Segmented constant-temperature modular electrothermal tea leaf fixation machine

A technology of constant temperature module and degreening machine, which is applied in tea processing before extraction, etc., can solve the problems of large temperature fluctuation range, inaccurate control mode, poor anti-interference ability, etc., achieve small temperature change range, improve processing environment conditions, heat energy The effect of less loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

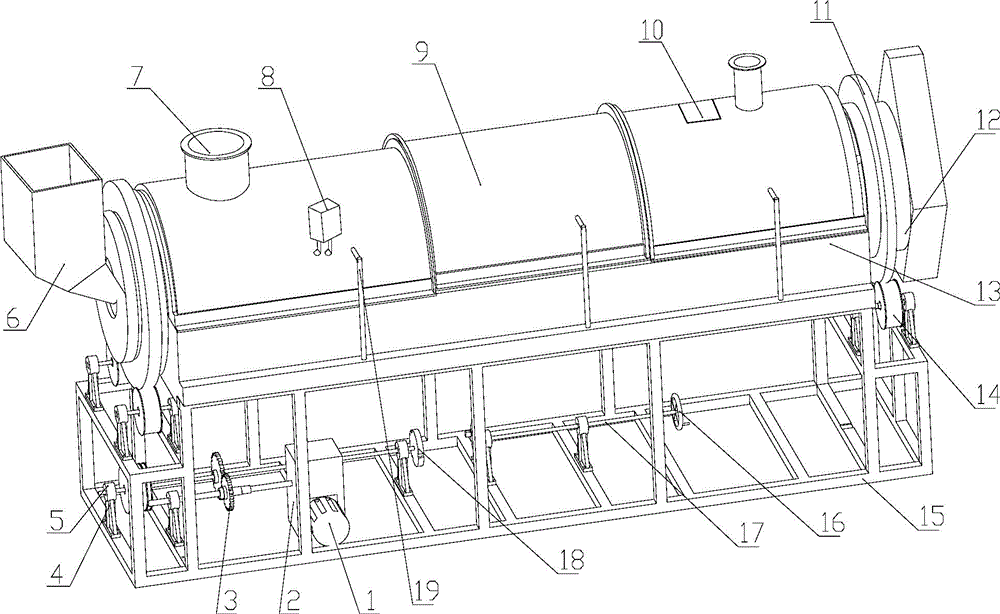

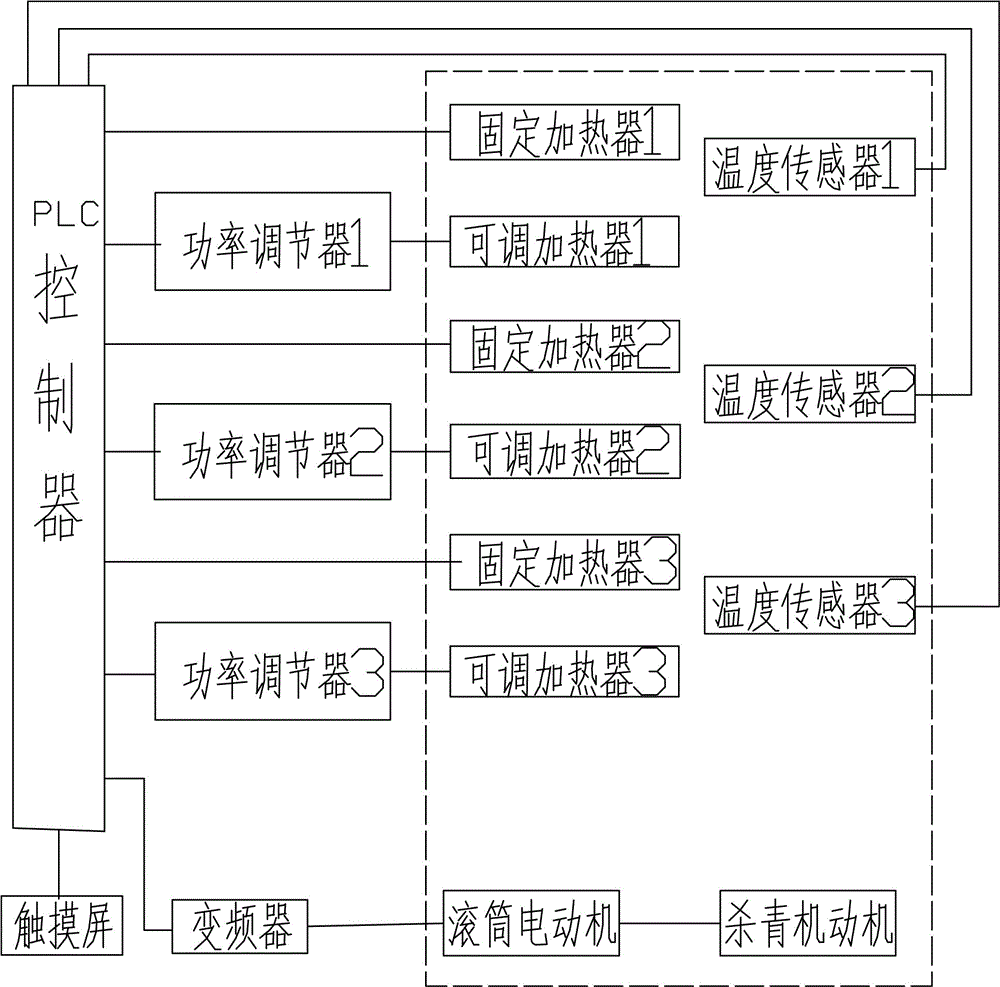

[0024] see figure 1 , segmental constant temperature modularized electric heating tea greening machine, which includes a frame 15, a motor 1 is installed on the frame 15, a drum base 13 is installed on the frame 15, a drum 11 is installed on the drum base 13, and the output shaft of the motor 1 A reduction box 2 is installed on the top, and a gear 3 is installed on the output shaft of the reduction box 2. The gear 3 drives the pulley 5 installed on the support base 4, and the pulley 5 drives the friction wheel meshed with the drum 11 to rotate the drum 11. The left end of the drum 11 is provided with an inlet funnel 6, the top of the drum 11 is provided with a vent hole 7 and a box cover 9, the box cover 9 is provided with a temperature control system 8, and the outer surface of the drum 11 is equipped with an electric heating plate 10, an electric heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com