Woodworking machine tool

A technology of woodworking machine tools and racks, which is applied in the direction of wood processing equipment, manufacturing tools, circular saws, etc. It can solve problems such as inability to limit positions, low work efficiency, and long time, so as to improve cutting efficiency, not damage the conveyor belt, and increase transmission speed. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

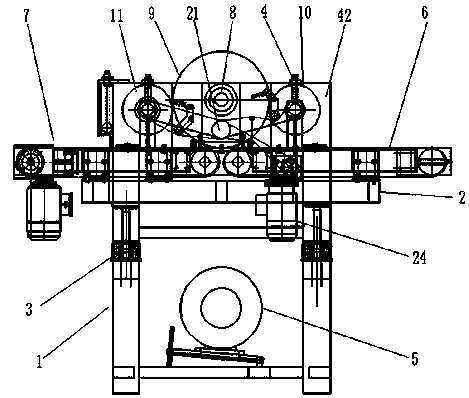

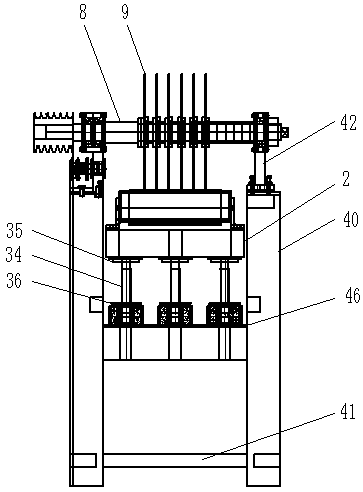

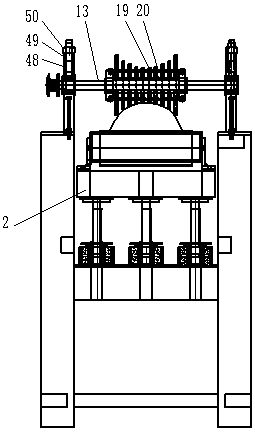

[0033] A woodworking machine tool, comprising a frame 1, a workbench 2, a wood conveying mechanism, a workbench lifting mechanism 3, a sawing mechanism, a sawing transmission mechanism, a pressure roller mechanism, a pressure material adjustment mechanism 4, and a pressure roller transmission mechanism. The sawing transmission mechanism includes a sawing transmission motor 5, and the sawing mechanism includes a sawing shaft 8. It is characterized in that: the workbench 2 is provided with a feeding conveying mechanism 6 and a discharging conveying mechanism 7 sequentially from front to back, A sawing shaft 8 is arranged above the middle of the feeding conveying mechanism 6 and the discharging conveying mechanism 7, and saw blades 9 are arranged at intervals on the sawing shaft 8, and the lowest point of the lower end of the saw blades 9 is located at the feeding conveying mechanism 6 It is in the middle of the material delivery mechanism 7 and lower than the upper end surface of...

Embodiment 2

[0042] A woodworking machine tool, comprising a frame 1, a workbench 2, a wood conveying mechanism, a workbench lifting mechanism 3, a sawing mechanism, a sawing transmission mechanism, a pressure roller mechanism, a pressure material adjustment mechanism 4, and a pressure roller transmission mechanism. The sawing transmission mechanism includes a sawing transmission motor 5, and the sawing mechanism includes a sawing shaft 8. It is characterized in that: the workbench 2 is provided with a feeding conveying mechanism 6 and a discharging conveying mechanism 7 sequentially from front to back, A sawing shaft 8 is arranged above the middle of the feeding conveying mechanism 6 and the discharging conveying mechanism 7, and saw blades 9 are arranged at intervals on the sawing shaft 8, and the lowest point of the lower end of the saw blades 9 is located at the feeding conveying mechanism 6 It is in the middle of the material delivery mechanism 7 and lower than the upper end surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com