Patents

Literature

51results about How to "Stable transmission speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

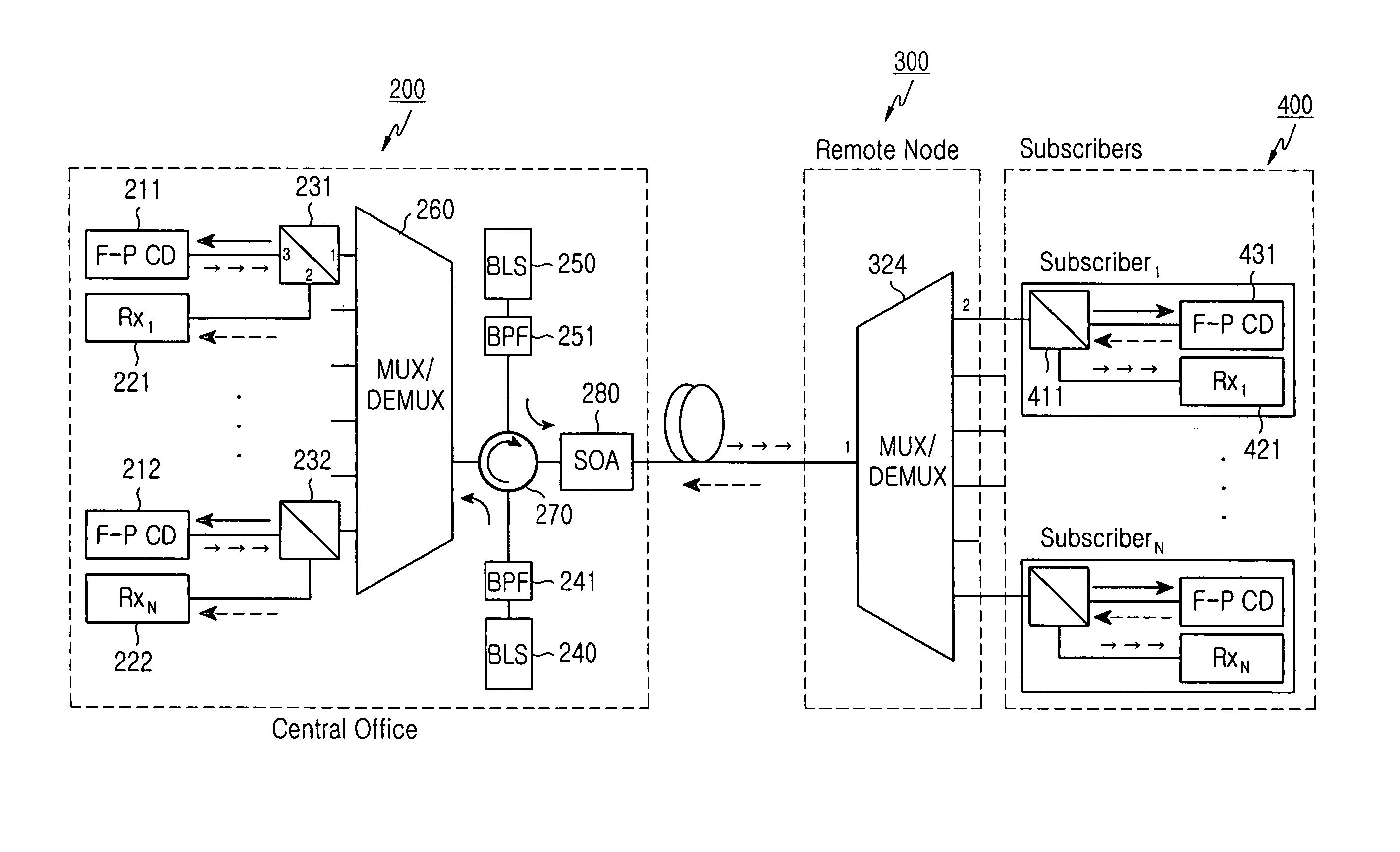

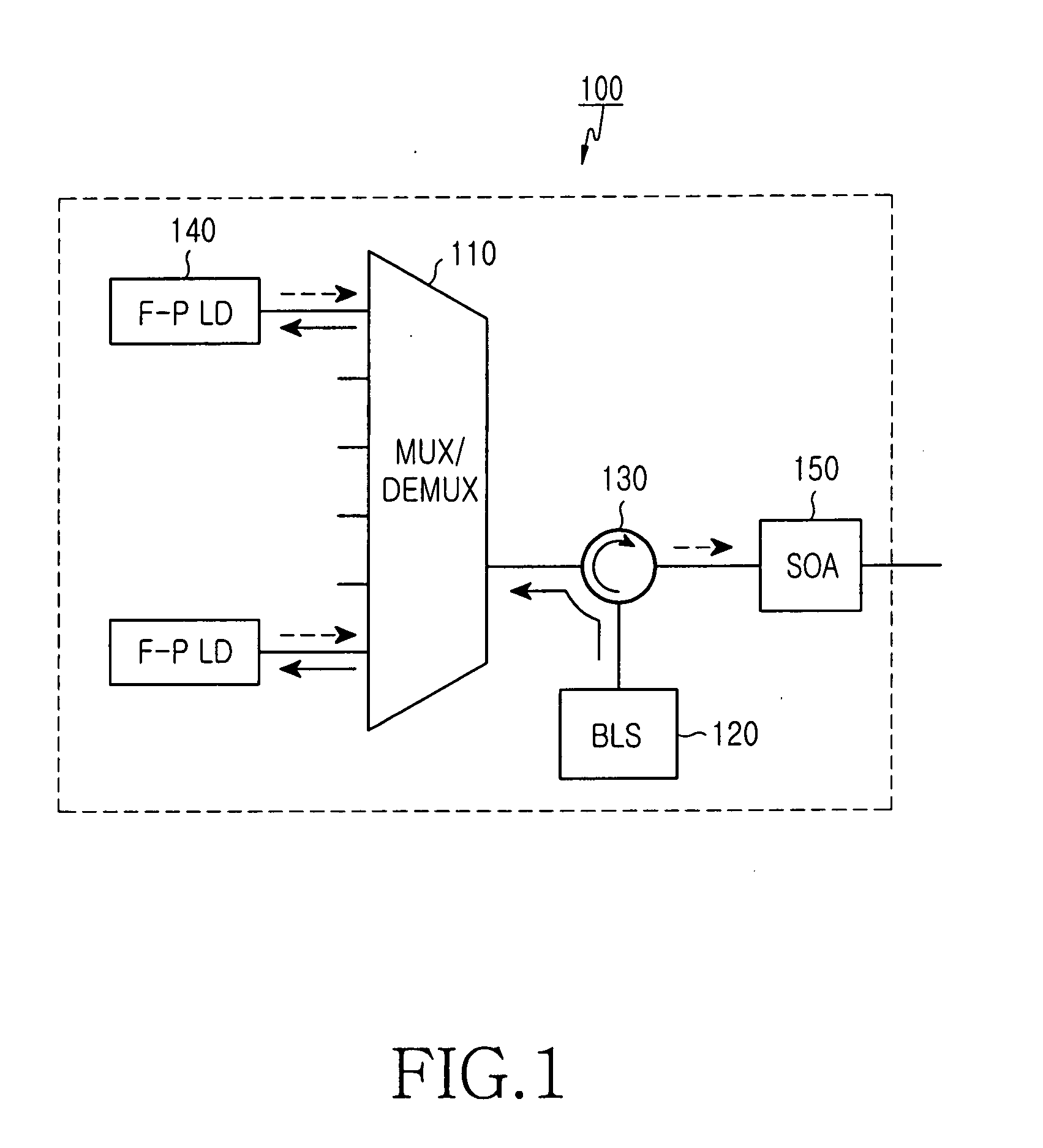

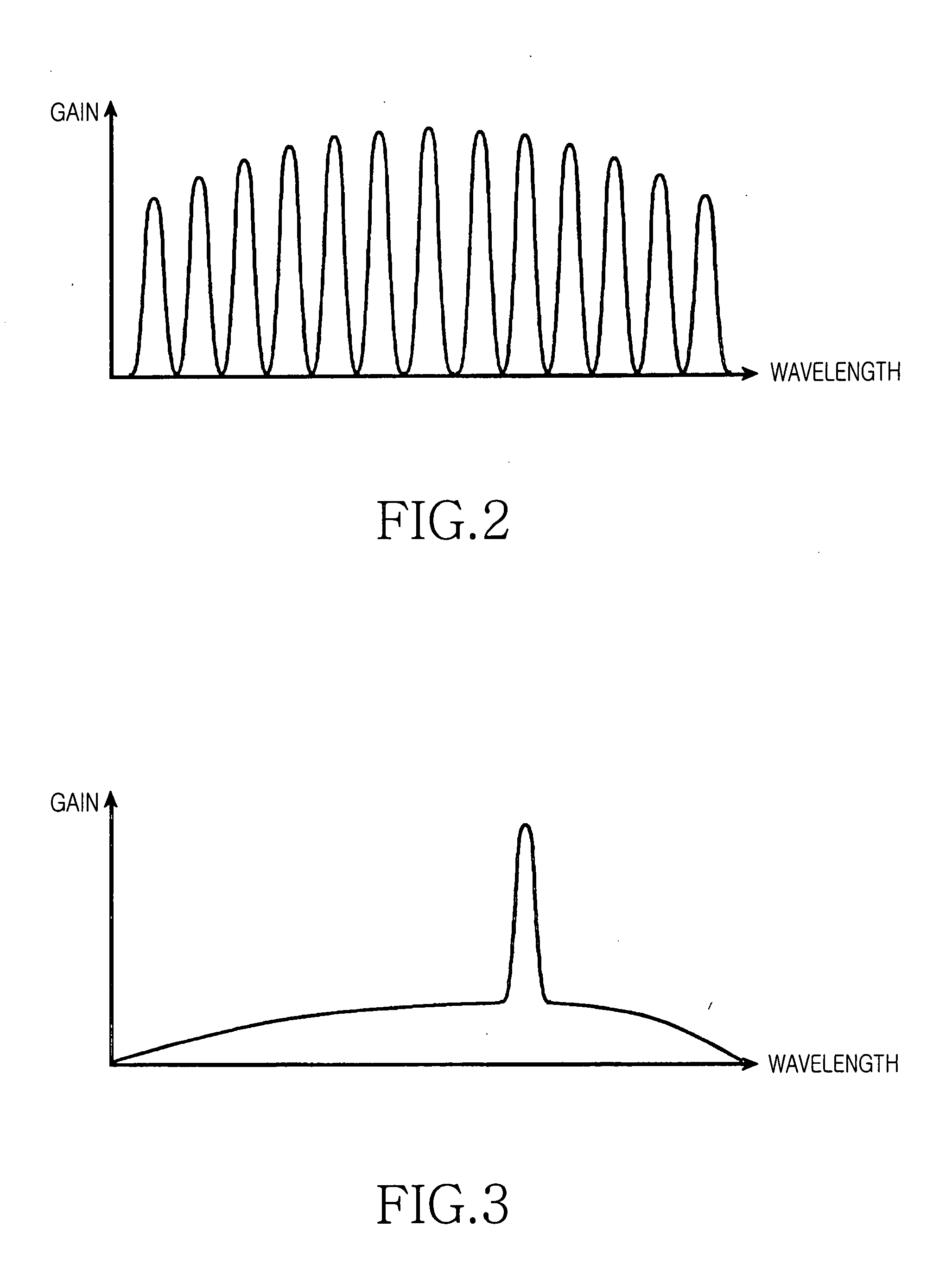

Multi-wavelength optical transmitter and bi-directional wavelength division multiplexing system using the same

InactiveUS20050041971A1Stable distanceStable transmission speedLaser detailsWavelength-division multiplex systemsMulti wavelengthTransmitter

A multi-wavelength optical transmitter which multiplexes a plurality of channels having different wavelengths into an optical signal for output includes lasers for generating mode-locked channels by corresponding incoherent light received in the lasers. The transmitter also has a semiconductor optical amplifier for amplifying, while in a gain saturation state, the optical signal multiplexed by the multiplexer / demultiplexer. Light from a broadband light source is directed by a circulator to the multiplexer / demultiplexer for demultiplexing among the lasers. Light back from the lasers is multiplexed and then directed by the circulator and amplified by a semiconductor optical amplifier for output external to the transmitter.

Owner:SAMSUNG ELECTRONICS CO LTD

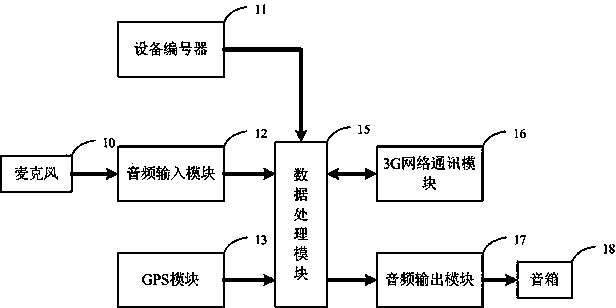

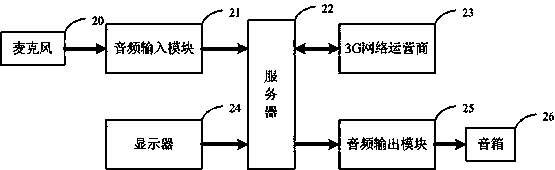

GPS (global positioning system) and 3G network based tour bus scheduling system and method

InactiveCN103531037AClear thinkingEasy to operateArrangements for variable traffic instructionsReal-time computingData analysis

Owner:天津恒达文博科技股份有限公司

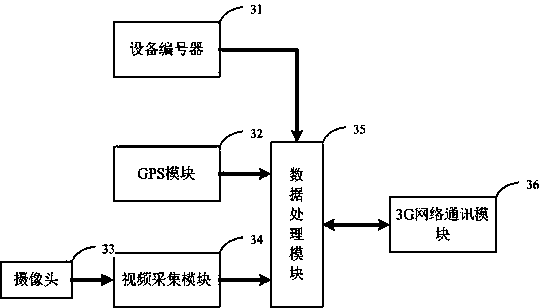

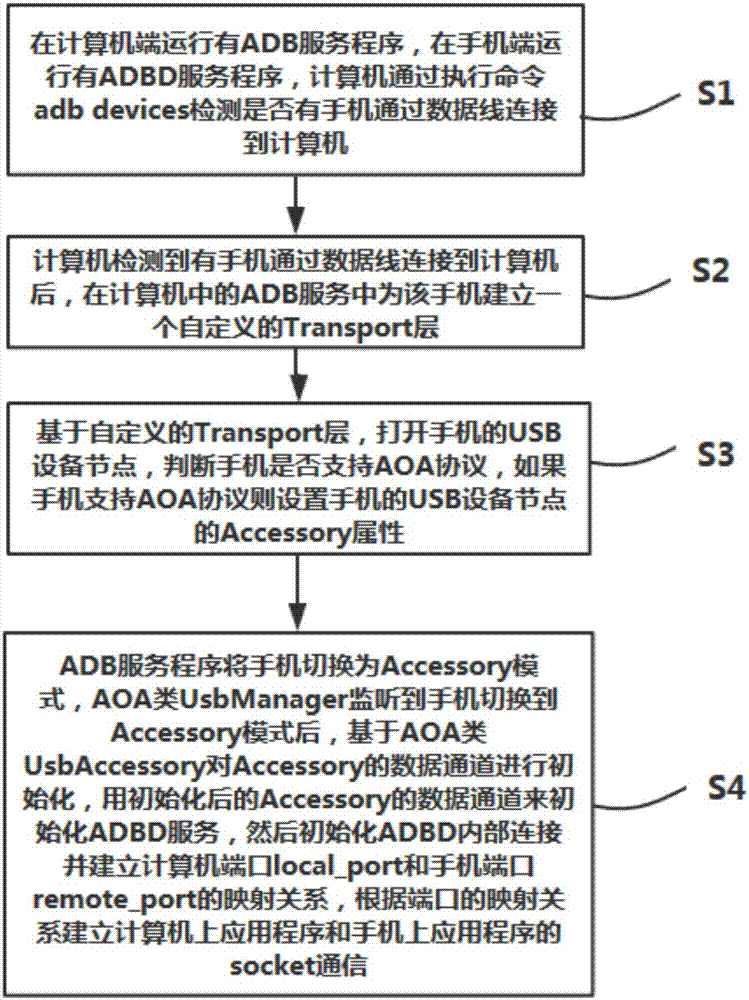

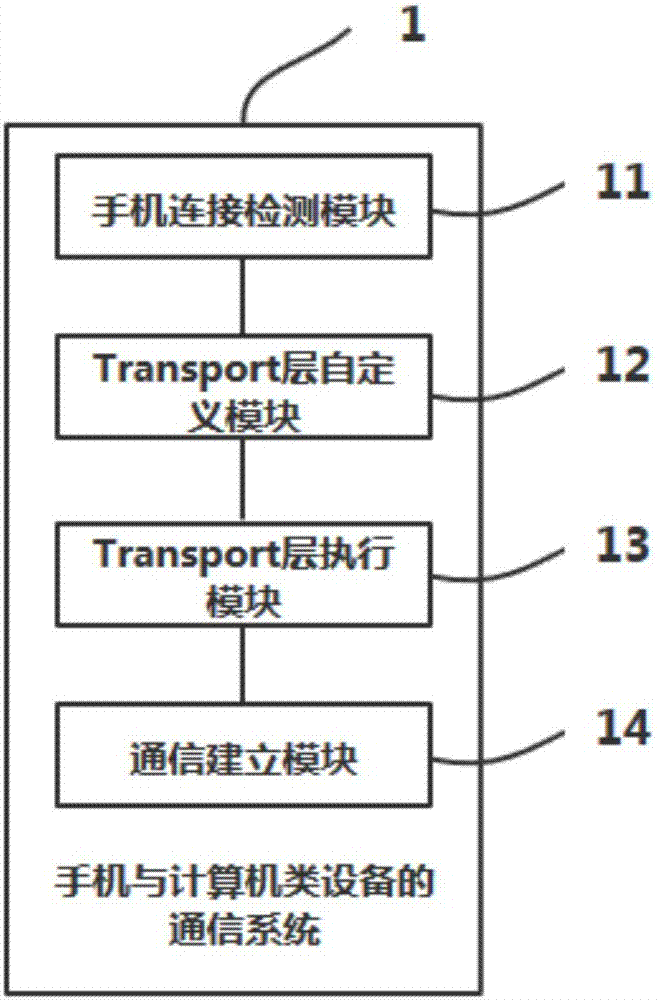

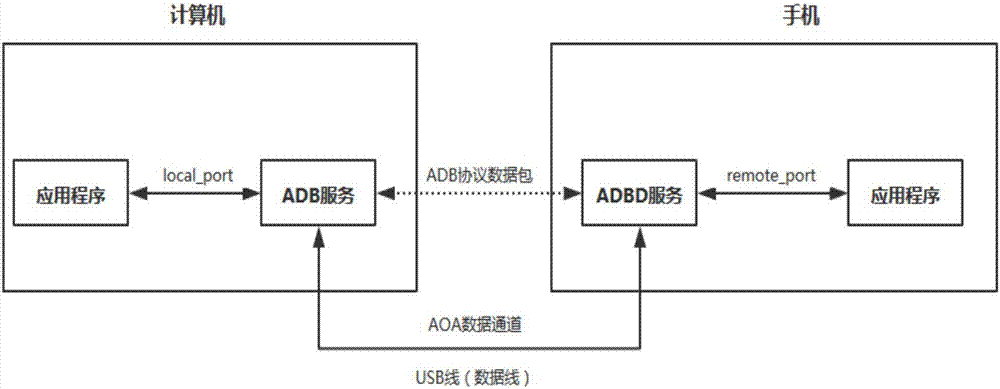

Communication method and system for mobile phone and computer equipment

ActiveCN107483696AAdaptableStable transmission speedTelephone sets with user guidance/featuresTransport layerApplication software

The invention discloses a communication method and system for a mobile phone and computer equipment. The method comprises the following steps: enabling an ADB service program to run at a computer side, enabling an ADBD service program to run at a mobile phone side, and detecting whether a mobile phone is connected to the computer through a data cable by the computer through an executive command adbdevices; after detecting that the mobile phone is connected to the computer through the data cable by the computer, establishing a self-defined Transport layer for the mobile phone in an ADB service of the computer, and setting the Accessory of a USB device node of the mobile phone; and switching the mobile phone into an Accessory mode, initializing a data channel of the Accessory, then initializing an ADBD service, and finally establishing the socket communication between applications on the computer and applications on the mobile phone. The beneficial effects are as follows: the invention is an adb data communication method based on an AOA protocol, which is fully compatible with the traditional adb communication, and is convenient, practical and strongly adaptable; and besides, data are transmitted in a wired way, the transmission speed is stable, and there is no need for users to open "developer options" and "USB debugging".

Owner:WUHAN CARBIT INFORMATION CO LTD

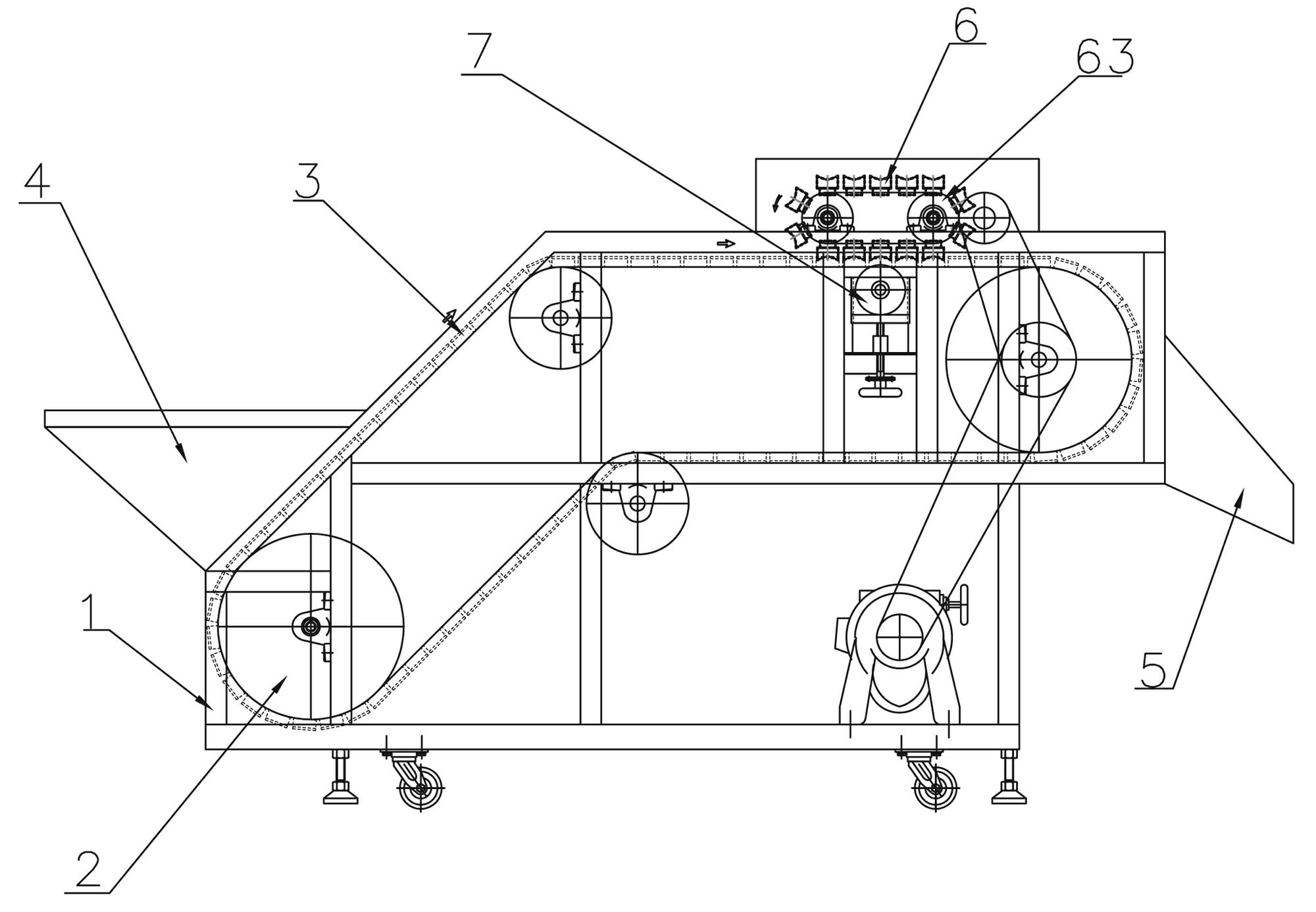

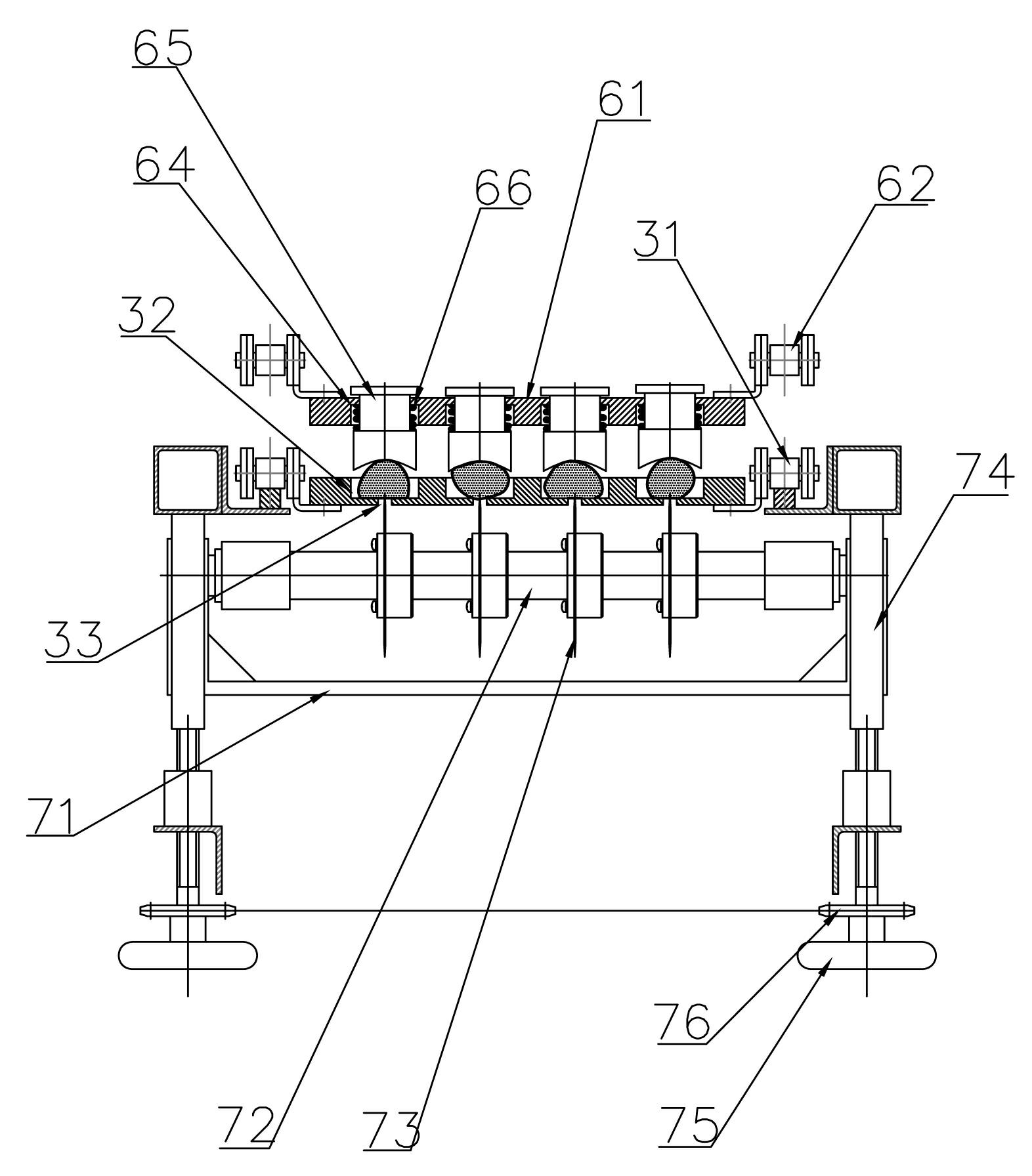

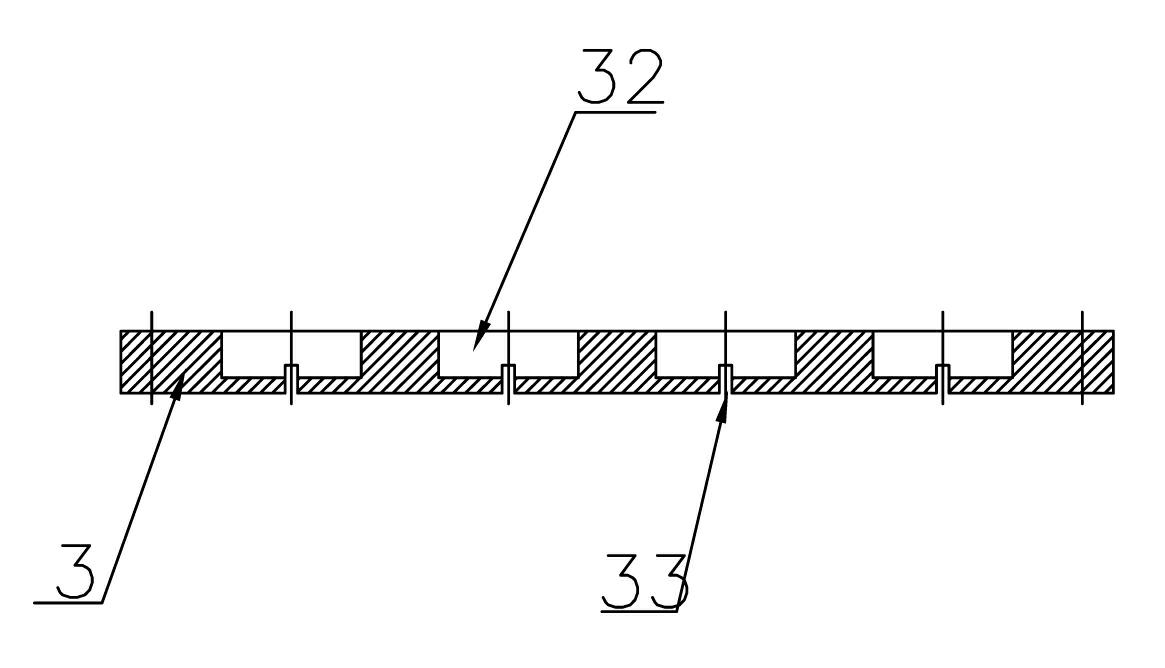

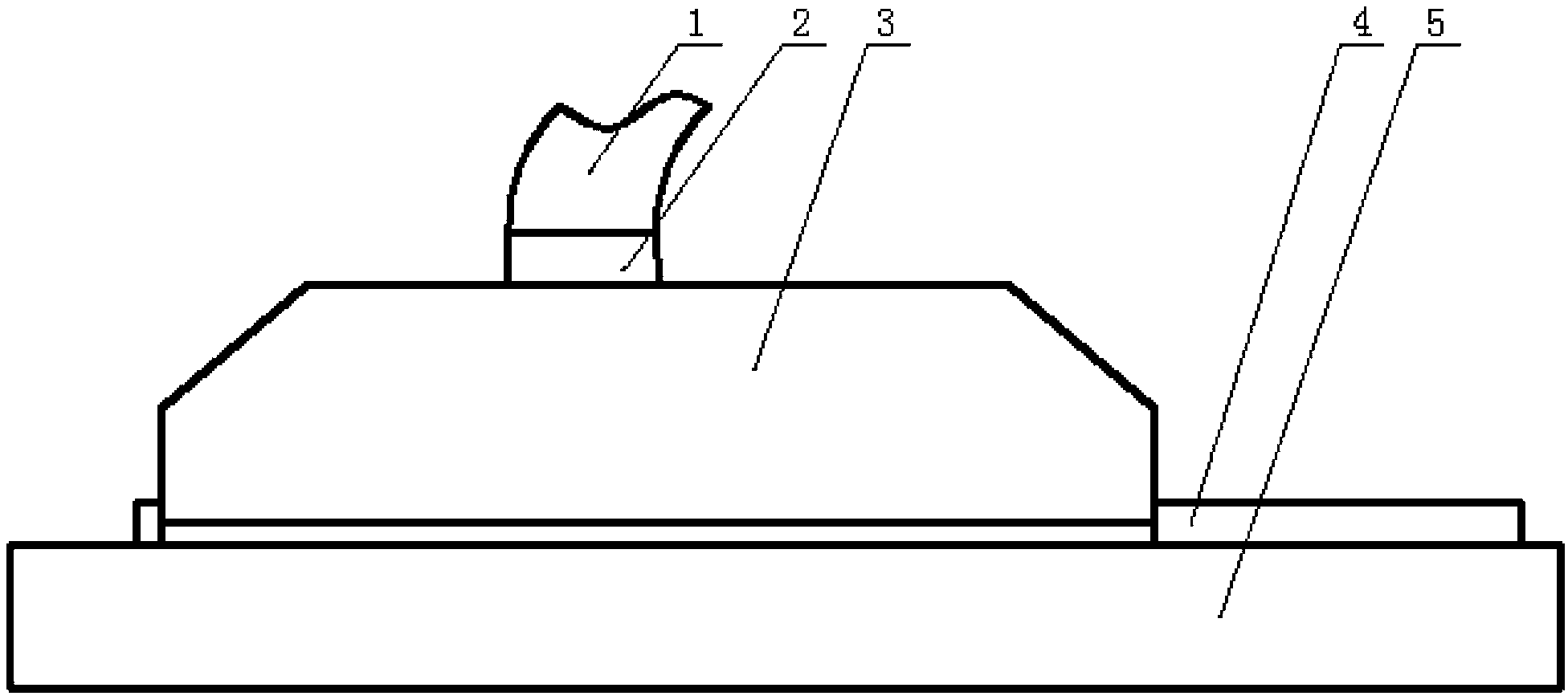

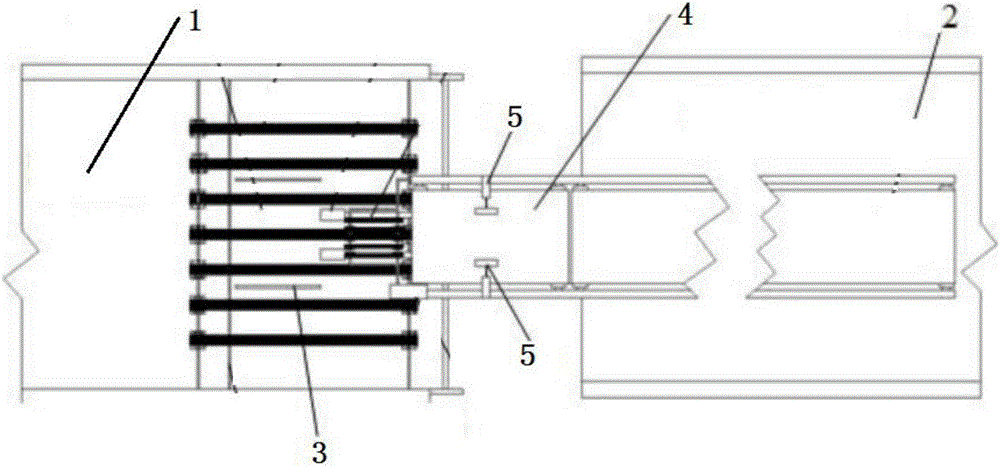

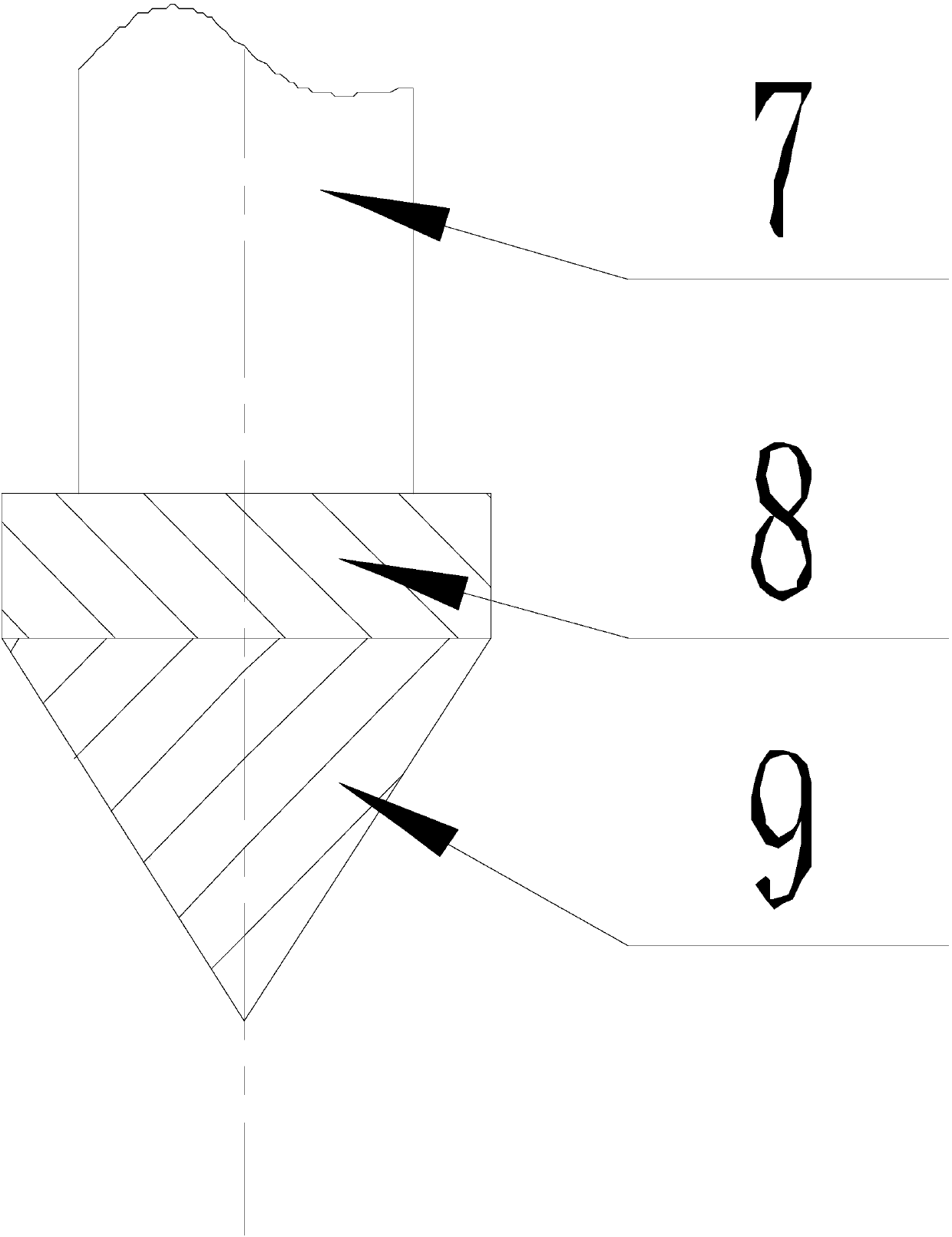

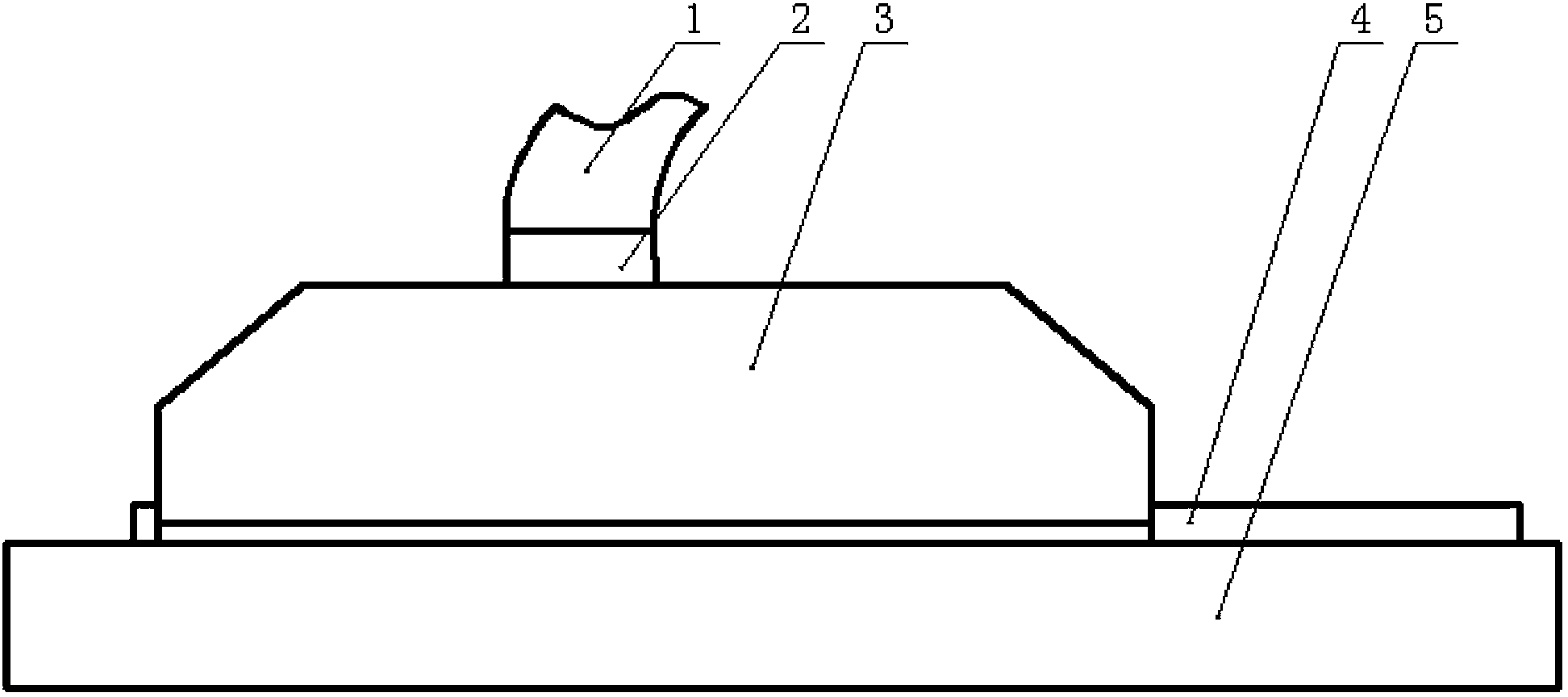

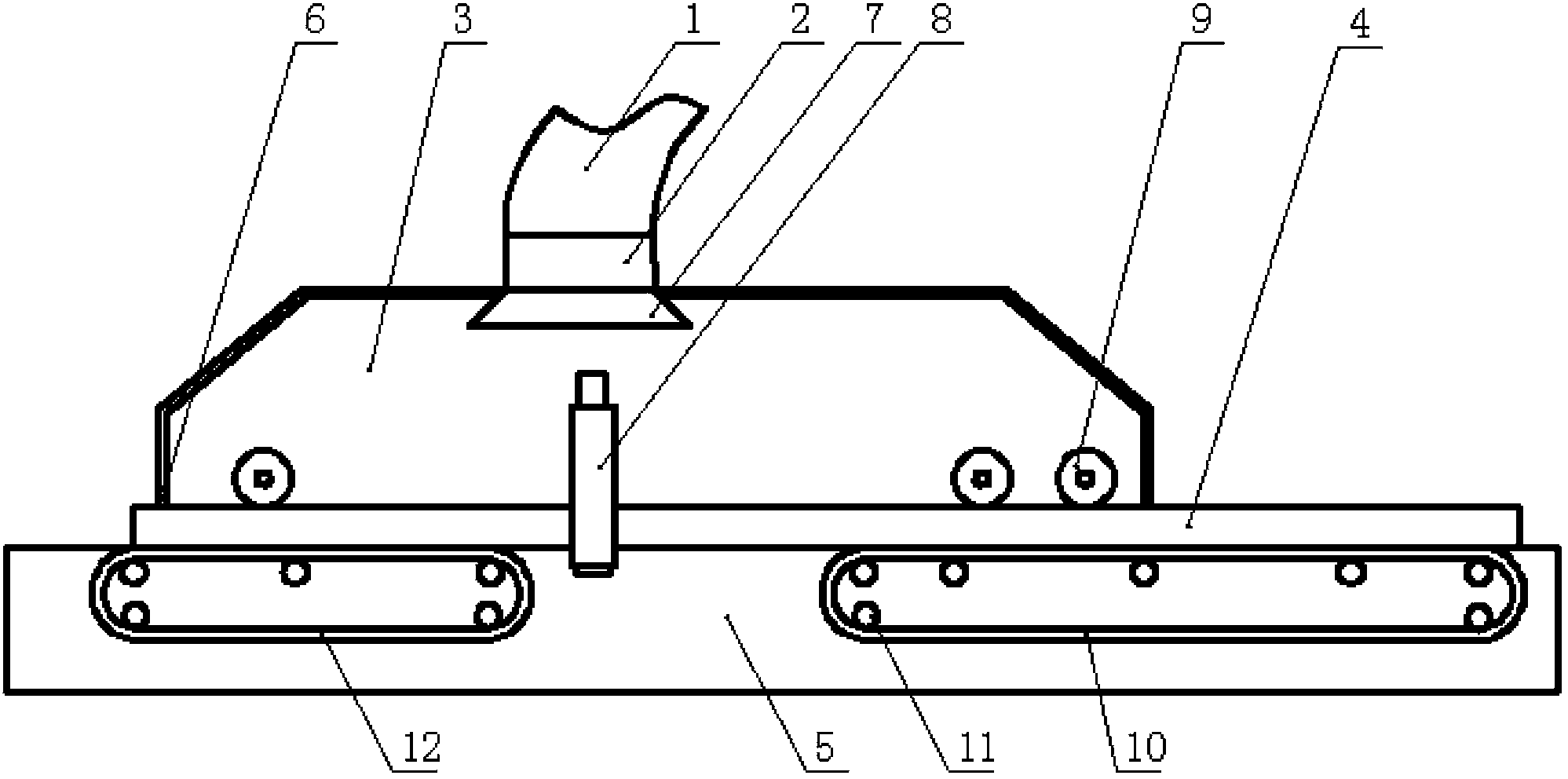

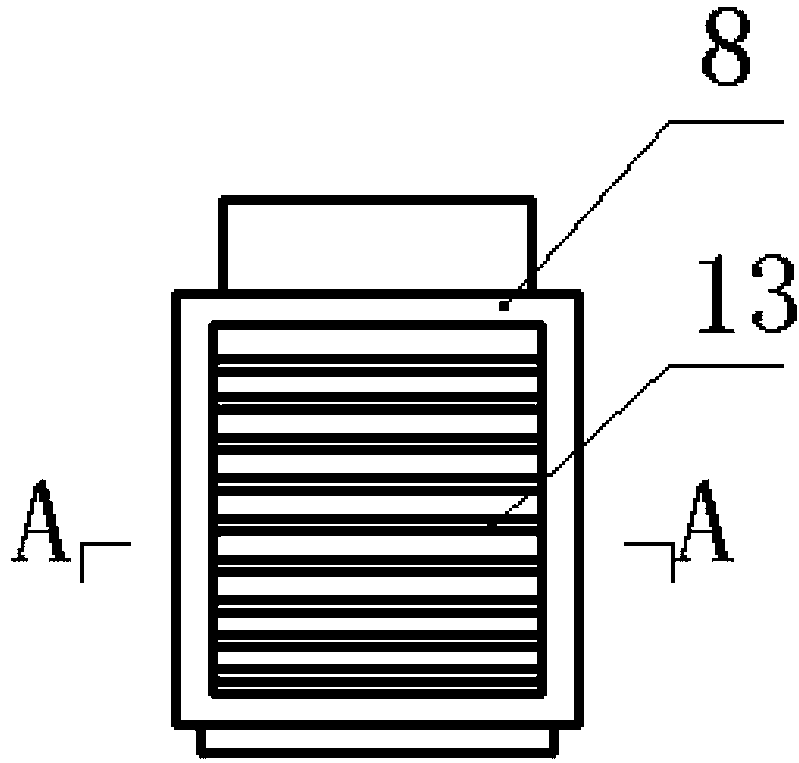

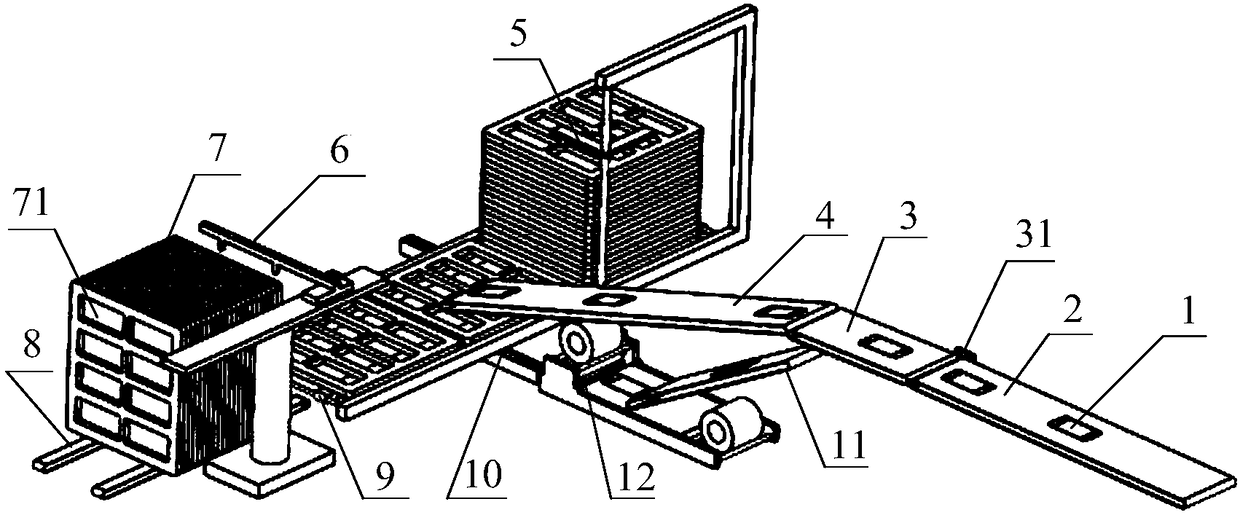

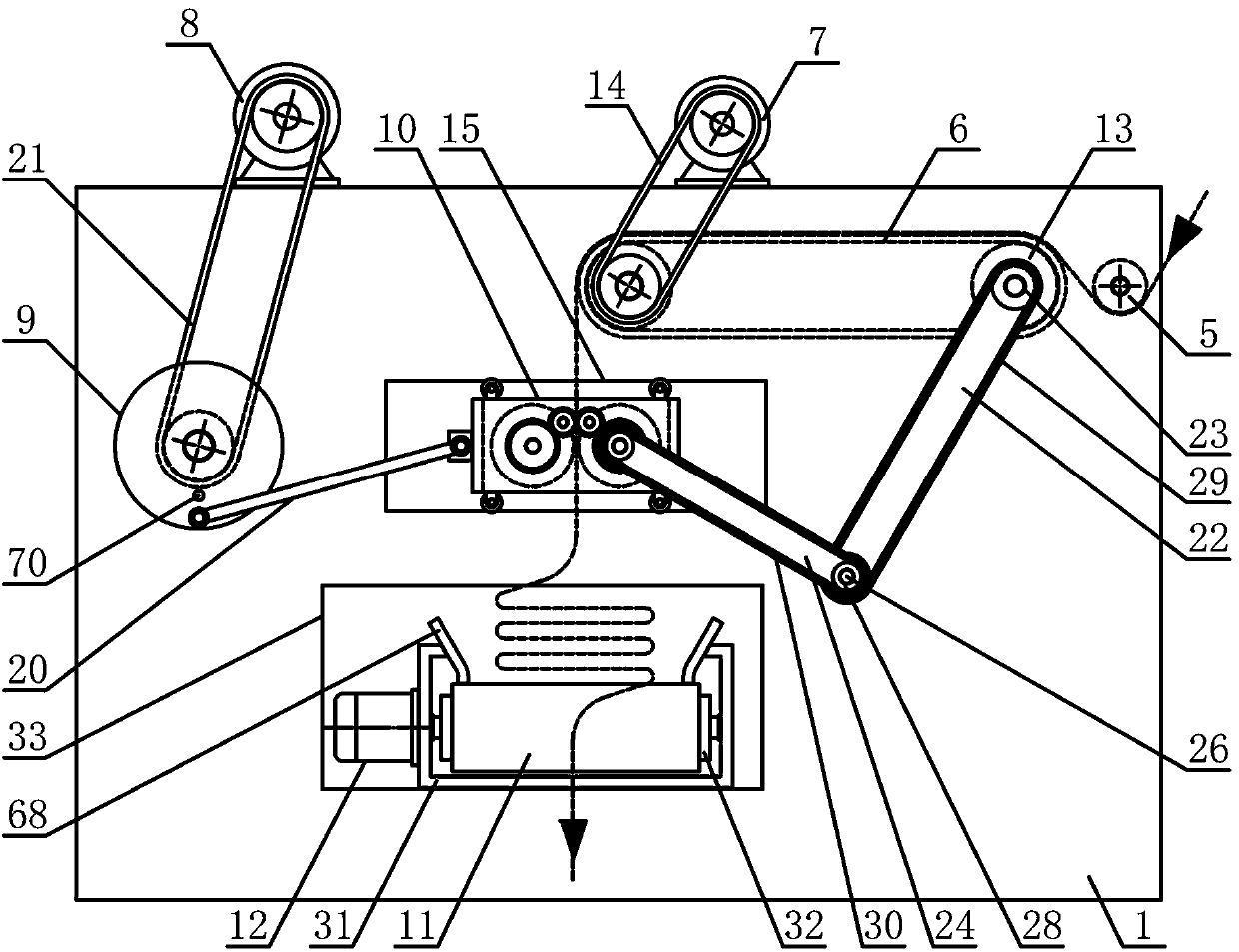

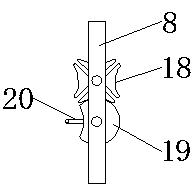

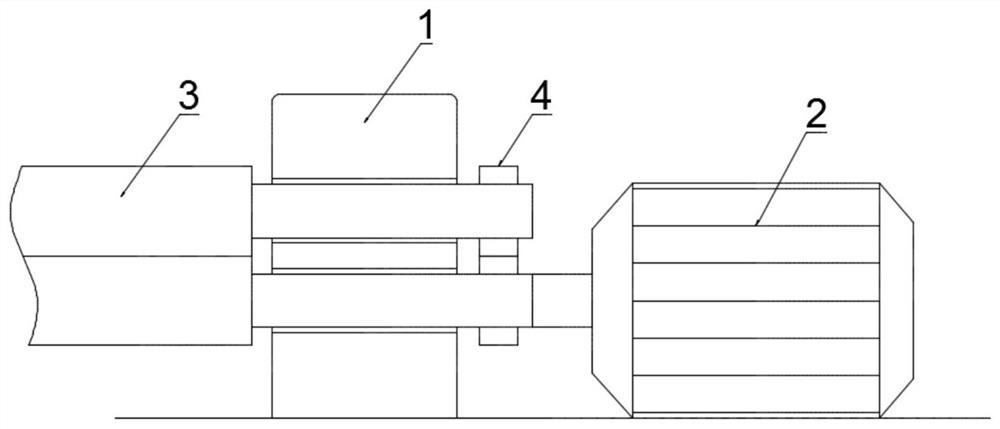

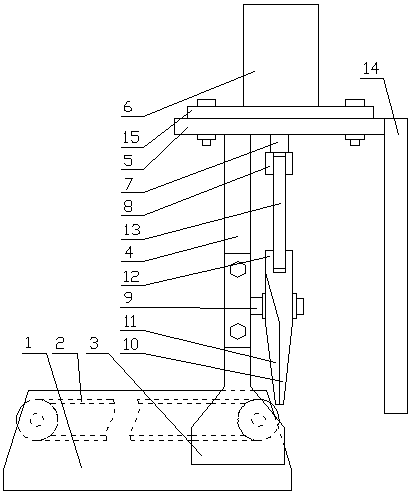

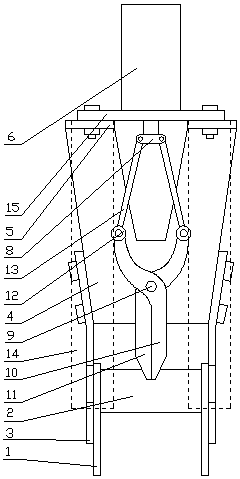

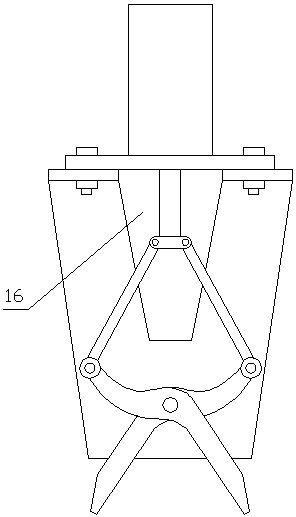

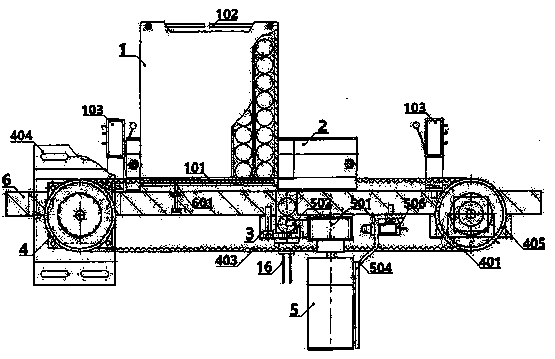

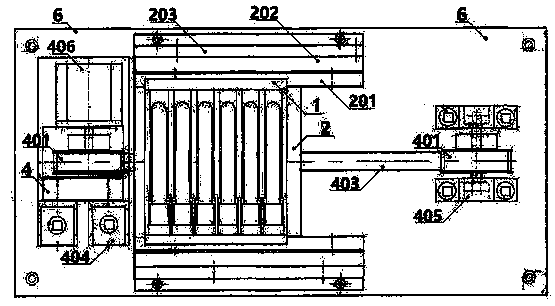

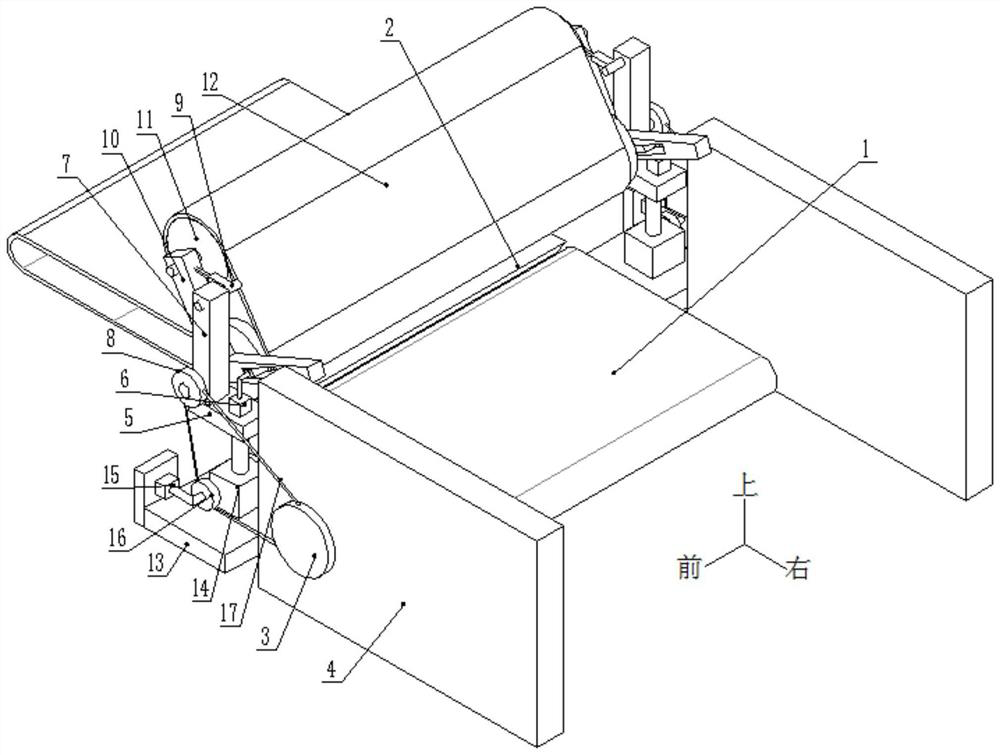

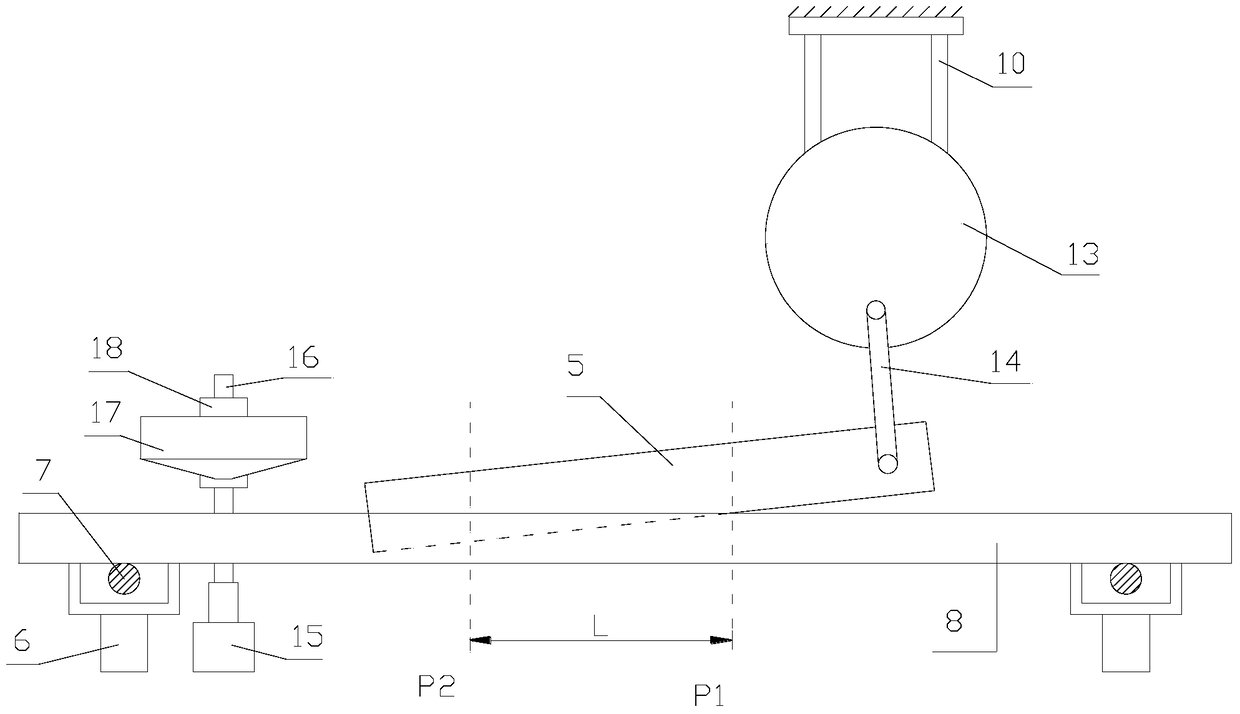

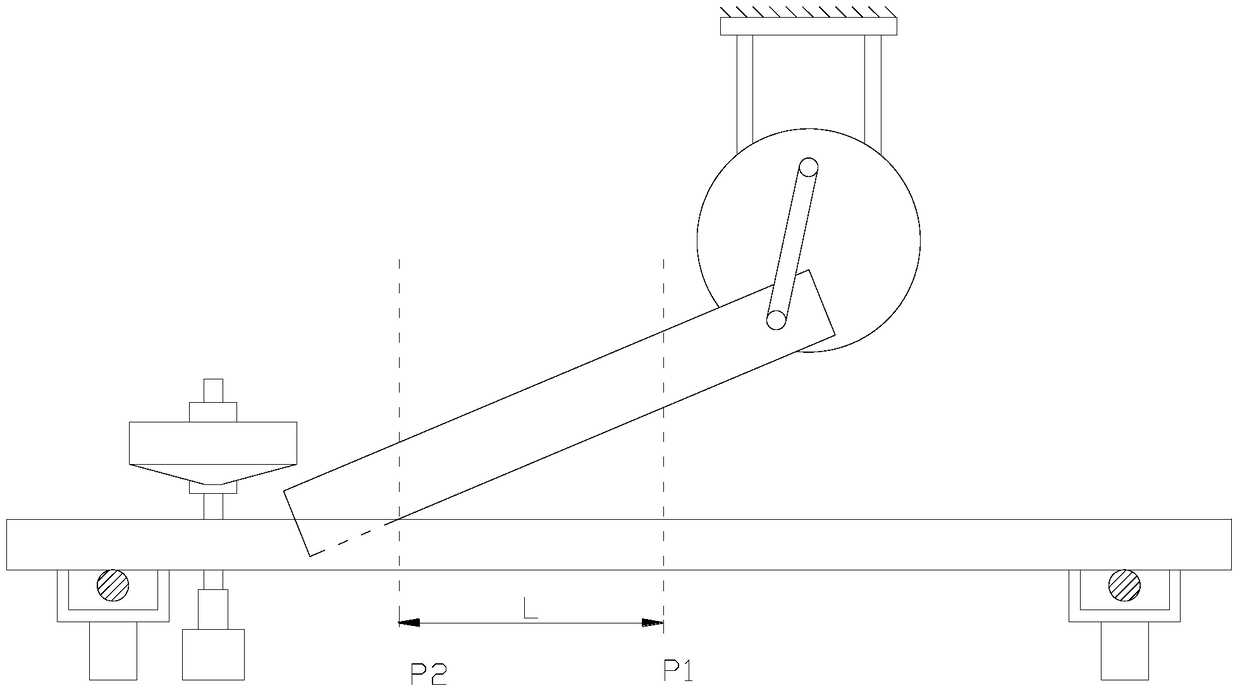

High-speed opening cutting device for chestnuts

InactiveCN102106592AImprove efficiencyStable transmission speedHuskingHullingMechanical equipmentRaw material

The invention discloses a high-speed opening cutting device for chestnuts, which comprises a machine frame, a feed groove and a discharge groove, wherein a plurality of transmission wheels and a loading plate capable of running circularly under the drive of the transmission wheels are arranged on the machine frame; a material pressing mechanism for pressing materials on the loading plate and the loading plate synchronously operate in mesh; the height of the loading plate at the feed groove is lower than that of the material pressing mechanism; an opening cutting mechanism is arranged at the position in which the material pressing mechanism is positioned on the lower part of the loading plate; and the opening cutting mechanism is used for cutting the chestnuts between the material pressing mechanism and the loading plate. In the chestnut cutting machine, chestnut raw materials are supplied to the loading plate from the feed groove, the loading plate drives the chestnut raw materials to lift and convey the chestnut raw materials to the opening cutting mechanism, the material pressing mechanism which is synchronously meshed with the loading plate can fix the chestnuts, the chestnuts are cut by the opening cutting mechanism on the lower part of the loading plate to ensure that the cut on the chestnuts are consistent in the opening cutting process, and the transmission speed of the chestnuts can be regulated by regulating the speed of the transmission wheels, so that the opening cutting efficiency of the chestnuts is higher. The high-speed opening cutting device is used in the field of agricultural mechanical equipment.

Owner:广东省农业机械研究所

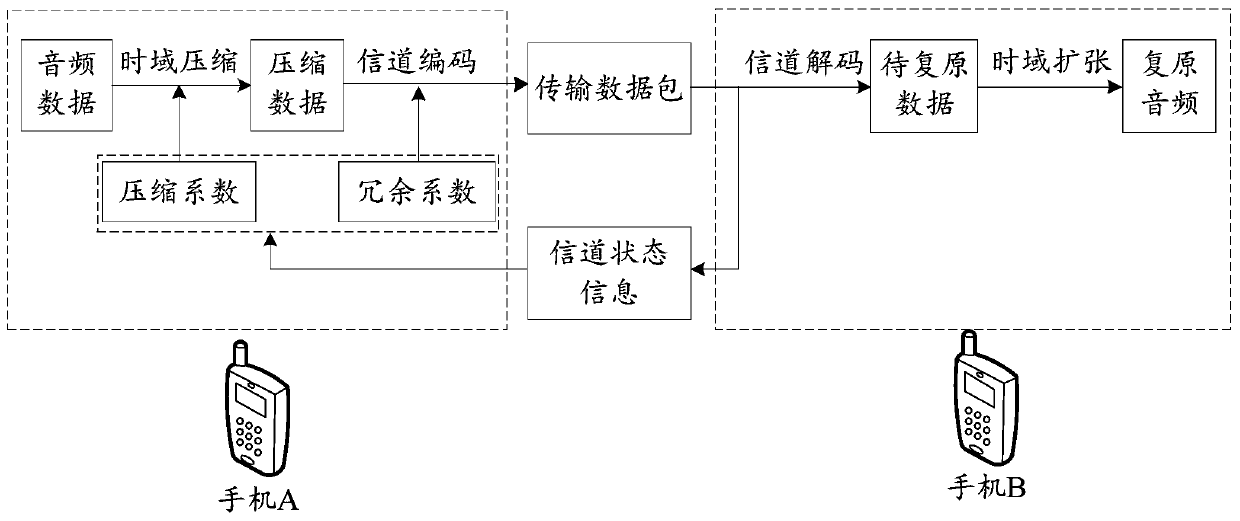

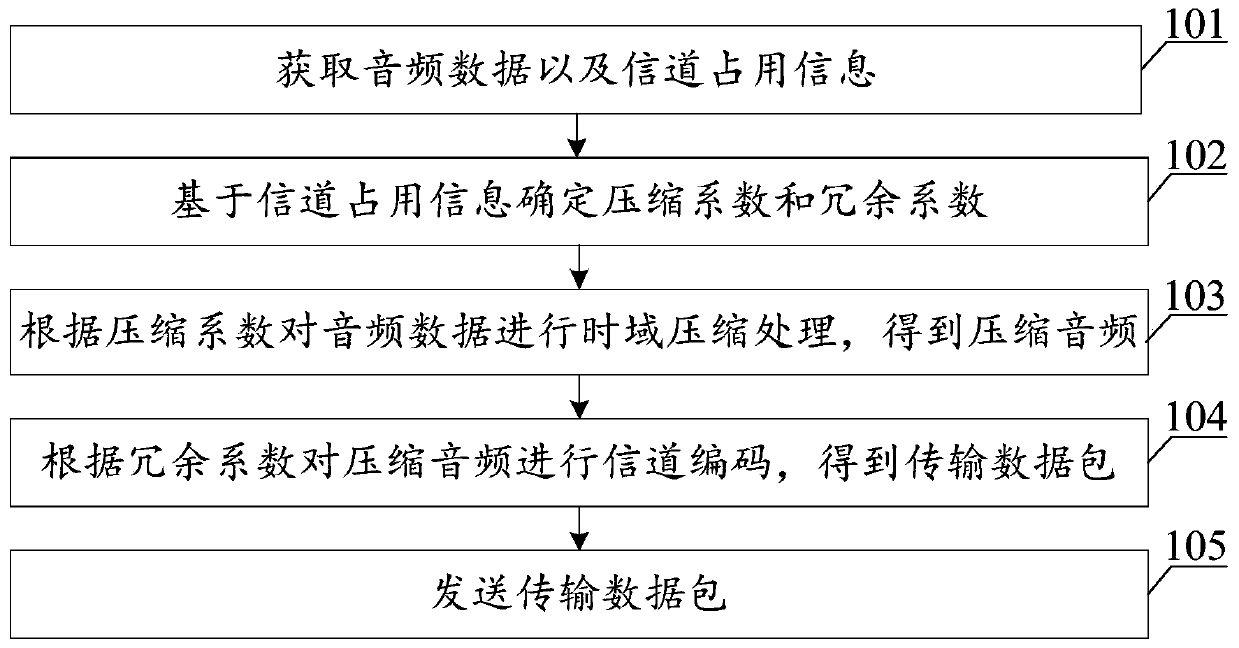

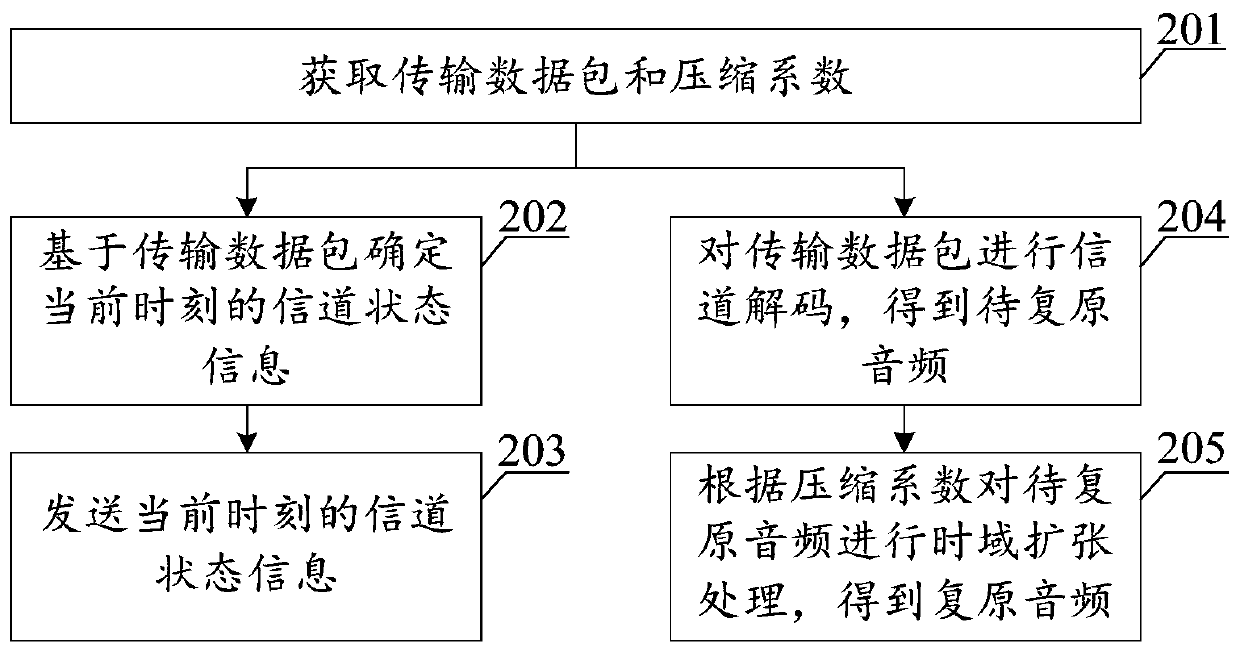

Data transmission method and device, terminal, storage medium and system

ActiveCN111314335AAccurate transmissionFull transferReceiver specific arrangementsSpeech analysisComputer hardwareTime domain

The embodiment of the invention discloses a data transmission method and device, a terminal, a storage medium and a system. According to the embodiment of the invention, the method comprises the steps: acquiring audio data and transmission state information; determining a compression coefficient and a redundancy coefficient based on the transmission state information; performing time domain compression processing on the audio data according to the compression coefficient to obtain compressed data; performing channel coding on the compressed data according to the redundancy coefficient to obtain a transmission data packet; and sending the transmission data package. In the embodiment of the invention, the transmission state information is analyzed; whether congestion, the packet loss and thelike exist in the current transmission of the channel can be judged; by modifying the compression coefficient, channel congestion and other conditions can be improved, and by modifying the redundancycoefficient, the packet loss and other conditions can be improved, so the utilization rate of a channel is improved while the correctness and integrity of data transmission are ensured, the data transmission speed is higher and more stable, and thus, the scheme can improve the efficiency of the data transmission method.

Owner:TENCENT TECH (SHENZHEN) CO LTD

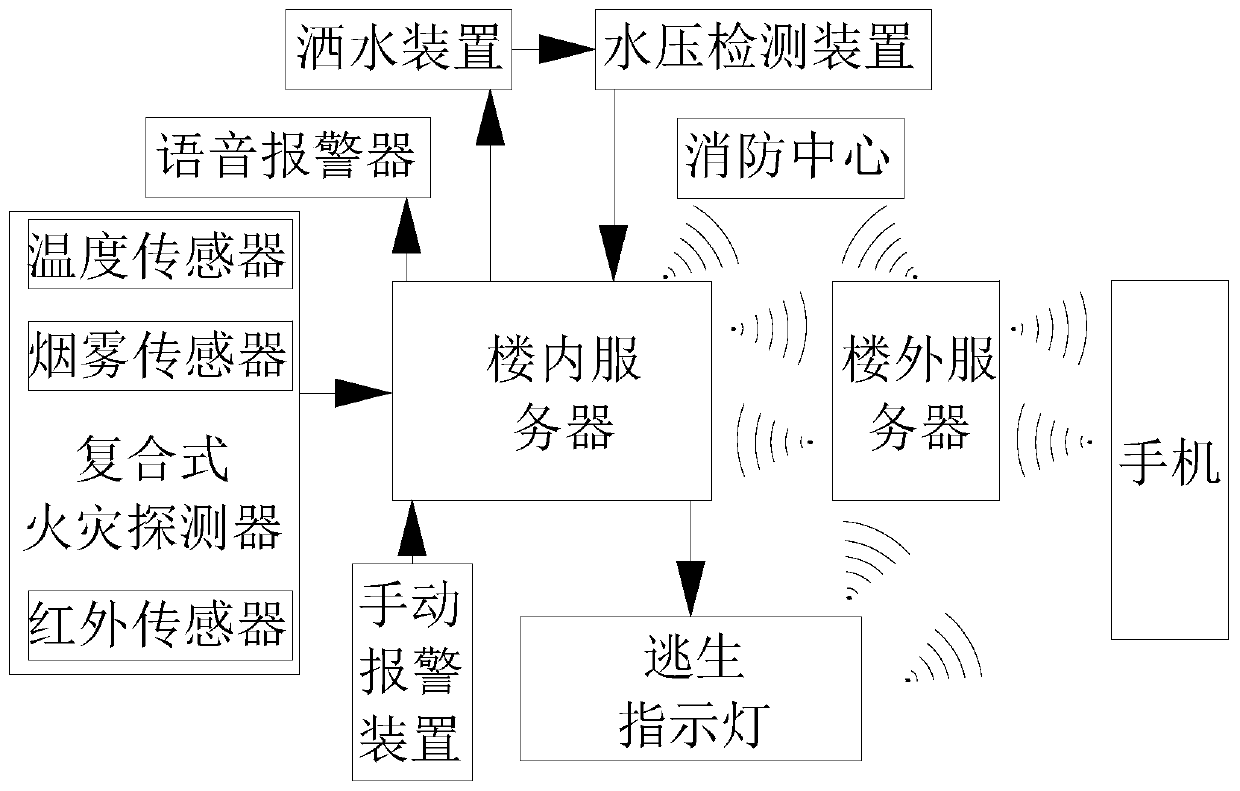

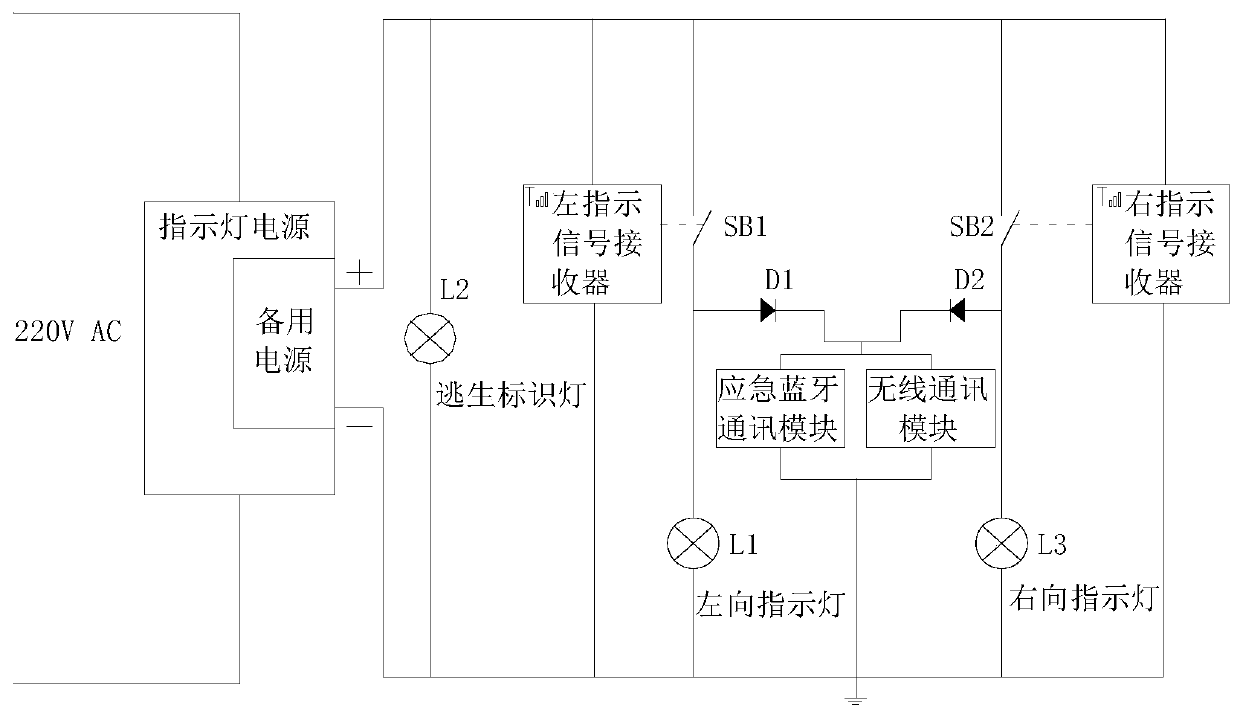

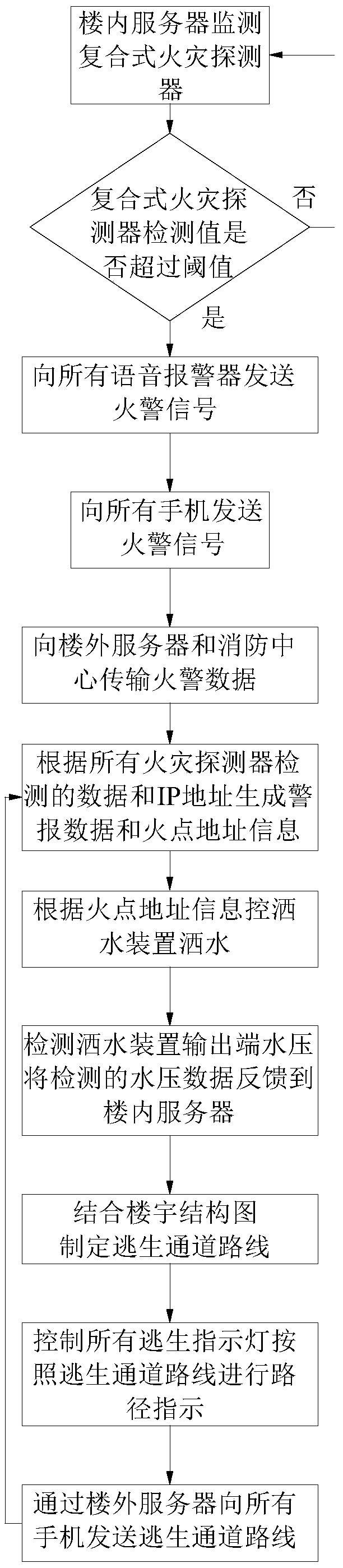

Dynamic building fire escape response method

ActiveCN111341045AGuaranteed stabilityReduce power consumptionSignalling system detailsSubstation equipmentFire detectorArchitectural engineering

Owner:重庆特斯联智慧科技股份有限公司

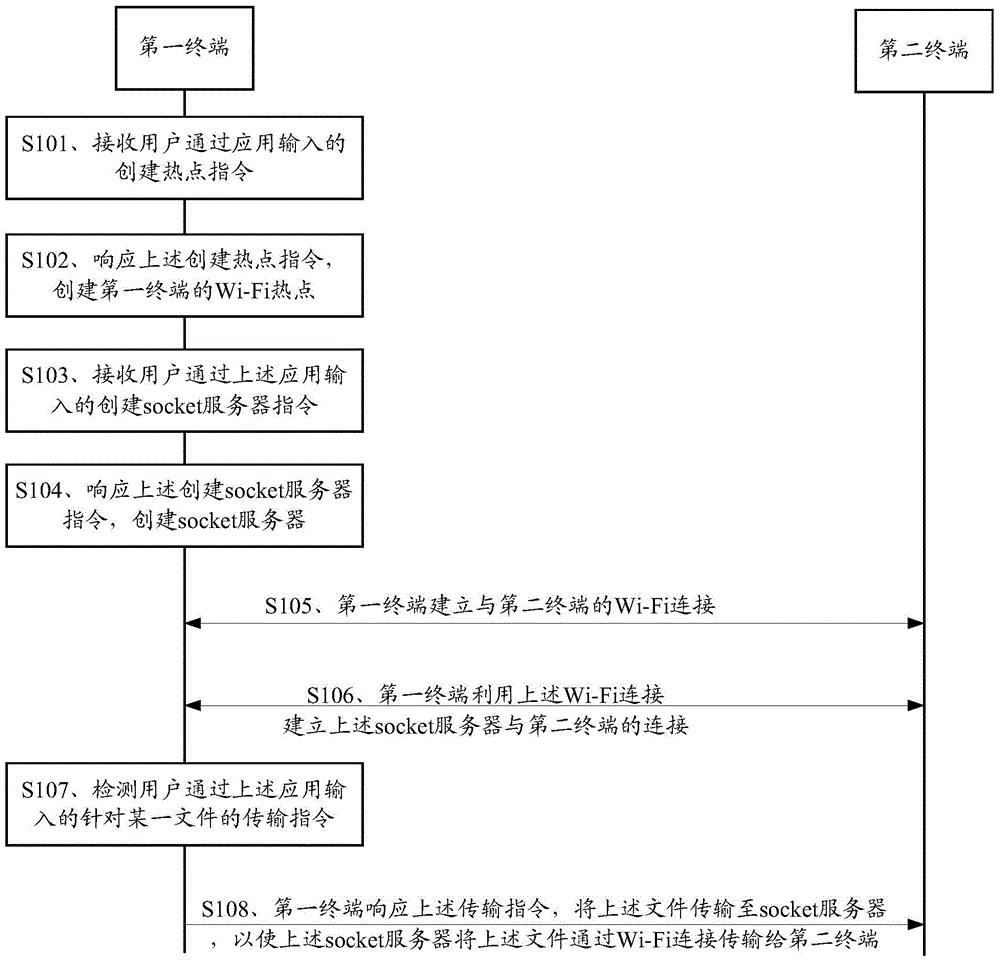

File transmission method and terminal

The embodiment of the invention discloses a file transmission method and a terminal. The method comprises the following steps that: a first terminal receives a hotspot creating command input by a user through an application; the first terminal creates a Wi-Fi hotspot in response to the hotspot creating command; the first terminal receives a socket server creating command input by the user through the application; the first terminal creates a socket server in response to the socket server creating command; the first terminal establishes Wi-Fi connection with a second terminal; the first terminal establishes connection between the socket server and the second terminal through Wi-Fi connection; the first terminal detects a transmission command input by the user through the application specific to a certain file; and the first terminal transmits the file to the socket server in response to the transmission command in order that the socket server transmits the file to the second terminal through Wi-Fi connection. Through adoption of the file transmission method and the terminal, the file transmission efficiency can be effectively increased under the situation of no flow consumption.

Owner:TENCENT TECH (SHENZHEN) CO LTD

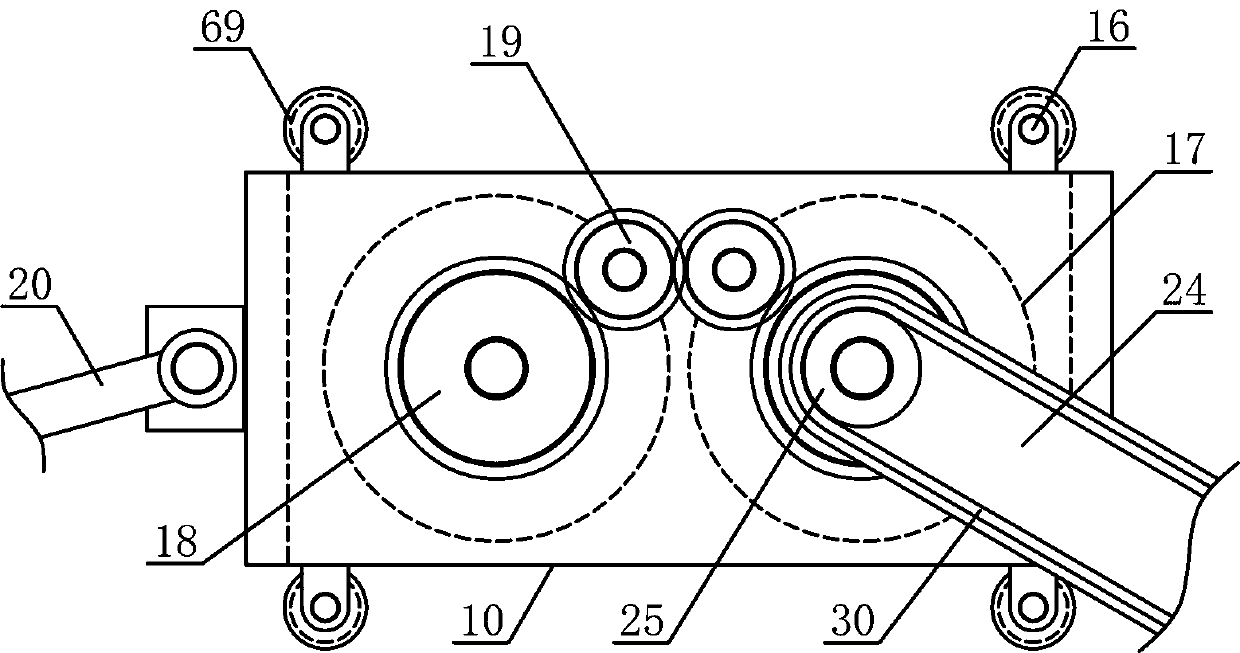

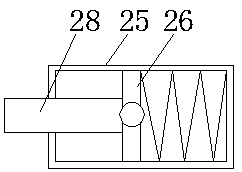

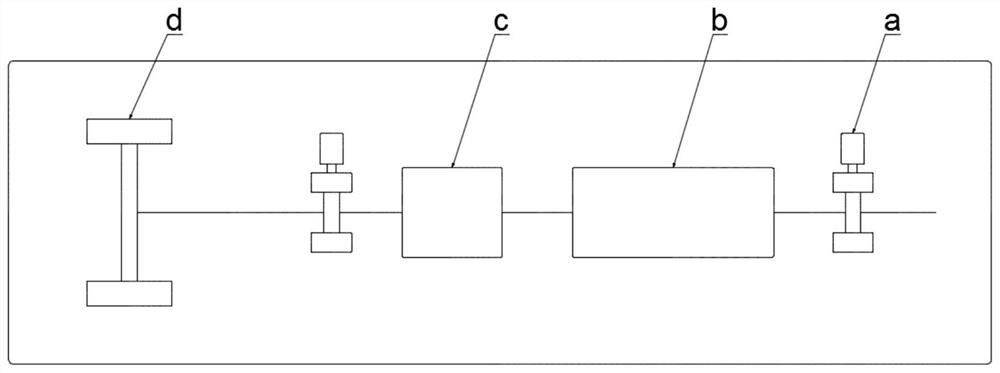

Medium transmission device

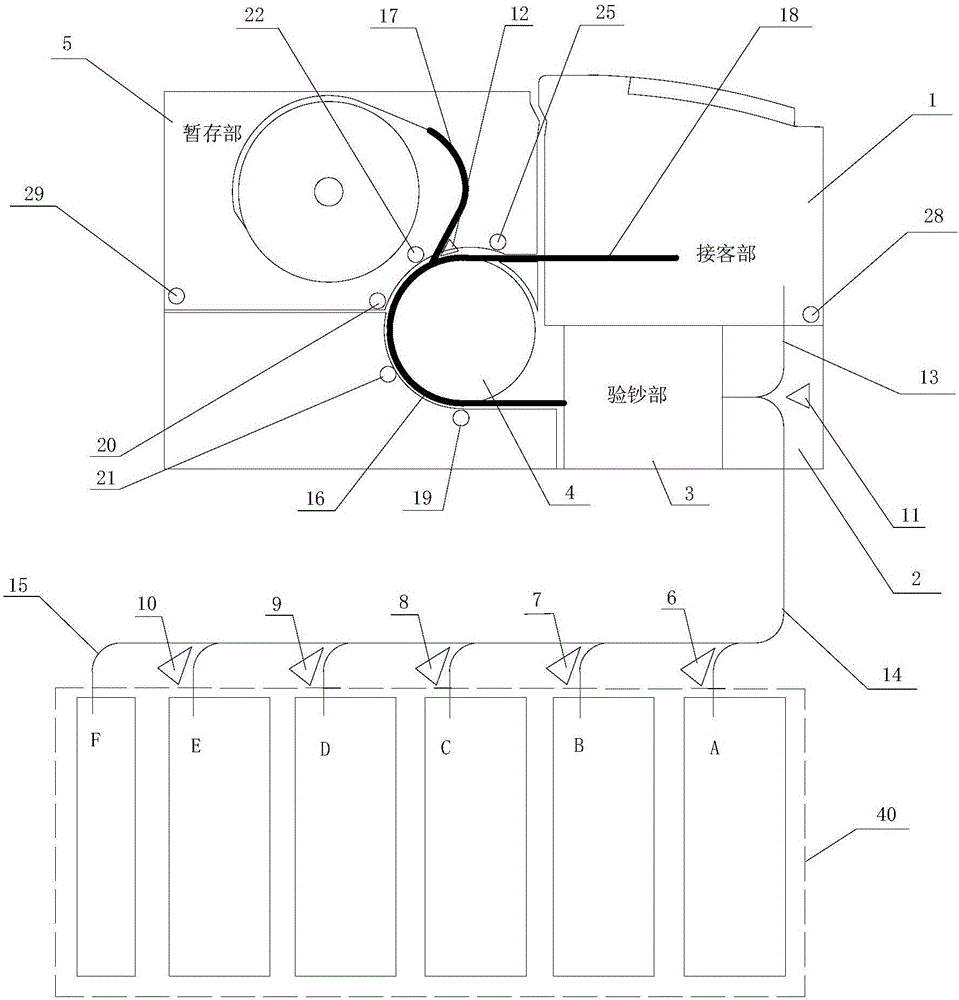

PendingCN106251477AProper and effective transmission of powerStable transmission speedCoin/currency accepting devicesTransmission channelUtilization rate

The invention discloses a medium transmission device, which comprises a client portion having a banknote depositing and withdrawing port, a banknote checking portion for identifying banknotes, a temporary storage portion for keeping the banknotes temporarily, a switching blade for switching the transmission direction of the banknotes, a banknote box for accommodating the banknotes, a first transmission channel connected with the client portion and the banknote checking portion, a second transmission channel connected with the banknote checking portion and the temporary storage portion, and a third transmission channel connected with the banknote checking portion and the banknote box. A transmission O portion is arranged at one side of the client portion and one side of the banknote checking portion; an arc transmission channel is formed in the peripheral surface of the transmission O portion; and the temporary storage portion is abutted against the transmission O portion, and the temporary storage portion is uniformly provided with a plurality of press rollers for applying uniform pressure to the transmission O portion. The medium transmission device ensures the banknotes have appropriate and effective transmission power and stable and consistent transmission speed in the transmission channel, thereby reducing probability of that the banknotes block the transmission channel and are blocked in the arc transmission channel, and ensuring normal transmission of the banknotes and utilization rate of the machine equipment.

Owner:SHENZHEN YIHUA COMP +2

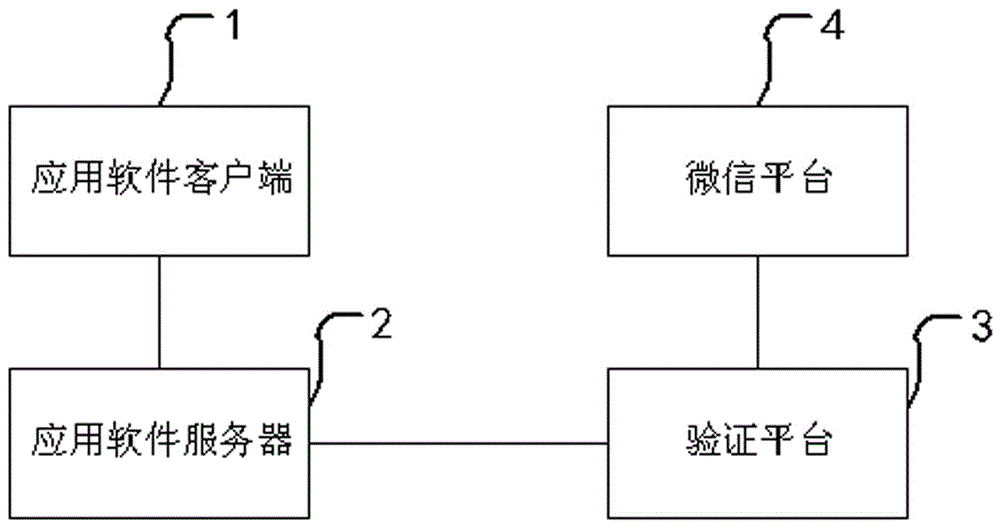

Application software verification method and system based on WeChat platform

InactiveCN106778290ALow costImprove experienceDigital data protectionDigital data authenticationApplication serverSoftware engineering

The invention discloses an application software verification method based on a WeChat platform, and is applied to a verification system which comprises an application software client side, an application software server and a verification platform. The invention also discloses an application software verification system based on the WeChat platform.

Owner:PHICOMM (SHANGHAI) CO LTD

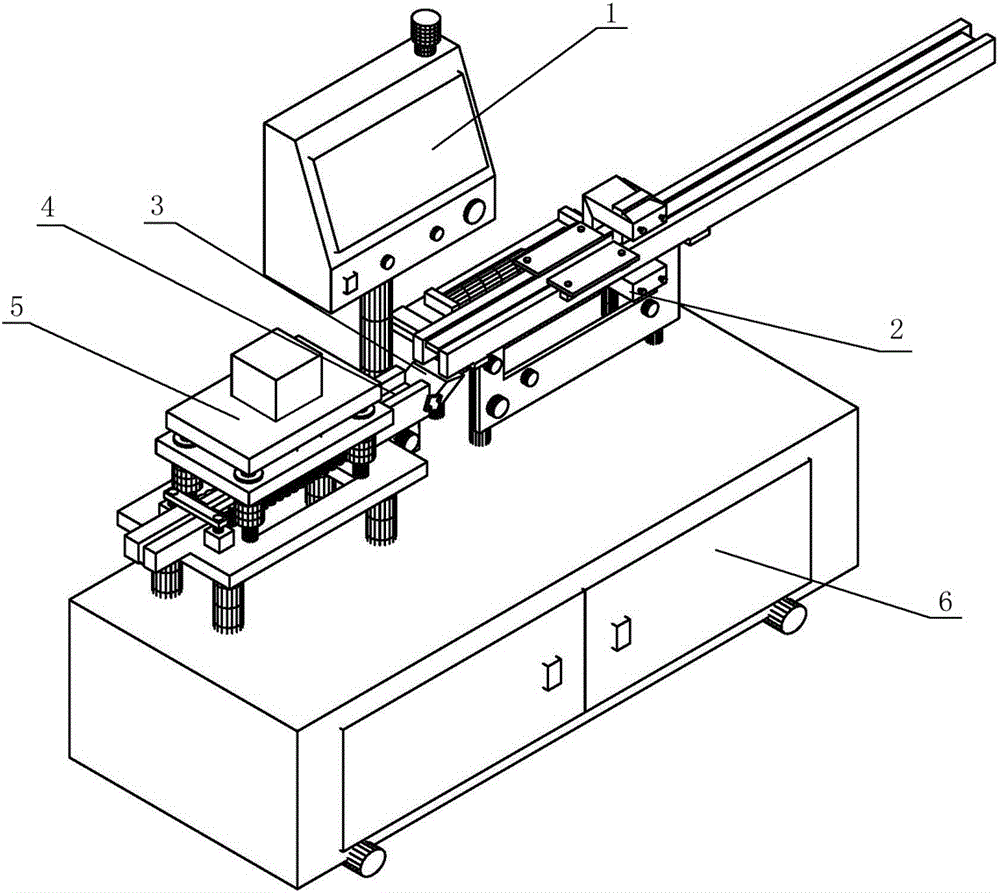

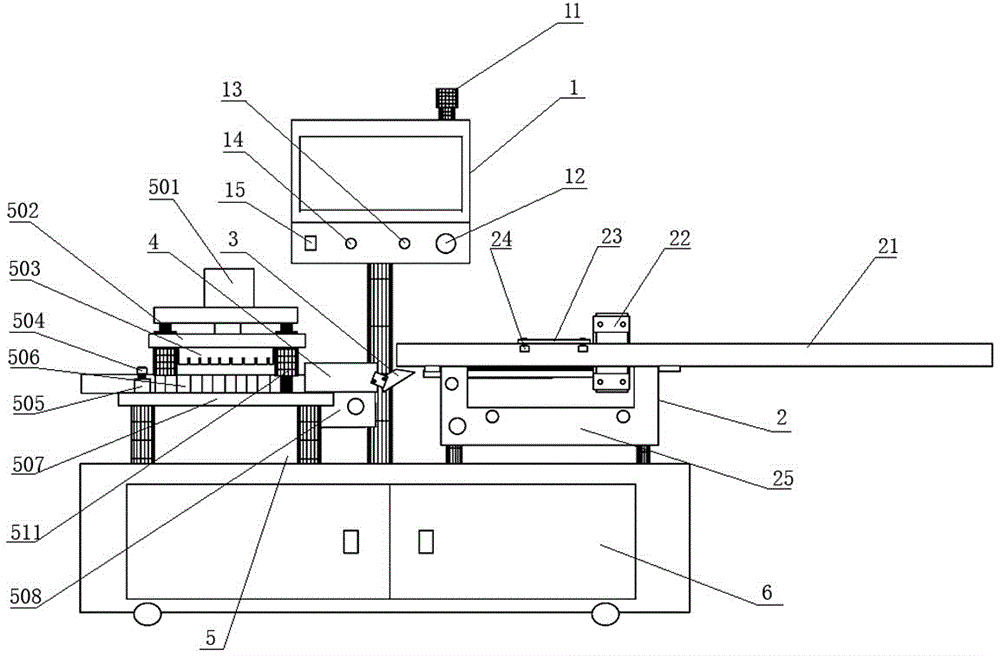

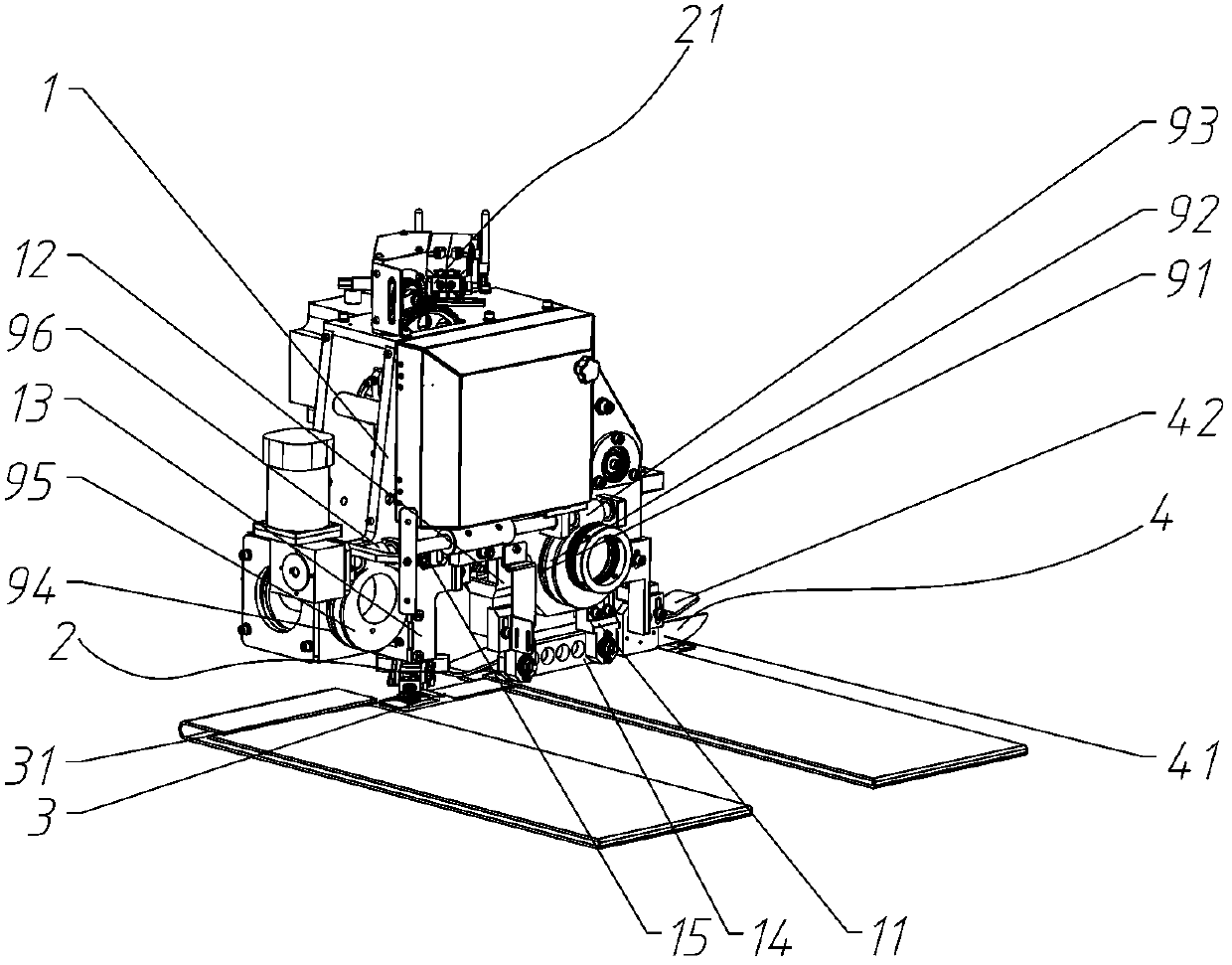

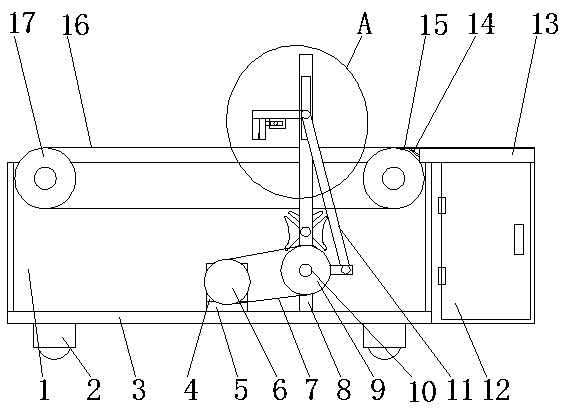

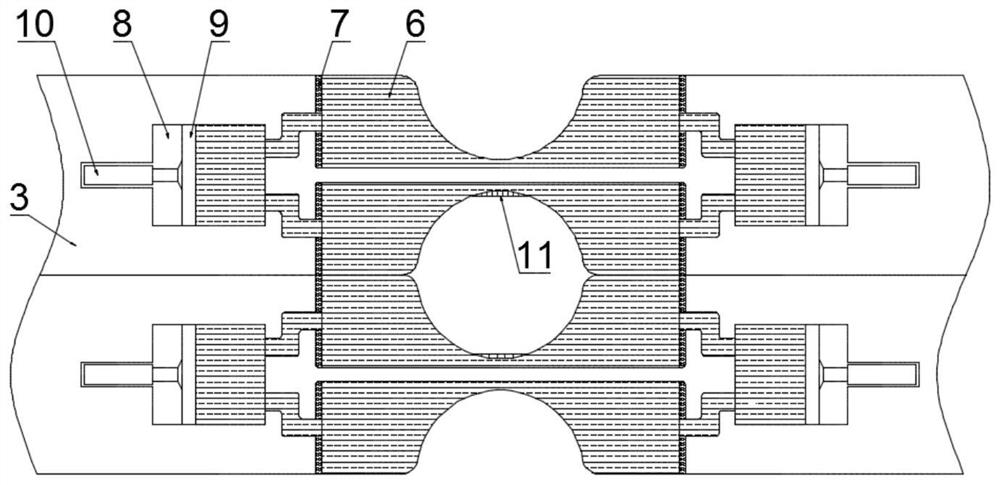

Automatic powder brushing and border cutting device of chip inductor

ActiveCN106548861AImprove cut qualitySmooth transmissionInductances/transformers/magnets manufactureCleaning using toolsInductorEngineering

The invention provides an automatic powder brushing and border cutting device of a chip inductor, and belongs to the technical field of chip inductor molding equipment. The device comprises a box body, a controller, a powder brushing mechanism and a border cutting mechanism, wherein the device is characterized in that the powder brushing mechanism is fixed at the right side of the upper end of the box body and comprises a first horizontal guide rail; a first conveyor belt is arranged in a groove of the first horizontal guide rail; two clamping plates are symmetrically arranged at two sides of the upper end of the first horizontal guide rail; a vertical air cylinder is arranged at the lower part of each clamping plate; a powder brushing rack is arranged at the right ends of the clamping plates; a first induction lamp is arranged at the right end of the powder brushing rack; a horizontal air cylinder is arranged at the rear part of the powder brushing rack; a second conveyor belt is arranged in a second horizontal guide rail of the border cutting mechanism, a third induction lamp is arranged at the right part of the second horizontal guide rail and pressure block control air cylinders are arranged at two sides of the second horizontal guide rail; and a cutter control air cylinder is arranged at the upper end of an upper support plate of the border cutting mechanism. The automatic powder brushing and border cutting device has the beneficial effects that the operation of the device is simple and automatic, the production cost is low, powder brushing and cutting are integrated, the cleaning effect is good, product positioning is accurate and the quality of a finished product is high.

Owner:JINING UNICHOKA ELECTRONICS CO LTD

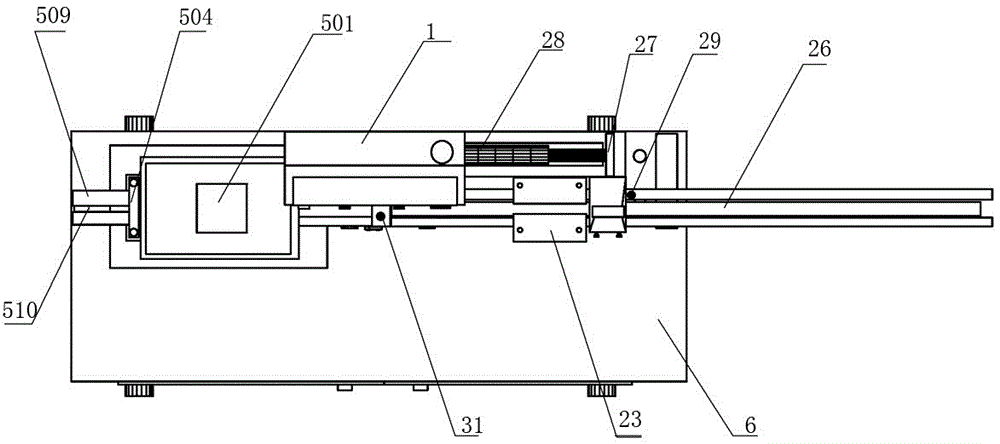

Solid wood cutting saw

InactiveCN104249390ALarge transmission forceStable transmission speedFeeding devicesCircular sawsSolid woodDrive motor

The invention relates to a solid wood cutting saw. The solid wood cutting saw comprises a machine base, a machine cover, conveying devices, a cutting saw body, a plurality of pressing rollers and a dust-sucking device, wherein the machine cover is fixedly arranged at the upper end of the middle part of the machine base; a workpiece inlet / outlet is formed between the lower part of each of the two transverse sides of the machine cover and the machine base; the conveying devices are transversely and coaxially arranged on the upper part in the machine base; the cutting saw body connected with a driving motor is arranged on the machine cover and the machine cover between the conveying devices; the pressing rollers are arranged in the machine cover on the two transverse sides of the cutting saw body at intervals; the dust-sucking device is arranged at the top of the machine cover above a cutting device. The solid wood cutting saw is simple in structure, scientific in design, uniform in pressure, high in processing efficiency and high in processing precision, the flatness of a product is improved, the labor intensity of workers is effectively reduced, and the production efficiency is improved.

Owner:天津福通木业有限公司

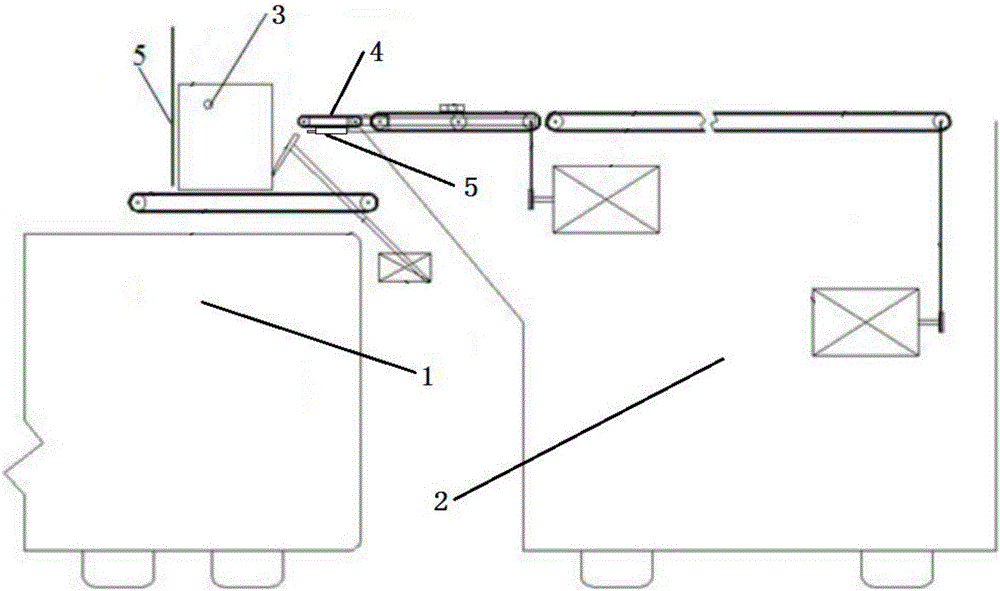

Product detecting machine and box pasting machine integrated forming device for printing

ActiveCN106042449AIncrease transfer rateIncrease speedPaper-makingBox making operationsButt jointMoulding device

The invention provides a product detecting machine and box pasting machine integrated forming device for printing. The product detecting machine and box pasting machine integrated forming device comprises a box pasting machine and a product detecting machine. A feeding groove is formed in the input end of the box pasting machine, and a conveying belt is arranged at the output end of the product detecting machine. The feeding groove is in butt joint with the conveying belt, an upper opening of the feeding groove is located in the front end of the conveying belt, and the horizontal height of the upper opening of the feeding groove is lower than the conveying belt. An air spraying device is arranged at the bottom of the conveying belt. Forward pushing force is provided for falling paper through airflow of spraying holes, it is guaranteed that the front end of the paper is ejected on a front end baffle of the feeding groove of the box pasting machine, and the problems that the paper is staggered and arranged disorderly are solved. Meanwhile, due to the fact that in the paper floating process, the forward pushing force is exerted on the paper, the conveying rate is increased, and the overall vehicle speed of the device is improved by about 3%. The device is simple, convenient to operate and high in practicability.

Owner:山东鲁信天一印务有限公司

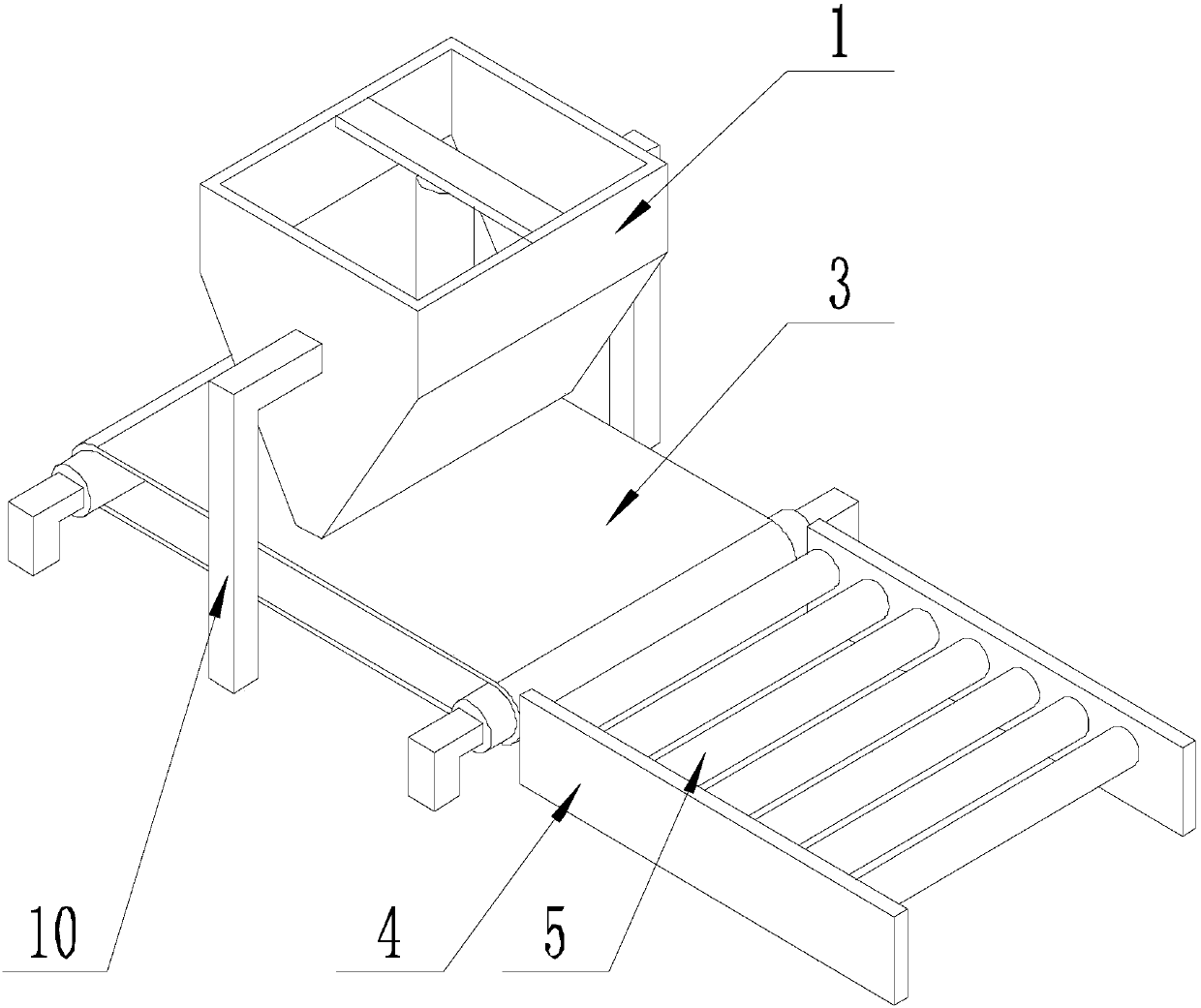

Cement mortar feeding device for tile sticking

InactiveCN107558703ATransmission speed is stableAccelerateBuilding constructionsAdhesive cementCement mortar

The invention discloses a cement mortar feeding device for sticking bricks, which comprises a hopper, a conveyor belt is arranged under the hopper, and a supporting device is arranged at the discharge end of the conveyor belt, the supporting device includes two fixing plates, and the fixing The plates are all parallel to the conveying direction of the conveyor belt, and several support rods are arranged between the fixed plates. Through the present invention, the speed of tile grouting is improved, and because the transmission speed of the conveyor belt is stable, the cement mortar can evenly fall on the back of the tile, avoiding the fact that there is no cement mortar in some parts between the back of some tiles and the corresponding wall or ground, or Excessive application of cement mortar will cause the cement mortar to squeeze out from the joints of the bricks when the bricks are glued.

Owner:蒋丽萍

Horizontal solid wood board slicing sawing machine

InactiveCN104249393ALarge transmission forceStable transmission speedSawing apparatusVeneer manufactureSolid woodEngineering

The invention relates to a horizontal solid wood board slicing sawing machine, which comprises a stand, a hood, a dust collection device, a pipeline, conveying devices and a cutting device, wherein the hood is fixedly arranged at the upper end of the middle part of the stand; the conveying devices are transversely and coaxially arranged on the inner upper part of the stand; the cutting device is arranged on the hood and the stand between the conveying devices, is connected with a driving device, and is structured in a way that a plurality of blades are fixedly arranged in a cutter frame at an equal interval; a plurality of pressure rollers are arranged at intervals in the hood on the two sides of the cutting device; a dust hood is arranged at the top of the hood above the cutting device; the dust collection device is connected to and arranged at the upper end of the dust hood; the pipeline is connected to the dust collection device. The horizontal solid wood board slicing sawing machine is simple in structure, scientific in design, uniform in pressure and high in machining efficiency and machining accuracy, the smoothness of a product is improved, the labor intensity of a worker is effectively reduced, and the production efficiency is improved.

Owner:TIANJIN KAIXIN WOOD IND

Planar object screening and discharging device

PendingCN108557439AEasy to operateSolve efficiency problemsPackagingConveyor partsTransmission beltButt joint

The invention relates to a planar object screening and discharging device. The device includes a detection conveyor belt, a swing screening conveyor belt is in butt joint with the front end of the detection conveyor belt, a reject screening conveyor belt is in butt joint with the front end of the swing screening conveyor belt, a Y-axis conveyor belt is arranged below the front end of the reject screening conveyor belt, an X-axis module is arranged below the Y-axis conveyor belt, and a tray conveyor belt and a material pulling device matched with the tray conveyor belt for use are arranged on one side of the Y-axis conveyor belt; a stacking device is arranged on the other side, and reject screening panel trays are vertically arrayed on the tray conveyor belt; a good product screening conveyor belt is arranged below the part, matched with the swing screening conveyor belt, of the reject screening conveyor belt, and a panel packing machine is arranged below the good product screening conveyor belt; the portion, close to the detection conveyor belt, of the swing screening conveyor belt is provided with a rotating shaft, the swing screening conveyor belt can rotate at a certain angle around the rotating shaft through a driving device to achieve switching between a reject screening work position and a good product screening work position, and therefore screening of rejects and good products of detected panels is achieved. The planar object screening and discharging device has the advantages of automatic flow, precise positioning, high work efficiency, a low maintenance cost and the like.

Owner:杭州智谷精工有限公司

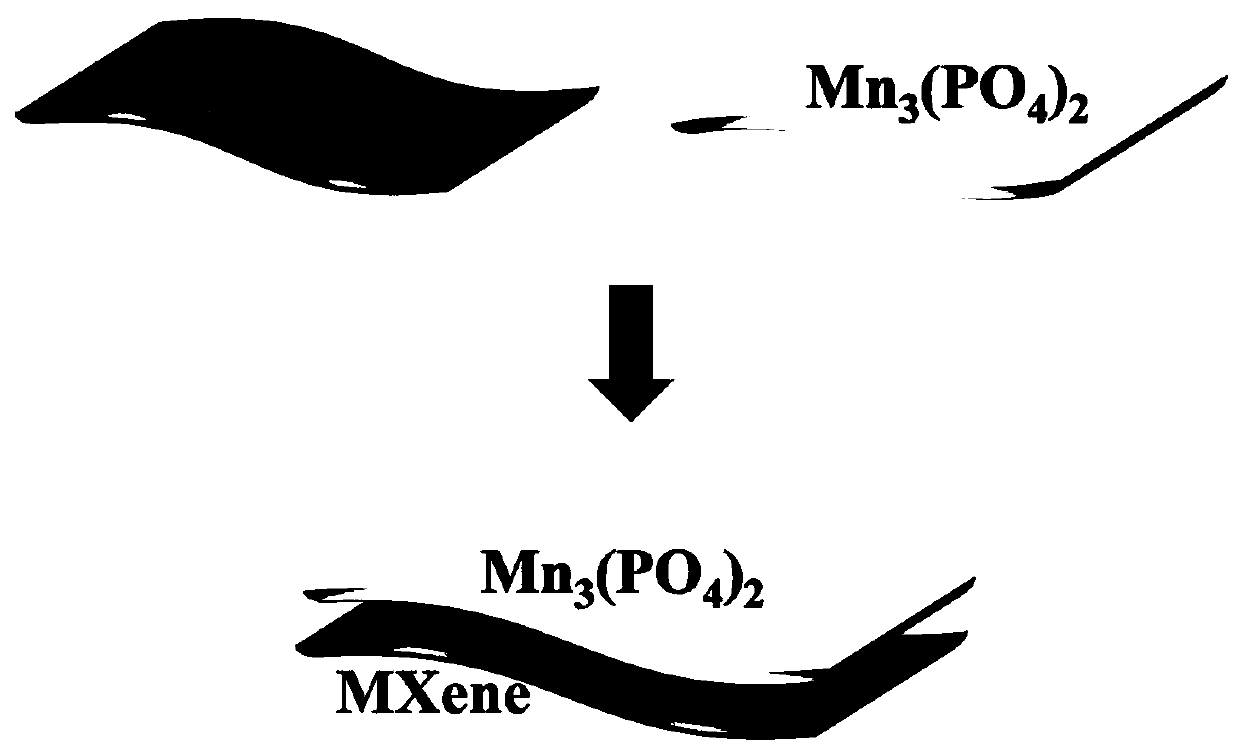

MXene/ manganese phosphate composite material, and preparation method and application thereof

PendingCN109900756AHigh electron transfer efficiencyStable transmission speedMaterial electrochemical variablesPhosphoric acidElectron transmission

The invention discloses an MXene / manganese phosphate composite material, and a preparation method and application thereof. The composite material is prepared by mixing flake-like MXene and flake-likemanganese phosphate, wherein the flake-like MXene and the flake-like manganese phosphate are both of a nanoscale size, and the charge mass ratio of the flake-like MXene to the flake-like manganese phosphate is 1:9.5-10.5. The preparation of the MXene / manganese phosphate composite material comprises the following steps that: after the flake-like MXene and the flake-like manganese phosphate are independently added into water, dispersing and drying to obtain the MXene / manganese phosphate composite material. The above prepared MXene / manganese phosphate composite material is applied to superoxide anion detection. The composite material disclosed by the invention has more active loci, both has excellent electron transmission efficiency and stable transmission speed, and is especially suitable for detecting superoxide anions.

Owner:SUZHOU UNIV OF SCI & TECH

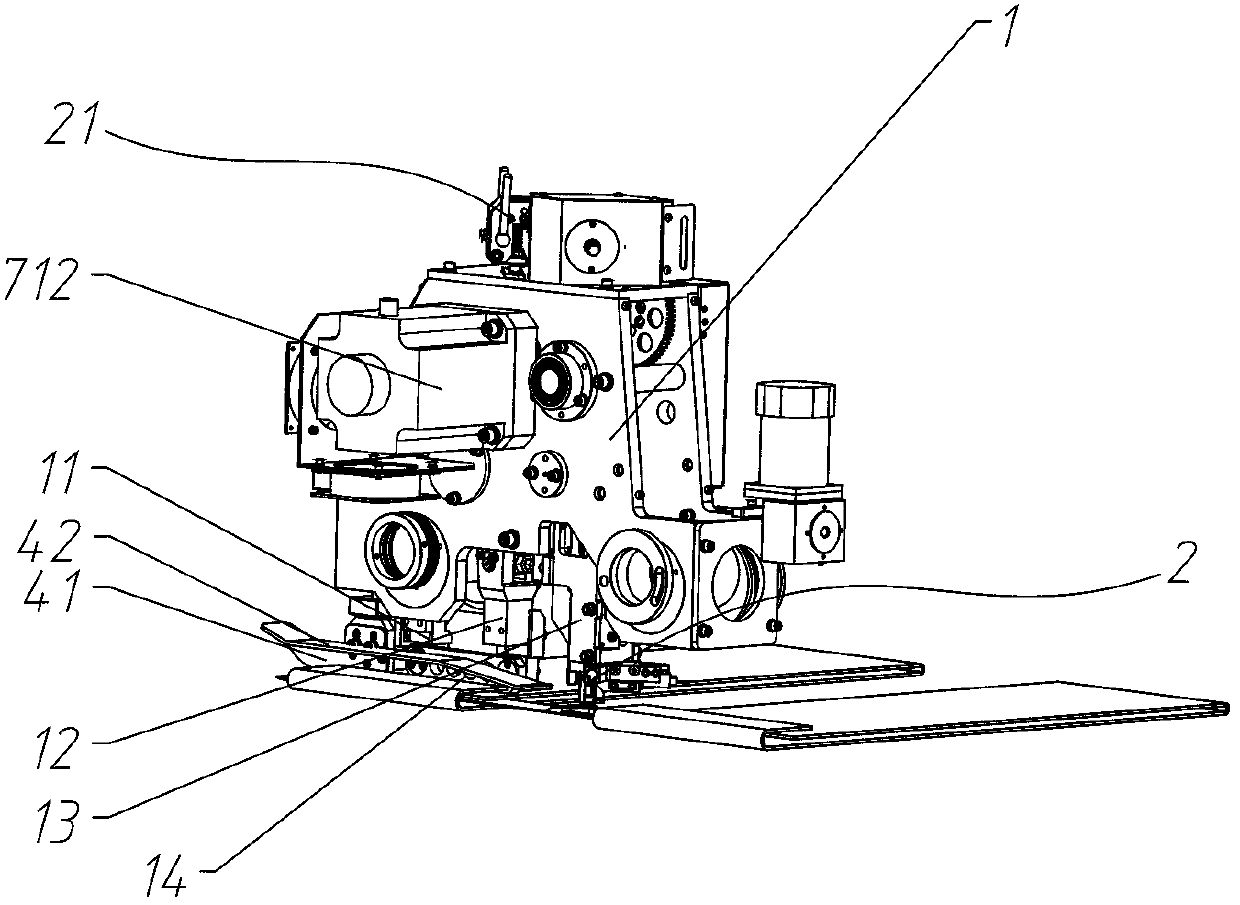

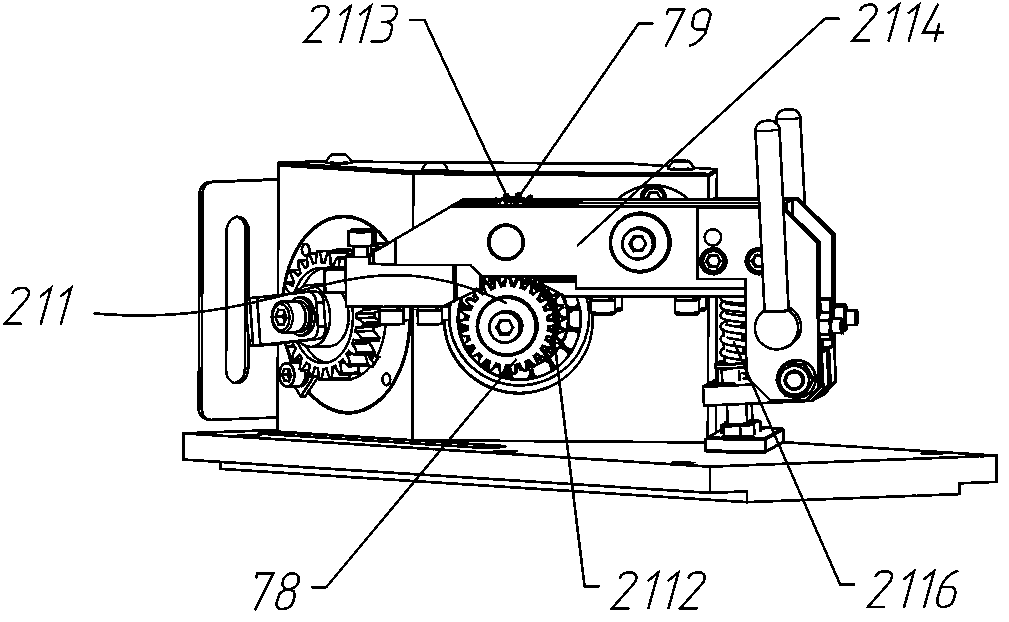

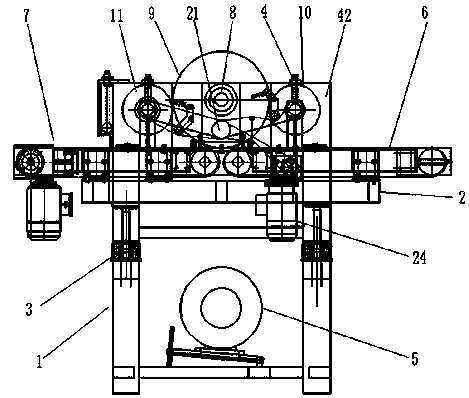

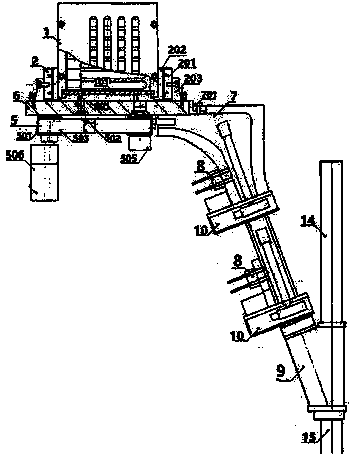

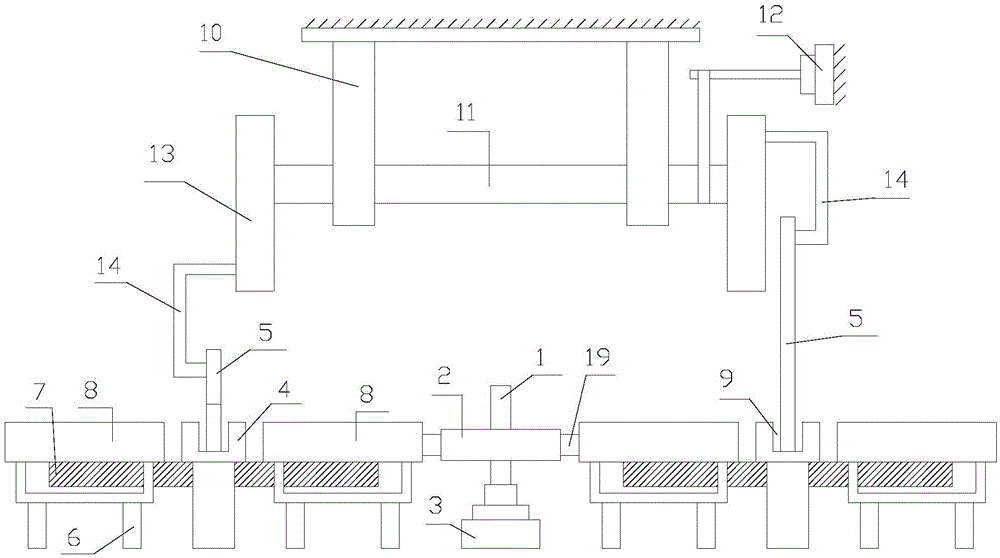

Synchronous movement mechanism for nailing and nailing machine

The invention belongs to the technical field of box nailing, and provides a synchronous movement mechanism for nailing and a nailing machine. The synchronous movement mechanism for nailing comprises arack, a first swing frame, a second swing frame, a first installation frame, a second installation frame and a first connecting frame, wherein the upper side of the first swing frame is rotatably arranged on the rack; the upper side of the second swing frame is rotatably arranged on the rack; the upper side of the first installation frame is rotatably arranged on the rack; the first installationframe is used for installing a nailing device; two sides of the second installation frame are hinged to the lower side of the first swing frame and the lower side of the second swing frame; the secondinstallation frame is used for installing a nailing base; one side of the first connecting frame is hinged to the middle of the second swing frame; and the other side of the first connecting frame ishinged to the first installation frame. Through the technical scheme, the problem that in the prior art, during nailing, the relative reset effect of the nailing device and a paperboard is poor is solved.

Owner:TANGSHAN JIAJIE PACKAGE MACHINERY MFG

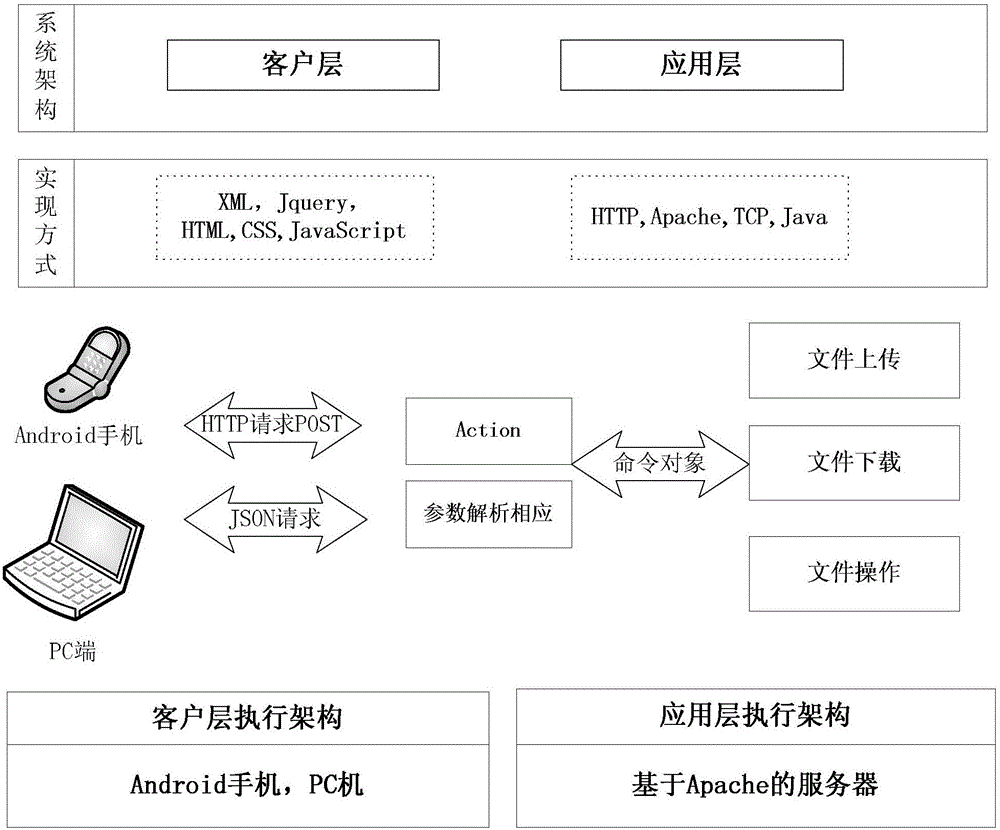

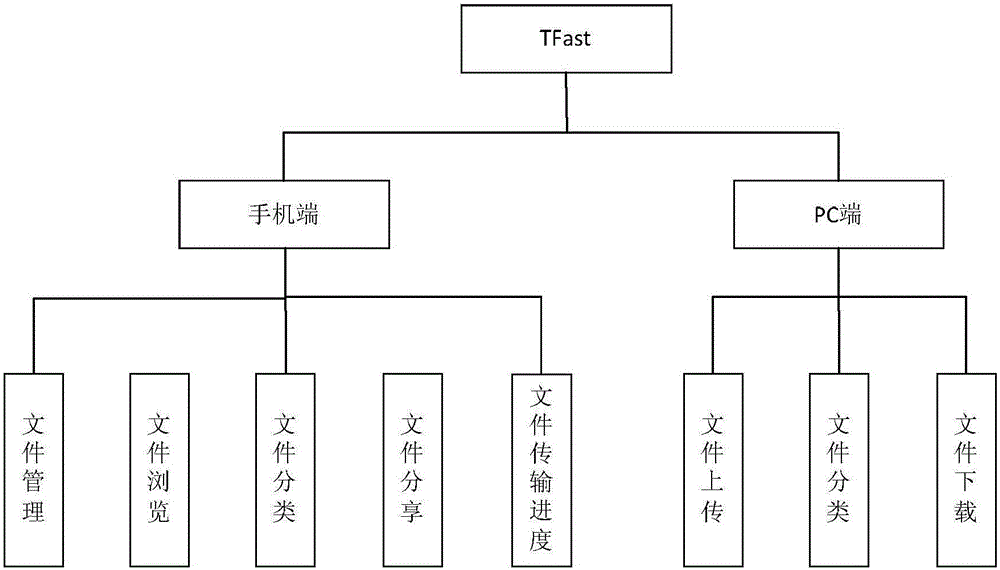

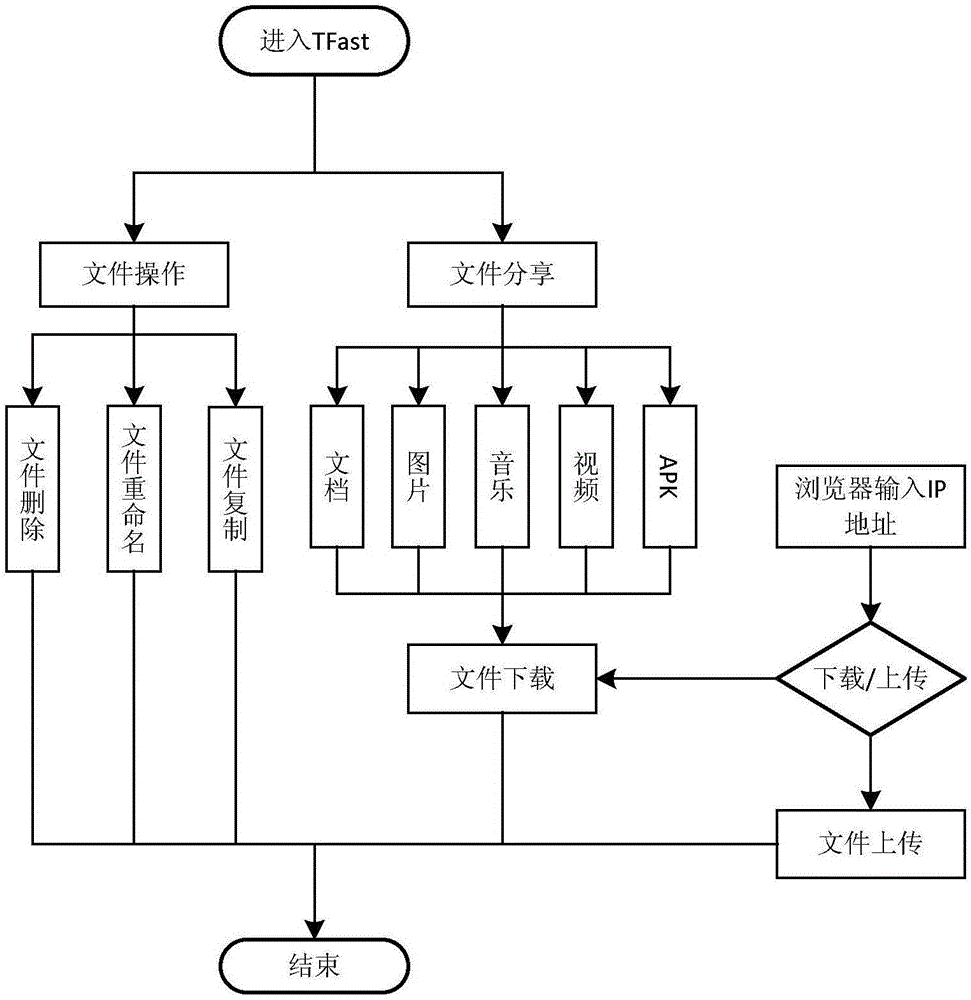

Apache server based cross-platform file transmission APP software system

InactiveCN106230968AImprove experienceImprove data securityTransmissionFile transmissionSoftware system

The invention disclose an Apache server based cross-platform file transmission APP software system, and relates to the Apache server based cross-platform file transmission technology. The cross-platform file transmission rate and stability are improved. A small server is established on a mobile phone through the adoption of an interface provided by the Apache server, thereby constructing a local area network with a router or other mobile phone terminals, the fast transmission between the mobile phone side and the PC side / between the mobile phone sides is realized. The file fast transmission between the terminals is realized in combination with the advantage of fast wireless local area network speed under the condition of constructing the Apache server. The file is uploaded or downloaded through the adoption of the thread and the HTTP protocol in task transmission, the unfinished part can be continuously uploaded or downloaded in the network failure. The system disclosed by the invention is suitable for a cross-platform file transmission occasion.

Owner:杨玲

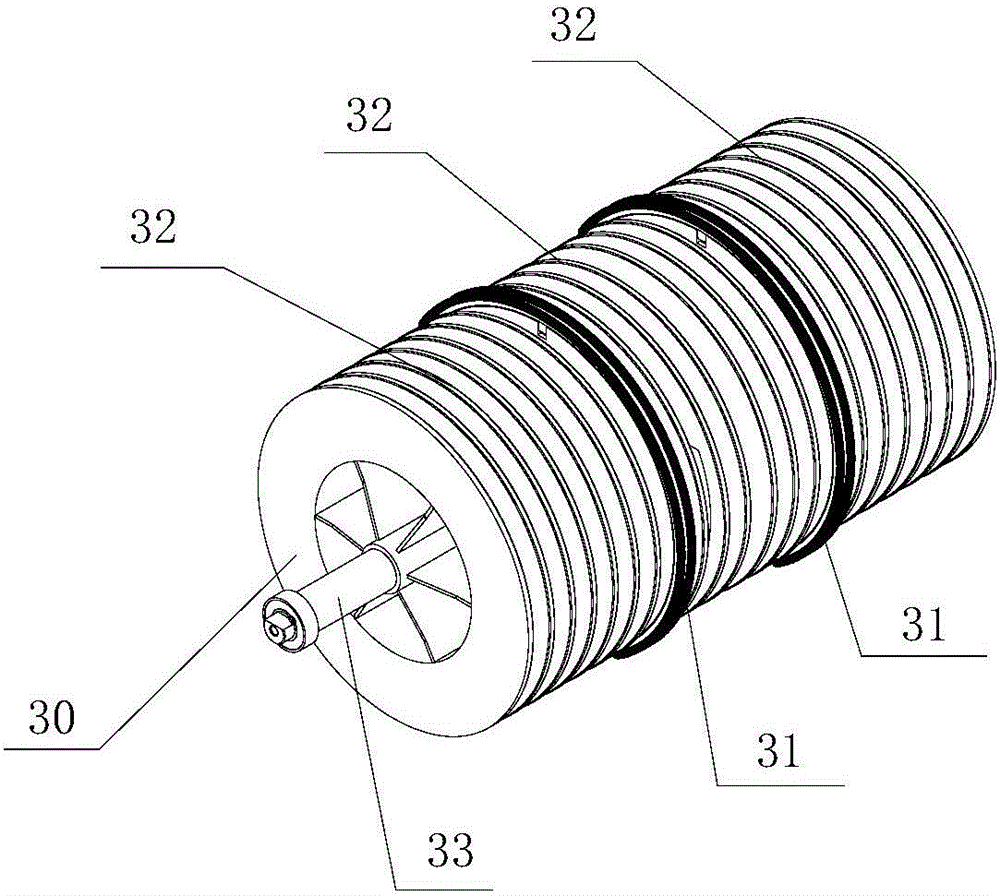

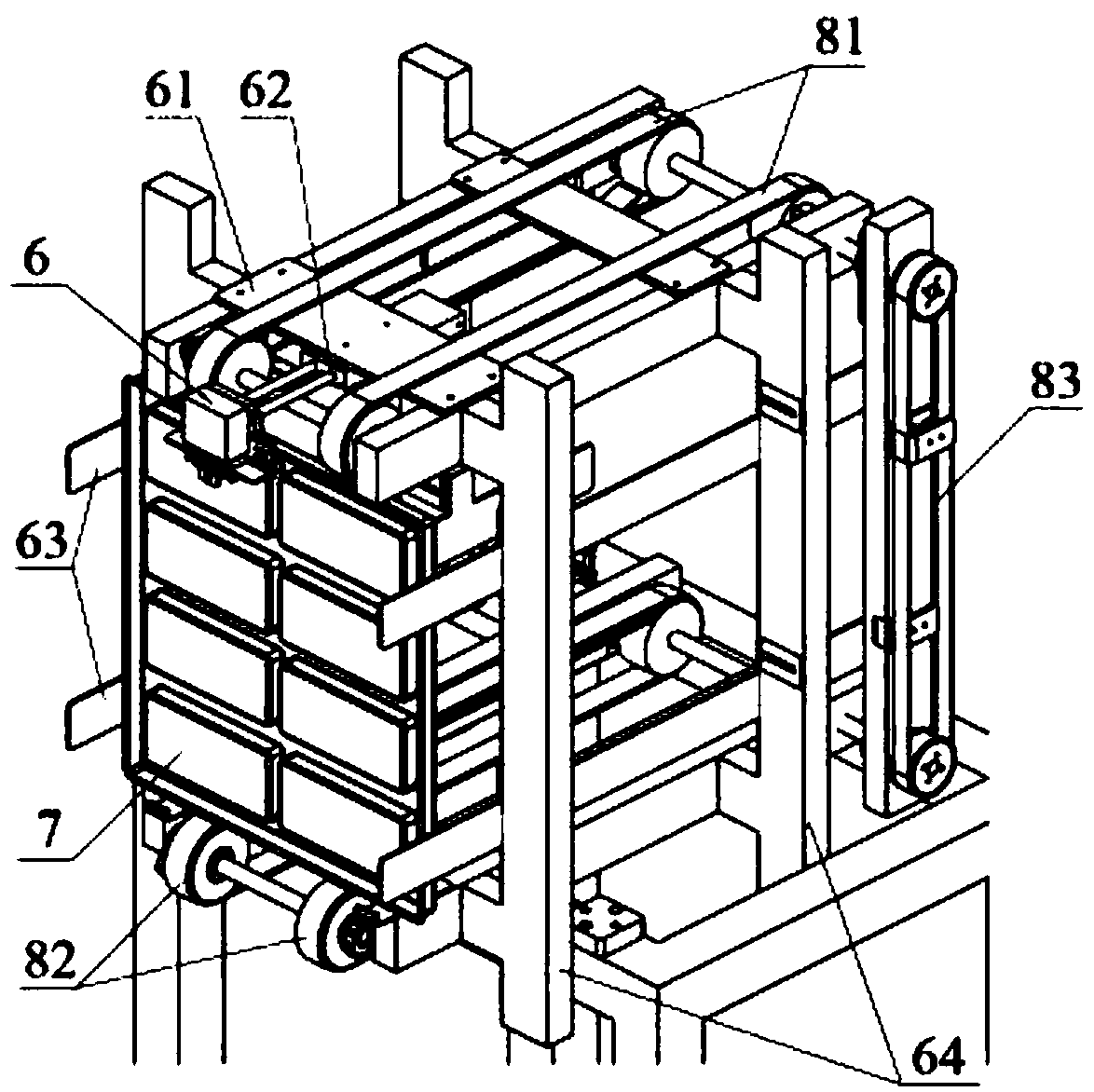

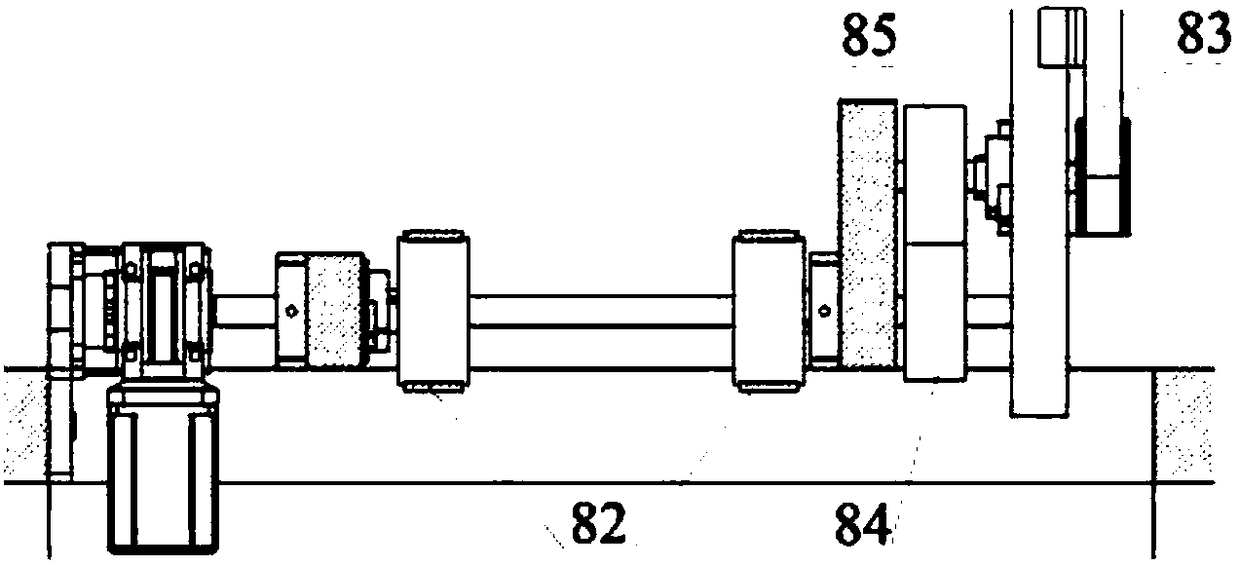

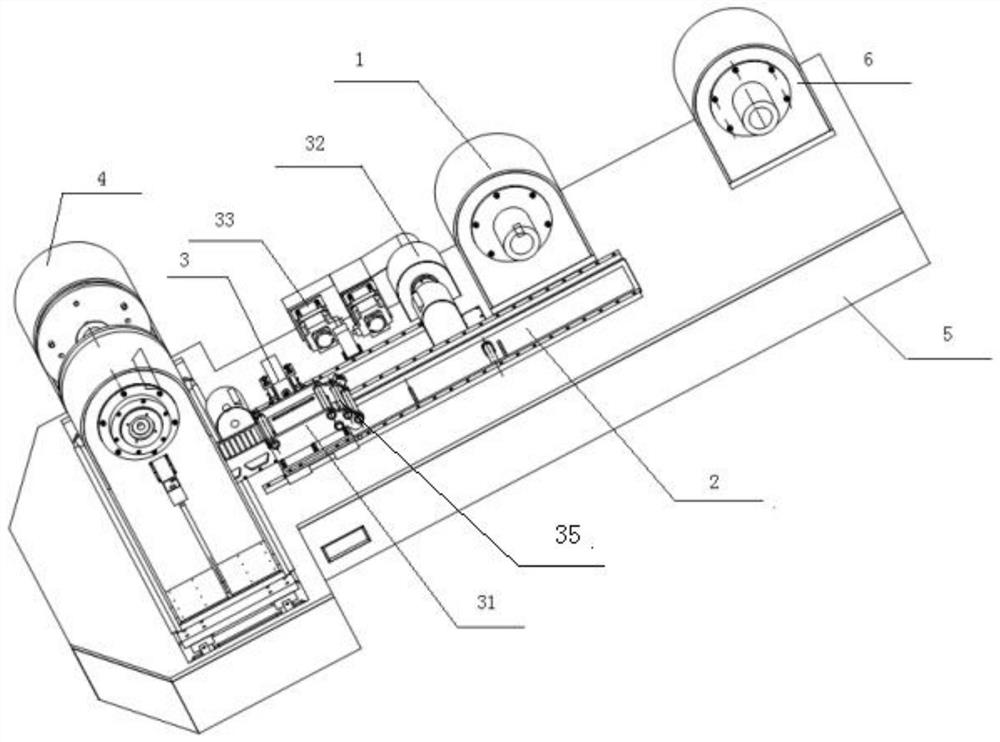

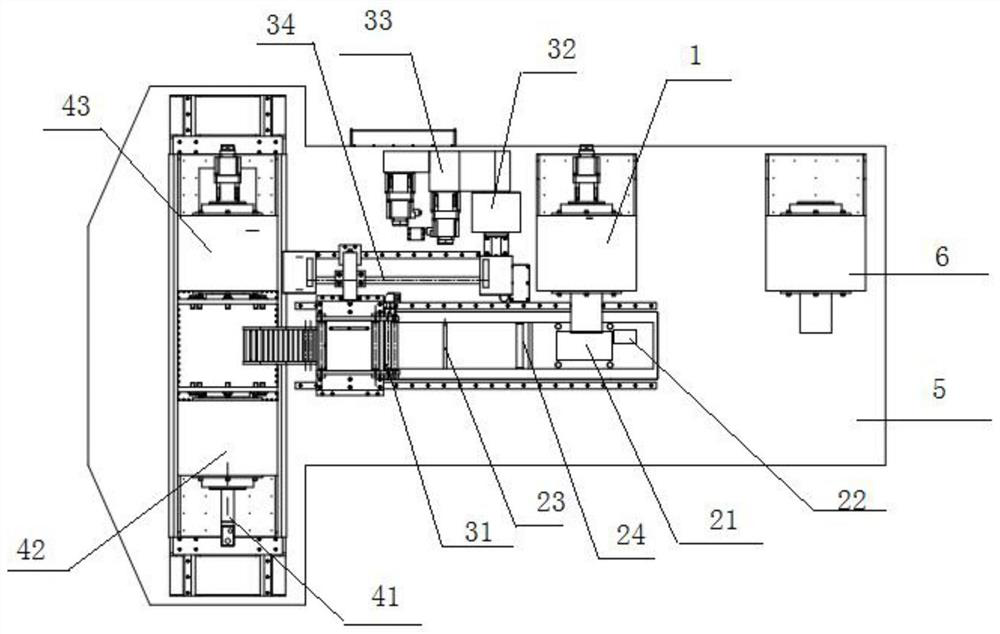

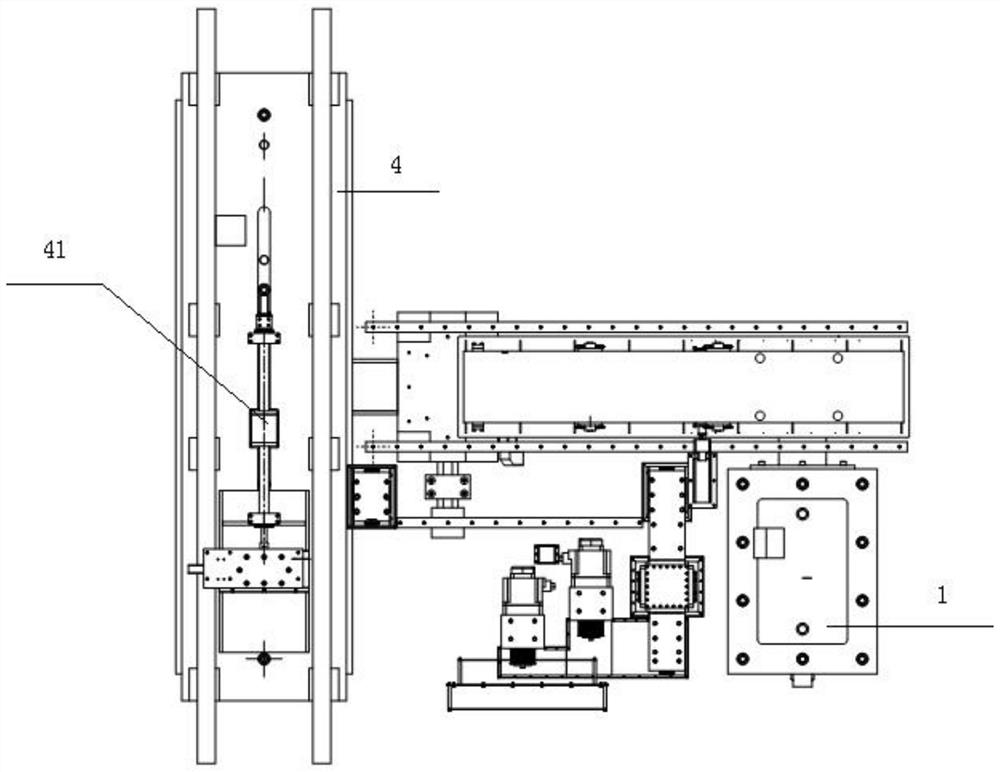

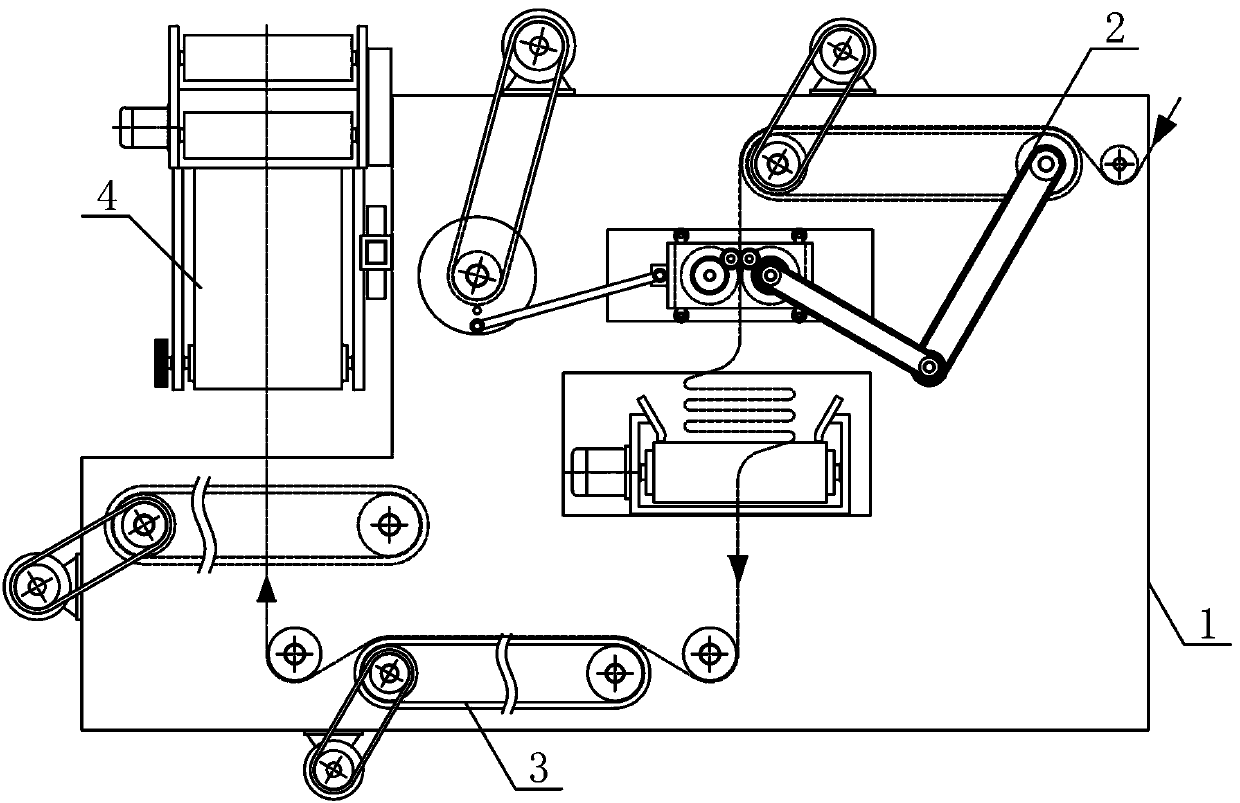

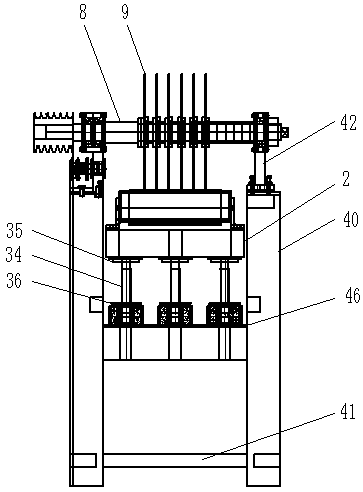

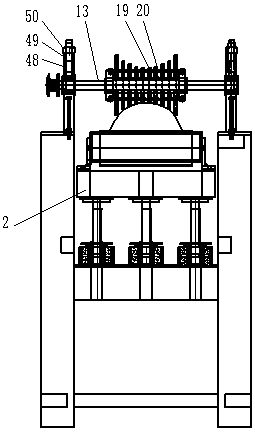

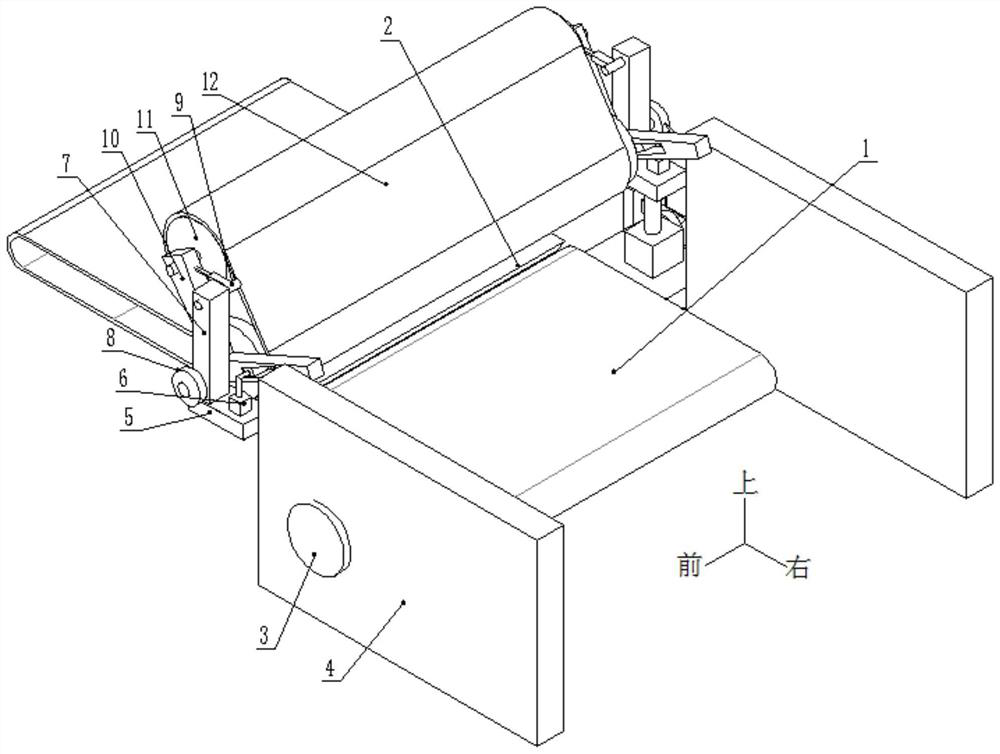

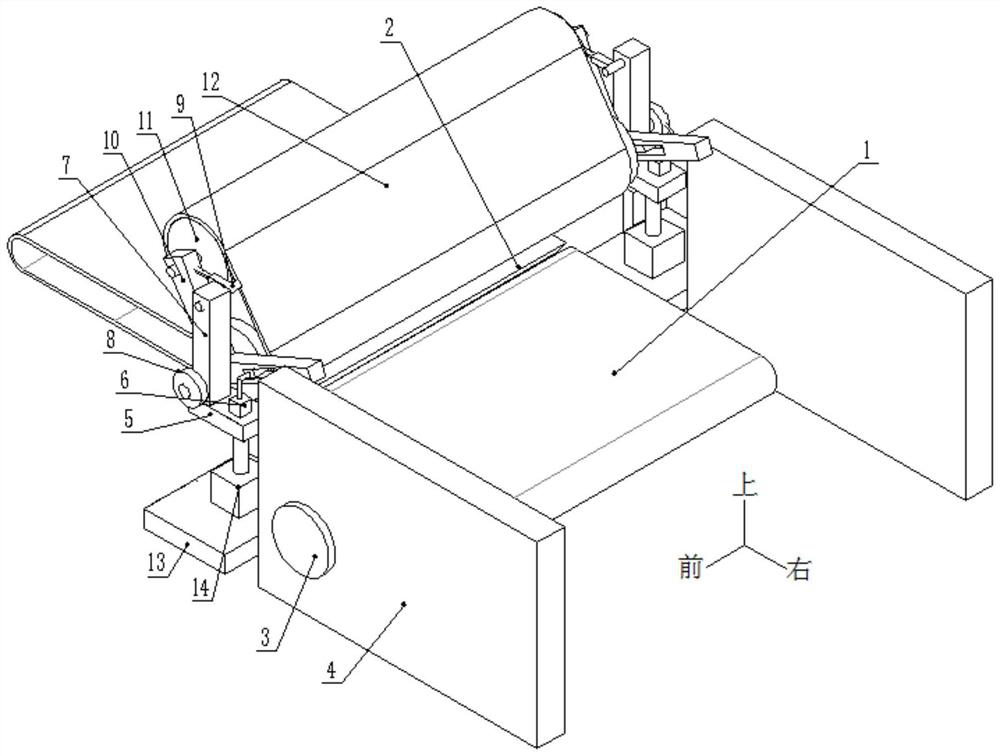

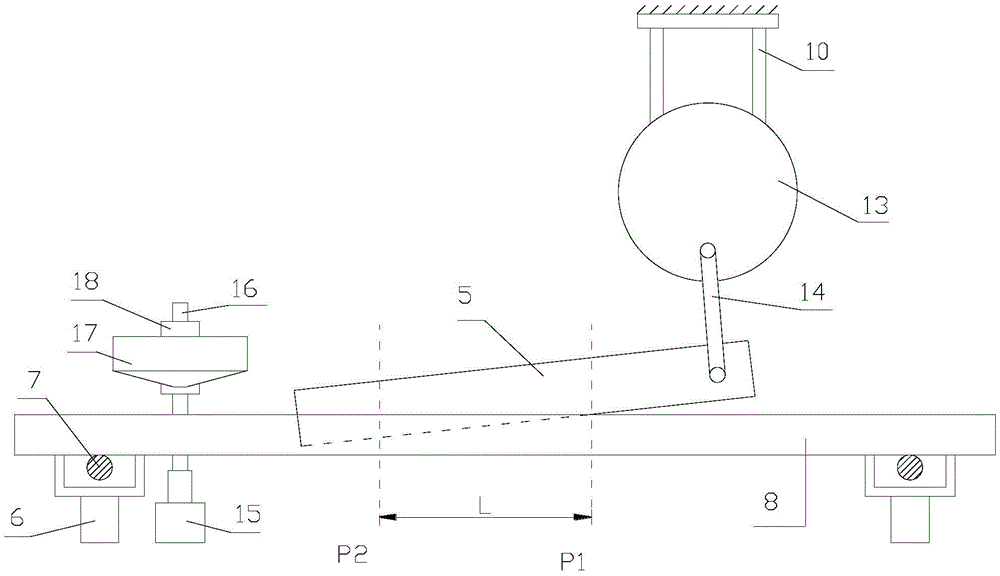

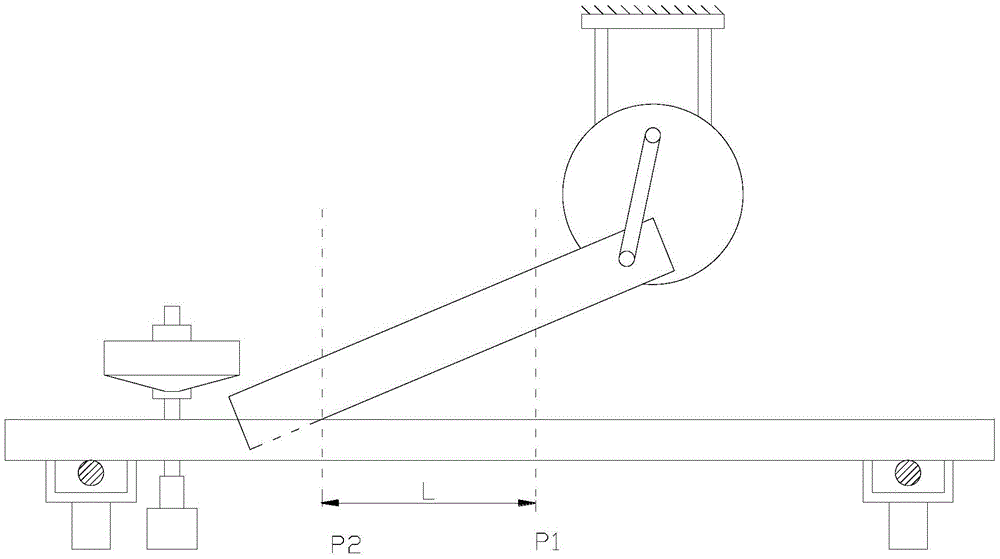

Three-dimensional winding forming device for amorphous strips of amorphous three-dimensional wound core transformer

ActiveCN111627688AAvoid breakingStable transmission speedInductances/transformers/magnets manufactureMaterial storageElectrical and Electronics engineering

The invention discloses a three-dimensional winding forming device for amorphous strips of an amorphous three-dimensional wound core transformer, and relates to the technical field of production and processing of amorphous strips. An adaptive transmission material storage unit can place the amorphous strips discharged by a discharging unit freely without constraint, the strips are avoided from break due to failure in high-frequency rapid discharging speed conversion of the discharging unit when a constant-tension relaxation control unit rapidly switches the spatial position of the wound stripsin the winding state of a three-dimensional winding unit, the constant-tension relaxation control unit can ensure that the conveying speed of the strips and the tangential strip winding angle are kept stable in the process that the amorphous strips are wound in a three-dimensional way in a rectangular single-frame inner tyre, and inconsistent fitting between layers of the strips or even crack ofthe strips due to non-uniform bearing of the wound strips when the winding speed and angle are changed is also avoided. An axial movement mechanism of the three-dimensional winding unit drives a driving rotation mechanism and a driven support mechanism to move synchronously and further to ensure stable three-dimensional winding of the amorphous strips.

Owner:JIHUA LAB

Continuous conveying and stacking device for wool spun gauze

PendingCN110129925AAccurate and smooth panning motionEfficient width adjustmentCarding machinesRotating discTextile processing

The invention discloses a continuous conveying and stacking device for a wool spun gauze and belongs to the field of textile processing machinery. A first conveying belt is horizontally arranged on the upper side of a wool spinning guide support, a swing connecting rod is arranged between a rotating disc and a swing support, a second conveying belt is horizontally arranged on the upper side of a bearing conveying support, a front transition guide roll and a rear transition guide roll are symmetrically arranged on a wool spinning guide support on two sides of a third conveying belt, a rotatingsupport is arranged on a reversing conveying support on the lower side of a third reversing rotating roll, a translation guide rod is horizontally arranged on one side of the rotating support, a reciprocating driving mechanism is arranged on the wool spinning guide support on one side of the transition guide rod, and a fourth conveying belt is horizontally arranged below the rotating support. Thedevice is reasonable in structure design, can stably and conveniently perform continuous and smooth stacking processing on the sparse wool spun gauze in the conveying process to form a dense wool spungauze, is high in automation degree and meets the processing use demands.

Owner:浙江秋黎服饰有限公司

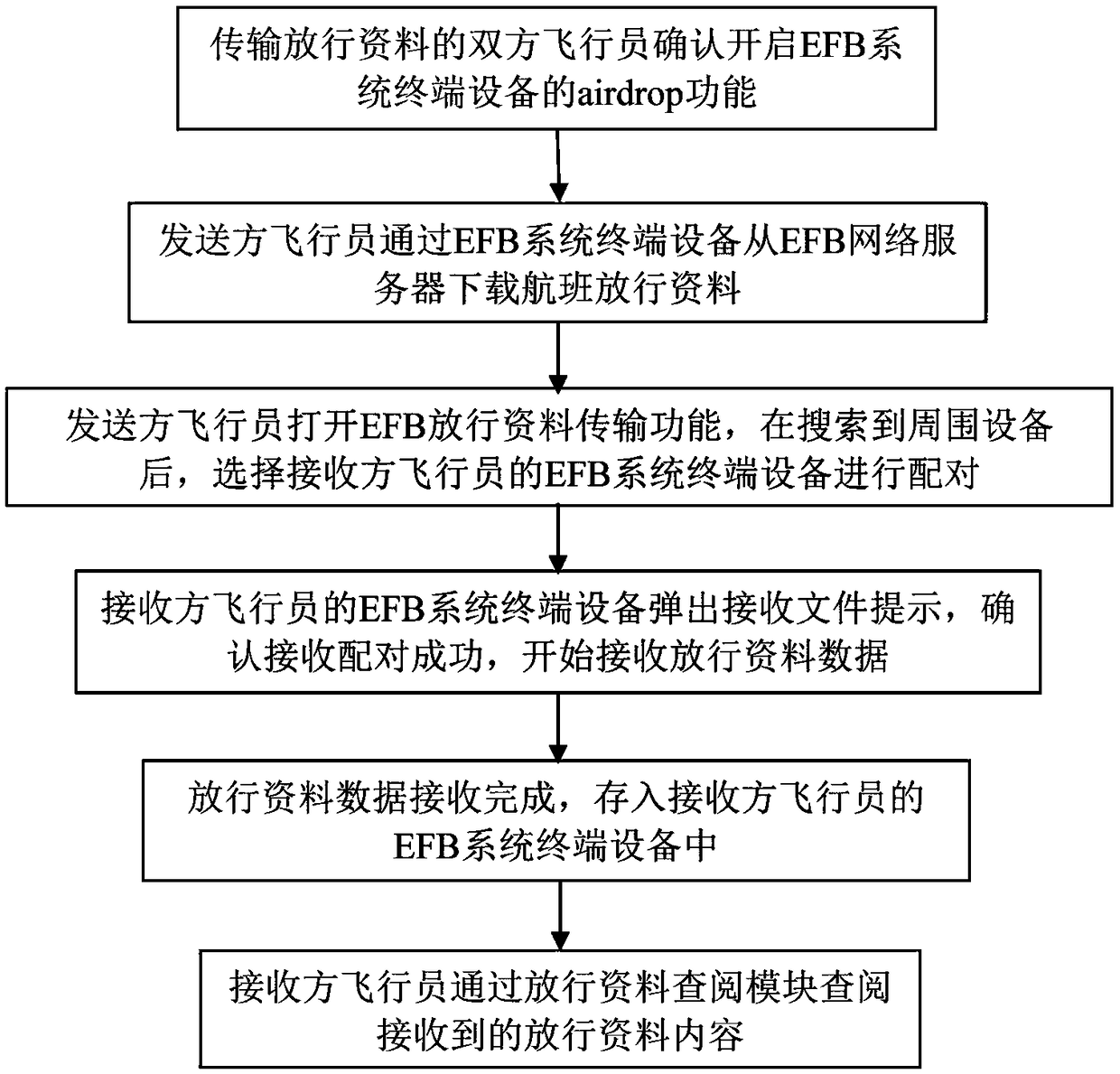

Method for transmitting release data between terminals of EFB system based on airdrop function

InactiveCN108769120ARelieve pressureFast dataTransmissionShort range communication serviceData synchronizationTraffic capacity

The invention discloses a method for transmitting release data between terminals of an EFB system based on an airdrop function, which mainly uses the airdrop function of an EFB terminal device such asan iPad to transmit the release data in an electronic flight bag (EFB) between pilots. This function is mainly applied to the electronic flight package software EFB system in civil aviation flight. The release data may be shared with other pilots of the same unit after being downloaded by a person in a unit, thereby achieving the purpose of quick data synchronization and traffic saving, avoidingall crew members from downloading data from the server, saving traffic, and reducing the server pressure. The release data between crew members may be synchronized without relying on the network, which saves download traffic and reduces flight preparation time for international flights. The invention is fast in transmission speed, stable, and small in interference, and the release data may be gotthrough this method for the situation that the release data cannot be opened or downloaded for some reasons, thereby reducing the risk of flight.

Owner:中航材导航技术(北京)有限公司

Cutting device for dairy product

InactiveCN108705582AEasy to put inConsistent cutting size and shapeMetal working apparatusIdler-wheelConveyor belt

The invention discloses a cutting device for a dairy product. The cutting device comprises a trolley frame, idler wheels, a bottom plate, a servo motor, a motor mounting base, a driving belt wheel, abelt, a supporting plate, an auxiliary belt wheel, a rotating shaft, a connecting rod, a locker, a storage table, a supporting rod, a transition plate, a conveyor belt, conveying wheels, a grooved wheel, a rotating plate, a fixed rod, a rectangular groove, a top plate, a fixed block, a movable block, a limit box, a baffle, a sliding rod and a push rod. The trolley frame is arranged above the bottom plate, the motor mounting base is arranged at the middle position of the top of the bottom plate, the servo motor is installed on the motor mounting base, the driving belt wheel is arranged on one side of the servo motor, and the output end of the servo motor is in transmission connection with the driving belt wheel. The supporting plate is arranged at the position, on one side of the servo motor, of the bottom plate. The supporting plate is perpendicular to the bottom plate. The conveying wheels are arranged at the two ends of the top of the trolley frame, and the conveyor belt is arrangedbetween the two conveying wheels. The rotating shaft is arranged at the position, close to the bottom, of the supporting plate.

Owner:刘黄莹

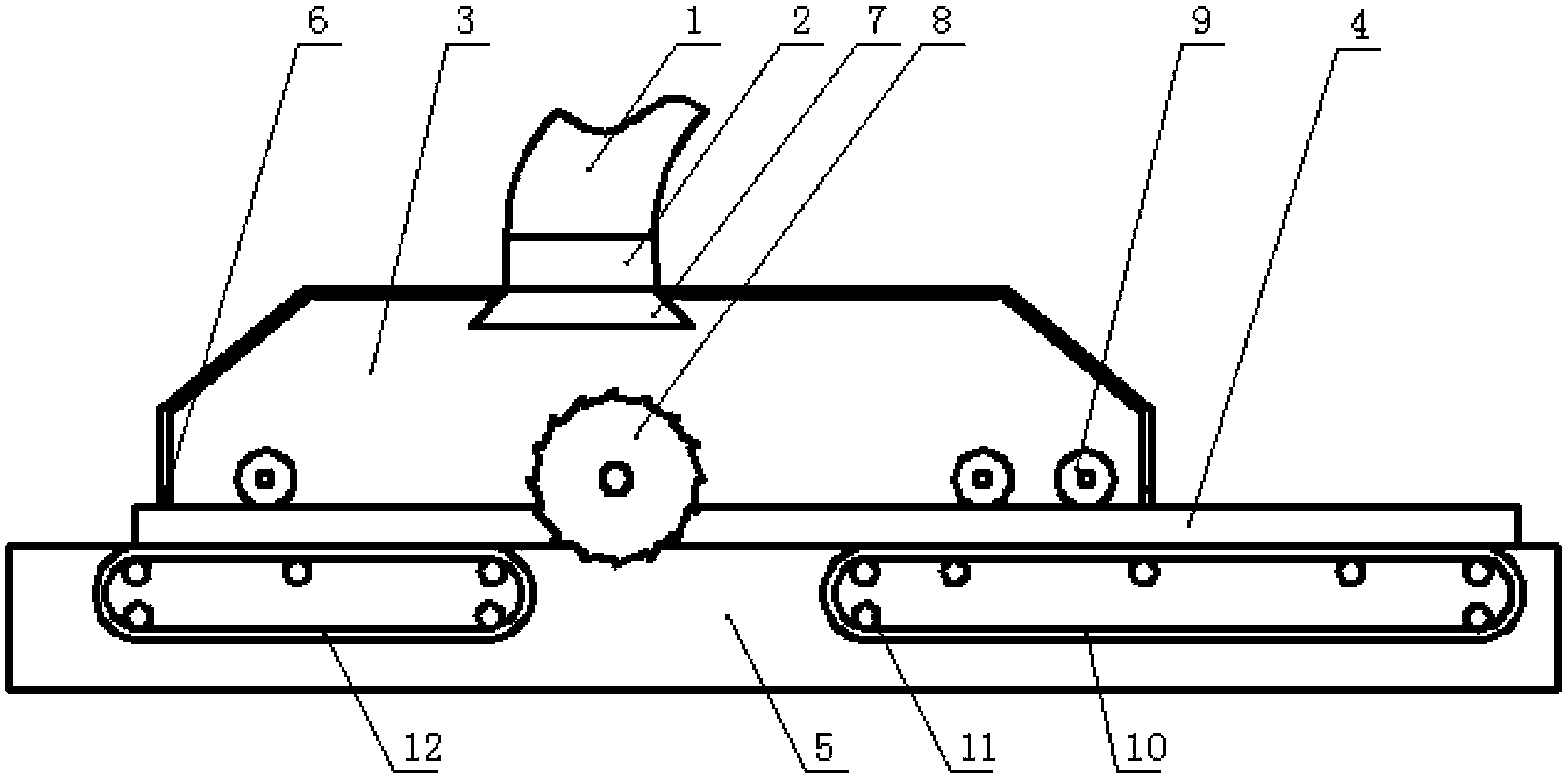

Woodworking machine tool

InactiveCN108705610AImprove cutting efficiencyNovel structureGuide fencesFeeding devicesSprocketEngineering

The invention relates to the technical field of woodworking machinery, in particular to a woodworking machine tool which comprises a rack, a working table, a wood conveying mechanism, a working tablelifting mechanism, a saw-cutting mechanism, a saw-cutting transmission mechanism, a pressure roller mechanism, a pressing and adjusting mechanism and a pressure roller transmission mechanism. A feeding conveyor and a discharging conveyor are arranged on the working table; a saw-cutting shaft is arranged above the middle between the feeding conveyor and the discharging conveyor; saw blades are arranged on the saw-cutting shaft at intervals; pressing columns are arranged on a discharging pressure roller or a feeding pressure roller at intervals; the lengths of the pressing columns are graduallyincreased from the middle of the discharging pressure roller or the feeding pressure roller; the discharging pressure roller and the feeding pressure roller are connected through a chain, a chain wheel and an output chain wheel on a pressure roller drive motor; and a lifting mechanism is arranged under the working table. The woodworking machine tool provided by the invention is low in production cost, high in levelling efficiency, free of damaging a conveyor belt, and capable of effectively limiting and saw-cutting woods with arched upper end surfaces, different axial heights and irregular radial arched surfaces.

Owner:王炳南

Cable insulation layer coating method

InactiveCN111968794ANot easy to eccentricEffective teleportation effectInsulating conductors/cablesInsulation layerElectric machinery

The invention discloses a cable insulation layer coating method, relating to the technical field of cladding machines. A conveying device, a coating device, a cooling device and a winding device are included, and the conveying device, the coating device, the cooling device and the winding device are all arranged on a workbench. A to-be-coated cable sequentially penetrates through the conveying device, the coating device, the cooling device, the conveying device and the winding device; the conveying device comprises a supporting frame, a conveying motor is fixedly connected to the outer side ofthe supporting frame, two rotating rollers are rotatably connected to the inner side of the supporting frame, and a gap between two electrorheological fluid bags can be controlled along with change of the diameter of a cable, so that the effective conveying effect can be achieved when different types of cables are wrapped. Moreover, the axes of the cables of different types are always located inthe center of a gap defined by the two electrorheological fluid bags, so that the cables are not prone to core shift in the conveying process, and the coating uniformity is high.

Owner:王成艳

Conveying belt type long strip-shaped food shearing mechanical device

InactiveCN108214632AFrequency stabilityCut length error is smallMetal working apparatusEngineeringMechanical engineering

The invention discloses a conveying belt type long strip-shaped food shearing mechanical device. The conveying belt type long strip-shaped food shearing mechanical device comprises a device main frame; a conveying belt is arranged at the middle part of the device main frame; the two sides of the front end of the device main frame are each detachably connected with a connecting leg; the top of eachconnecting leg is detachably connected with the side part of a vertical plate frame; a top plate frame is welded at the top of the vertical plate frame; the top of the top plate frame is detachably connected with a shearing cylinder; a piston rod of the shearing cylinder is matched with a double-side articulating base; the front part of the vertical plate frame is fixedly connected with a centershaft; the center shaft is rotationally matched with a front knife arm and a rear knife arm; the tops of the front knife arm and the rear knife arm are each provided with a connecting lug in a weldingmanner; and each connecting lug is connected with the double-side articulating base through a connecting rod. The conveying belt type long strip-shaped food shearing mechanical device is matched withthe conveying belt for use, can be used for continuously cutting long strip-shaped foods, uses less manpower, and is high in work efficiency, low in manufacturing cost and easy to popularize and use.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

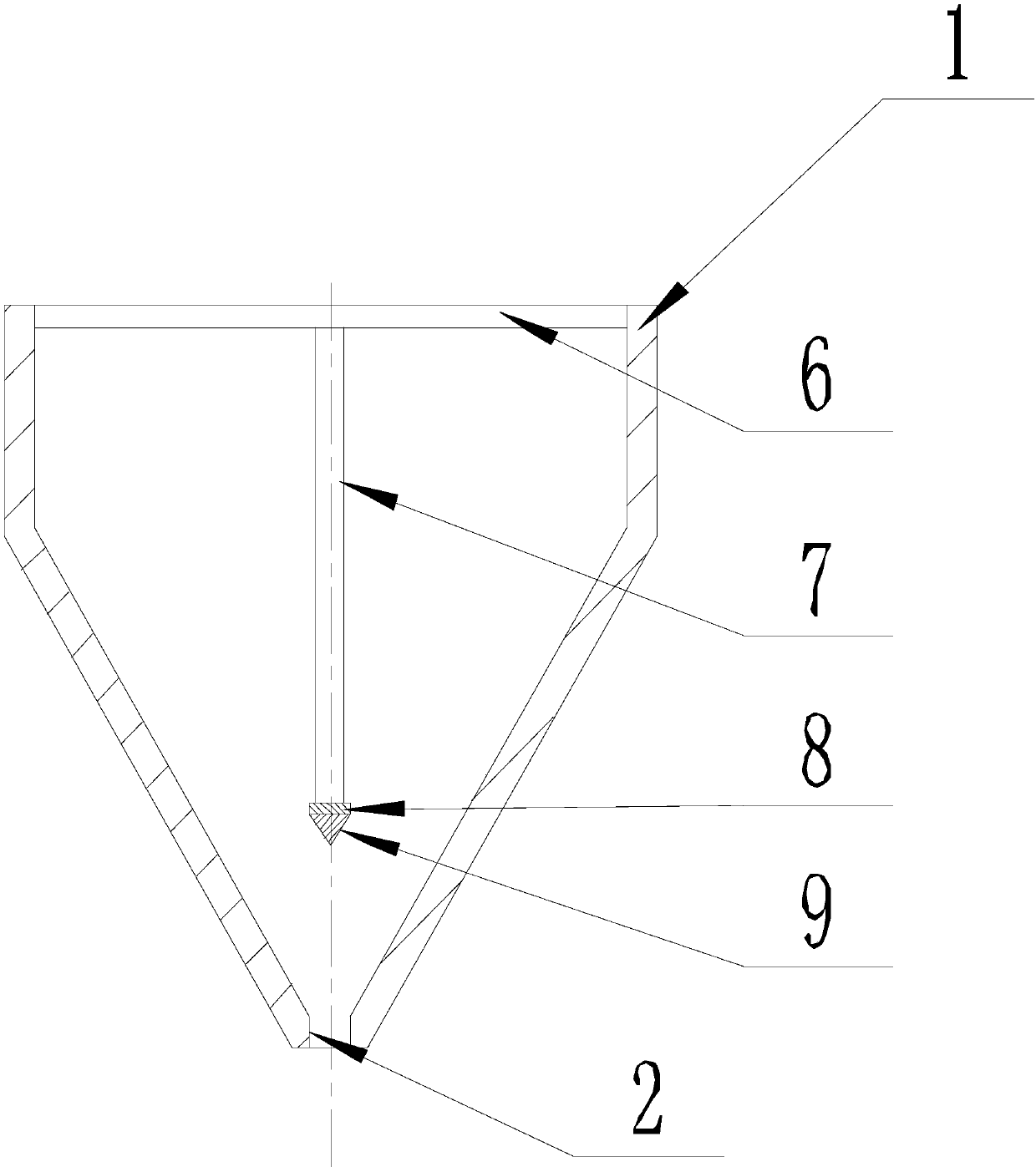

HT2518C full-intelligent medical sample sending station

InactiveCN110817438AEasy transferTransmission continuesConveyorsPositive pressureTransmission technology

The invention discloses an HT2518C full-intelligent medical sample sending station which is special sending equipment for medical test tubes. A sample bin of the equipment is designed in an insertingmode. 48 samples can be stored in the sample bin at a time, and intelligent sending can be realized only by directly placing the samples into the sample bin at a blood sampling point and then inserting the sample bin into a sample bin positioning base of the station. The sample bin is driven by a stepping motor, runs in steps, is automatically verified and has high positioning accuracy, a sample out-of-bin groove is arranged below the sample bin and provided with a sliding groove, a speed reducing motor drives a striking plate to strike the samples out of the bin groove to enter a special-shaped pipeline, sample sending is completed under the control of a double-pipeline sliding valve, a positive pressure suspension type transmission technology is adopted for system sending, and a laser sensor performs multi-point detection. The machine has the greatest advantage that operating time of operators can be saved for hospitals, and the equipment can send medical blood sample test tubes withreal high efficiency, high intelligence and high stability.

Owner:九江恒创源科技有限公司 +1

Outlet can-supporting device of pop-top can cleaning and drying machine

ActiveCN112141669ASolve the problem of prone to dumpingPrevent dumpingConveyorsConveyor partsDrive wheelTransmission belt

The invention provides an outlet can-supporting device of a pop-top can cleaning and drying machine. The device comprises a conveying mechanism, a transition plate and a power assembly, wherein the conveying mechanism is located in the cleaning and drying machine, and the two sides of the conveying mechanism are each provided with a righting mechanism. Each righting mechanism comprises a mountingplate, a first electric push rod, a vertical plate, a driving wheel, a first telescopic rod, a connecting frame, a driven wheel and a conveying belt, wherein the mounting plate is arranged on one sideof the conveying mechanism, the first electric push rod and the vertical plate are arranged on the mounting plate, the driving wheel and the first telescopic rod are mounted on the vertical plate, the connecting frame is mounted between the driving wheel and the vertical plate, one end of the connecting frame is movably connected with the movable end of the first electric push rod, the driven wheel is arranged at the other end of the connecting frame and connected with the driving wheel through the conveying belt, and the driven wheel is connected with the movable end of the first telescopicrod.

Owner:济南联合制罐有限公司

Metal plate cutting device for retractable door production

ActiveCN105665810AGuaranteed uptimeReduce noiseShearing machinesShearing machine accessoriesGear wheelEngineering

The invention discloses a metal plate cutting device for retractable door production. The device comprises a support rod, a driving gear, a first power unit, two conveying mechanisms and a driving mechanism; the support rod is arranged in the vertical direction; the driving gear is mounted on the support rod, and the axis of the driving gear is overlapped with the axis of the support rod; the first power unit drives the driving gear to rotate; the two conveying mechanisms are distributed on two sides of the driving gear; the conveying mechanisms include support tables, cutters, support frames, lead screws and two moving plates; accommodating tanks are formed in the support tables; first ends of the cutters are hinged to the accommodating tanks; projections of the cutters on the support tables are positioned in the accommodating tanks; the driving mechanism drives the cutters to enter or deviate from the accommodating tanks; and the cutting directions of the cutters in the two conveying mechanisms are opposite. The device is simple in structure and convenient for use.

Owner:天津智投技术成果转化有限公司

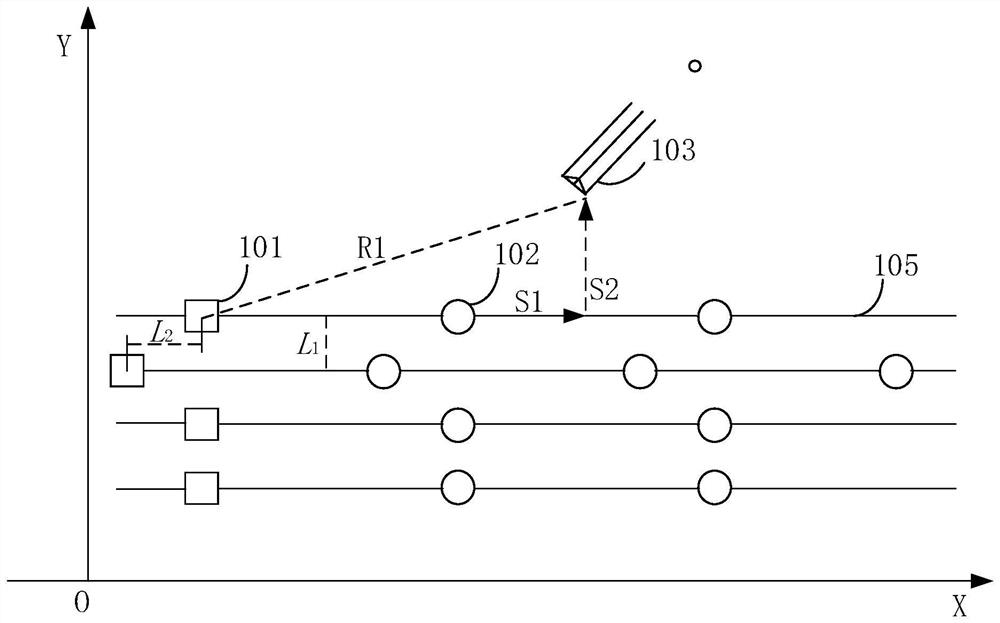

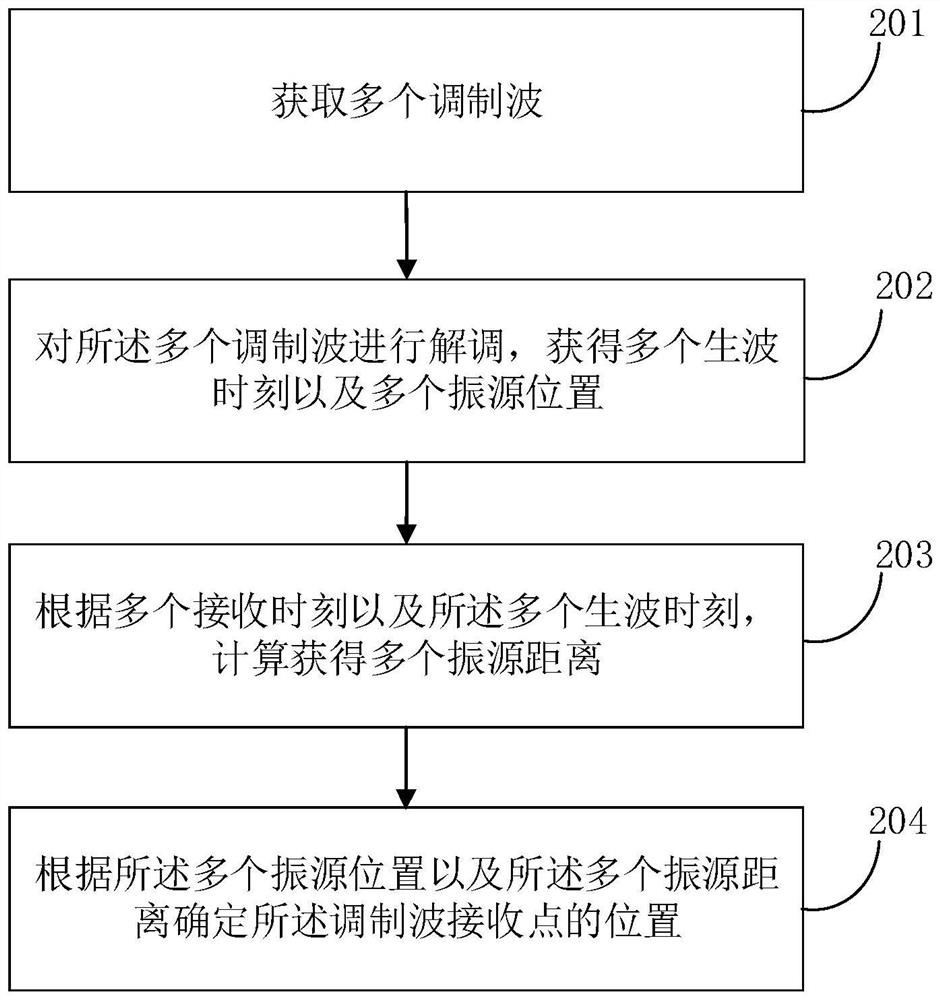

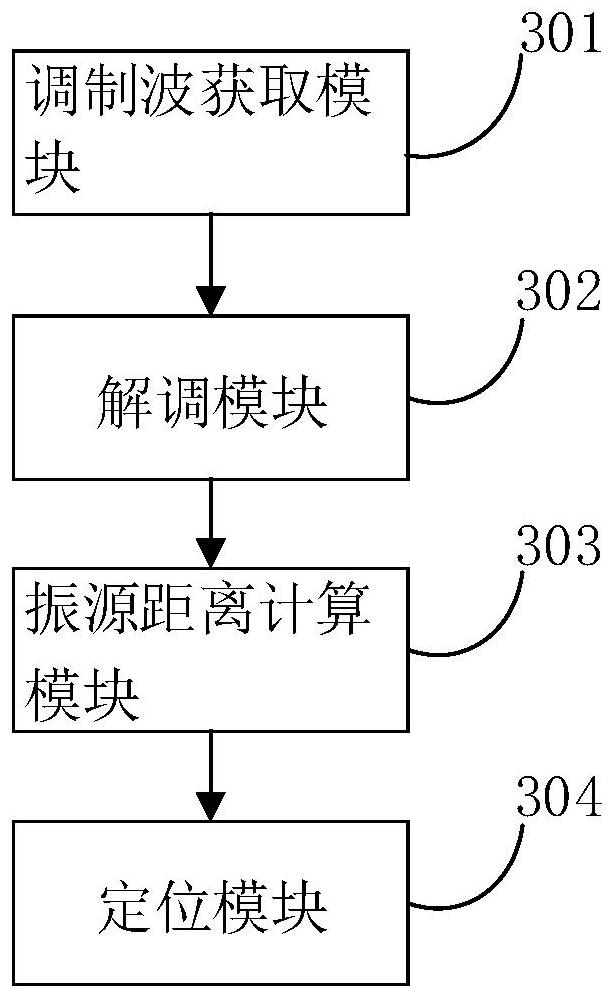

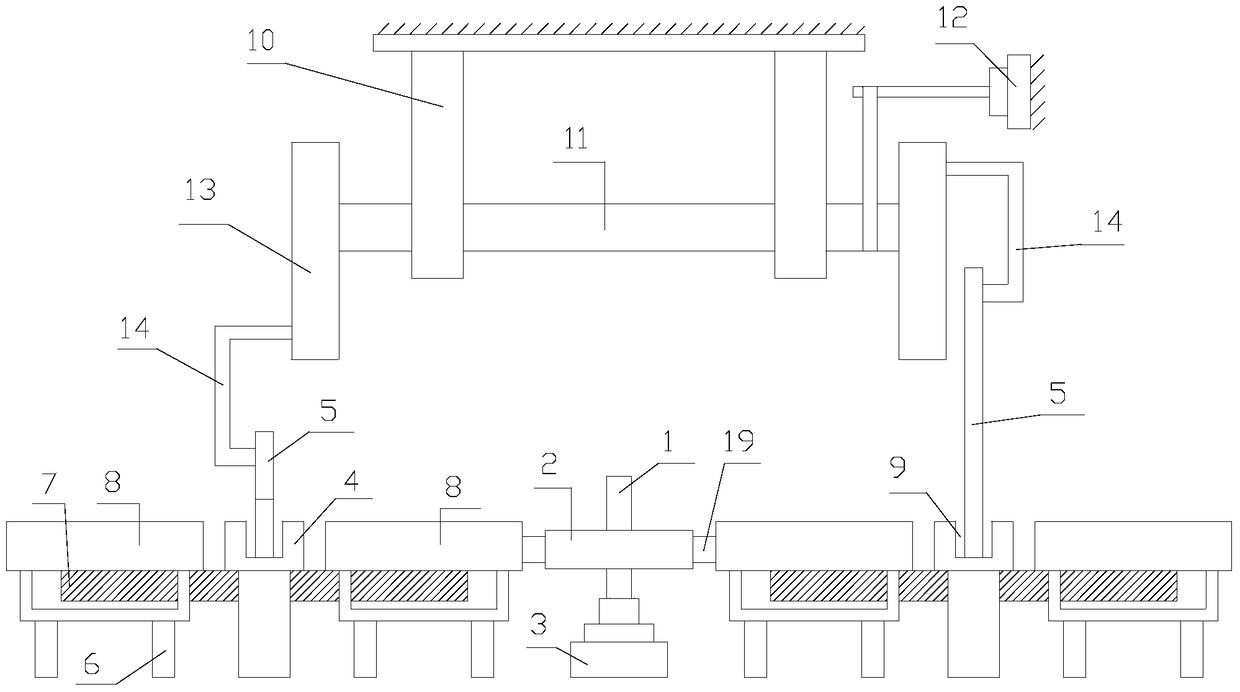

Power line sound wave loading device and method based on sound wave positioning

PendingCN114660541AStable transmission speedSafe to usePosition fixationSeismologyLight waveElectric signal

The invention relates to the technical field of power line protection, in particular to a power line sound wave loading device and a method based on sound wave localization, and the sound wave localization method comprises the following steps: firstly, obtaining a plurality of modulated waves, then analyzing the modulated waves to obtain a vibration source position and a wave generation moment, and then, according to the wave generation moment and the vibration source position, obtaining a plurality of modulated waves; according to the embodiment of the invention, sound waves are used as carriers, the transmission speed of the sound waves is relatively stable, and the transmission speed of the sound waves is slower than that of electromagnetic waves and light waves, so that under the condition of the same time precision, the transmission speed of the sound waves is relatively stable, and the transmission speed of the sound waves is lower than that of the electromagnetic waves and the light waves. The positioning precision is far higher than that of a carrier using electromagnetic waves or light waves, the requirements of most engineering surveying can be met, mechanical waves are used as the carrier, the power line cannot be damaged, transmission of electric signals cannot be affected, and use is safer.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

A metal plate cutting device for the production of retractable doors

ActiveCN105665810BGuaranteed uptimeReduce noiseShearing machinesShearing machine accessoriesGear wheelEngineering

The invention discloses a metal plate cutting device for retractable door production. The device comprises a support rod, a driving gear, a first power unit, two conveying mechanisms and a driving mechanism; the support rod is arranged in the vertical direction; the driving gear is mounted on the support rod, and the axis of the driving gear is overlapped with the axis of the support rod; the first power unit drives the driving gear to rotate; the two conveying mechanisms are distributed on two sides of the driving gear; the conveying mechanisms include support tables, cutters, support frames, lead screws and two moving plates; accommodating tanks are formed in the support tables; first ends of the cutters are hinged to the accommodating tanks; projections of the cutters on the support tables are positioned in the accommodating tanks; the driving mechanism drives the cutters to enter or deviate from the accommodating tanks; and the cutting directions of the cutters in the two conveying mechanisms are opposite. The device is simple in structure and convenient for use.

Owner:天津智投技术成果转化有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com