System for making shoes automatically from polyurethane

A production system and automatic production technology, which is applied to footwear, other household appliances, household appliances, etc., can solve the problems of high labor intensity of operators, unhealthy operators, long standby time of pouring machines, etc., to improve product quality, Guarantee your health and improve the effect of production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

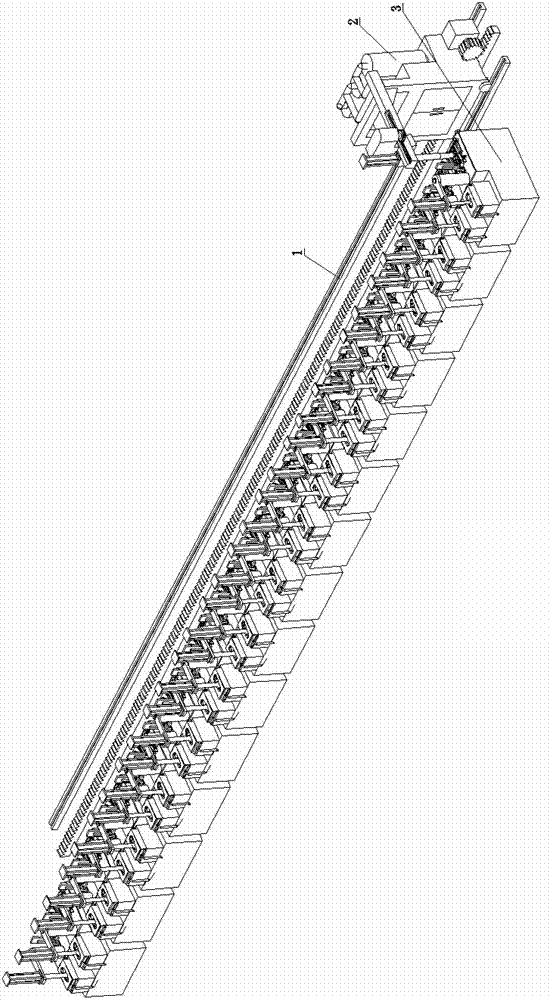

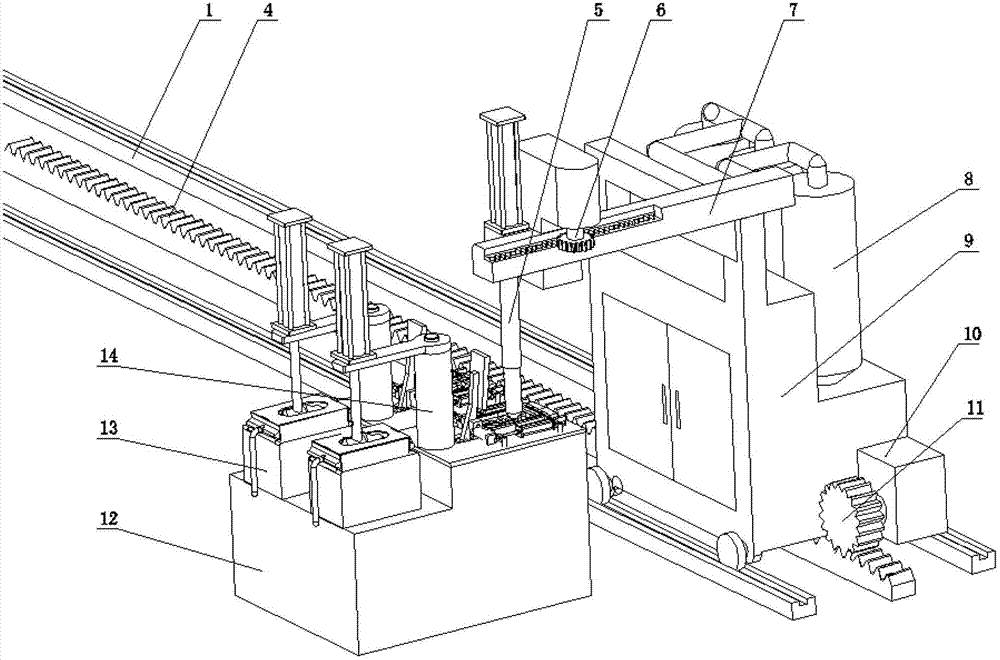

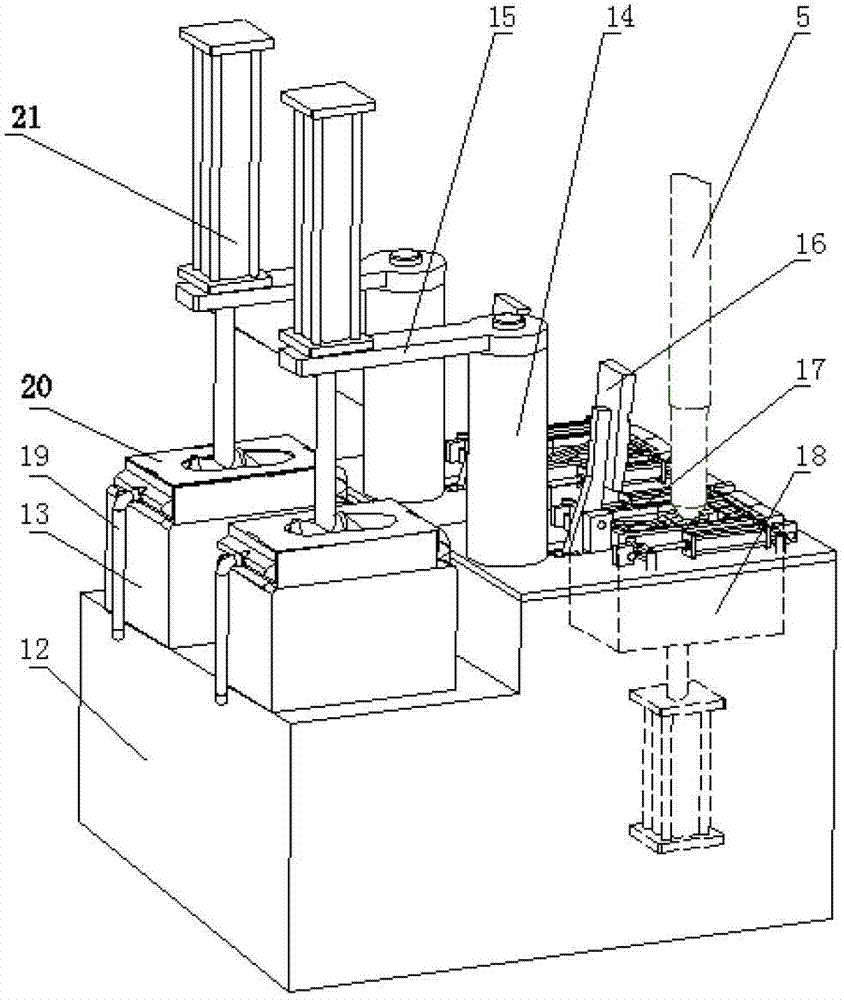

[0022] A polyurethane automatic shoe-making production system, including a pouring machine 2, a parallel guide rail 1 and an automatic shoe-making machine 3. The pouring machine is coaxially guided and moved and installed on two parallel guide rails. A plurality of parallel automatic shoe-making machines are arranged at a position parallel to the running direction of the machine. Among them, the pouring machine includes a pouring base 9, a pouring arm 7, an injection head 5, a storage tank 8, and an adjustment structure 6. On the pouring base, A cantilever pouring arm is installed, and the cantilever end of the pouring arm is vertically equipped with an injection head, which communicates with a storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com