Outlet can-supporting device of pop-top can cleaning and drying machine

A technology for dryers and cans, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve problems such as prone to dumping, reduce the damage rate of tanks, prevent tanks from dumping, and ensure quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

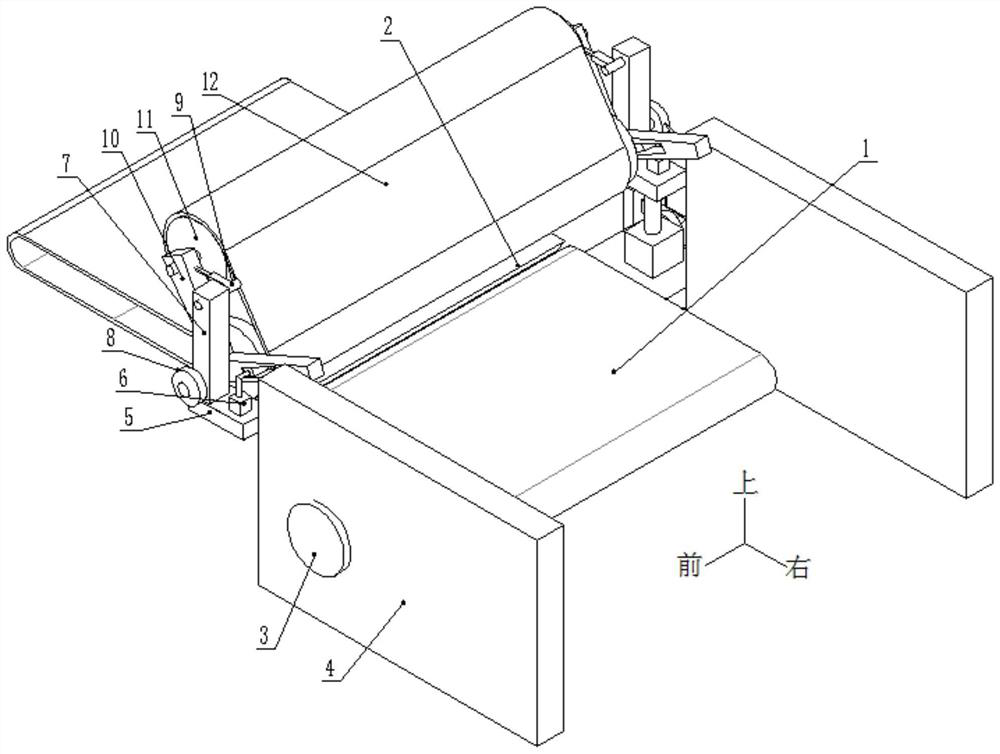

[0035] A device for supporting cans at the outlet of a can cleaning and drying machine, such as figure 1 As shown, it includes a transmission mechanism 1, a transition plate 2 and a power assembly 3, wherein a transmission mechanism 1 is located in the washing and drying machine 4, and the two sides of the transmission mechanism 1 are respectively equipped with a centralizing mechanism, and the centralizing mechanism includes installation Plate 5, first electric push rod 6, vertical plate 7, driving wheel 8, first telescopic rod 9, connecting frame 10, driven wheel 11 and conveyor belt 12. The righting mechanism is used for righting the pop cans that pass through the transition plate 2.

[0036] Such as figure 1 As shown, one side of the transmission mechanism 1 is provided with a mounting plate 5, the mounting plate 5 is provided with a first electric push rod 6 and a riser 7, and the drive wheel 8 and the first telescopic rod 9 are installed on the riser 7. A connecting fr...

Embodiment 2

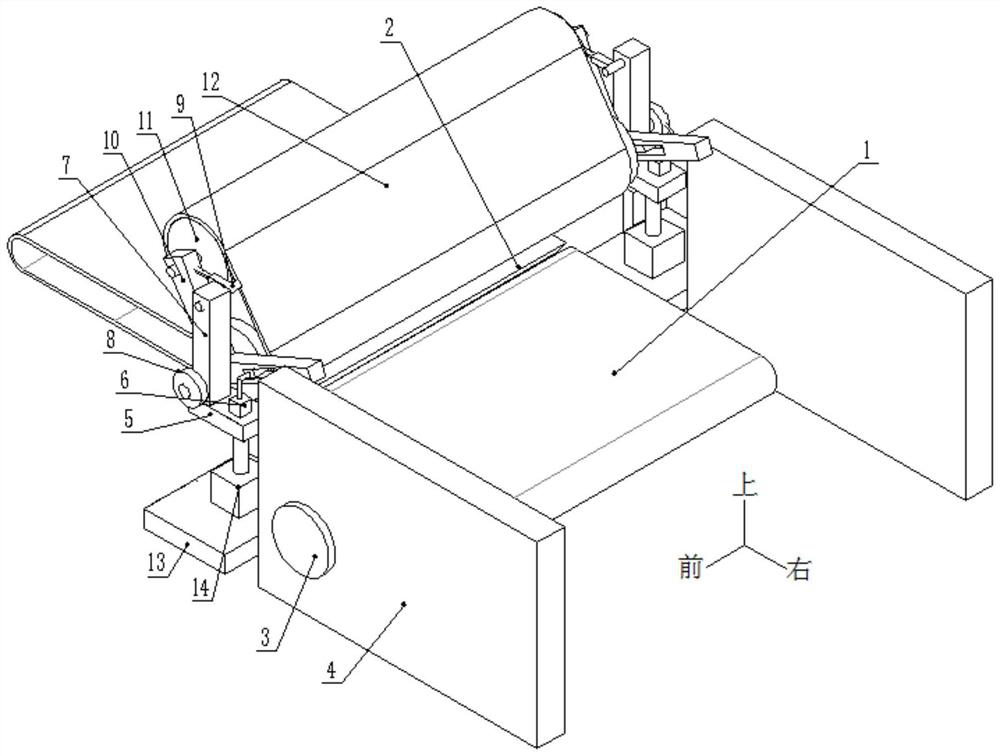

[0042] On the basis of Example 1, such as figure 2 As shown, one side of the transmission structure 1 is provided with a horizontal plate 13, and the horizontal plate 13 is provided with a second electric push rod 14 connected to the mounting plate 5, and the movable end of the second electric push rod 14 moves to drive; the mounting plate 5 It is movably connected with the cleaning and drying machine 4 frame, and one side of the mounting plate 5 is provided with a bump, and one side of the cleaning and drying machine 4 frame is provided with a groove matched with the bump, which guides the movement of the mounting plate 5.

[0043] The specifications of cans are different. For cans of different heights, the position of the righting device needs to be adjusted in time to achieve the original righting effect. Before use, the staff starts the second electric push rod 14, the movable end of the second electric push rod 14 moves to make the installation plate 5 move along the was...

Embodiment 3

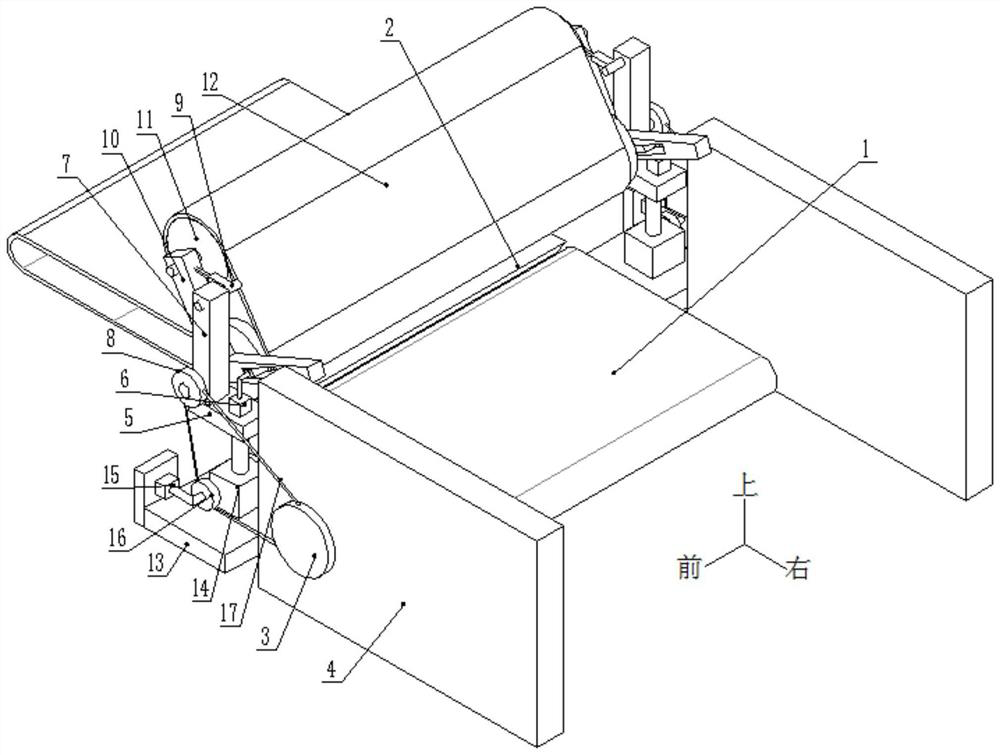

[0045] On the basis of Example 2, such as Figure 3-Figure 6 As shown, the power source adopts the power assembly on the cleaning and drying machine 4; the side of the mounting plate 5 is provided with a lockable second telescopic rod 15, and the second telescopic rod 15 is provided with a connecting wheel 16. The driving wheel 8 includes two wheels symmetrically distributed around the vertical plate 7 , and a matching chain 17 is arranged between the connecting wheel 16 and the power assembly and the outer driving wheel 8 .

[0046] The driving wheel 8 and the connecting wheel 16 are provided with annular limiting plates; the driving wheel 8, the connecting wheel 16 and the power assembly are on the same level.

[0047] Such as Figure 9 As shown, the second telescopic rod 15 includes a fixed sleeve 151, a movable rod 152 and a locking assembly, the fixed sleeve 151 is provided with a movable rod 152 moving along it, and the fixed sleeve 151 is provided with a fixed movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com