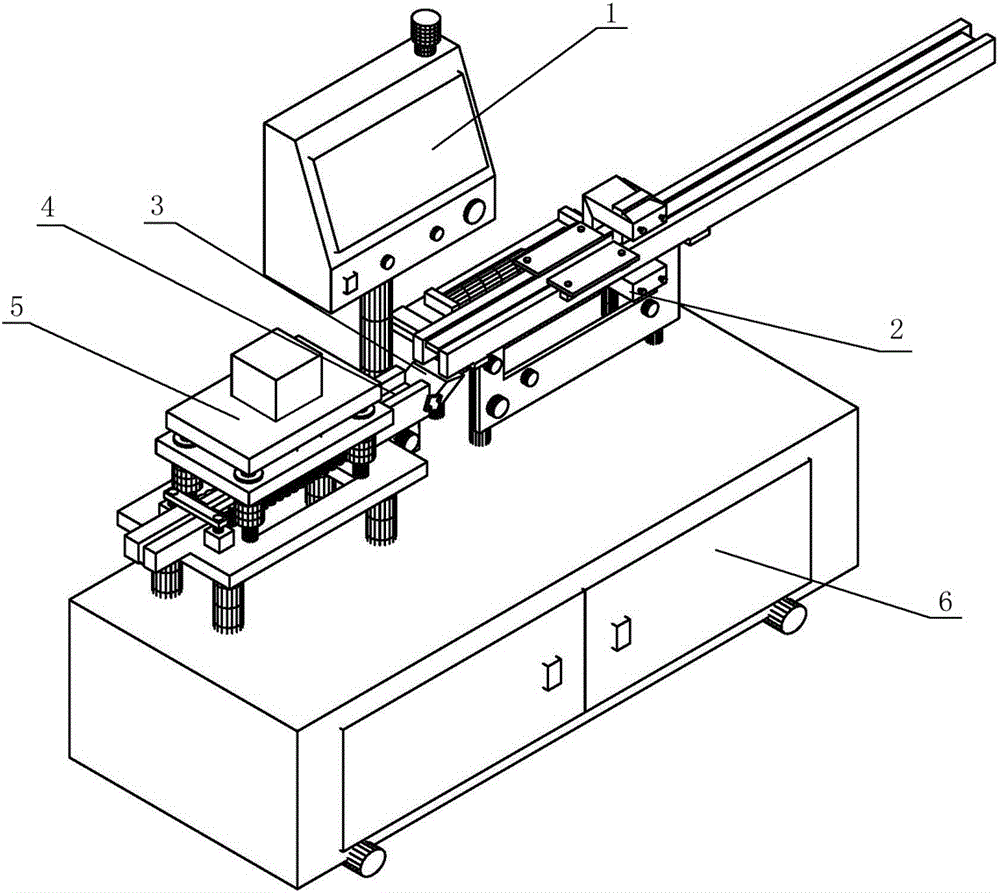

Automatic powder brushing and border cutting device of chip inductor

A chip inductor and automatic brushing technology, which is applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve the problems of reduced cutting quality, inaccurate positioning, and high production costs, and achieve stable transmission speed and accurate product positioning , good cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

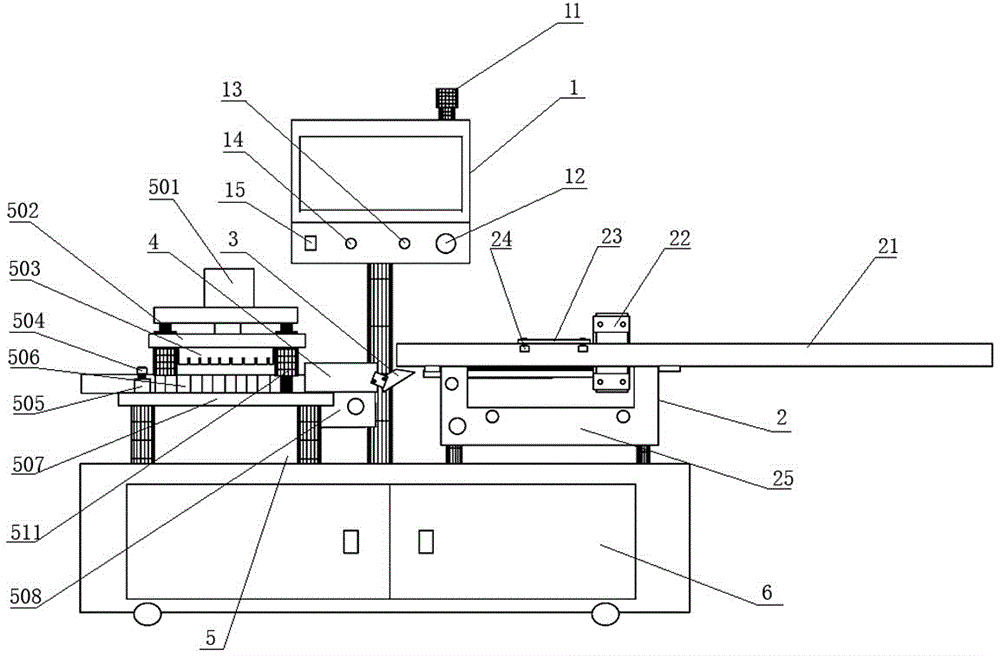

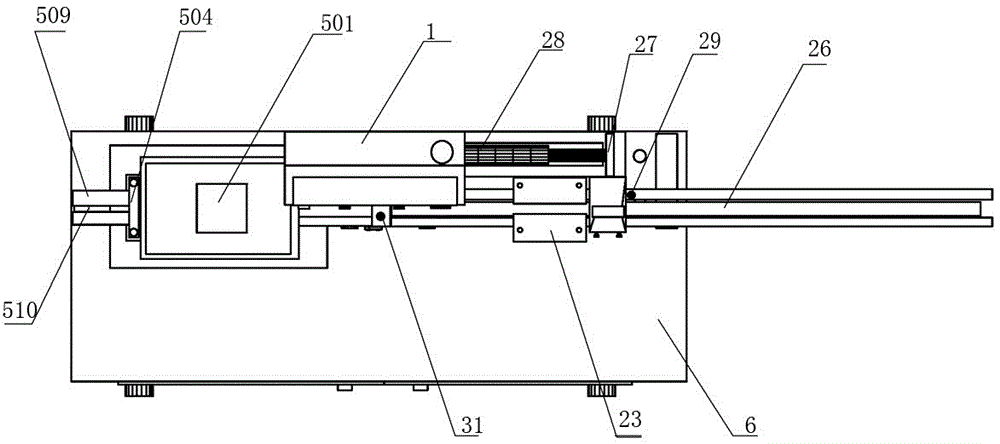

Embodiment 1

[0032] Embodiment 1: The operation process of the chip inductor automatic powder brushing and cutting frame device is: before the product starts powder coating and cutting, first check the program input preparation of the controller 1 and the operation safety of the equipment, and then press the power switch 15 and Start the switch 14, and now the first conveyor belt 26 starts to start, then put the inductance bracket directly on the first conveyor belt 26 of the powder brushing mechanism 2, and when the inductance bracket is sent to the powder brushing position and passes through the first induction light 29, the first induction light After 29 is detected, the first induction lamp 29 transmits the signal to the controller 1, and the controller 1 calculates the time for the product to reach the bottom of the splint 23 according to the length of the product according to the internally set program. When the product reaches the bottom of the splint 23 , the controller 1 drives the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com