Multi-pass metal drawing device based on water lubrication drawing

A drawing device and water-lubricated technology, applied in the direction of the wire drawing die, etc., can solve the problems that cannot meet the requirements of water-based lubricant drawing processing, cannot enter the water-based lubricant, cannot adhere to the pipe well, and achieve Reasonable design, good lubrication and cooling effects, and the effect of improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention are described in detail below: this embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention, and these all belong to the protection scope of the present invention.

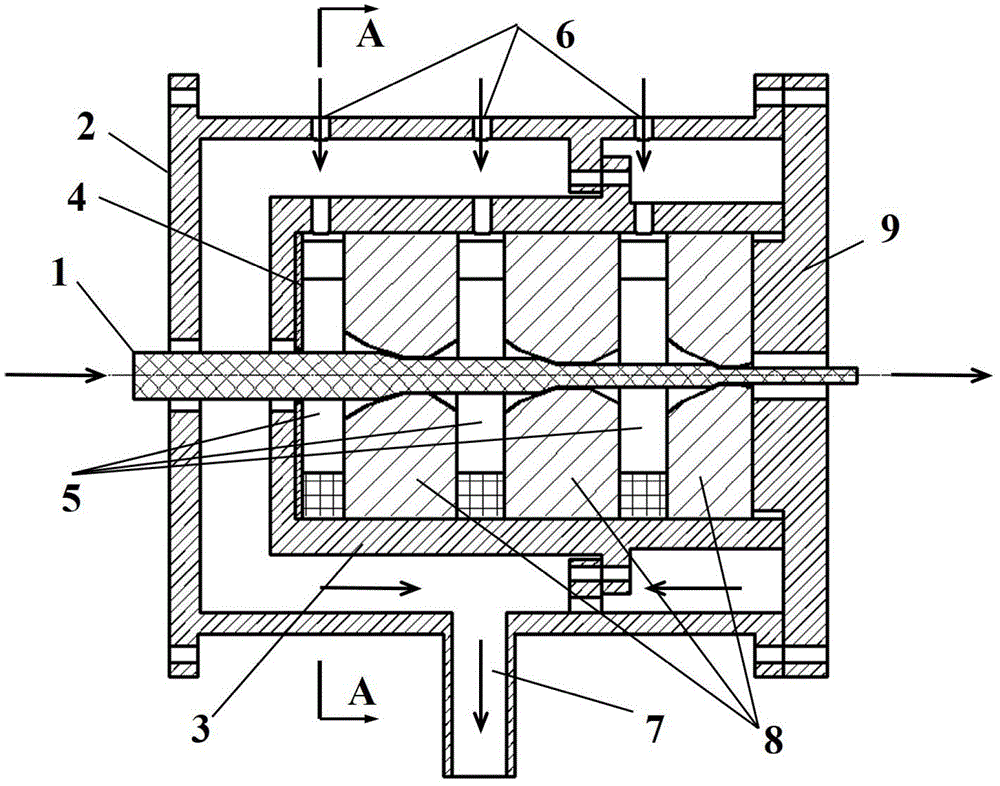

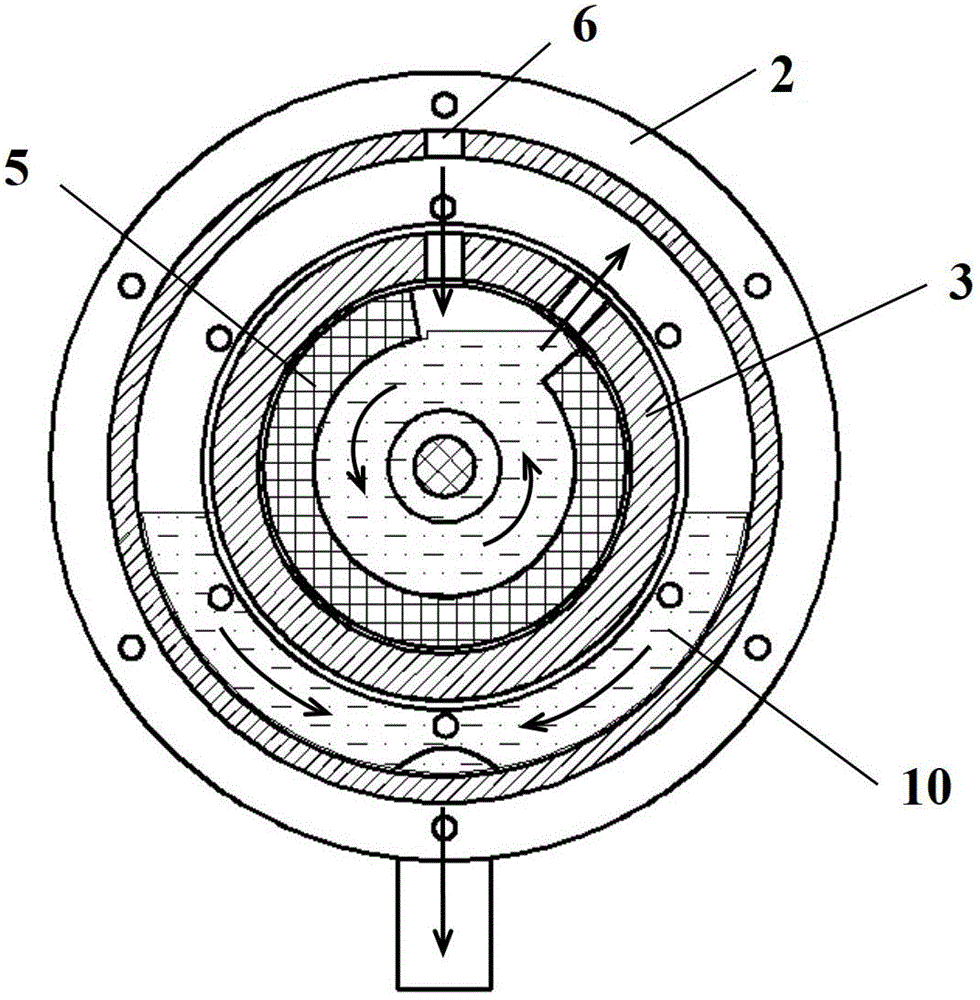

[0024] This embodiment provides a multi-pass metal drawing device based on water-lubricated drawing, including a bracket 2, a drawing chamber 3 fixed inside the bracket 2, a mold set 8 arranged inside the drawing chamber 3, and a sealing ring 4 and the lubricating chamber group 5, and the cover plate 9 fixed on the bracket 2, the drawing cavity 3 communicates with the bracket 2, and the lubricating chamber group 5 is filled with lubricant 10 during the drawing process, so that the pipe wire 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com