Flame-retardant and anti-corrosive coating for power equipment

A kind of electric equipment, corrosion-resistant technology, applied in the electric power field, can solve the problems such as the inability of real-time technical analysis and judgment of equipment status and the lack of condition maintenance conditions, and achieve the effect of superior flame retardant and improved product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

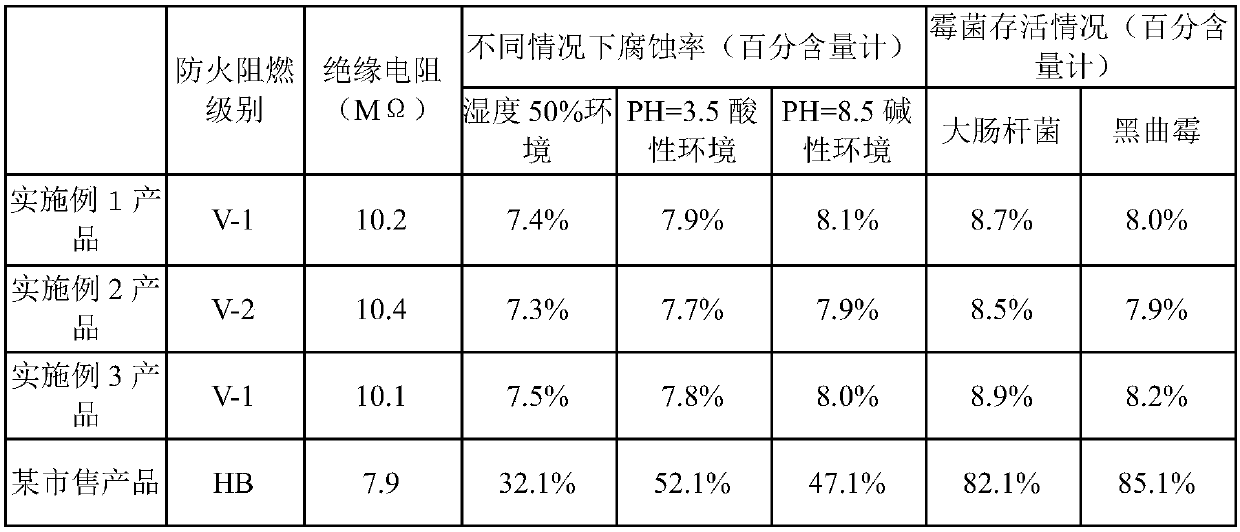

Embodiment 1

[0016] The flame-retardant and corrosion-resistant coating for electric equipment in this embodiment consists of the following components in parts by mass: 10 parts of melamine copolymer resin, 8 parts of styrene-maleic anhydride copolymer, 8 parts of nitrile rubber powder, polychlorinated 6 parts of biphenyl, 8 parts of ammonium polyphosphate, 8 parts of triphenyl phosphate, 6 parts of zinc hydroxystannate, 8 parts of diazolidinyl urea, 8 parts of propiconazole, 6 parts of calcium hypochlorite, 6 parts of silver sulfadiazine 6 parts, limonene 6 parts, sodium phosphate 8 parts, flake graphite powder 6 parts, diaminodiphenylmethane 4 parts, calcium sulfate dihydrate 8 parts, zinc fluoride 6 parts, zircon powder 4 parts, aluminum phosphate powder 6 parts , 4 parts of zinc sulfate, 4 parts of jade powder, 6 parts of glass fiber powder, 6 parts of transformer oil, 6 parts of propylene glycol methyl ether acetate, 6 parts of amyl propionate, 6 parts of aminopropyl triethoxysilane, a...

Embodiment 2

[0022] The flame-retardant and corrosion-resistant coating for electric equipment in this embodiment consists of the following components in parts by mass: 12 parts of melamine copolymer resin, 10 parts of styrene-maleic anhydride copolymer, 10 parts of nitrile rubber powder, polychlorinated 8 parts of biphenyl, 10 parts of ammonium polyphosphate, 10 parts of triphenyl phosphate, 8 parts of zinc hydroxystannate, 10 parts of diazolidinyl urea, 10 parts of propiconazole, 8 parts of calcium hypochlorite, 8 parts of silver sulfadiazine 8 parts, limonene 8 parts, sodium phosphate 10 parts, flake graphite powder 8 parts, diaminodiphenylmethane 6 parts, calcium sulfate dihydrate 10 parts, zinc fluoride 8 parts, zircon powder 6 parts, aluminum phosphate powder 8 parts , 6 parts of zinc sulfate, 6 parts of jade powder, 8 parts of glass fiber powder, 8 parts of transformer oil, 8 parts of propylene glycol methyl ether acetate, 8 parts of amyl propionate, 8 parts of aminopropyl triethoxys...

Embodiment 3

[0028]The flame-retardant and corrosion-resistant coating for electric equipment in this embodiment consists of the following components in parts by mass: 14 parts of melamine copolymer resin, 12 parts of styrene-maleic anhydride copolymer, 12 parts of nitrile rubber powder, polychlorinated 10 parts of biphenyl, 12 parts of ammonium polyphosphate, 12 parts of triphenyl phosphate, 10 parts of zinc hydroxystannate, 12 parts of diazolidinyl urea, 12 parts of propiconazole, 10 parts of calcium hypochlorite, 10 parts of silver sulfadiazine 10 parts of limonene, 12 parts of sodium phosphate, 10 parts of flake graphite powder, 8 parts of diaminodiphenylmethane, 12 parts of calcium sulfate dihydrate, 10 parts of zinc fluoride, 8 parts of zircon powder, 10 parts of aluminum phosphate powder , 8 parts of zinc sulfate, 8 parts of jade powder, 10 parts of glass fiber powder, 10 parts of transformer oil, 10 parts of propylene glycol methyl ether acetate, 10 parts of amyl propionate, 10 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com