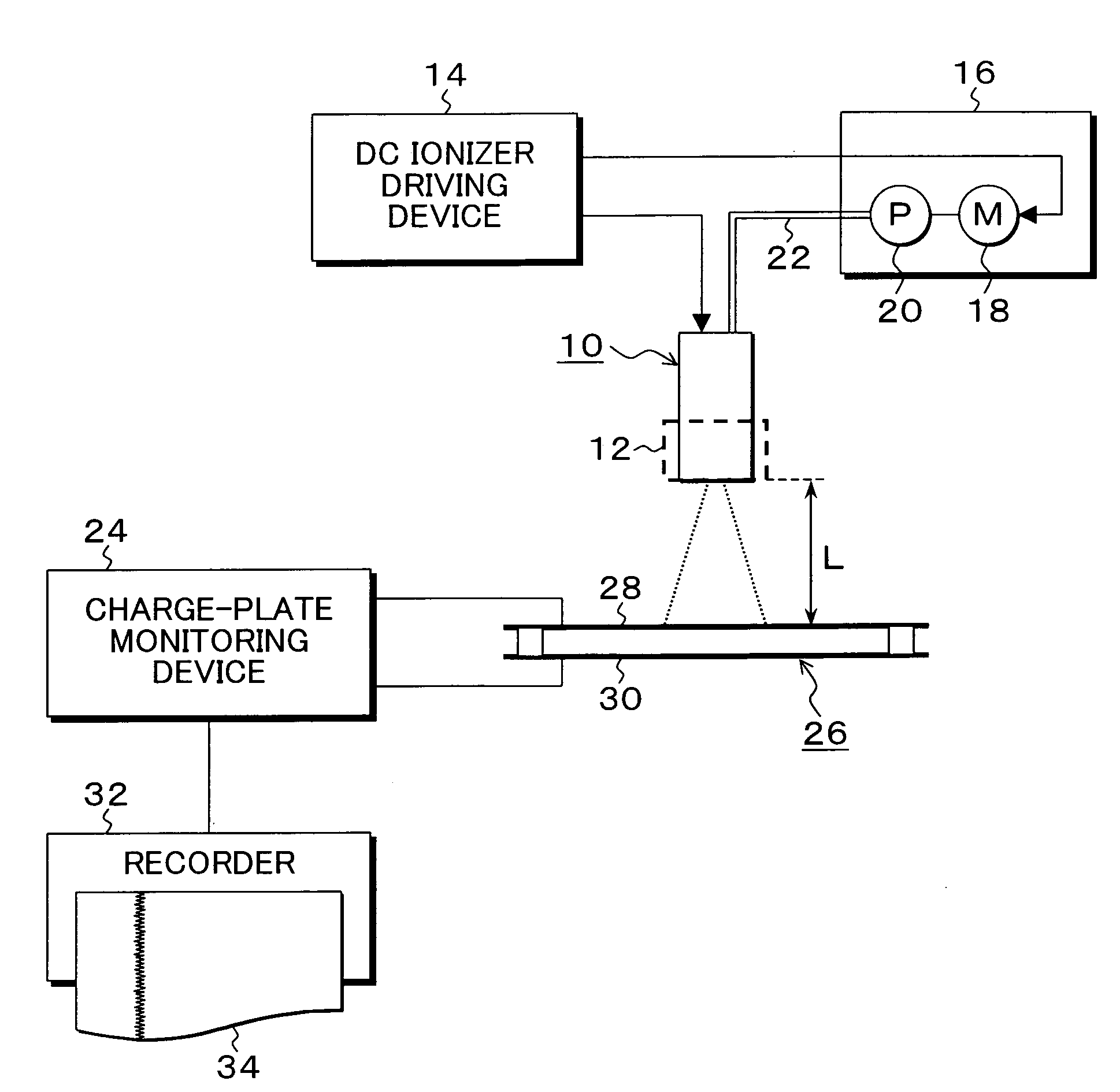

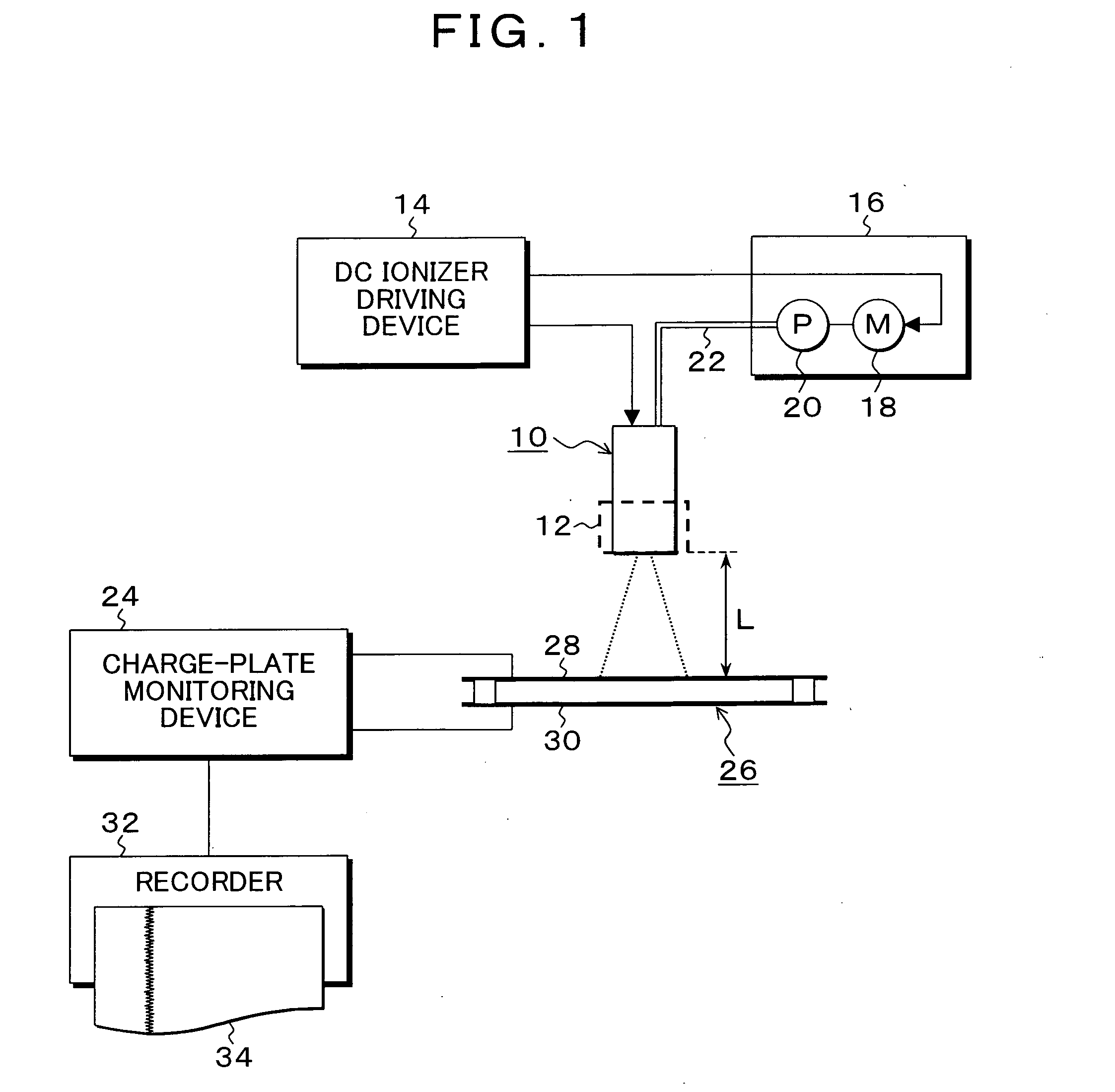

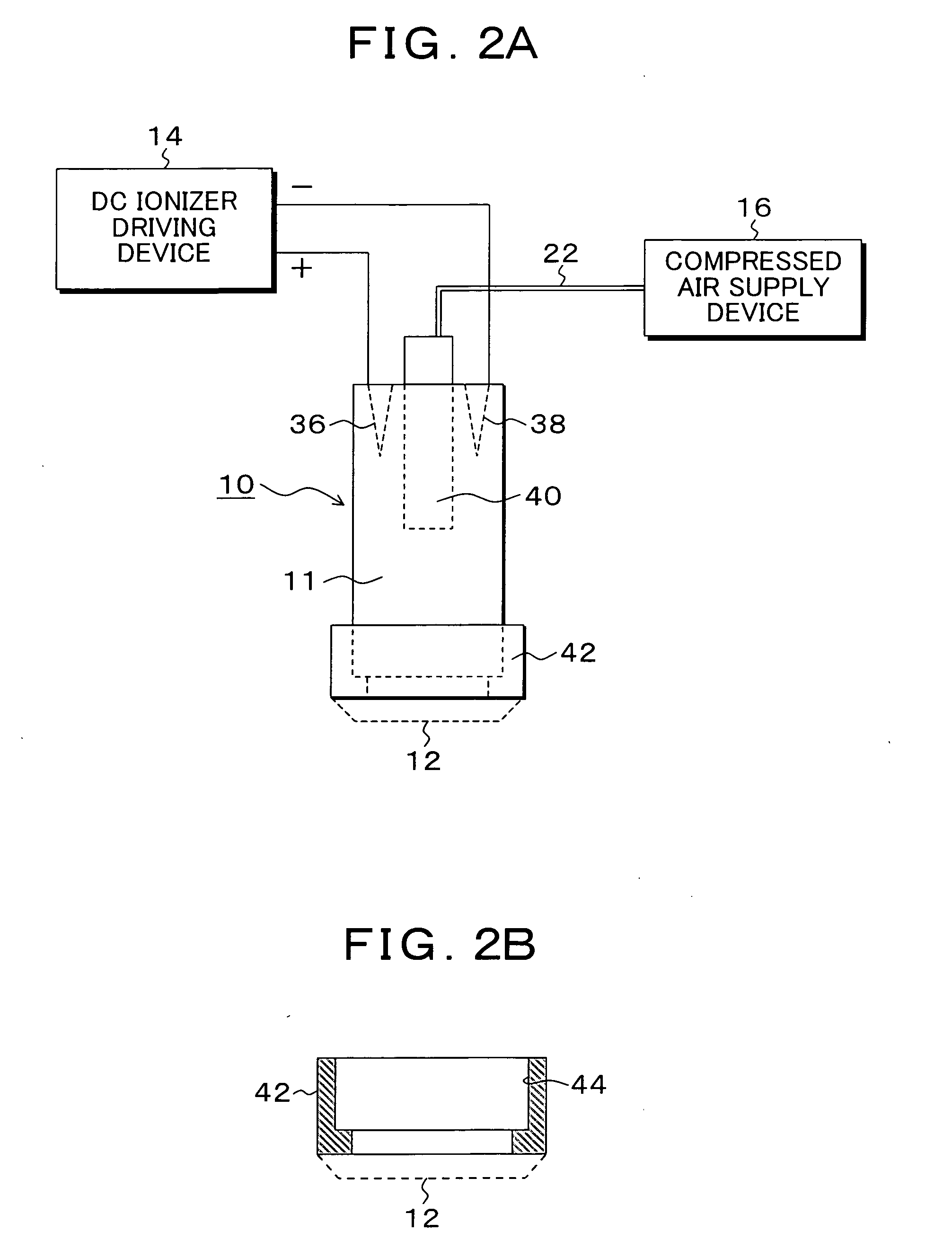

Spot-type ionizer evaluation method and spot-type ionizer

InactiveUS20080030918A1Difficult to processImprove productivityVacuum gauge using ionisation effectsElectrostatic separationEngineeringStatic electricity

A spot-type DC ionizer is placed above and apart from a measurement plate of a charge plate monitoring device. A grid using a metal net is attached to a nozzle opening. The pressure of compressed air is set at a predetermined value, and use distance between the measurement plate and the nozzle opening is set at a predetermined distance L. When ion balance and an ion balance variation are within threshold values, static elimination time is measured. If the static elimination time is longer than a threshold time, the air pressure is increased until the static elimination time is equal to or shorter than a threshold time. In this manner, the optimal air pressure for a particular use distance is determined.

Owner:TOSHIBA STORAGE DEVICE CORP

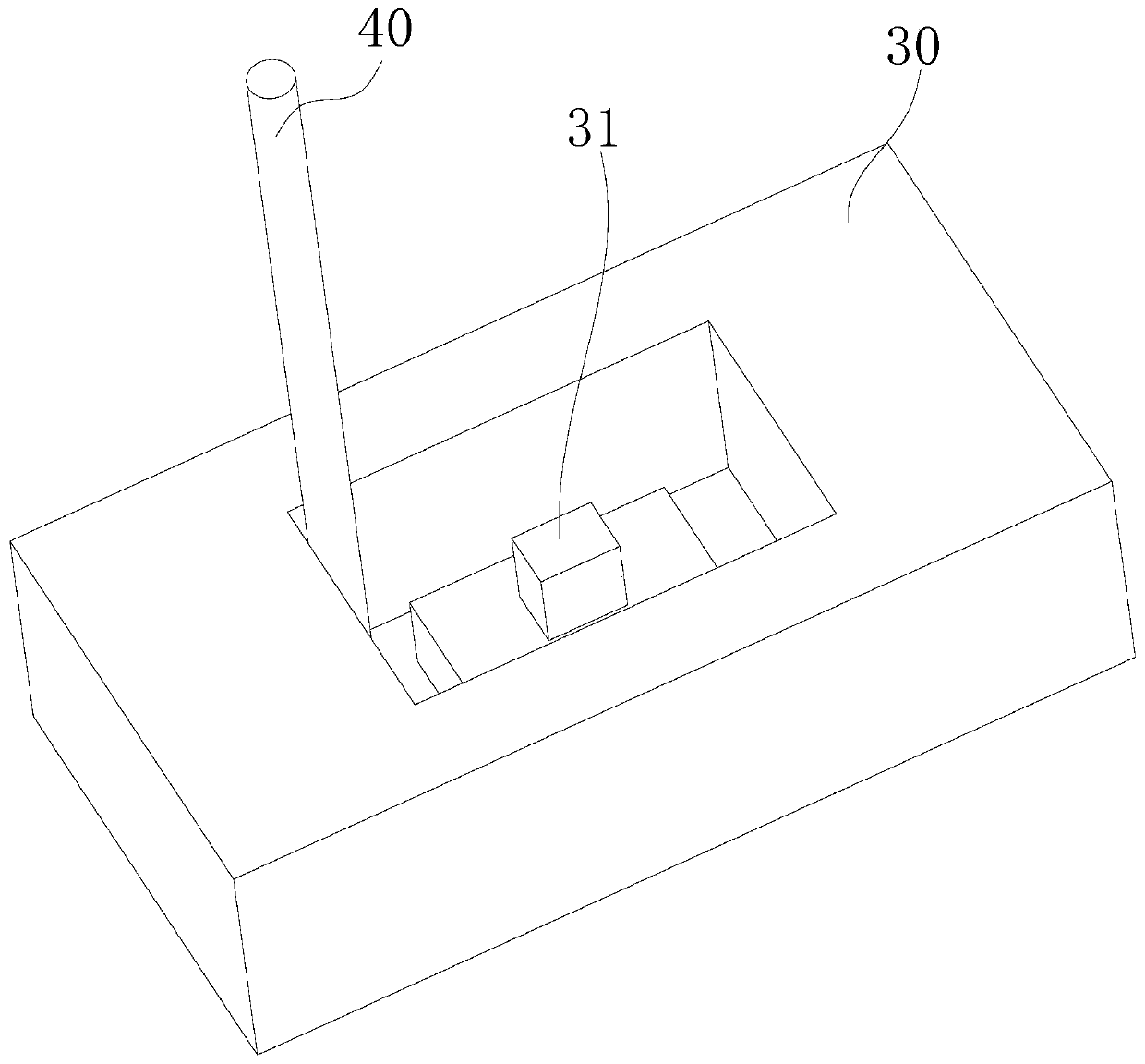

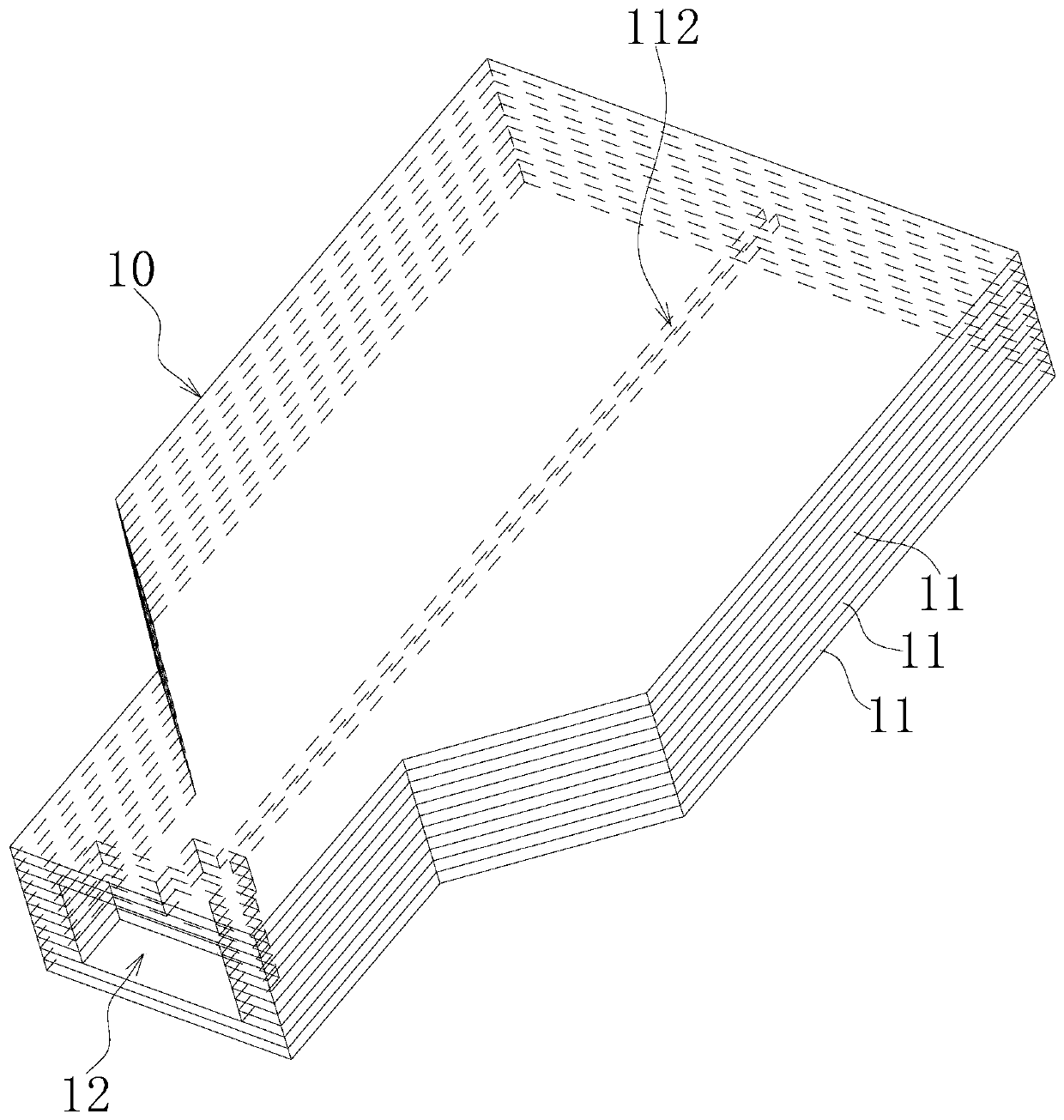

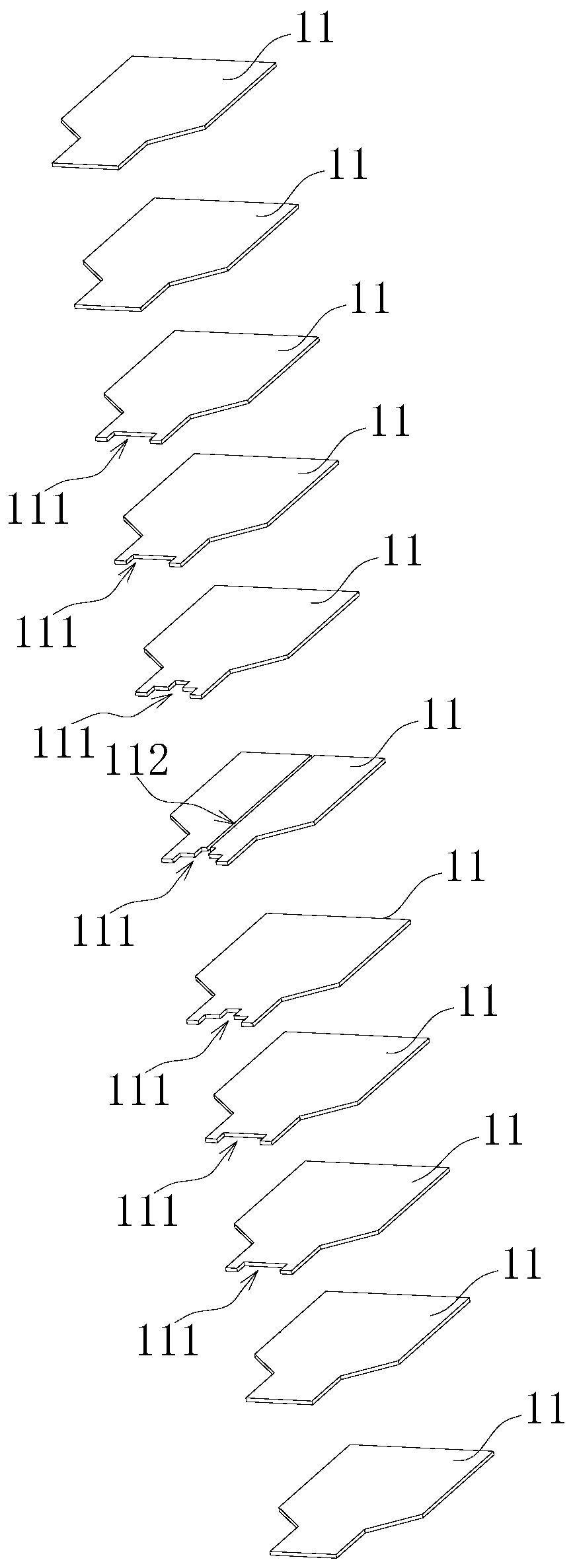

Micro electrochemical machining electrode, machining method thereof, and micro electrochemical machining device

PendingCN111185642AFacilitate timely updatesGuaranteed processing environmentMachining electrodesElectrical-based machining electrodesPhysicsEngineering

The invention belongs to the technical field of micro electrochemical machining, and particularly relates to a micro electrochemical machining electrode, a machining method thereof, and a micro electrochemical machining device. The micro electrochemical machining electrode comprises a plurality of electrode sheets, the electrode sheets are sequentially arranged in a laminated mode to form an electrode sheet assembly, two-dimensional microstructures used for machining a workpiece are arranged at one ends of a plurality of electrode sheets in the electrode sheet assembly, and the two-dimensionalmicrostructures are arranged in one-to-one correspondence and define a three-dimensional chamber which is adaptive to the shape of a three-dimensional microstructure on the workpiece; and circulationgrooves are formed in the surfaces of one or more electrode sheets in the electrode sheet assembly, the first ends of the circulation grooves extend out of the corresponding electrode sheets, and thesecond ends of the circulation grooves communicate with the three-dimensional chamber. According to the micro electrochemical machining electrode, the timely renewal of an electrolyte and the rapid discharge of electrolytic products in a machining area are accelerated, a good machining environment is ensured, the situation that a ''dead water area'' appears when the surface of a complex microstructure is machined is avoided, and the machining and using requirements of the large-depth three-dimensional microstructure can be met.

Owner:SHENZHEN UNIV

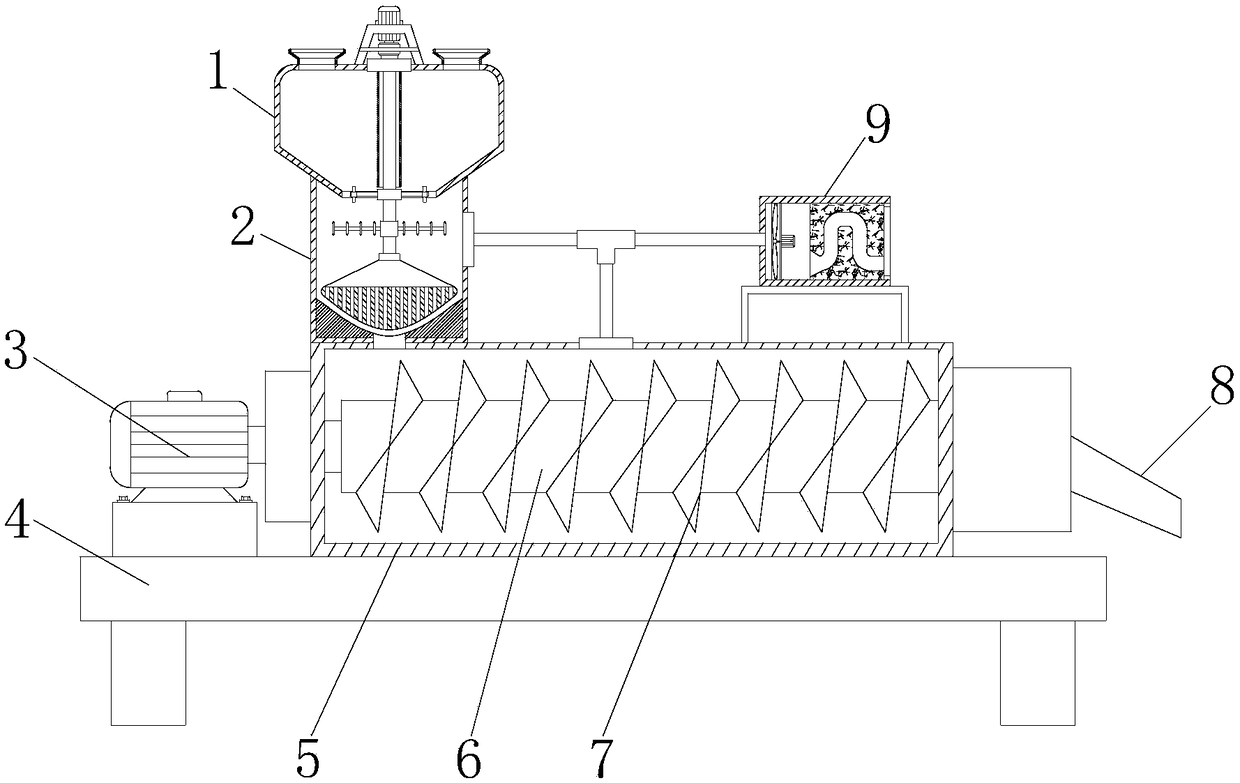

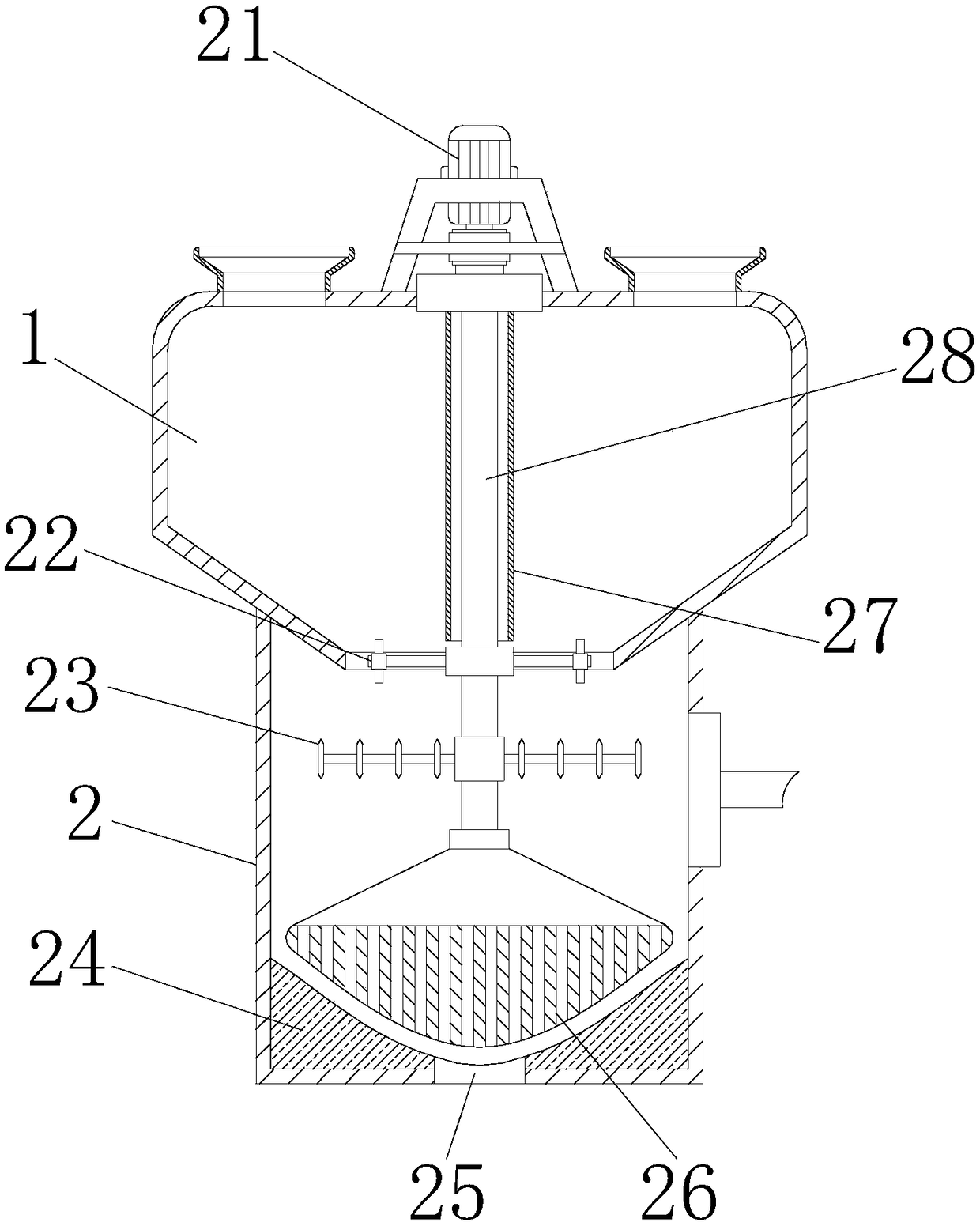

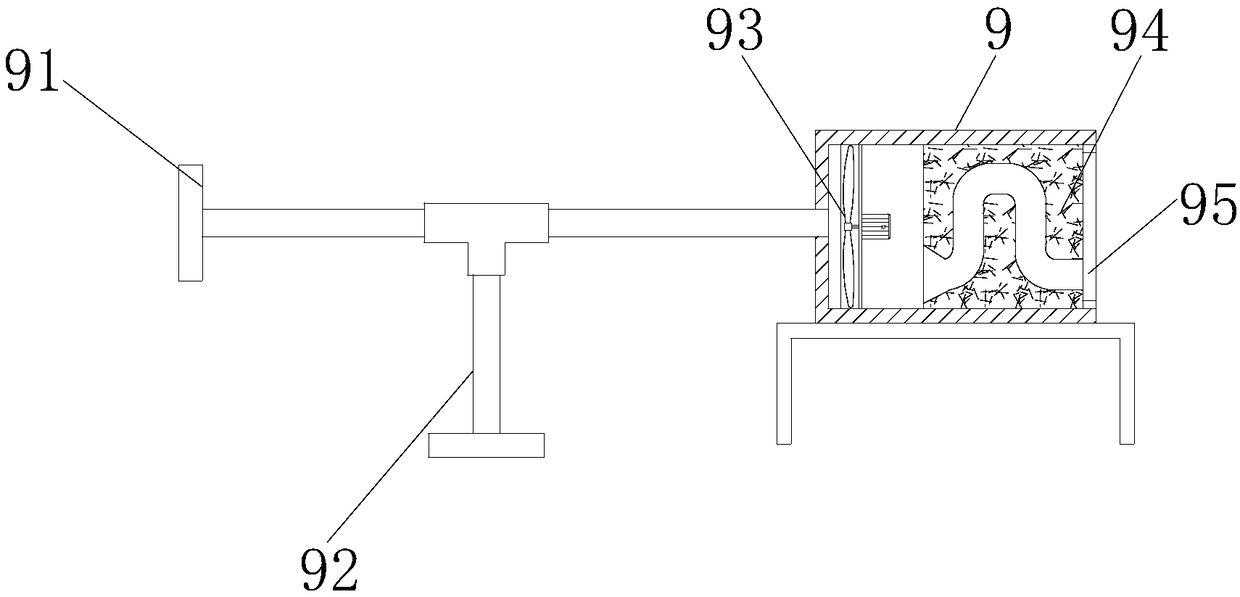

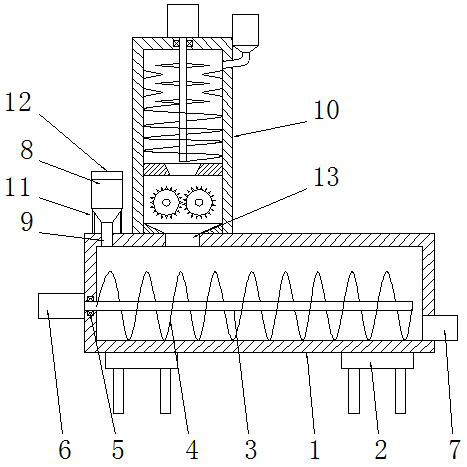

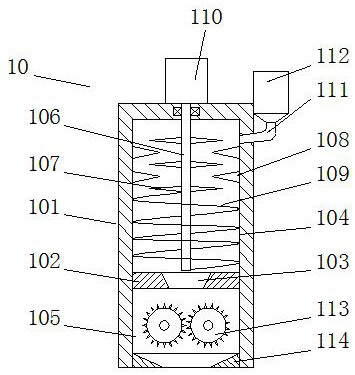

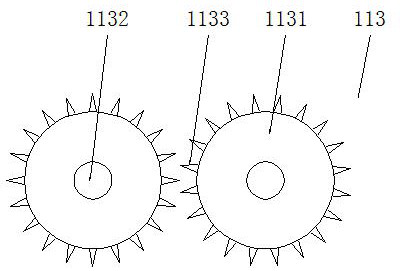

High-efficiency granulator for organic fertilizer production

InactiveCN108855540AImprove granulation efficiencyImprove the processing environmentGas treatmentDispersed particle separationSpiral bladeElectric machinery

The invention discloses a high-efficiency granulator for organic fertilizer production. The high-efficiency granulator for organic fertilizer production comprises an unloading hopper, a driving motor,a base, a conveying cylinder, a spiral rotating shaft, spiral blades and a discharge port; the conveying cylinder is mounted at the upper end of the base; the spiral rotating shaft is mounted in theconveying cylinder; the spiral blades are arranged on the surface of the spiral rotating shaft; and the driving motor is mounted at one end of the conveying cylinder opposite to the spiral rotating shaft. A crushing hopper is mounted on the unloading hopper; a stepper motor drives a connecting shaft to rotate; through an anti-blockage unloading rod, materials fall into the crushing hopper from theunloading hopper; the falling raw materials are contacted with a rotated crushing blade for primary crushing; the raw materials after primary crushing fall into a gap between a grinding base and a grinding disc; through rotation of the grinding disc, the materials are further crushed and refined; the crushed raw materials are discharged into the conveying cylinder from an unloading port; and through dual crushing, the raw materials are fined, and the granulation efficiency of organic fertilizers is improved.

Owner:福州立农环保科技有限公司

Pier head height control method for automatic drilling and riveting machine

The invention discloses a pier head height control method for an automatic drilling and riveting machine. According to the method, a lining extends out of an attached wall plate and then is braked and locked, a pressing-riveting ejector rod does linear feed motion, the relative distance between the front end face of a pressing-riveting head and the front end face of the lining is measured by a length gauge, a closed position loop feedback system is formed, errors caused by mechanical transmission and electric control are compensated for and corrected, the height of a pier head of a rivet is accurately controlled in closed-loop control, a force sensors monitors the pressing-riveting force in real time, the pressing-riveting force and the height of the pier head are mutually verified, and therefore the height of the pier head of the rivet can be accurately controlled in the pressing-riveting process of the drilling and riveting machine. After pressing-riveting is completed, the lining retracts, and then the pressing-riveting process is completed. According to the method, the height of the pier head can be accurately controlled in the pressing-riveting process of the drilling and riveting machine.

Owner:ZHEJIANG UNIV

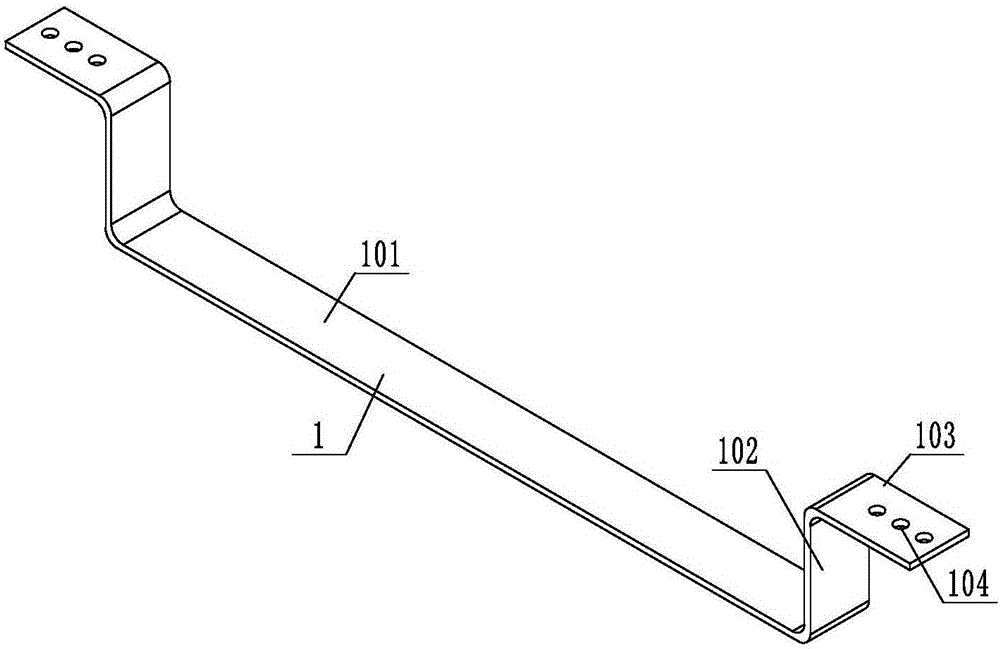

Radial fastening device of high-strength hot rolled strip steel coil

InactiveCN106697369AEasy to packEasy to transportBinding material applicationBundling machine detailsStrip steelEngineering

The invention relates to the field of hot rolled strip steel packaging, in particular to a radial fastening device of a high-strength hot rolled strip steel coil. The radial fastening device comprises a radial fastening strip. The radial fastening strip comprises a large horizontal plate, middle connection plates, small horizontal plates and bolt holes. The large horizontal plate, the middle connection plates and the small horizontal plates are formed by cold-bending hot rolled strip steel. The middle connection plates and the small horizontal plates are each symmetrically arranged on the two sides of the large horizontal plate in a bent mode. The multiple bolt holes are formed in the small horizontal plates. Through the design of the radial fastening strip, an auxiliary storage table and an automatic transport mechanism, the degree of automation is increased, efficiency is improved, excessive manual participation is avoided, labor is saved, and the problem of casualties in the operation process is avoided.

Owner:SHANDONG IRON & STEEL CO LTD

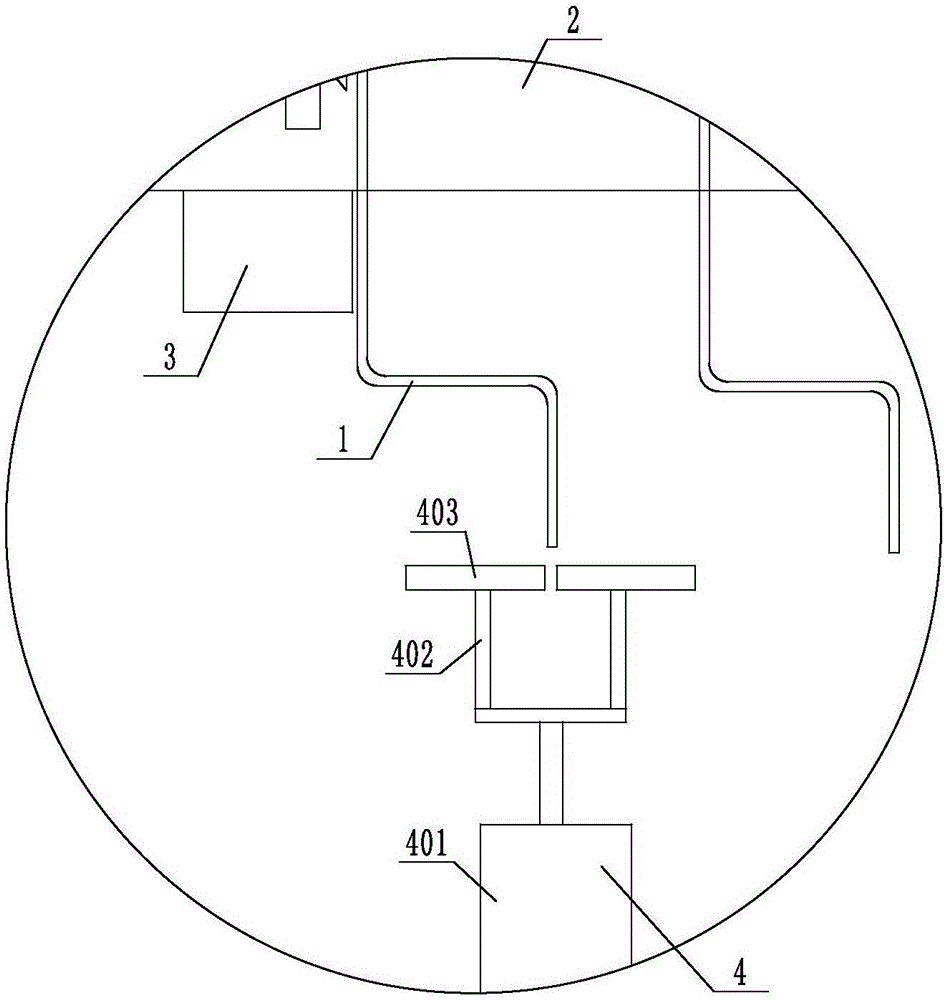

Crushing and stirring device for meat processing based on step-by-step crushing technology

InactiveCN111701673AEasy to processImprove processing efficiencyTransportation and packagingMixersElectric machineryEngineering

The invention discloses a crushing and stirring device for meat processing based on a step-by-step crushing technology. The device comprises a mixing cylinder, wherein brackets are symmetrically arranged on the left side and the right side of the bottom end of the mixing cylinder; one end of the mixing cylinder is connected to a discharging pipe in a penetrating manner, and a mixing motor is fixedly arranged on the other end of the mixing cylinder; a mixing shaft is fixedly arranged in the mixing cylinder; one end of the mixing shaft penetrates through the side wall of the mixing cylinder andis rotatably connected to the mixing motor; a first auger matched with the discharging pipe sleeves the mixing shaft; a step-by-step pulverizer and an additive hopper are arranged on the top end of the mixing cylinder; and the bottom end of the step-by-step pulverizer is connected to the mixing cylinder through a communicating hole in a penetrating manner. According to the device, the whole processing process is capable of crushing meat materials by utilizing the step-by-step pulverizer while the meat materials are mixed in the mixing cylinder by utilizing the first auger, and finally, the discharging operation is completed through the discharging pipe, so that the crushing processing and mixing processing are carried out on the same equipment, the meat processing procedure is simplified,and the meat processing efficiency is greatly improved.

Owner:张勇

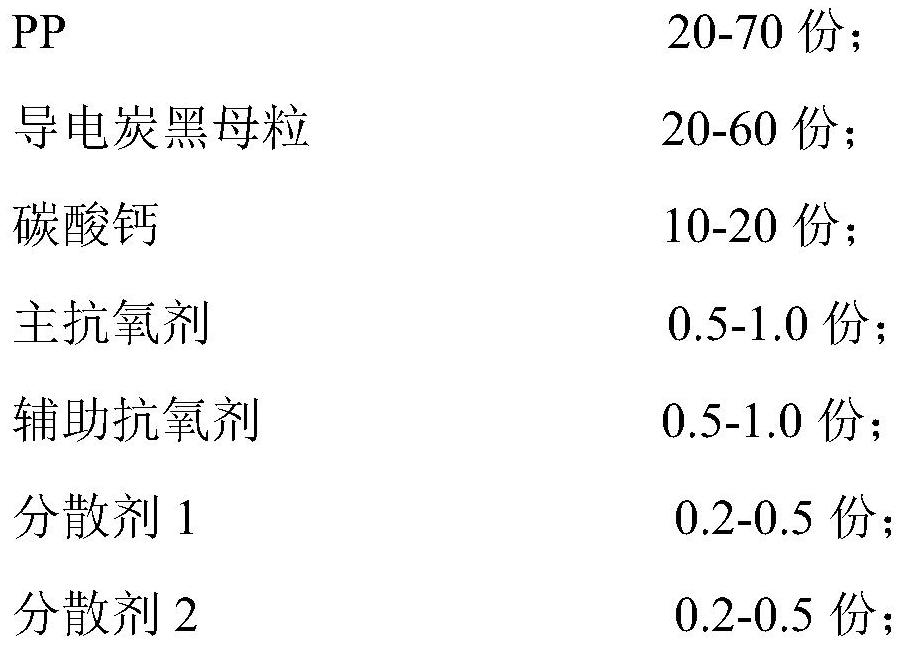

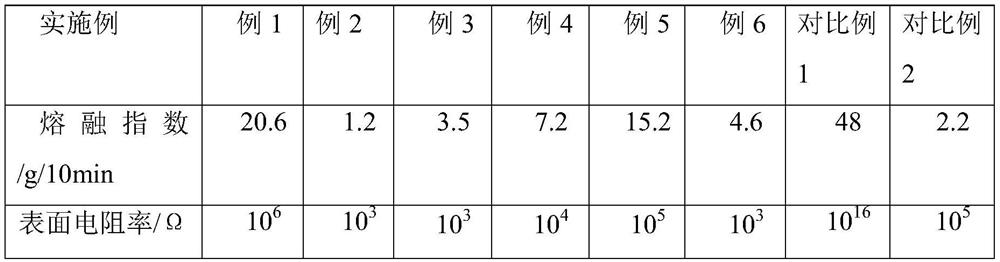

Conductive polypropylene material and preparation method thereof

InactiveCN111621088AEvenly dispersedImprove the processing environmentMasterbatchSurface resistivity

The invention discloses a conductive polypropylene material and a preparation method thereof. The conductive polypropylene material comprises the following components in parts by weight: 20-70 parts of PP; 20 to 60 parts of conductive carbon black master batch; 10 to 20 parts of calcium carbonate; 0.5 to 1.0 part of a main antioxidant; and 0.5 to 1.0 part of an auxiliary antioxidant; the preparation method comprises the following steps: mixing, extruding and granulating the raw materials. Wherein the conductive carbon black masterbatch is prepared from 40 parts of high-pressure low-density polyethylene; 25 parts of a lubricant; and 35 parts of conductive carbon black are internally mixed. The surface resistivity of the prepared conductive polypropylene material can be reduced to 103, and the conductivity of the conductive polypropylene material can be more uniform by using the conductive carbon black master batch.

Owner:HEFEI GENIUS NEW MATERIALS

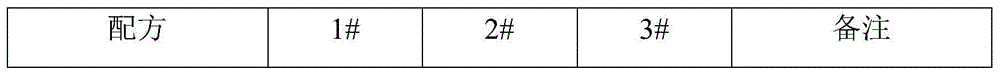

Antimony-based compounding flame retardant masterbatch for PVC and preparation method thereof

The present invention discloses an antimony-based compounding flame retardant masterbatch for PVC and a preparation method thereof, and belongs to the technical field of flame retardant materials. The masterbatch includes the following raw materials by weight: 25-40 parts of antimony trioxide, 13-25 parts of molybdenum trioxide, 8-13 parts of montmorillonite, 3-8 parts of organic tin, 3-6 parts of a coupling agent, and 20 to 35 parts of a carrier PVC resin. The flame retardant masterbatch is prepared from the steps of antimony trioxide surface modification, raw material mixing and granulation. The present invention employs antimony trioxide, molybdenum trioxide and montmorillonite and other environmentally friendly halogen-free flame retardants as a compounding flame retardant system, integrates the advantages of the system in synergistic flame retardant, and smoke suppression performance, improves the flame retardancy and smoke suppression of the compounding complex retardant masterbatch. Addition of the flame retardant masterbatch can greatly improve the limiting oxygen index of the PVC composite material and reduce the amount of smoke, and the flame retardant masterbatch has the characteristics of high flame retardancy, strong smoke suppression, no additive migration, easiness to use, and easy dispersion.

Owner:广西华锑科技有限公司

Rock wool cutting device

InactiveCN112092047AAvoid pollutionEasy to collectMetal working apparatusElectric machineryDust pollution

The invention discloses a rock wool cutting device which comprises a workbench and a dust collecting box, the interior of the workbench is rotationally connected with two winding drums distributed ina horizontal structure through bearings, a conveying belt is wound between the two winding drums, and conveying rollers distributed in an equidistant structure are rotationally connected between the inner walls of the two opposite sides of the workbench through bearings; and the conveying rollers are located in the conveying belt, a first motor is installed on one side of the outer wall of the front face of the workbench through bolts, and the end, located outside the workbench, of one winding drum is fixedly connected with an output shaft of the first motor through a coupler. By means of therock wool cutting device, dust generated during cutting can enter the dust collecting box, so that dust pollution is prevented, and the machining environment is improved; and meanwhile, during cutting, compression rollers can compress rock wool products on the conveying belt under the action of springs so that rock wool cannot tilt on the conveying belt during cutting, rock wool positioning is more stable, shutdown for rock wool tidying is avoided, and the rock wool processing efficiency can be improved.

Owner:河南富源岩棉有限公司

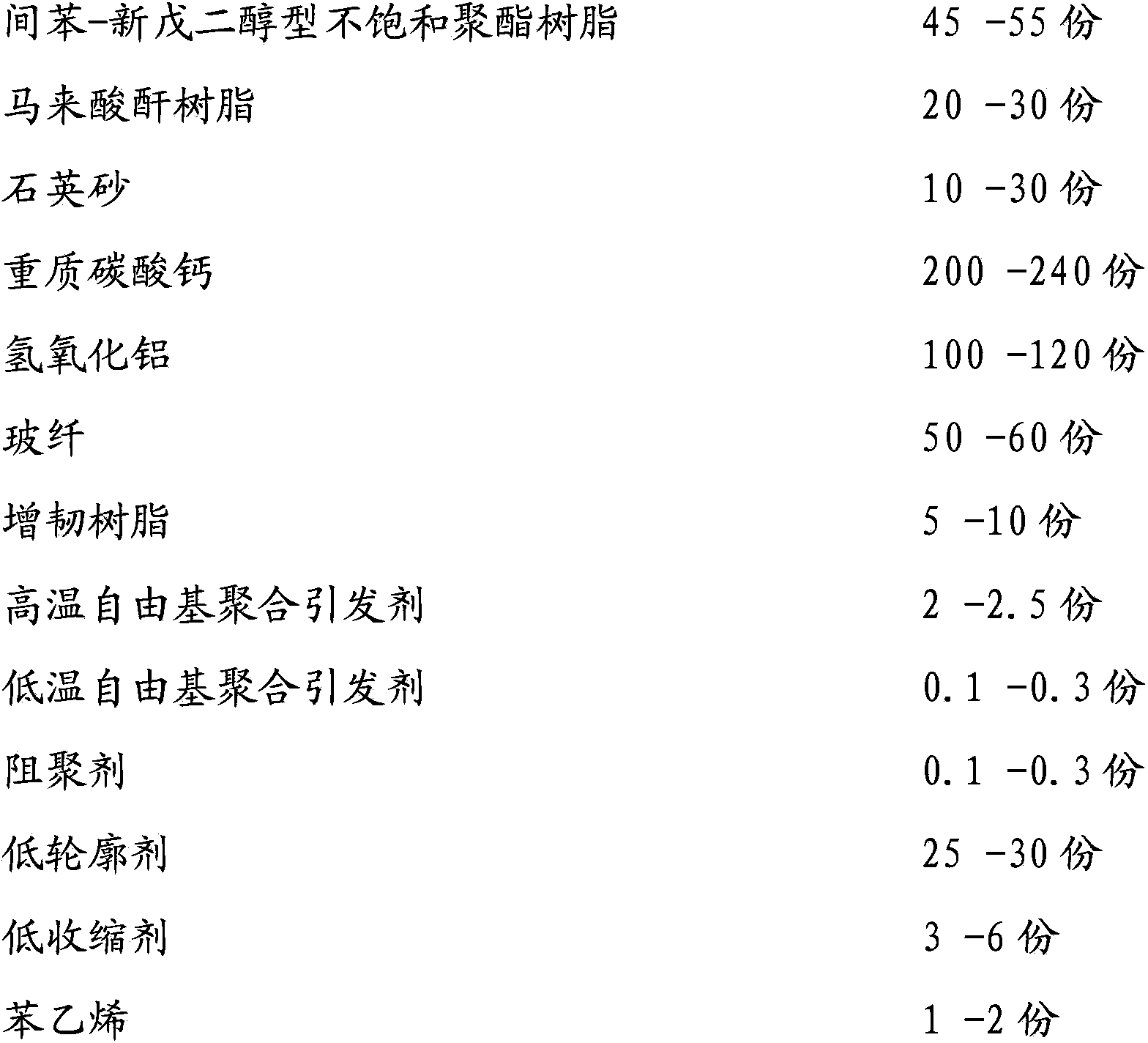

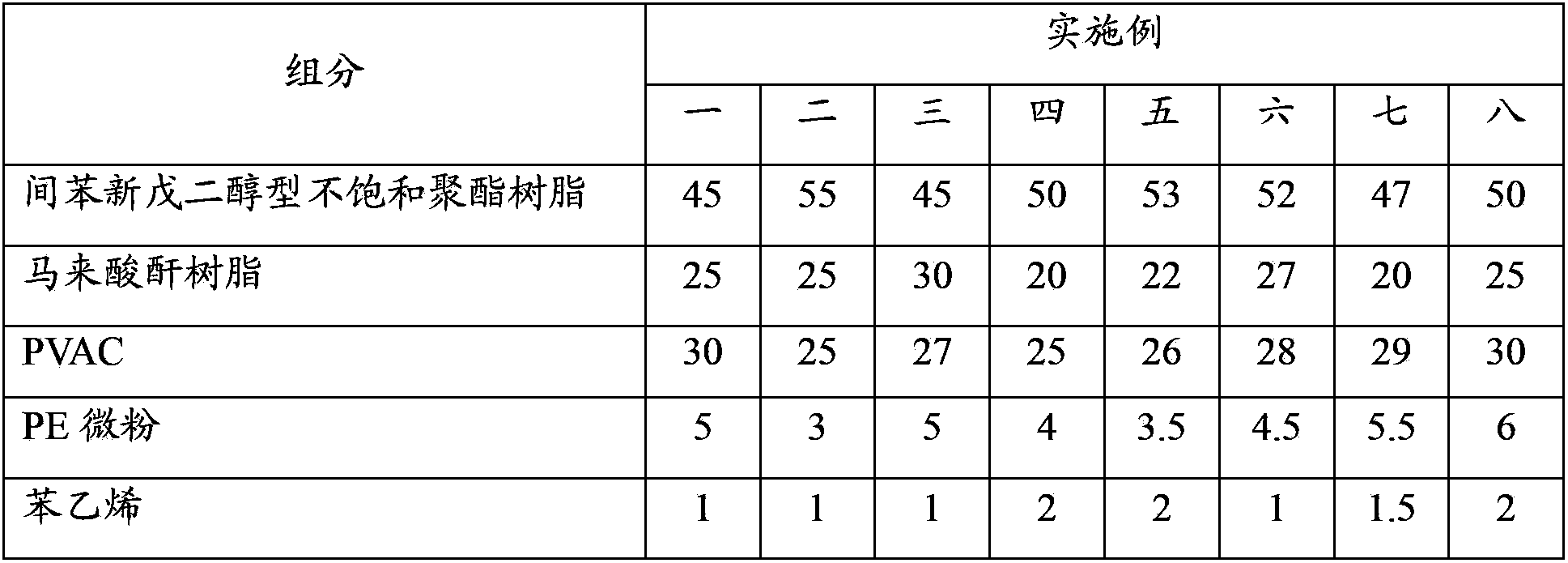

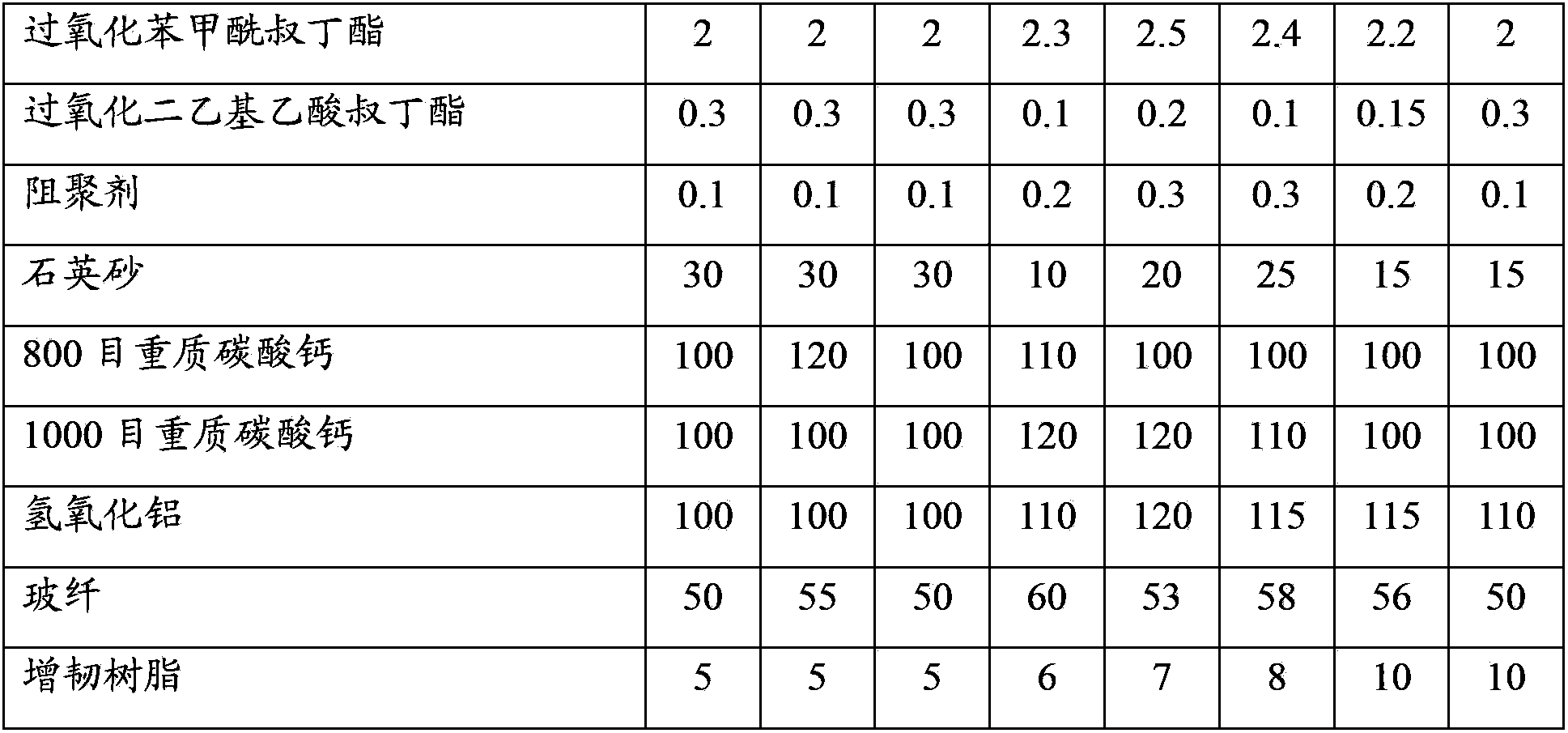

Unsaturated polyester molding compound

InactiveCN103570883AGood formabilityImprove the processing environmentPlastic/resin/waxes insulatorsCross-linkChemical structure

The present invention relates to an unsaturated polyester molding compound, particularly to an unsaturated polyester molding compound adopted as a double insulation material for an electric tool. The unsaturated polyester molding compound comprises, by weight, 45-55 parts of an isophthalic-neopentyl glycol type unsaturated polyester resin, 20-30 parts of a maleic anhydride resin, 10-30 parts of quartz sand, 200-240 parts of heavy calcium carbonate, 100-120 parts of aluminium hydroxide, 50-60 parts of glass fiber, 5-10 parts of a toughening resin, 2-2.5 parts of a high temperature free radical polymerization initiator, 0.1-0.3 part of a low temperature free radical polymerization initiator, 0.1-0.3 part of a polymerization inhibitor, 25-30 parts of a low profile agent, 3-6 parts of a low shrinkage agent, and 1-2 parts of styrene. The unsaturated polyester molding compound has the following advantages that: formability of the unsaturated resin is adopted, the functional filler and the special additive are matched, and the glass fiber is added to reinforce, such that the novel special functionality composite material relying on excellent forming ability of the unsaturated resin is achieved; and the chemical structure of the product is a cross-linking network structure, and the heat distortion temperature of the product is 273 DEG C and is about 25 DEG C higher than the heat distortion temperature of the conventional material, such that the product can achieve excellent thermal strength property when being used for high power electric mallets, electric breakers and the like, wherein the previous material does not have the excellent thermal strength property.

Owner:SHANGHAI ZAOJIE COMPOSITE TECH CO LTD

Smooth color master batch used for PET and preparation method thereof

The invention discloses smooth color master batch used for PET and a preparation method thereof. The smooth color master batch comprises following components by weight: 30-70% of a carrier, 4-10% of an anti-blocking agent, 10-30% of a smoothing agent, 10-20% of pigments, 1-5% of a dispersant, 0.1-1% of a coupling agent and 0.1-1% of an antioxidant. Beneficial effects of the color master batch and the preparation method are that: compared with the prior art, the color master batch is applied in PET film or film products, and the color master batch has characteristics of good anti-blocking smoothing effects, even coloring, good dispersibility, high concentration, simple operation, using convenience, capability of improving performances and the processing environment of products, and the like.

Owner:QINGDAO XINZHAN PLASTIC

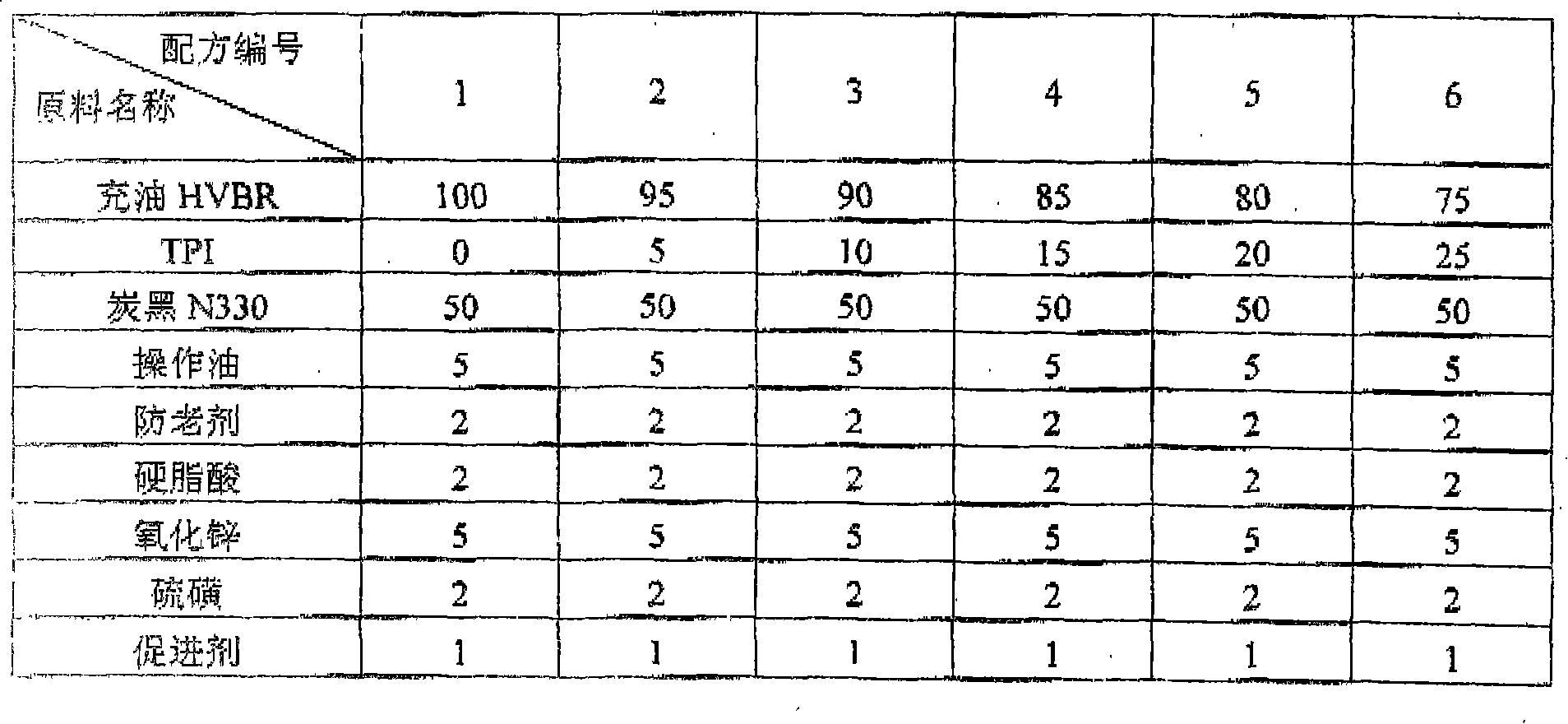

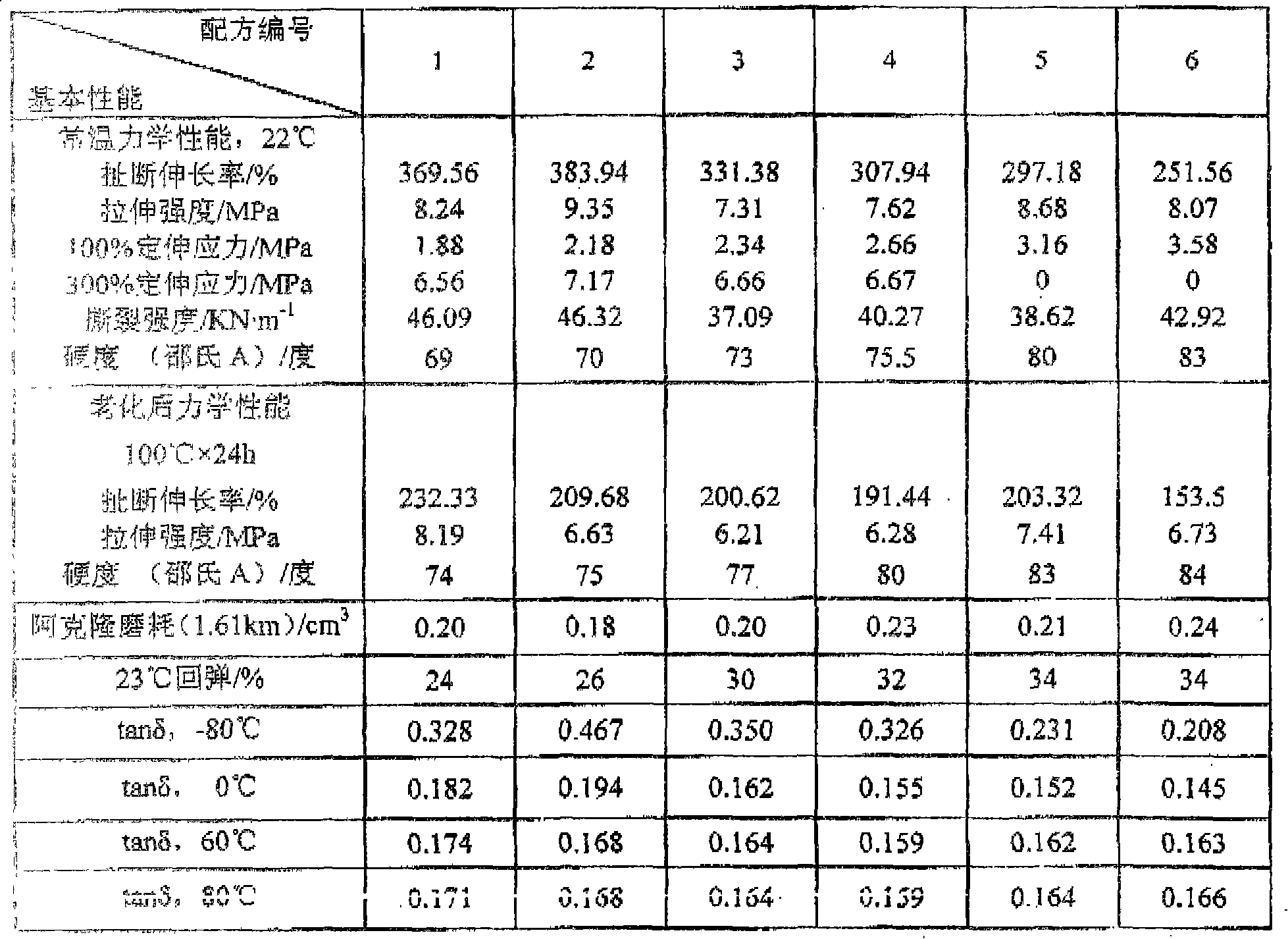

High trans-1,4-polyisoprene modified by oil-extended high vinyl polybutadiene rubber by molybdenum catalyst system

The invention provides a blend of oil-extended high vinyl polybutadiene rubber (HVBR) by molybdenum catalyst system and high trans-1,4-polyisoprene (TPI), which is prepared by blending and sulfurization through blending or banburying processing technology. For example, when the blending ratio of the TPI to the HVBR is 25 to 75 mass portions, the blend can reduce rolling resistance by 20 percent than a sizing material with the blending ratio of 0 to 100; and when the blending ratio of the TPI to the HVBR is 5 to 95 mass portions, the blend can reduce the rolling resistance and maintain good wet traction.

Owner:周兆敏

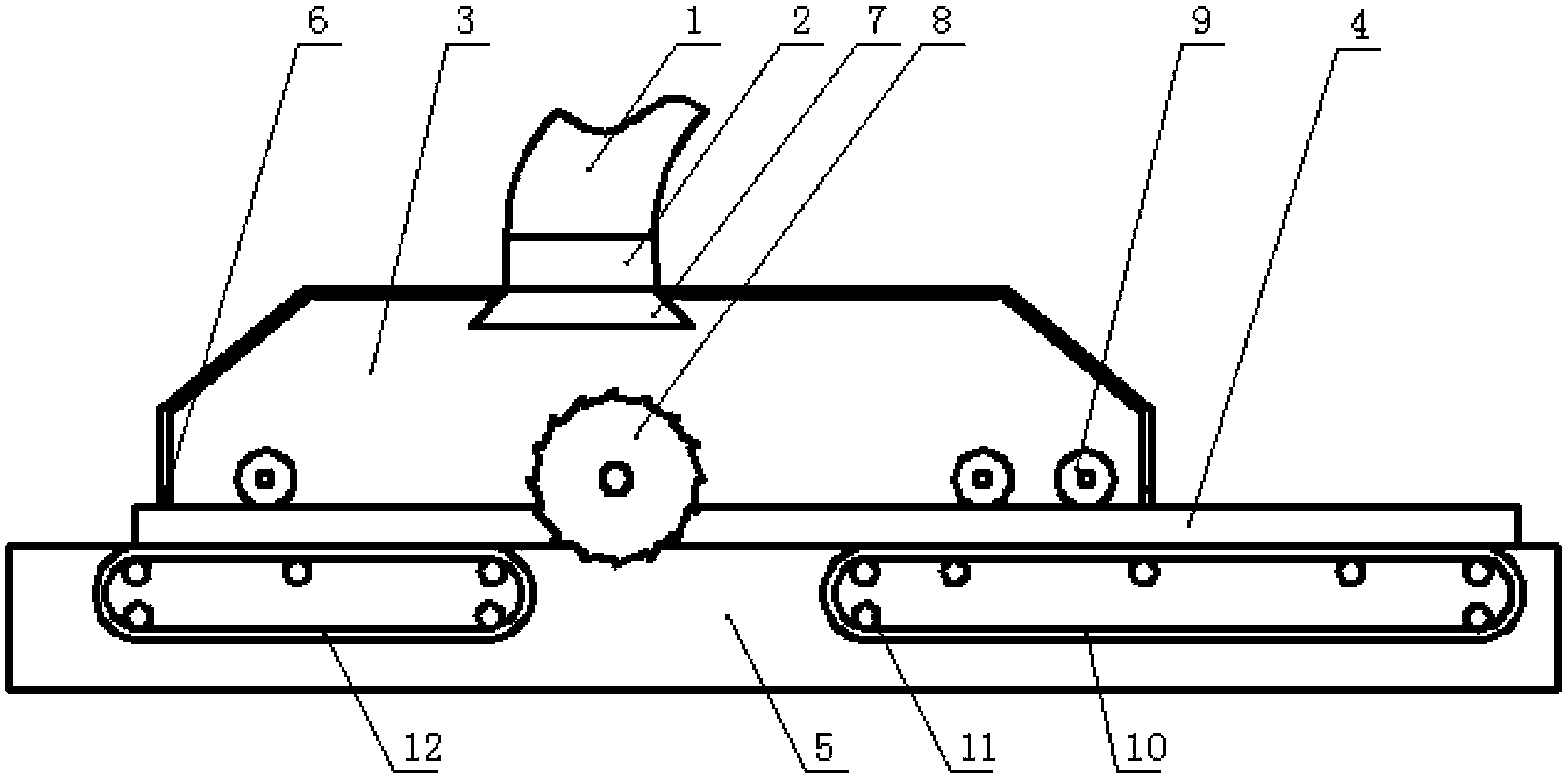

Solid wood cutting saw

InactiveCN104249390ALarge transmission forceStable transmission speedFeeding devicesCircular sawsSolid woodDrive motor

The invention relates to a solid wood cutting saw. The solid wood cutting saw comprises a machine base, a machine cover, conveying devices, a cutting saw body, a plurality of pressing rollers and a dust-sucking device, wherein the machine cover is fixedly arranged at the upper end of the middle part of the machine base; a workpiece inlet / outlet is formed between the lower part of each of the two transverse sides of the machine cover and the machine base; the conveying devices are transversely and coaxially arranged on the upper part in the machine base; the cutting saw body connected with a driving motor is arranged on the machine cover and the machine cover between the conveying devices; the pressing rollers are arranged in the machine cover on the two transverse sides of the cutting saw body at intervals; the dust-sucking device is arranged at the top of the machine cover above a cutting device. The solid wood cutting saw is simple in structure, scientific in design, uniform in pressure, high in processing efficiency and high in processing precision, the flatness of a product is improved, the labor intensity of workers is effectively reduced, and the production efficiency is improved.

Owner:天津福通木业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com