Planar object screening and discharging device

A flat object and panel technology, applied in the field of flat object screening and cutting equipment, can solve the problems of low work efficiency, high labor intensity, and low processing cost, and achieve the effects of easy maintenance, improved work efficiency, and low vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments (embodiments). The specific embodiments described here are only used to explain the present invention, but not as a basis for limiting the present invention.

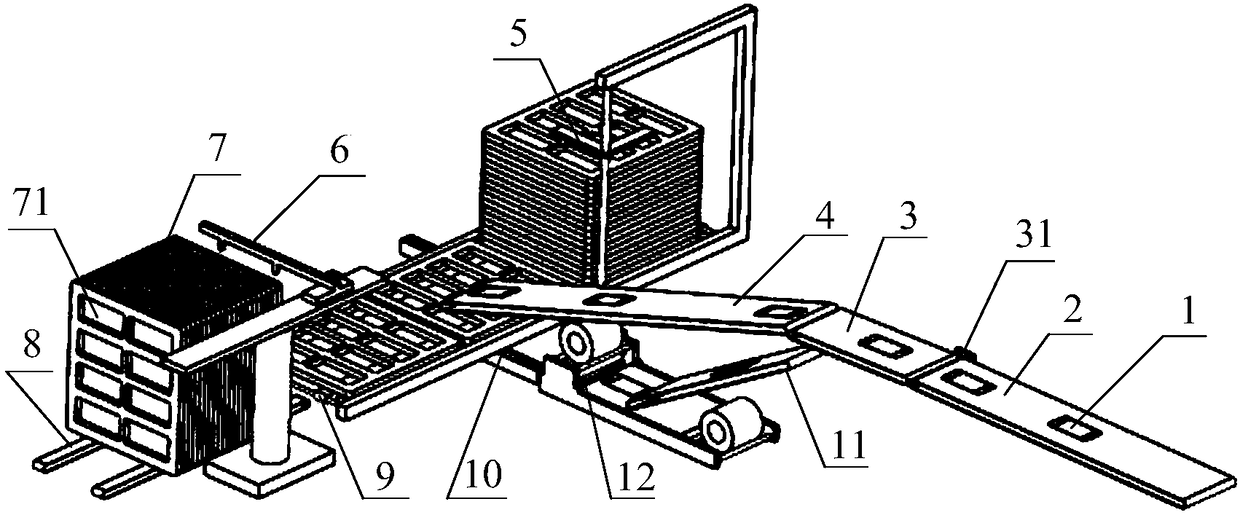

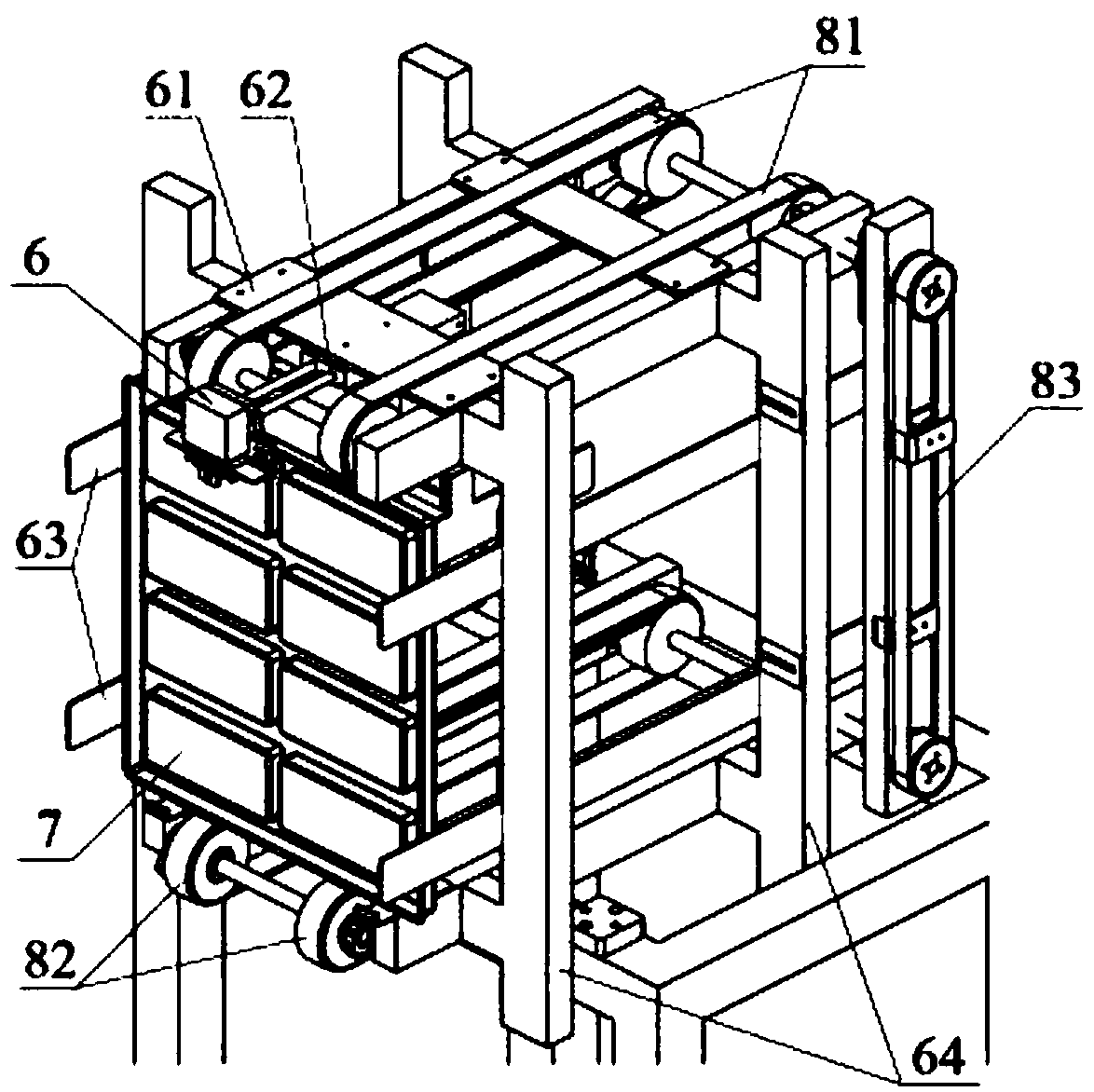

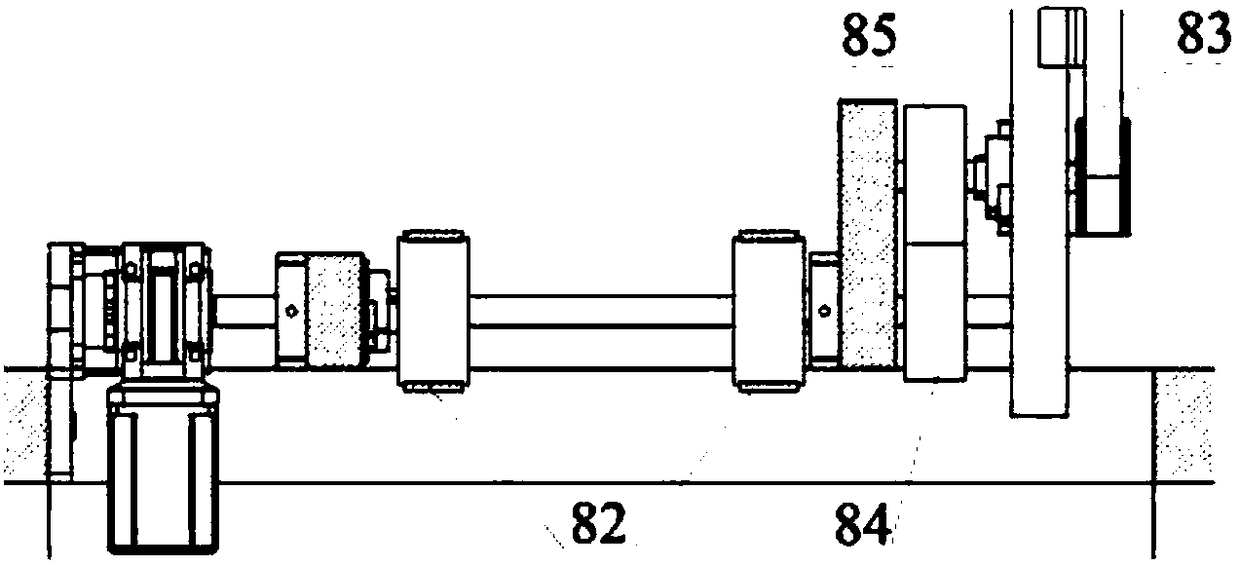

[0025] see figure 1 , the planar object screening and blanking device of the present invention includes a detection conveyor belt 2, a swing screening conveyor belt 3 is docked at the front end of the detection conveyor belt 2, and a poor selection conveyor belt 4 is docked at the front end of the swing screening conveyor belt 3. A Y-axis conveyor belt 9 perpendicular to and parallel to the ground, an X-axis module 10 is provided below the Y-axis conveyor belt 9, a pallet conveyor belt 8 and a feeding device 6 are provided on one side of the Y-axis conveyor belt 9, and a stacking device 5 is provided on the other side , the inferior selection panel tray 7 is vertically closely arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com