Unsaturated polyester molding compound

A molding compound, unsaturated technology, used in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of unsatisfactory heat resistance and strength, low heat resistance, etc., and achieve obvious cost advantages, good strength, The effect of improving the processing environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail below, so that the understanding of those skilled in the art:

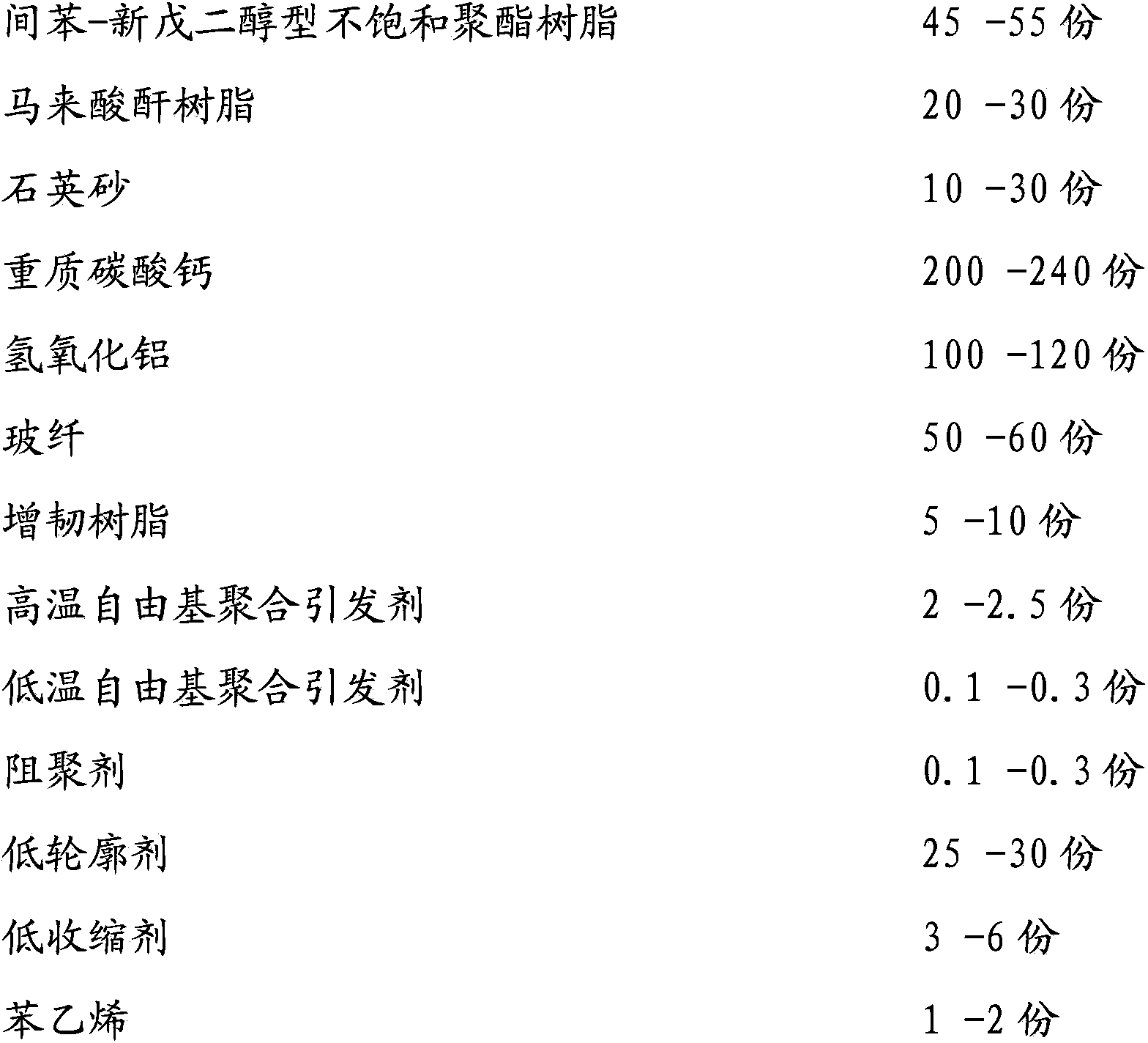

[0027] Unsaturated polyester molding compound comprises the following components in the present invention:

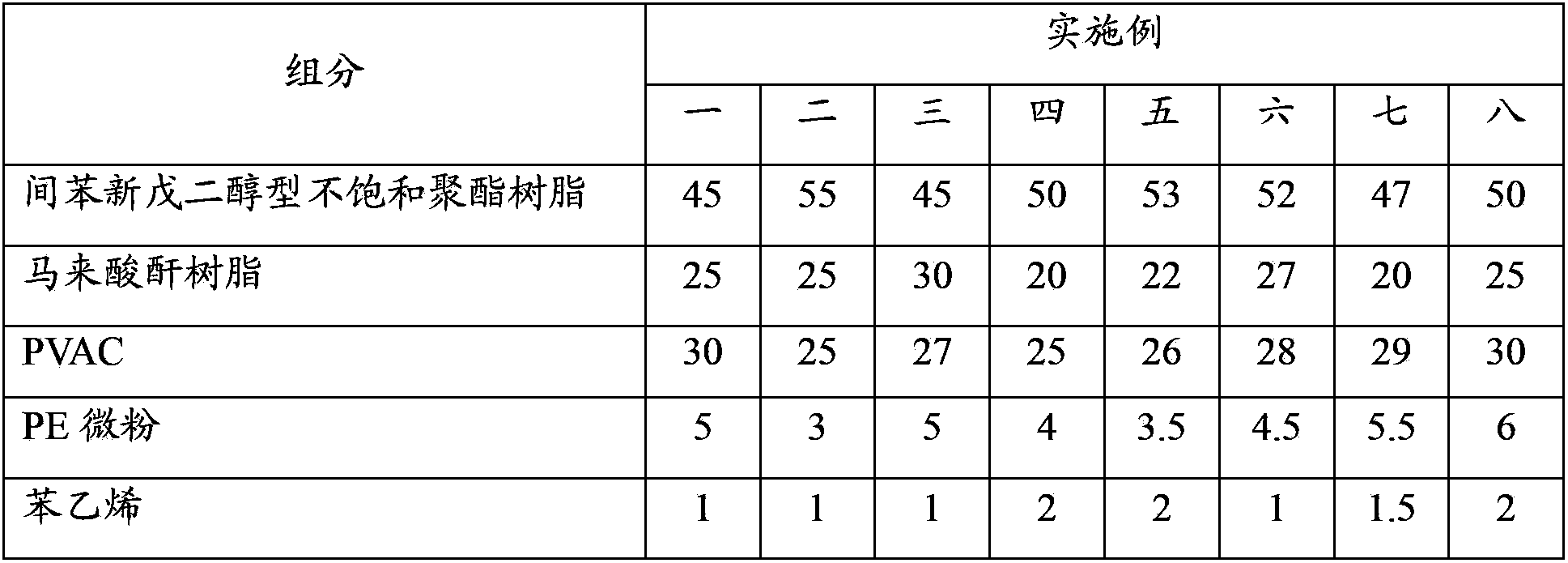

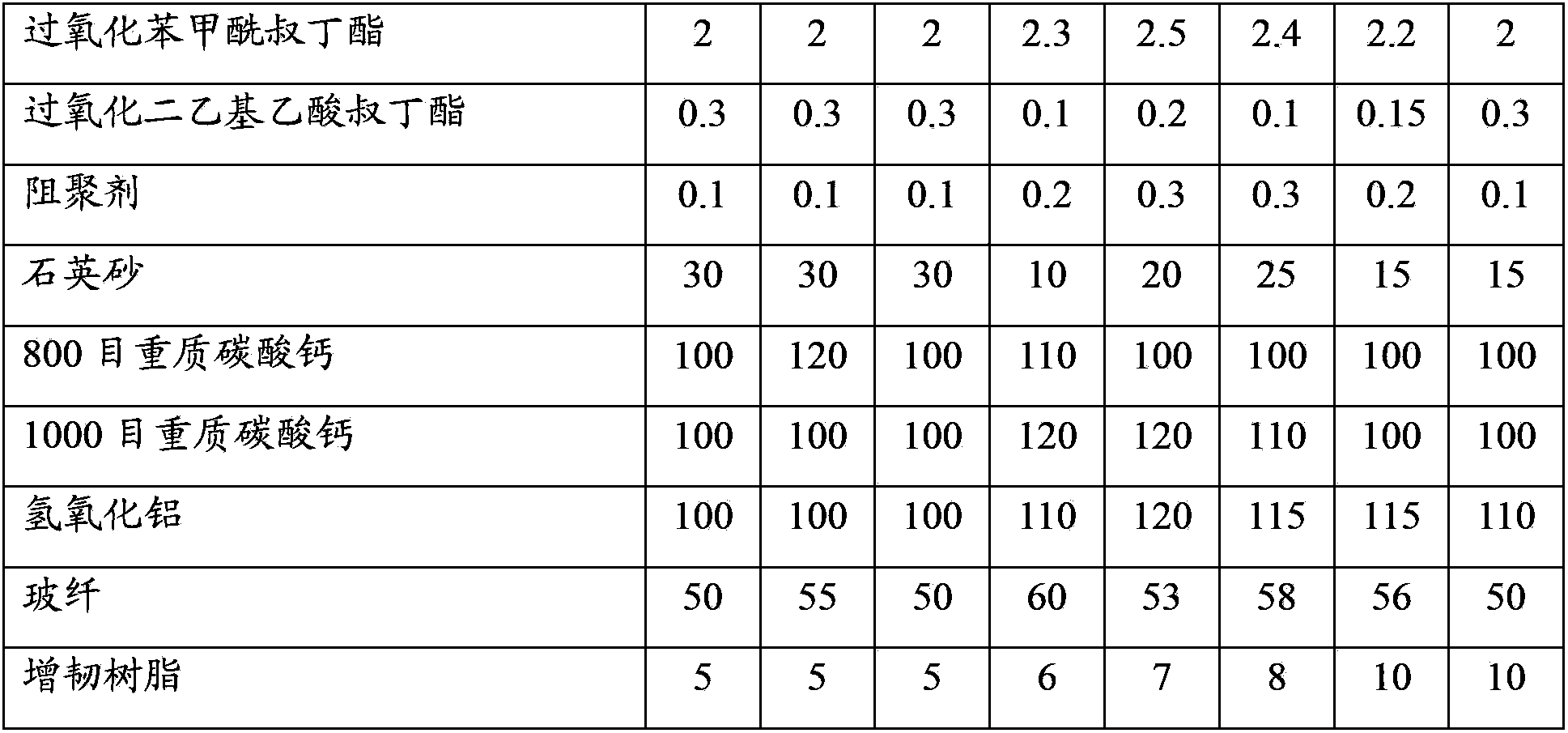

[0028] 1. m-phenylene-neopentyl glycol type unsaturated polyester resin, using unsaturated polyester resin as the matrix, using the excellent fluidity of unsaturated polyester resin, and the firmness of polymer cross-linking reaction, combined with special Functional fillers to achieve special performance.

[0029] 2. Maleic anhydride resin to achieve high cross-linking density and solve the heat resistance of the matrix.

[0030] 3. Low-profile agent, also known as low-profile additive, can modify unsaturated polyester resin to solve the micro-cracks of product curing shrinkage. In this embodiment, polyvinyl acetate (PVAC) is chosen.

[0031] 4. Low shrinkage agent, also known as low shrinkage additive, can also modify unsaturated polyester res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com