Sapphire crystal etching and polishing compound machine tool

A sapphire wafer, composite processing technology, applied in surface polishing machine tools, grinding machine tools, metal processing equipment and other directions, can solve problems such as damage and low polishing efficiency, achieve compact machine tool structure, improve processing efficiency, and facilitate loading and unloading. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

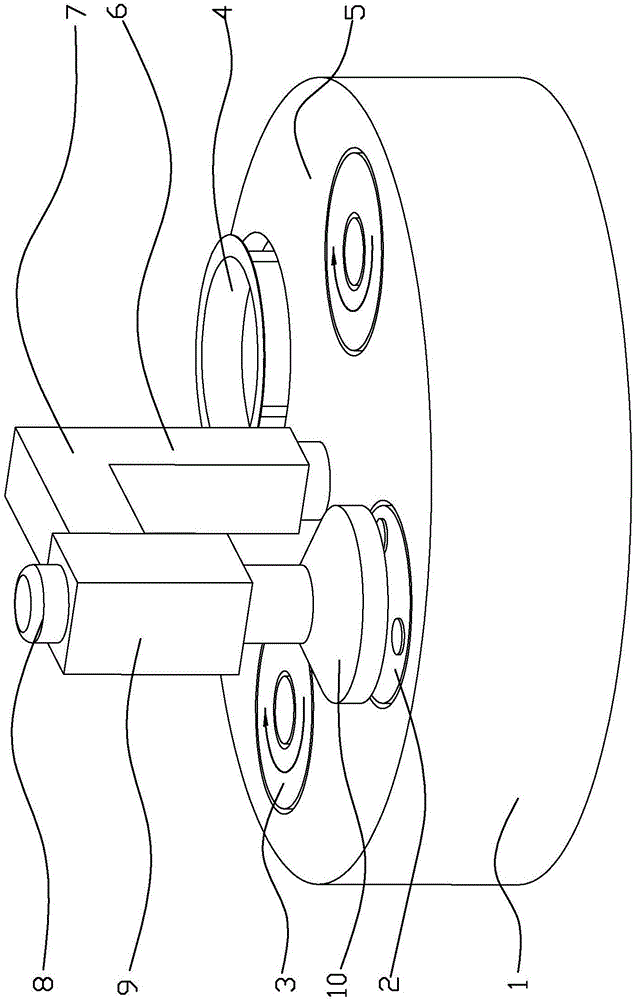

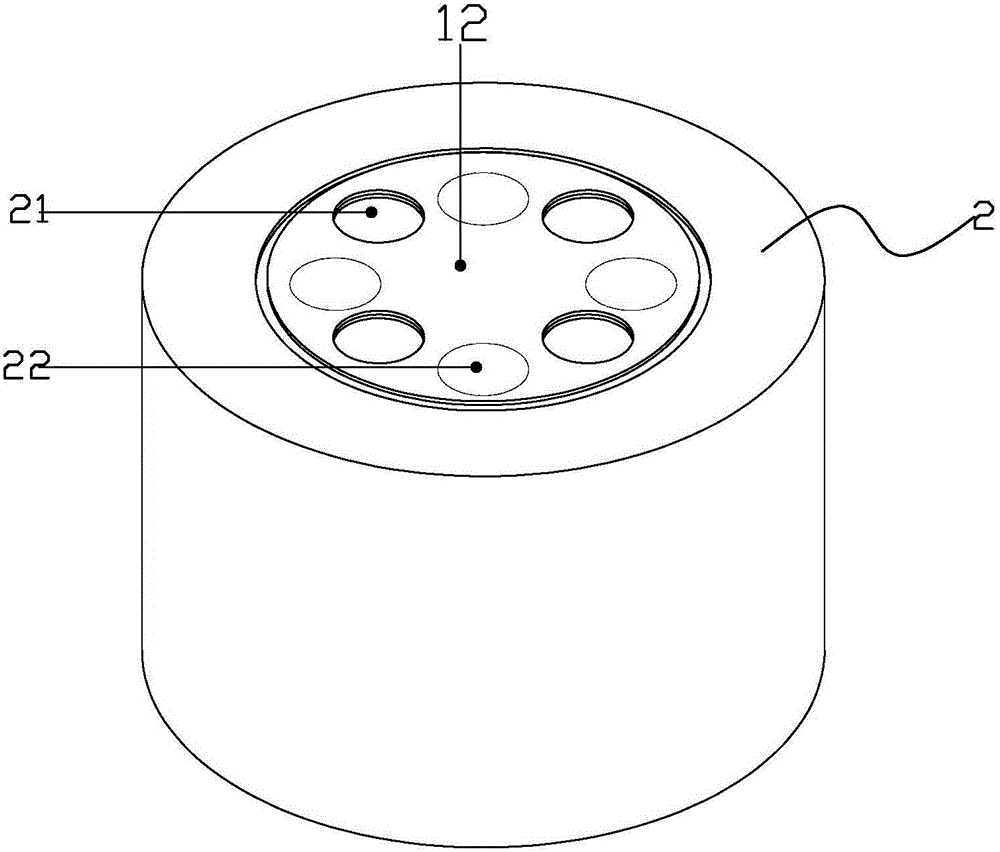

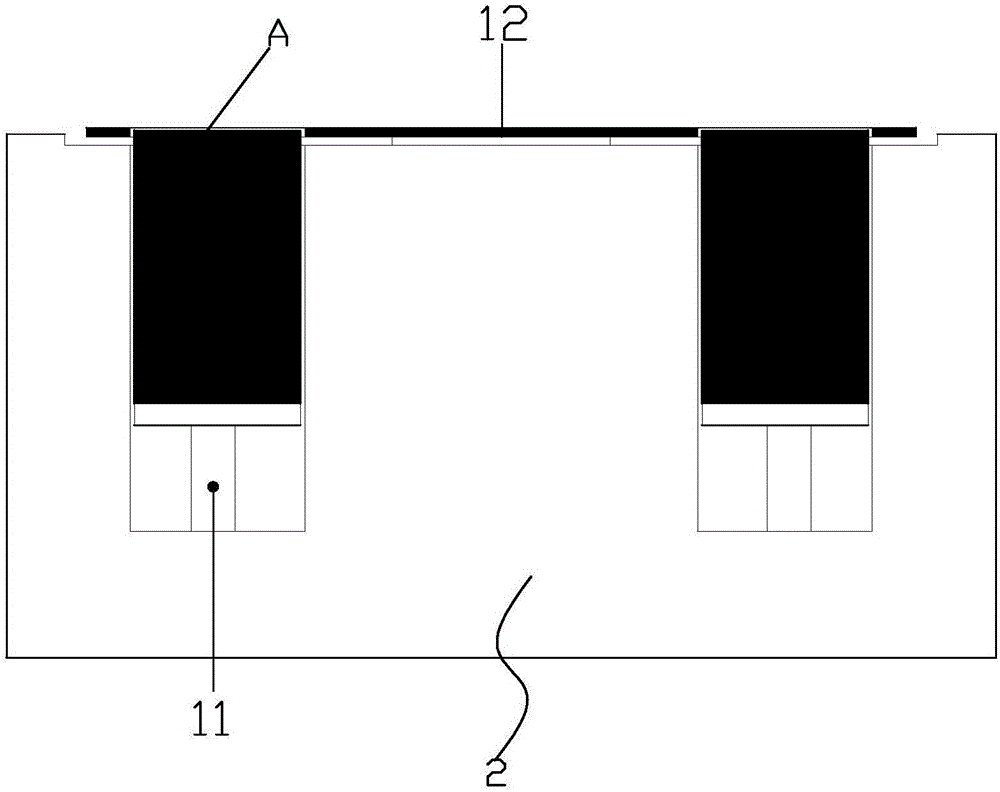

[0030] Please check figure 1 , Sapphire wafer A corrosion and polishing compound processing machine tool, including a machine 1, a vertical rotating arm 6, a spindle system 9, a first motor 8, a loading tray 10 and a negative pressure mechanism. The object tray 10 is provided with a suction hole, and the negative pressure mechanism is connected to the suction hole to make the object tray 10 absorb the wafer through the negative pressure, release the wafer through the negative pressure, and preferably, the number of the suction holes is multiple And arranged according to the rules.

[0031] The top surface of the machine platform 1 is provided with a loading and unloading station 2, a rough throwing station 3, a corrosion station 4 and a fine throwing station 5 arranged at intervals in the circumferential direction. Position 3, corrosion position 4 and fine polishing position 5 are arranged in a circular array.

[0032] The vertical rotating arm 6 is arranged at the axis of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com