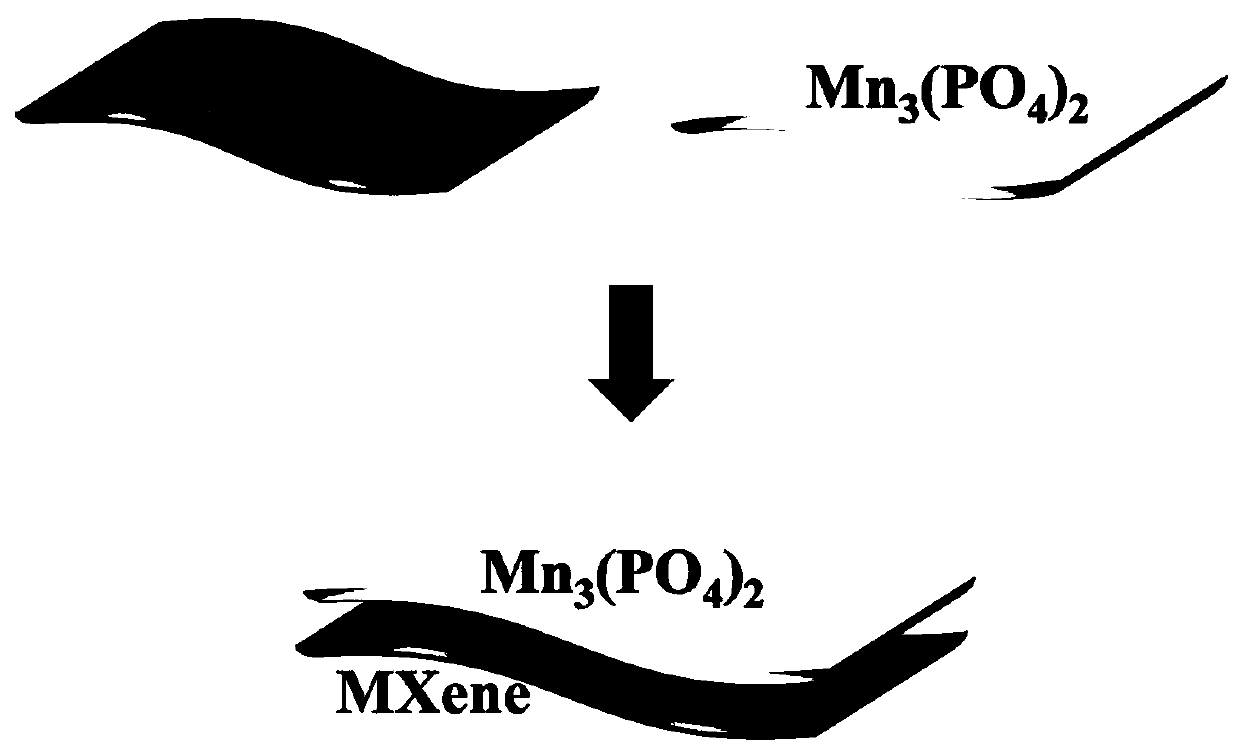

MXene/ manganese phosphate composite material, and preparation method and application thereof

A manganese phosphate composite material and composite material technology, applied in the field of electrochemical biosensing, can solve the problems of uneven binding, insufficient active sites, unsatisfactory detection speed and accuracy, etc., to achieve more active sites and stable transmission speed , the effect of increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Prepare 300mL of 0.001mol / L manganese chloride solution for use; then prepare a mixture of 0.001mol / L potassium dihydrogen phosphate and 0.00185mol / L 4-hydroxyethylpiperazineethanesulfonic acid solution, and then add some potassium hydroxide to make the pH value of the solution 7.1; then slowly add the prepared mixed solution to the manganese chloride solution, heat it in a water bath under constant stirring, finally centrifuge and wash with water, and freeze-dry to obtain white precipitated phosphoric acid Manganese trihydrate;

[0042] (2) Prepare 50 mL of a solution of manganese phosphate trihydrate with a concentration of 0.004 mol / L, add it to a hydrothermal reaction kettle and react for 3.5 hours at 250°C; then wash the precipitate with centrifugal water, put it in a vacuum drying oven and dry it at 120°C for 5 hours, Obtain anhydrous δ-manganese phosphate;

[0043] (3) Add anhydrous δ-manganese phosphate to N,N-dimethylformamide to make a 0.5mg / mL solution, ...

Embodiment 2

[0056] (1) Prepare 500mL of 0.001mol / L manganese chloride solution for use; then prepare 500mL of 0.001mol / L potassium dihydrogen phosphate and 0.00180mol / L of 4-hydroxyethylpiperazineethanesulfonic acid Solution, then add some sodium hydroxide to make the pH value of the solution 7.0; then slowly add the prepared mixed solution to the manganese chloride solution, heat it in a water bath under constant stirring, finally centrifuge and wash with water, and freeze-dry to obtain white precipitated phosphoric acid Manganese trihydrate;

[0057] (2) Prepare 100 mL of a solution of manganese phosphate trihydrate with a concentration of 0.0035 mol / L, add it to a hydrothermal reaction kettle and react for 3.5 hours at 245°C; then wash the precipitate with centrifugal water, put it in a vacuum drying oven and dry it at 120°C for 5 hours, Obtain anhydrous δ-manganese phosphate;

[0058] (3) Add anhydrous δ-manganese phosphate to N,N-dimethylformamide to make a 0.5mg / mL solution, ultras...

Embodiment 3

[0063](1) Prepare 200mL of 0.001mol / L manganese chloride solution for use; then prepare 200mL of 0.001mol / L potassium dihydrogen phosphate and 0.002mol / L of 4-hydroxyethylpiperazineethanesulfonic acid solution, and then add some potassium hydroxide to make the pH value of the solution 7.0; then slowly add the prepared mixed solution to the manganese chloride solution, heat it in a water bath under constant stirring, finally centrifuge and wash with water, and freeze-dry to obtain white precipitated phosphoric acid Manganese trihydrate;

[0064] (2) Prepare 50 mL of a solution of manganese phosphate trihydrate with a concentration of 0.0035 mol / L, add it to a hydrothermal reaction kettle and react for 3.5 hours at 255°C; then wash the precipitate by centrifugation and dry it in a vacuum drying oven at 115°C for 5.5 hours , to obtain anhydrous δ-manganese phosphate;

[0065] (3) Add anhydrous δ-manganese phosphate to N,N-dimethylformamide to make a 0.5mg / mL solution, ultrasonic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com