Antimony-based compounding flame retardant masterbatch for PVC and preparation method thereof

A flame-retardant masterbatch and antimony-based technology, which is applied in the field of flame-retardant materials, can solve the problems of limited flame-retardant and smoke suppression effects, difficulty in general use, and no patents found for antimony-based flame-retardant masterbatches. Environmental protection, cost saving, and improved flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

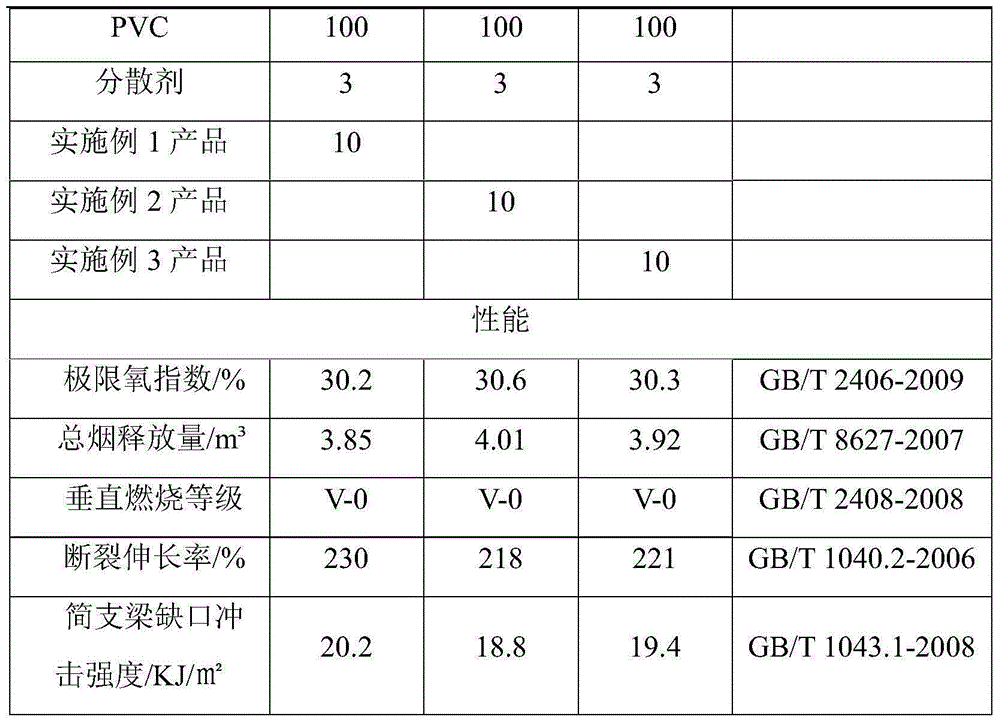

Embodiment 1

[0029] Weigh respectively according to the following proportions: 35 kg of PVC resin, 40 kg of antimony trioxide (main content over 99.6%, particle size 1.0 μm), 25 kg of molybdenum trioxide, 13 kg of montmorillonite, 8 kg of organotin, titanic acid 6 kg of ester coupling agent.

[0030] S1: Antimony trioxide modification: Weigh antimony trioxide and titanate according to the above amount and put them into a high-speed mixer for modification. The modification temperature is 140°C, the stirring rate is 4000rpm / min, and the stirring time is 3.5h;

[0031] S2: Put the modified antimony trioxide and other components (except PVC resin particles) into the variable frequency high-speed mixer for high-speed mixing, the speed is 3000rpm / min, and the temperature is controlled at 75°C; the uniformly mixed materials Transfer to the secondary mixing equipment, add PVC resin granules, and mix at a low speed, the rotation speed is 900rpm / min, the mixing time is 7min, and the temperature is n...

Embodiment 2

[0035] Weigh respectively according to the following proportions: 20 kg of PVC resin, 25 kg of antimony trioxide (main content over 99.6%, particle size 1.0 μm), 13 kg of molybdenum trioxide, 8 kg of montmorillonite, 3 kg of organotin, aluminate 3 kg of ester coupling agent.

[0036] S1: Antimony trioxide modification: Weigh antimony trioxide and titanate according to the above amounts and put them into a high-speed mixer for modification. The modification temperature is 100°C, the stirring rate is 2000rpm / min, and the stirring time is 4.5h.

[0037] S2: Put the modified antimony trioxide and other components (except PVC resin particles) into the variable frequency high-speed mixer for high-speed mixing, the speed is 2000rpm / min, and the temperature is controlled at 90°C; the uniformly mixed materials Transfer to the secondary mixing equipment, add PVC resin granules, and mix at a low speed, the speed is 6000rpm / min, the mixing time is 10min, and the temperature is not control...

Embodiment 3

[0041] Weigh respectively according to the following proportions: 28 kg of PVC resin, 32 kg of antimony trioxide (main content over 99.6%, particle size 1.0 μm), 19 kg of molybdenum trioxide, 10 kg of montmorillonite, 6 kg of organotin, titanic acid 4 kg of ester coupling agent.

[0042] S1: Antimony trioxide modification: Weigh antimony trioxide and titanate according to the above amounts and put them into a high-speed mixer for modification. The modification temperature is 120° C., the stirring rate is 3000 rpm / min, and the stirring time is 4 hours.

[0043] S2: Put the modified antimony trioxide and other components (except PVC resin particles) into a variable frequency high-speed mixer for high-speed mixing, the speed is 4000rpm / min, and the temperature is controlled at 60°C; the uniformly mixed materials Transfer to the secondary mixing equipment, add PVC resin granules, and mix at a low speed with a rotation speed of 1200rpm / min and a mixing time of 5min without temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com