A method for increasing the yield of riboflavin by using an oxygen carrier and its fermentation device

A technology of riboflavin and oxygen carrier, applied in specific-purpose bioreactors/fermenters, methods based on microorganisms, fermentation, etc., can solve the complex reaction of pure chemical synthesis, affect the prospects of industrial production, and riboflavin production Reduce and other problems, to achieve the effect of improving the substrate conversion rate, shortening the fermentation cycle, and increasing the dissolved oxygen capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

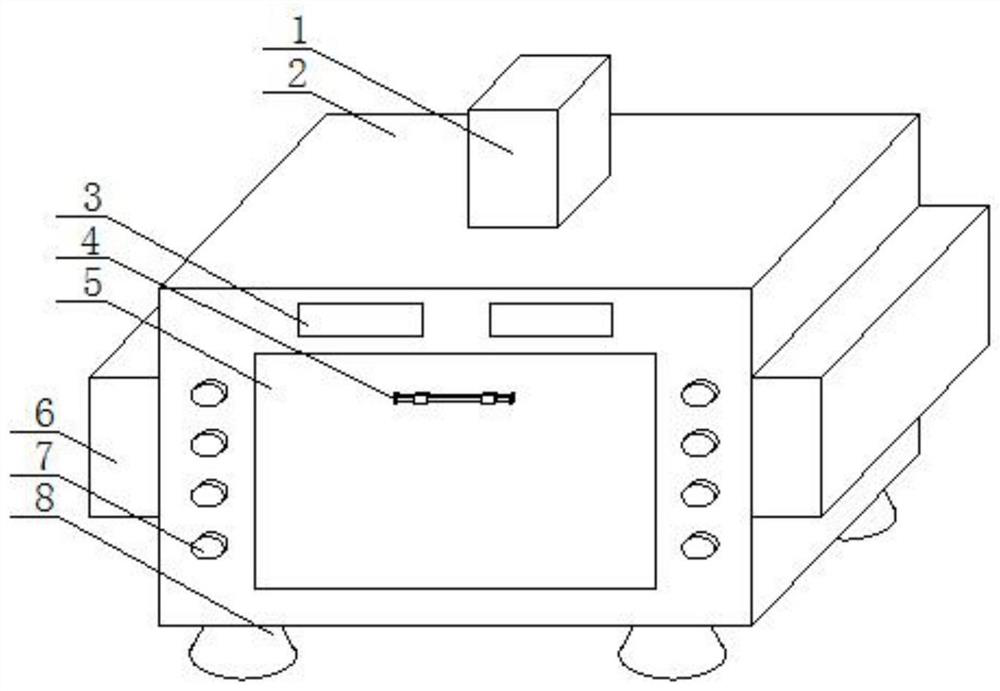

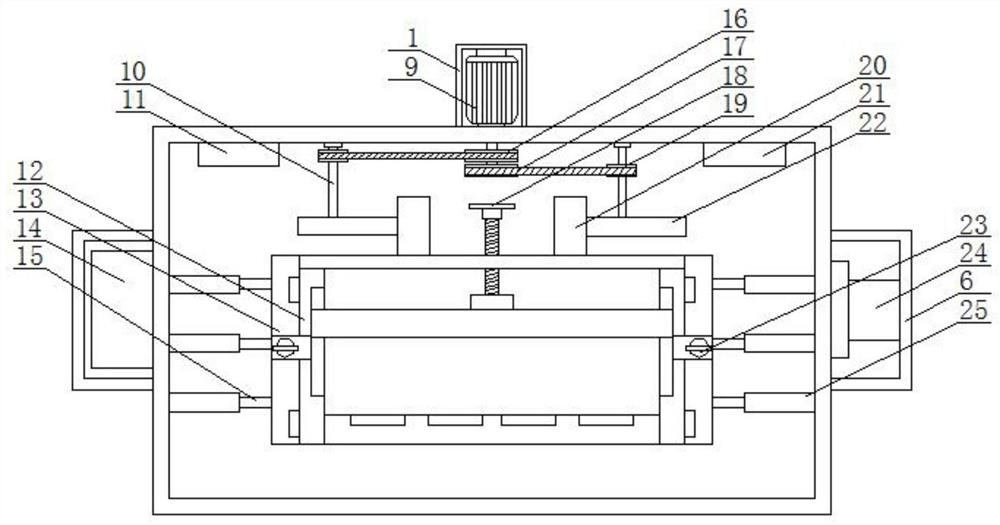

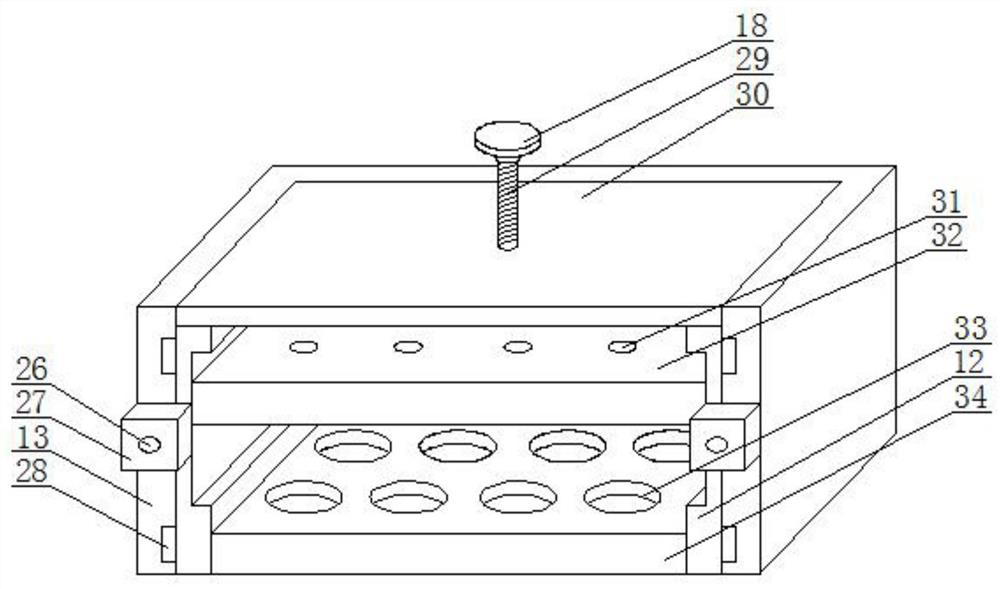

Image

Examples

Embodiment 1

[0038] This embodiment includes the following steps:

[0039] Seed culture: Inoculate the riboflavin-producing bacteria Bacillus subtilis into the seed medium, and culture it with shaking at 35°C and 200-240rpm on a fermentation device for 24 hours to obtain the seed medium;

[0040] Fermentation culture: Inoculate the obtained seed culture liquid into the fermentation medium, add sterile oxygen carrier n-dodecane at 0 hours after the fermentation starts, and the amount of n-dodecane added is 1%, and finally obtain the fermentation liquid containing riboflavin , the fermentation condition is: 500mL baffle Erlenmeyer flask, liquid volume is 30 milliliters, at 30-38 ℃, 200-240rpm fermenting equipment shaking culture for 120 hours.

[0041] Yield detection: the method is the same as that of Comparative Example, and the content of riboflavin in the fermented liquid of Example 1 is 12632 μg / mL, which is 10.6% higher than that of Comparative Example.

Embodiment 2

[0043] This embodiment includes the following steps:

[0044] Seed culture: Inoculate the riboflavin-producing bacteria Bacillus subtilis into the seed medium, and culture it with shaking at 35°C and 200-240rpm on a fermentation device for 24 hours to obtain the seed medium;

[0045] Fermentation culture: Inoculate the obtained seed culture liquid into the fermentation medium, add sterile oxygen carrier n-dodecane to the fermentation medium for 60 hours, and the addition amount of n-dodecane is 4%, finally obtain the fermentation liquid containing riboflavin, The fermentation conditions are: 500mL baffled Erlenmeyer flask with a liquid volume of 30ml, shake culture at 30-38°C, 200-240rpm fermentation equipment for 90 hours.

[0046] Yield detection: the method is the same as that of the comparative example. The riboflavin content in the fermented liquid of Example 2 is 13034 μg / mL, which is 12.4% higher than that of the comparative example, and the fermentation period is short...

Embodiment 3

[0048] This embodiment includes the following steps:

[0049] Seed culture: Inoculate the riboflavin-producing bacteria Bacillus subtilis into the seed medium, and culture it with shaking at 35°C and 200-240rpm on a fermentation device for 24 hours to obtain the seed medium;

[0050] Fermentation culture: inoculate the obtained seed culture solution into the fermentation medium, add sterile oxygen carrier n-dodecane to the fermentation medium for 50 hours, the addition of n-dodecane is 3%, and finally obtain the fermentation solution containing riboflavin, The fermentation conditions are: 500mL baffled Erlenmeyer flask with a liquid volume of 30ml, shake culture at 30-38°C, 200-240rpm on a fermentation device for 105 hours.

[0051] Yield detection: the method is the same as that of the comparative example, and the riboflavin content in the fermented liquid of Example 3 is 15820 μg / mL, which is 38.5% higher than that of the comparative example, and the fermentation period is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com