Three-dimensional winding forming device for amorphous strips of amorphous three-dimensional wound core transformer

A technology of three-dimensional wound iron core and amorphous strip, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., and can solve the problem of strip fracture, uneven stress on the strip, and the impact on the production of three-dimensional wound iron core transformers Efficiency and other issues to achieve the effect of avoiding breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

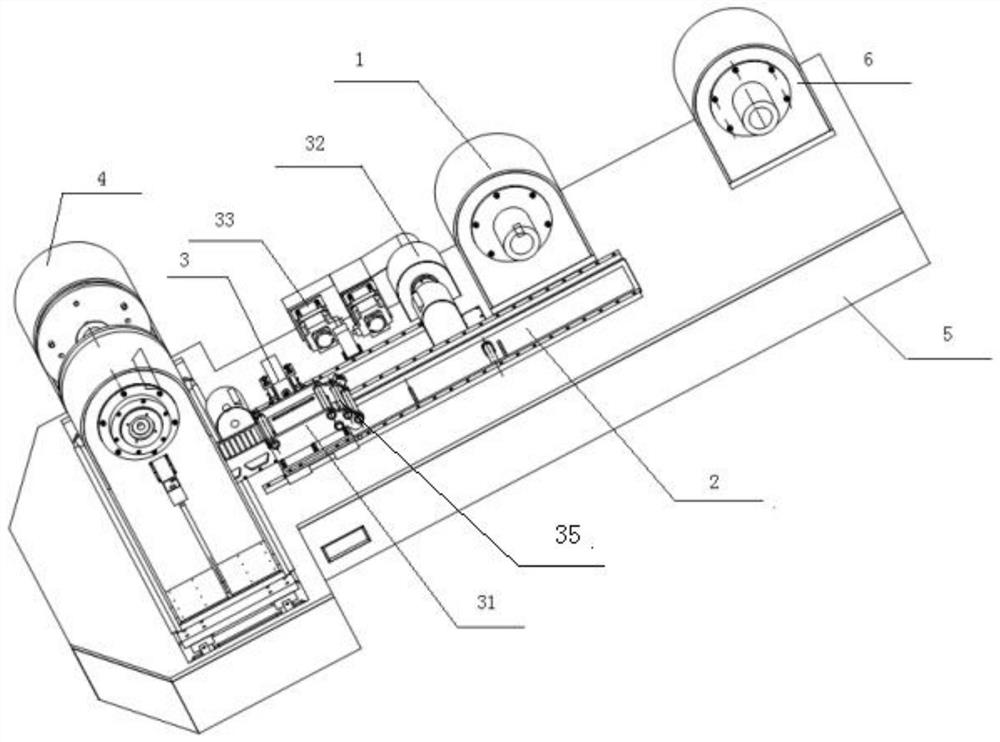

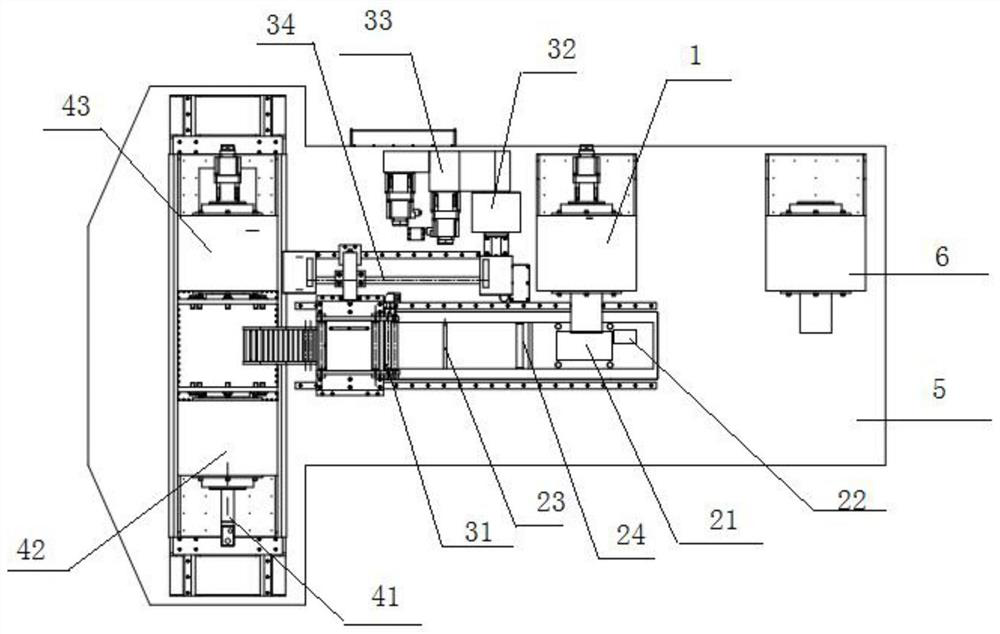

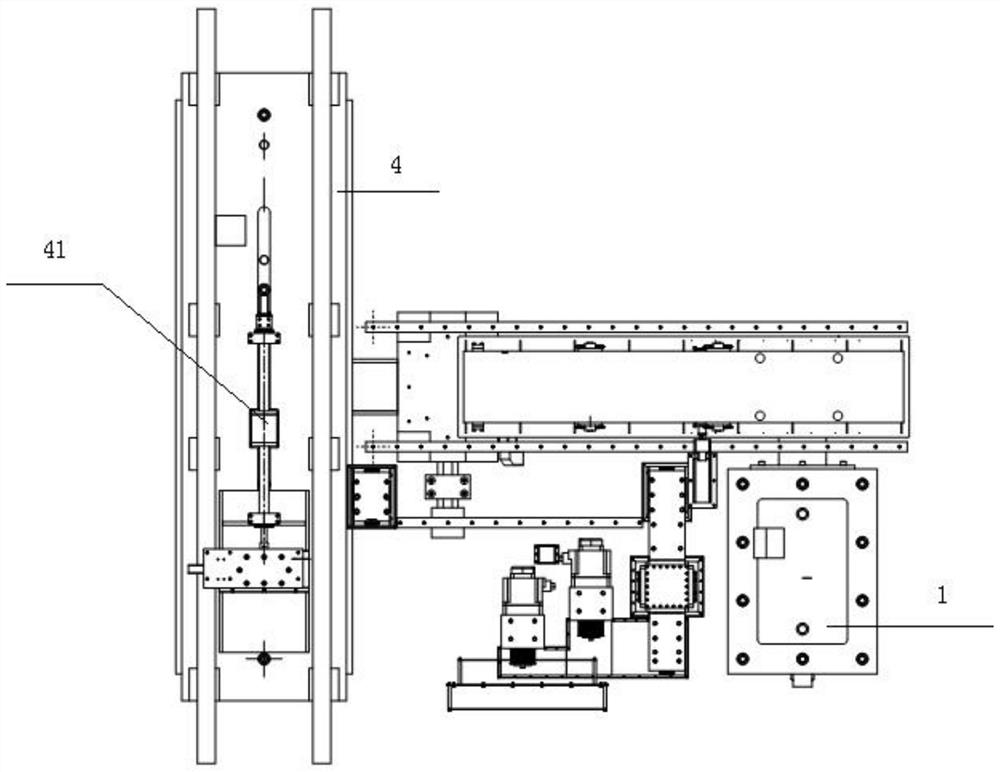

[0045] Such as Figure 1-Figure 3As shown, the unwinding unit 1 is fixed in the base 5 in a box-type structure, and is used to place the rolled amorphous strip. The axial movement mechanism 41 of the three-dimensional winding unit 4 is installed on the base 5, and the three-dimensional winding unit 4 There is a mould, which is used to roll the amorphous strip into an amorphous three-dimensional roll structure. The self-adaptive storage unit 2 is set between the unwinding unit 1 and the three-dimensional winding unit 4, and a weighing unit 21 is set at the bottom, in order to avoid transmission When the strip is broken, the strip released by the unwinding unit 1 falls freely on the weighing unit 21 in the adaptive transmission storage unit 2, and the weighing unit 21 detects the strip that has entered the adaptive transmission storage unit 2. When the value of the weight exceeds the threshold value, that is, after the adaptive transmission storage unit 2 has stored some strips,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com