Antimony oxide compound flame-retardant PVC soft composite material and preparation method thereof

A composite material, antimony oxide technology, applied in the field of flame retardant materials, can solve the problems of limited improvement of smoke suppression and environmental protection performance, only solve the problems of flame retardancy, etc., to reduce human injury, eliminate dust, and achieve the effect of soft and smooth texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

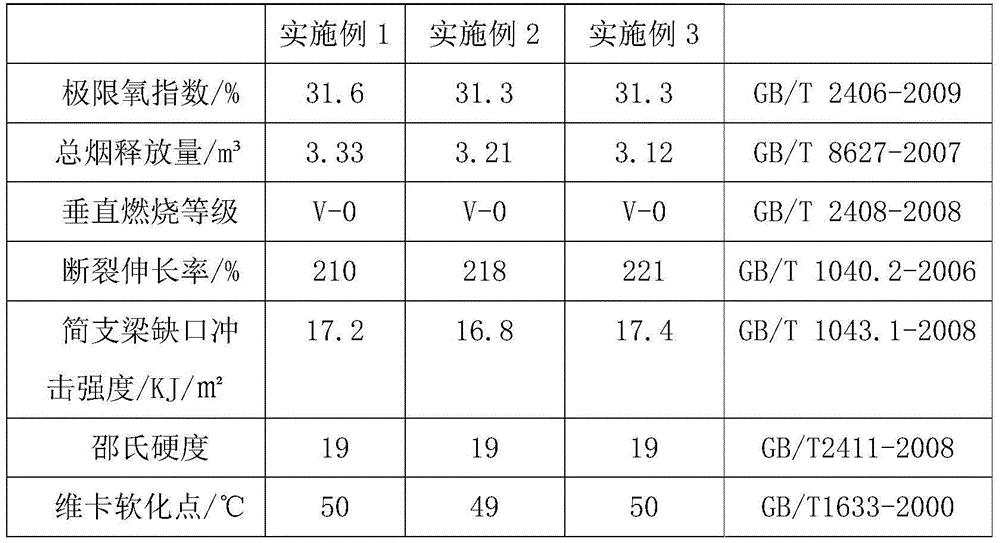

Examples

Embodiment 1

[0030] Weigh respectively according to the following proportions: 100 parts of PVC (SG-3), 65 parts of plasticizer, 10 parts of antimony trioxide, 9 parts of ammonium molybdate, 7 parts of montmorillonite, 7 parts of calcium zinc stabilizer, and 8 parts of EVA , 2 parts of epoxy soybean oil, 6 parts of coupling agent, 3 parts of dispersant.

[0031] Antimony oxide composite flame-retardant PVC soft composite material, the preparation method of which comprises the following steps:

[0032] S1. Modification: modify the surface of antimony trioxide with a coupling agent at a modification temperature of 140° C., a stirring rate of 4000 rpm / min, and a stirring time of 3.5 hours to obtain modified antimony trioxide.

[0033] S2, mixing: place the modified antimony trioxide and PVC (SG-3), plasticizer, ammonium molybdate, montmorillonite, calcium zinc stabilizer, EVA, epoxy soybean oil, and dispersant prepared in S1 Intermittent graded mixing was carried out in the frequency convers...

Embodiment 2

[0037] Weigh respectively according to the following proportions: 100 parts of PVC (SG-3), 55 parts of plasticizer, 5 parts of antimony trioxide, 4 parts of ammonium molybdate, 3 parts of montmorillonite, 3 parts of calcium zinc stabilizer, 3 parts of EVA , 0.5 parts of epoxidized soybean oil, 3 parts of coupling agent, and 1 part of dispersant.

[0038] Antimony oxide composite flame-retardant PVC soft composite material, the preparation method of which comprises the following steps:

[0039] S1. Modification: modify the surface of antimony trioxide with a coupling agent at a modification temperature of 110° C., a stirring rate of 2000 rpm / min, and a stirring time of 4.5 hours to obtain modified antimony trioxide.

[0040] S2, mixing: place the modified antimony trioxide and PVC (SG-3), plasticizer, ammonium molybdate, montmorillonite, calcium zinc stabilizer, EVA, epoxy soybean oil, and dispersant prepared in S1 Intermittent graded mixing was carried out in the frequency co...

Embodiment 3

[0044] Weigh respectively according to the following proportions: 100 parts of PPVC (SG-3), 60 parts of plasticizer, 8 parts of antimony trioxide, 7 parts of ammonium molybdate, 5 parts of montmorillonite, 5 parts of calcium zinc stabilizer, and 6 parts of EVA , 1.2 parts of epoxidized soybean oil, 4 parts of coupling agent, and 2 parts of dispersant.

[0045] Antimony oxide composite flame-retardant PVC soft composite material, the preparation method of which comprises the following steps:

[0046] S1. Modification: modify the surface of antimony trioxide with a coupling agent at a modification temperature of 125° C., a stirring rate of 3000 rpm / min, and a stirring time of 4 hours to obtain modified antimony trioxide.

[0047]S2, mixing: place the modified antimony trioxide and PVC (SG-3), plasticizer, ammonium molybdate, montmorillonite, calcium zinc stabilizer, EVA, epoxy soybean oil, and dispersant prepared in S1 Intermittent graded mixing was carried out in the frequency...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com