Cement mortar feeding device for tile sticking

A technology of cement mortar and supporting device, which is applied in the direction of construction and building structure, can solve the problems of uneven cement mortar, long time consumption, extrusion of cement mortar, etc., to reduce friction, increase speed, and stabilize transmission speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

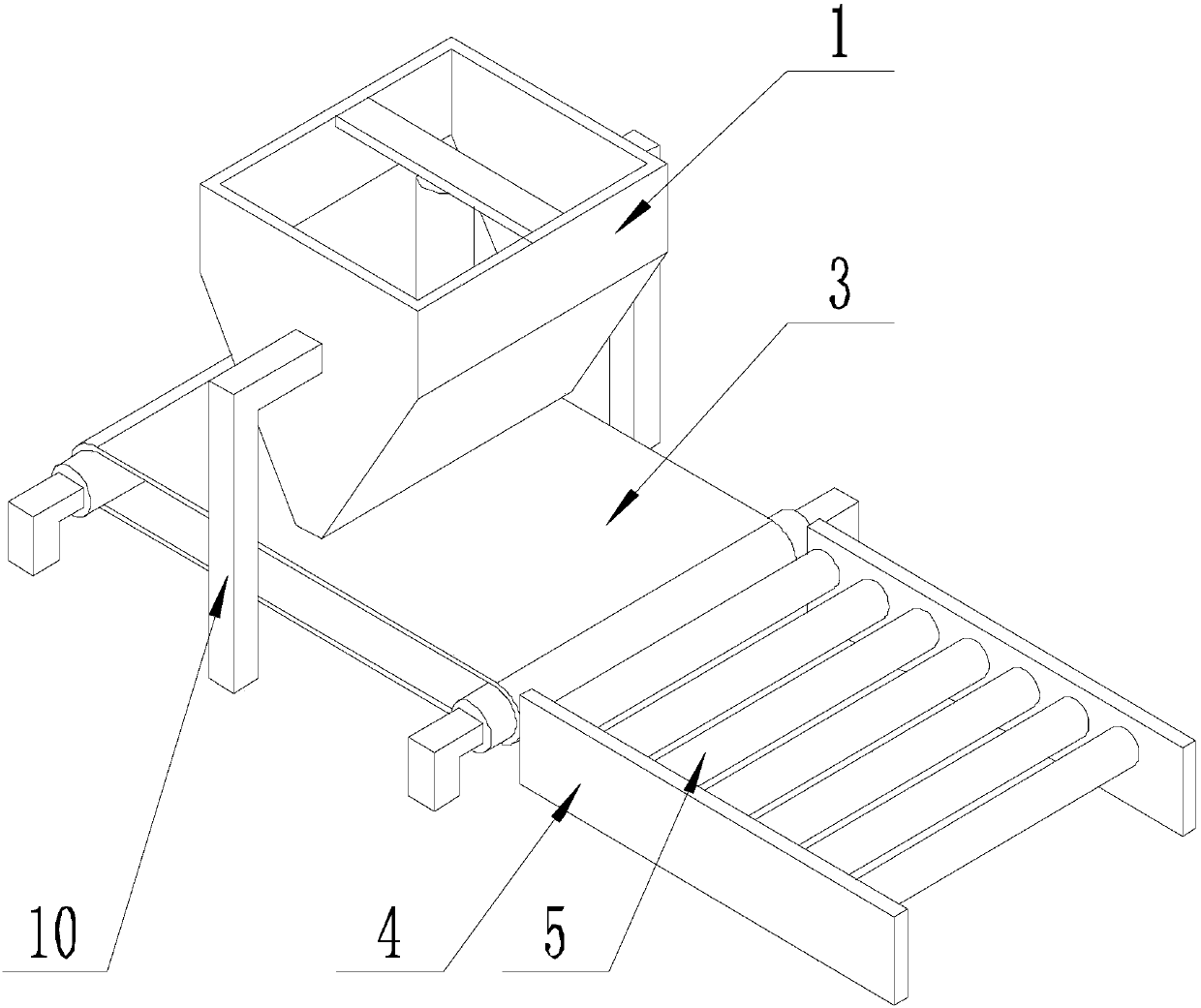

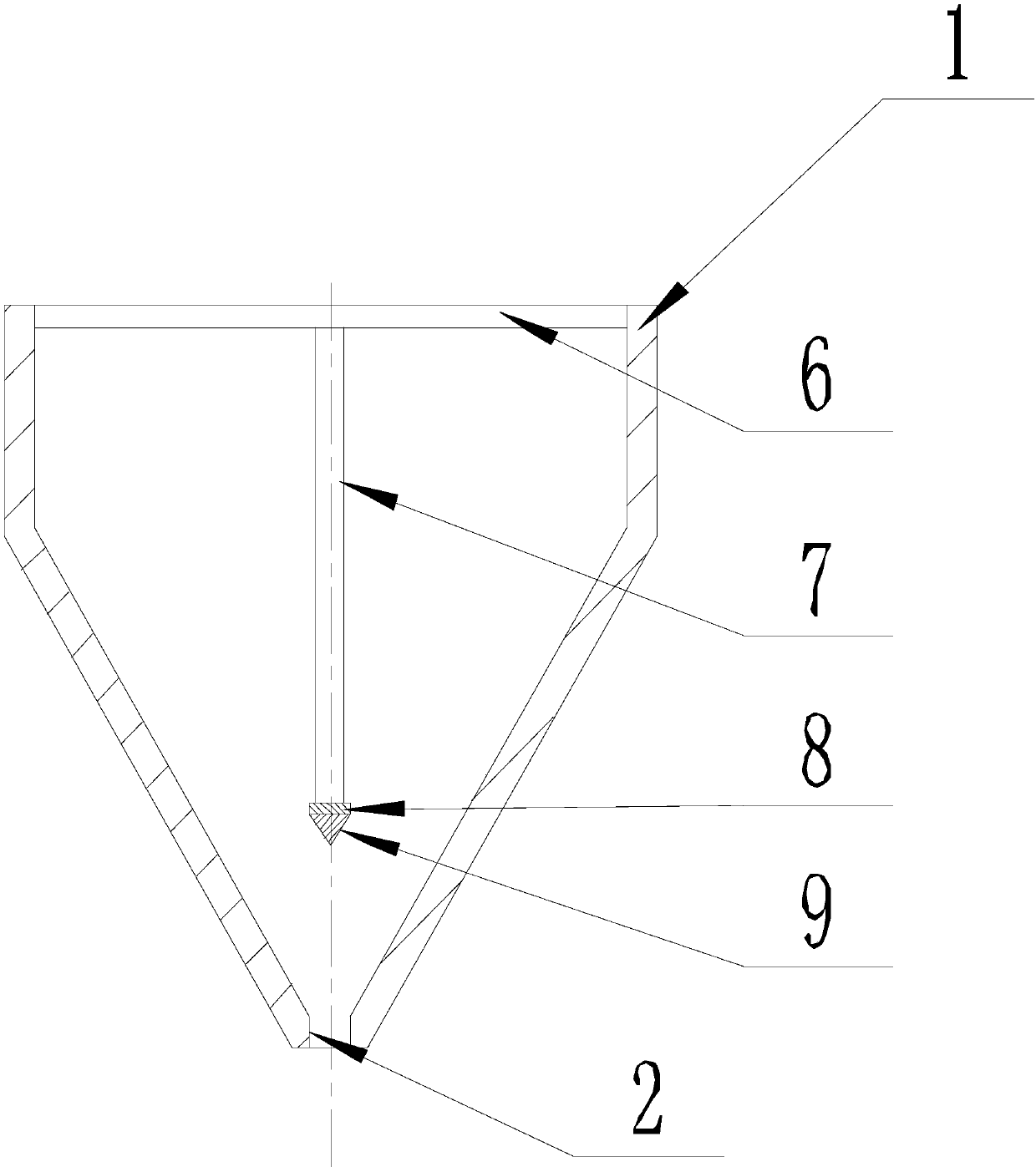

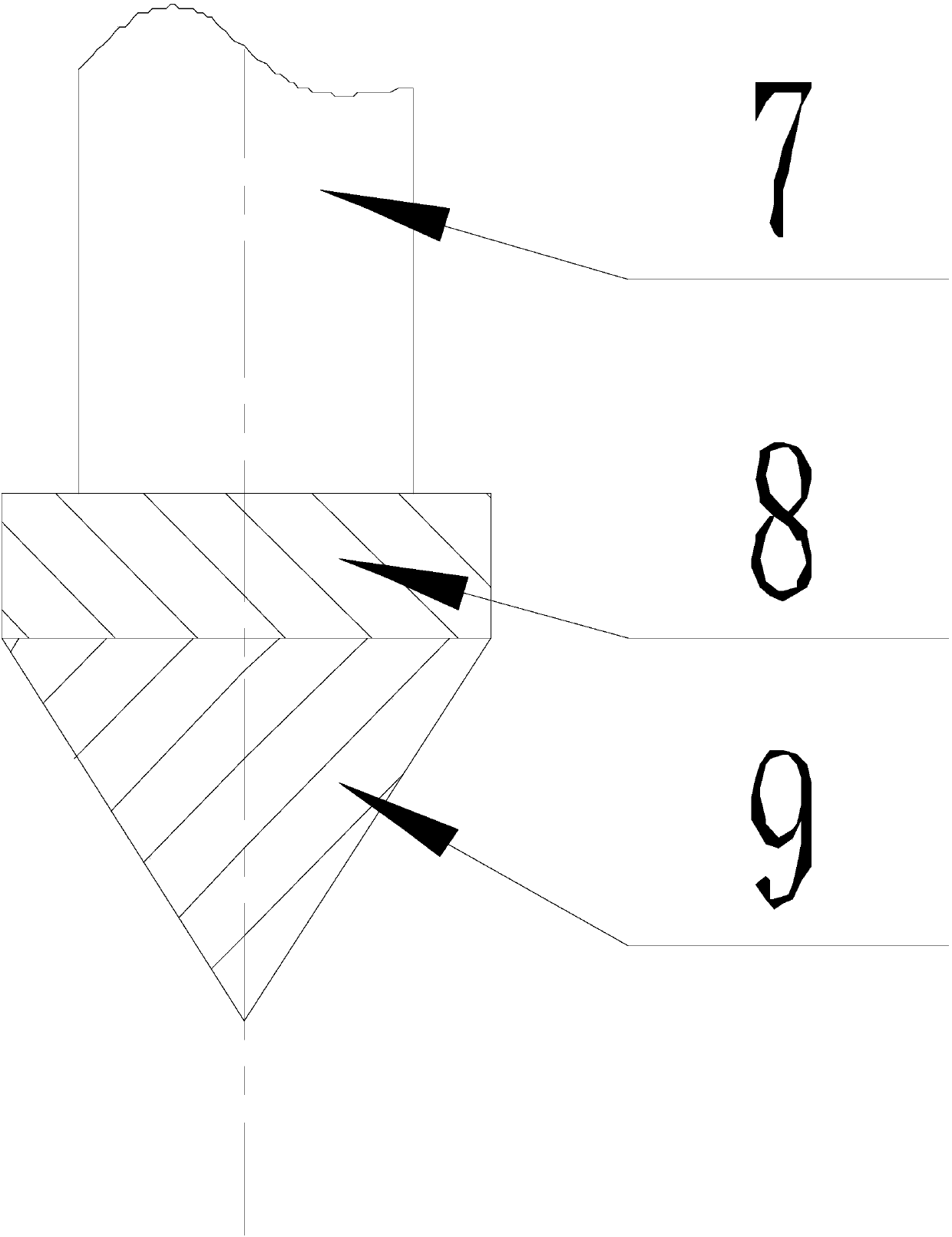

[0027] Such as Figure 1-Figure 3 As shown, the cement mortar feeding device for sticking bricks of the present invention includes a hopper 1, a conveyor belt 3 is arranged below the hopper 1, and a support device is provided at the discharge end of the conveyor belt 3, and the support device includes two fixed plate 4, the fixed plates 4 are all parallel to the transmission direction of the conveyor belt 3, and several support rods 5 are arranged between the fixed plates 4, the axes of the support rods 5 are all perpendicular to the transmission direction of the conveyor belt 3, and the support rods 5. One end away from the ground is tangent to the upper surface of the conveyor belt 3.

[0028] Place the tiles on the conveyor belt 3 in turn, and make the back of the tiles face up, and the smooth surface is in contact with the conveyor belt 3, then start the conveyor belt 3, mix the cement mortar and pour it into the hopper 1, along with the conveyor belt 3 The tiles move to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com