Flame-retardant corrosion-resistant paint for power equipment

A power equipment, corrosion-resistant technology, applied in anti-corrosion coatings, fire-retardant coatings, anti-fouling/underwater coatings, etc., can solve the problems of equipment status, such as the inability to perform real-time technical analysis and judgment, and the lack of condition-based maintenance conditions, and achieve superior performance. Flame retardant, the effect of improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

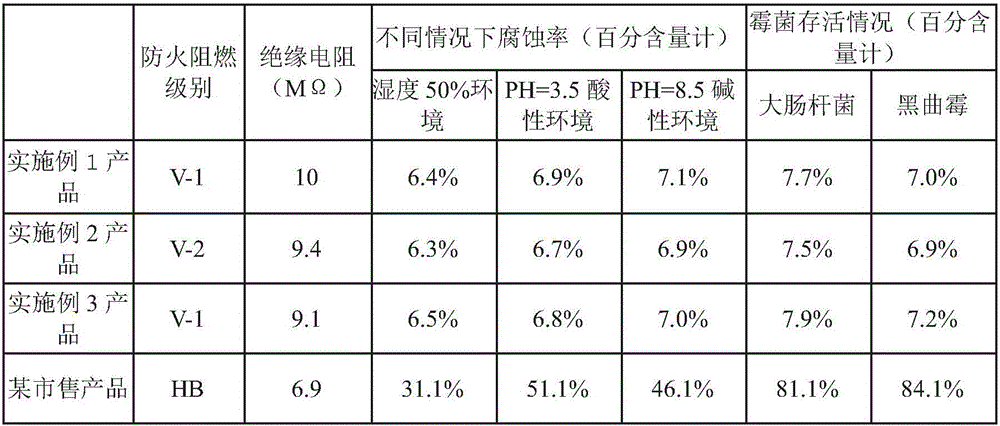

Examples

Embodiment 1

[0016] The flame-retardant and corrosion-resistant coating for electric equipment in this embodiment is composed of the following components in parts by mass: 24 parts of SEBS thermoplastic elastomer, 22 parts of polyester urethane resin, 22 parts of halogenated butyl rubber, dipropylene glycol 20 parts of methyl ether, 22 parts of peanut oil, 22 parts of polyglycerin, 20 parts of coal tar, 22 parts of sandalwood oil, 22 parts of imperata, 20 parts of silver sulfadiazine, 20 parts of hydrogen peroxide, 20 parts of aluminum phosphide, 22 parts of tourmaline powder, 20 parts of lead difluoride powder, 18 parts of silicon dioxide powder, 22 parts of titanium dioxide powder, 20 parts of fly ash, 18 parts of calcium fluoride powder, 20 parts of modified attapulgite powder, 18 parts of corundum powder, triethylene glycol 18 parts of diisocaprylate, 18 parts of polyacrylonitrile fiber, 16 parts of aluminum stearate, 12 parts of nano-zinc oxide, 10 parts of oxalic acid, 10 parts of iso...

Embodiment 2

[0022] The flame-retardant and corrosion-resistant coating for electric equipment in this embodiment is composed of the following components in parts by mass: 26 parts of SEBS thermoplastic elastomer, 24 parts of polyester urethane resin, 24 parts of halogenated butyl rubber, dipropylene glycol 22 parts of methyl ether, 24 parts of peanut oil, 24 parts of polyglycerin, 22 parts of coal tar, 24 parts of sandalwood oil, 24 parts of imperata, 22 parts of silver sulfadiazine, 22 parts of hydrogen peroxide, 22 parts of aluminum phosphide, 24 parts of tourmaline powder, 22 parts of lead difluoride powder, 20 parts of silicon dioxide powder, 24 parts of titanium dioxide powder, 22 parts of fly ash, 20 parts of calcium fluoride powder, 22 parts of modified attapulgite powder, 20 parts of corundum powder, triethylene glycol 20 parts of diisocaprylate, 20 parts of polyacrylonitrile fiber, 18 parts of aluminum stearate, 14 parts of nano-zinc oxide, 12 parts of oxalic acid, 12 parts of iso...

Embodiment 3

[0028] The flame-retardant and corrosion-resistant coating for electric equipment in this embodiment is composed of the following components in parts by mass: 28 parts of SEBS thermoplastic elastomer, 26 parts of polyester urethane resin, 26 parts of halogenated butyl rubber, dipropylene glycol 24 parts of methyl ether, 26 parts of peanut oil, 26 parts of polyglycerol, 24 parts of coal tar, 26 parts of sandalwood oil, 26 parts of imperata, 24 parts of silver sulfadiazine, 24 parts of hydrogen peroxide, 24 parts of aluminum phosphide, 26 parts of tourmaline powder, 24 parts of lead difluoride powder, 22 parts of silicon dioxide powder, 26 parts of titanium dioxide powder, 24 parts of fly ash, 22 parts of calcium fluoride powder, 24 parts of modified attapulgite powder, 22 parts of corundum powder, triethylene glycol 22 parts of diisocaprylate, 22 parts of polyacrylonitrile fiber, 20 parts of aluminum stearate, 16 parts of nano-zinc oxide, 14 parts of oxalic acid, 14 parts of iso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com