Bottle holding device

A consistent, curved panel technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve problems such as inconvenience in work and prone to tipping, and achieve uniform elasticity, increase friction, and prevent tipping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

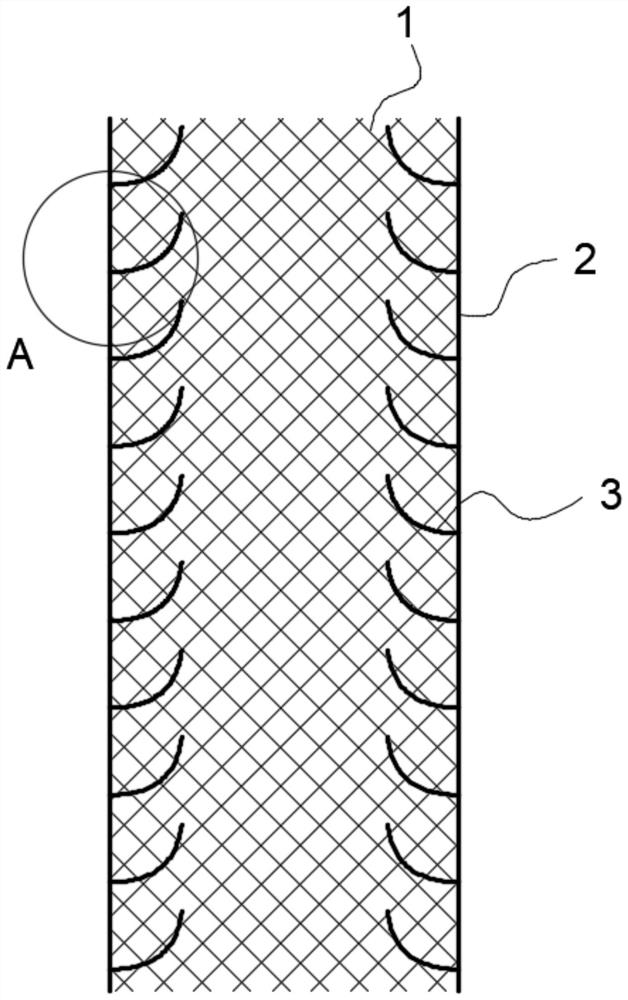

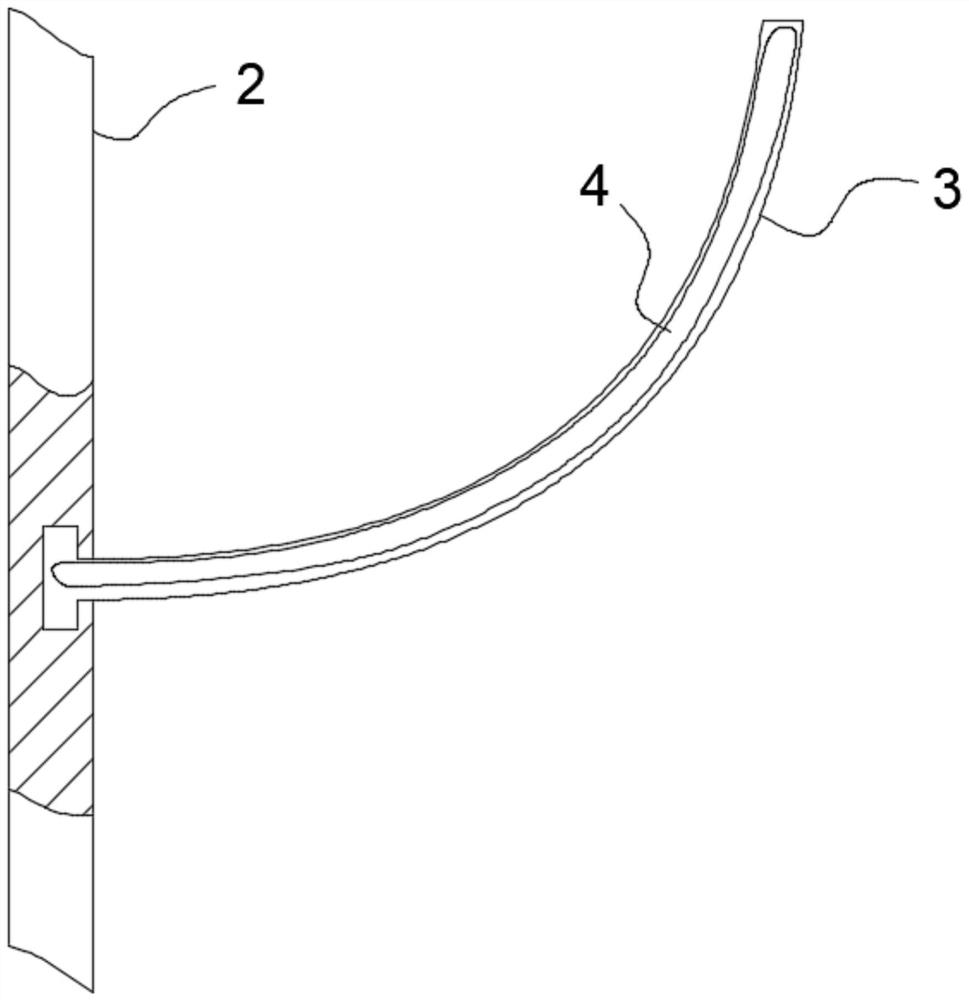

[0031] Such as figure 1 with figure 2 As shown, a bottle holding device includes a mesh belt 1, two baffles 2 and a plurality of curved panels 3, the baffles 2 are arranged on both sides of the mesh belt 1, and ampoules are stacked on the mesh belt 1 through a bottle pushing device , move together with the operation of the mesh belt 1, the curved panels 3 are soft and bendable, all the curved panels 3 are located between the two baffles 2, one end of the curved panels 3 is fixed on the baffles 2, all the curved panels 3 The bending direction is the same, the curved panel 3 is not higher than the height of the baffle 2, the number of curved panels 3 provided on the baffle 2 on both sides is the same, the tangent line between the curved panel 3 and the baffle 2 is the same as that of the curved panel 3 side vertical;

[0032] Because the capacity of ampoule bottle is 10ml or 20ml, so when making curved panel 3, the length of curved panel 3 is 35cm, less than the spacing betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com