Sanding equipment for furniture part

A technology for sanding and parts, applied in the field of furniture manufacturing, can solve the problems of cumbersome operation, low work efficiency, single processing object, etc., and achieve the effect of reducing technical requirements, improving processing efficiency, and improving processing environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

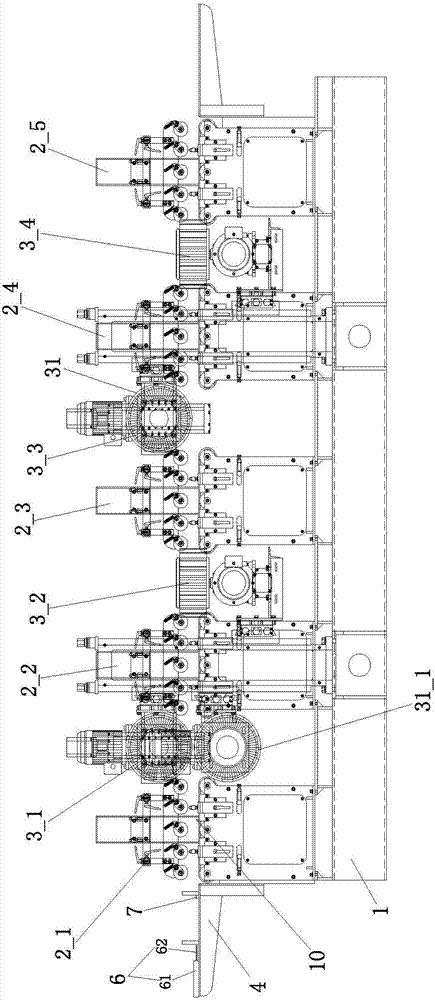

[0046] As a preferred embodiment of the present invention, in conjunction with the attached Figure 1-3 , the described sanding equipment for furniture parts includes:

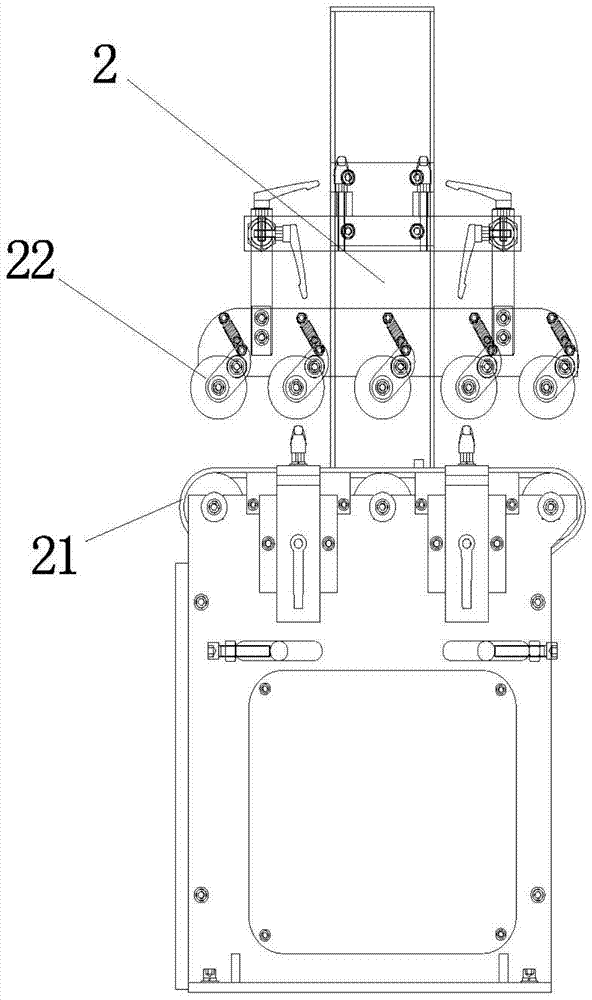

[0047] The conveying device 2 includes a conveying belt 21 for conveying furniture parts along the conveying direction;

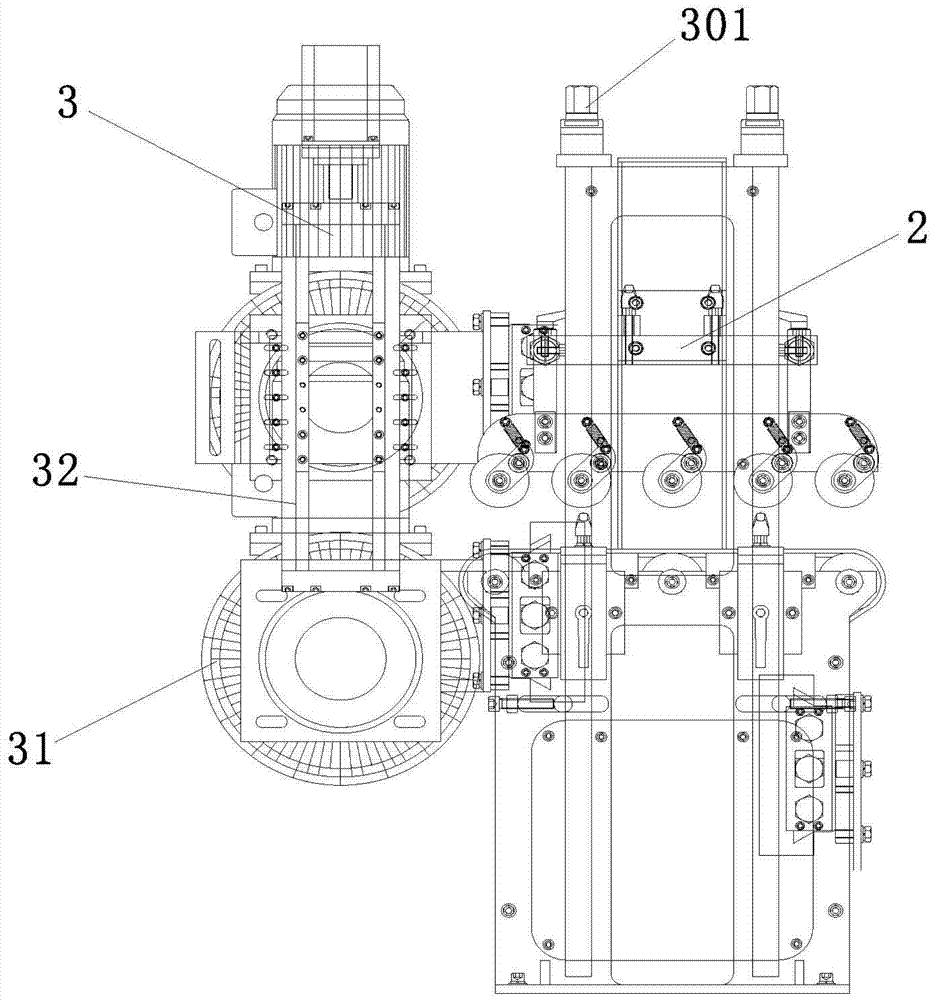

[0048] A sanding device 3, including a sander 31, for polishing at least one surface of a furniture part;

[0049] The feeding platform 4 is arranged on the upstream of the conveying device 2, and is used to carry the above-mentioned furniture parts and send them to the conveying device 2; and

[0050] A control device connected to the conveying device 2 and the sanding device 3 to control the conveying device 2 and the sanding device 3;

[0051]The conveying device 2 also includes a conveying pressure wheel 22 arranged above the conveying belt 21, and the conveying pressure roller 22 and the conveying belt 21 clamp the furniture parts and transmit them along the conveying direction;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com