Crushing and stirring device for meat processing based on step-by-step crushing technology

A meat processing and stirring device technology, which is applied in the direction of meat processing equipment, processed meat, applications, etc., can solve the problems of unfavorable meat processing procedures, increased production procedures, and lack of equipment, etc., to simplify the meat processing procedures and improve Processing quality, effect of improving mixing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

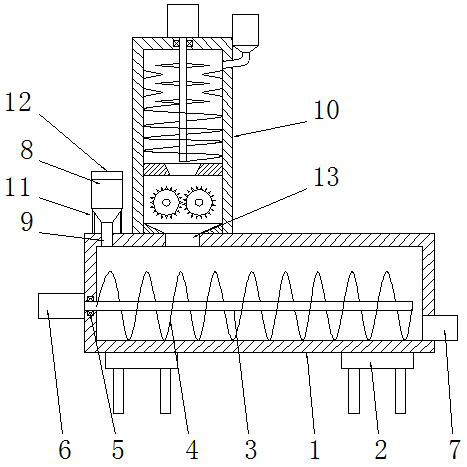

[0028] See figure 1 , a crushing and stirring device for meat processing based on step-by-step crushing technology, comprising a mixing cylinder 1, the mixing cylinder 1 is a cylindrical structure, the left and right sides of the bottom of the mixing cylinder 1 are symmetrically provided with brackets 2, and the mixing One end of the barrel 1 is connected to the discharge pipe 7, the other end of the mixing barrel 1 is fixedly installed with a mixing motor 6, and a mixing shaft 3 is arranged inside the mixing barrel 1, and one end of the mixing shaft 3 runs through the side wall of the mixing barrel 1 And rotatably connected on the mixing motor 6, the mixing shaft 3 is rotatably connected on the mixing cylinder 1 through the bearing 5, the mixing shaft 3 is sleeved with the first auger 4 matched with the discharge pipe 7, the mixing cylinder 1 The top is provided with a step pulverizer 10 and an additive hopper 8, the additive hopper 8 is arranged on the left side of the step ...

Embodiment 2

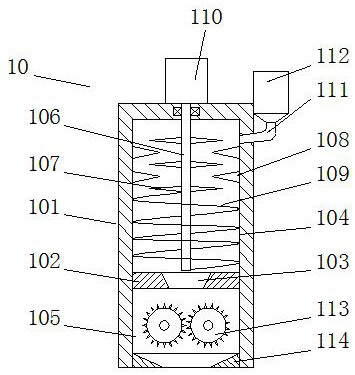

[0031] See figure 2 , and the difference from embodiment 1 is that: the step-by-step pulverizer 10 includes a pulverizing cylinder 101, the pulverizing cylinder 101 is a cylindrical structure with an open bottom, and the pulverizing cylinder 101 is fixedly installed on the top of the mixing cylinder 1, and pulverizing The cylinder 101 connects through the communication hole 13, and the top of the grinding cylinder 101 is fixedly connected to the grinding cylinder 101. The bottom of the inner chamber of the grinding cylinder 101 is provided with a partition 102, and the partition 102 is provided with a feeding hole 103. The partition 102 crushes the The inner cavity of the barrel 101 is divided into a first crushing chamber 104 and a second crushing chamber 105, the first crushing chamber 104 is connected above the second crushing chamber 105 through the feeding hole 103, and the first crushing chamber 104 is provided with Pulverizing shaft 106, the axis of the pulverizing sha...

Embodiment 3

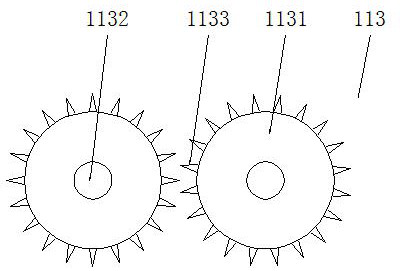

[0033] See image 3 The difference from Embodiment 2 is that the roller knife crushing mechanism 113 includes two crushing rollers 1131, and the two crushing rollers 1131 are symmetrically arranged on the left and right sides of the second crushing chamber 105, and the crushing rollers 1131 pass through the roller shaft 1132 is rotatably connected to the side wall of the second crushing chamber 105, and the outer circular surface of the crushing roller 1131 is uniformly provided with several roller knives 1133, and the roller knives 1133 are triangular cutter structures, and one end of the roller shaft 1132 runs through the first The side wall of the second crushing chamber 105 is connected to the external motor (not shown in the figure) in rotation, and the external motor cooperates with the roller shaft 1132 to drive the crushing roller 1131 to rotate at a high speed, and then use the crushing roller 1131 to drive the roller knife 1133 to rotate at a high speed, That is, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com