Patents

Literature

110 results about "Zinc fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc fluoride (ZnF₂) is an inorganic chemical compound. It is encountered as the anydrous form and also as the tetrahydrate, ZnF₂ · 4H₂O (rhombohedral crystal structure). It has a high melting point and has the rutile structure containing 6 coordinate zinc, which suggests appreciable ionic character in its chemical bonding. Unlike the other zinc halides, ZnCl₂, ZnBr₂ and ZnI₂, it is not very soluble in water.

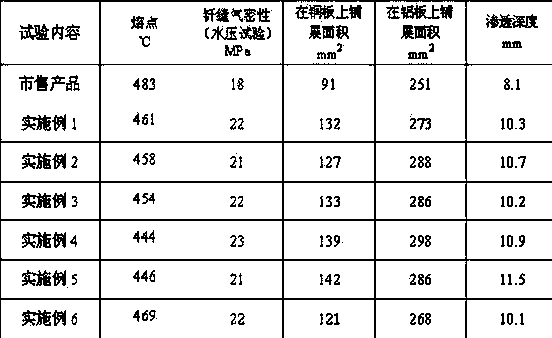

Brazing flux without corrosion for aluminum and aluminum alloy brazing

InactiveCN101439449ASimple preparation processLow costWelding/cutting media/materialsSoldering mediaPotassium fluorideTin Fluorides

The invention relates to a corrosion-free soldering flux used for braze welding aluminium and aluminium alloy. Counted by weight percentage, the soldering flux used for braze welding the aluminium and aluminium alloy comprises the following components: 32.0-34.0 percent of cesium fluoride, 44.0-46.5 percent of aluminium fluoride, 20.5-23.5 percent of potassium fluoride, 0.5-2.5 percent of one, two or three materials selected from tin fluoride, zinc fluoride and lithium fluoride. The corrosion-free soldering flux of the invention has low melting point and better soldering performance.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

Novel brazing flux used for stainless steel and aluminum brazing

InactiveCN103521942AEasy to prepareLow costWelding/cutting media/materialsSoldering mediaCopper fluoridePotassium

The invention relates to brazing flux used for brazing, in particular to novel brazing flux used for stainless steel and aluminum brazing. The composition of the brazing flux comprises potassium fluoroaluminate+potassium hexafluoroaluminate (KA1F4+K3A1F6) eutecticum, zinc fluoride (ZnF2), copper fluoride (CuF2), and stannic fluoride (SnF4). The novel brazing flux is free of corrosion, and ingredient preparation is simple and convenient, so that production cost is low. Under high temperature, the madefaction and the spreadability of the brazing flux are favorable to the madefaction and the spreadability of brazing filler metal. Welded products are thin in welding joint, high in strength, free of cold solder joints, free of brazing filler metal stacking, and small in residue of brazing flux after welding. Moreover, the residue is easy to clean up. The novel brazing flux used for stainless steel and aluminum brazing is low in cost, simple in preparation, and high in practical value.

Owner:QINGDAO SHENGJIA INFORMATION TECH

Deep ultraviolet magnesium fluoride crystal growth method

InactiveCN102925963ASmall sizeImprove integrityPolycrystalline material growthBy pulling from meltProcess equipmentCzochralski method

The invention discloses deep ultraviolet magnesium fluoride crystal growth method and relates to the technical field of single crystal growth. The method comprises the steps of placing mixed powder of magnesium fluoride (MgF2) and zinc fluoride (ZnF2), and seed crystal in a platinum crucible, placing the platinum crucible into a single crystal furnace, adding nitrogen into the single crystal furnace, and growing magnesium fluoride single crystal by means of an open-type czochralski method. The method is good in integrity of grown crystal, bubble-free and inclusion-complex-free, large in crystal size, not prone to cracking, high in ultraviolet band transmittance rate, high in yield, simple in process equipment, low in energy consumption, and beneficial for industrial production.

Owner:合肥嘉东光学股份有限公司

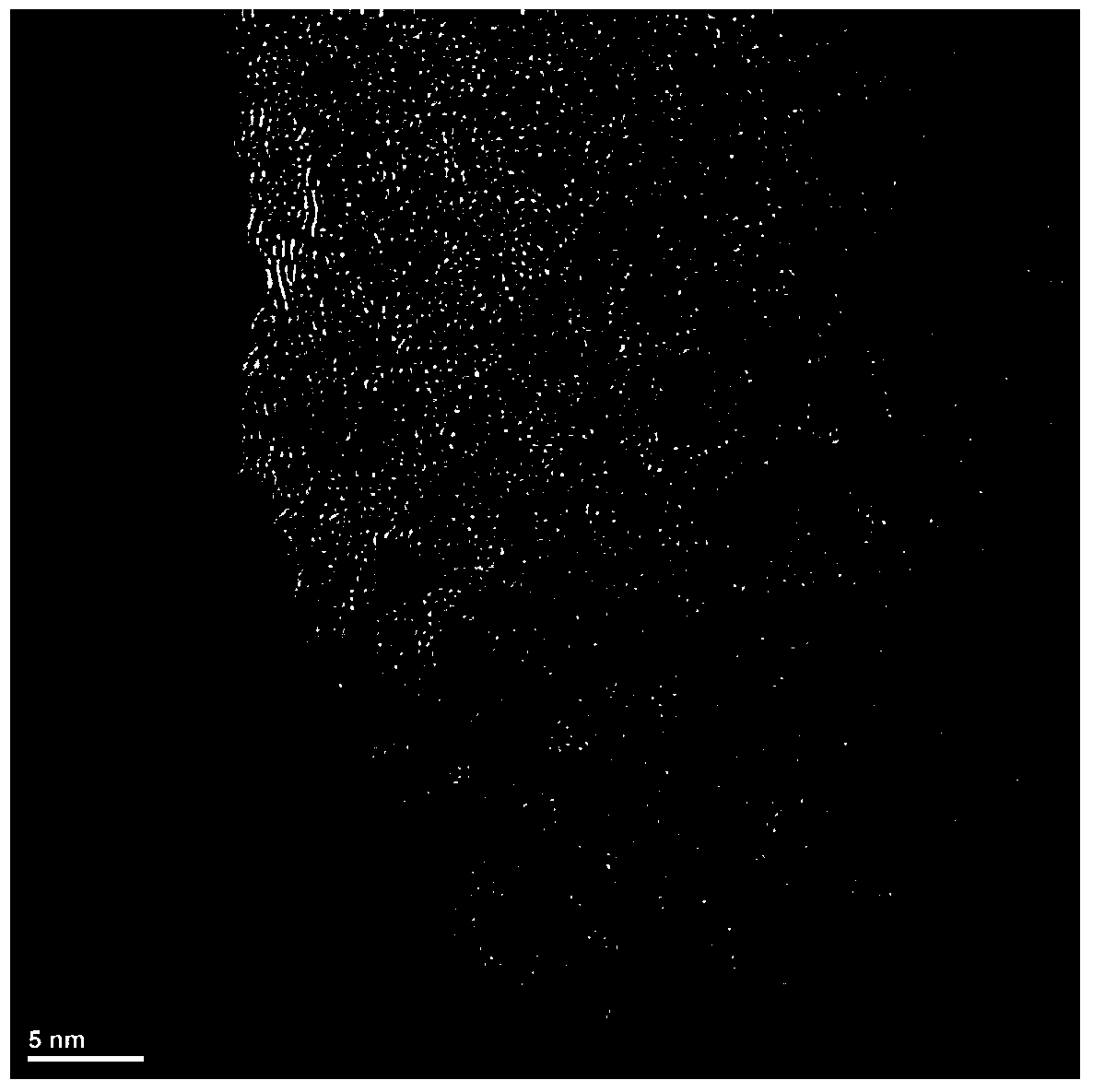

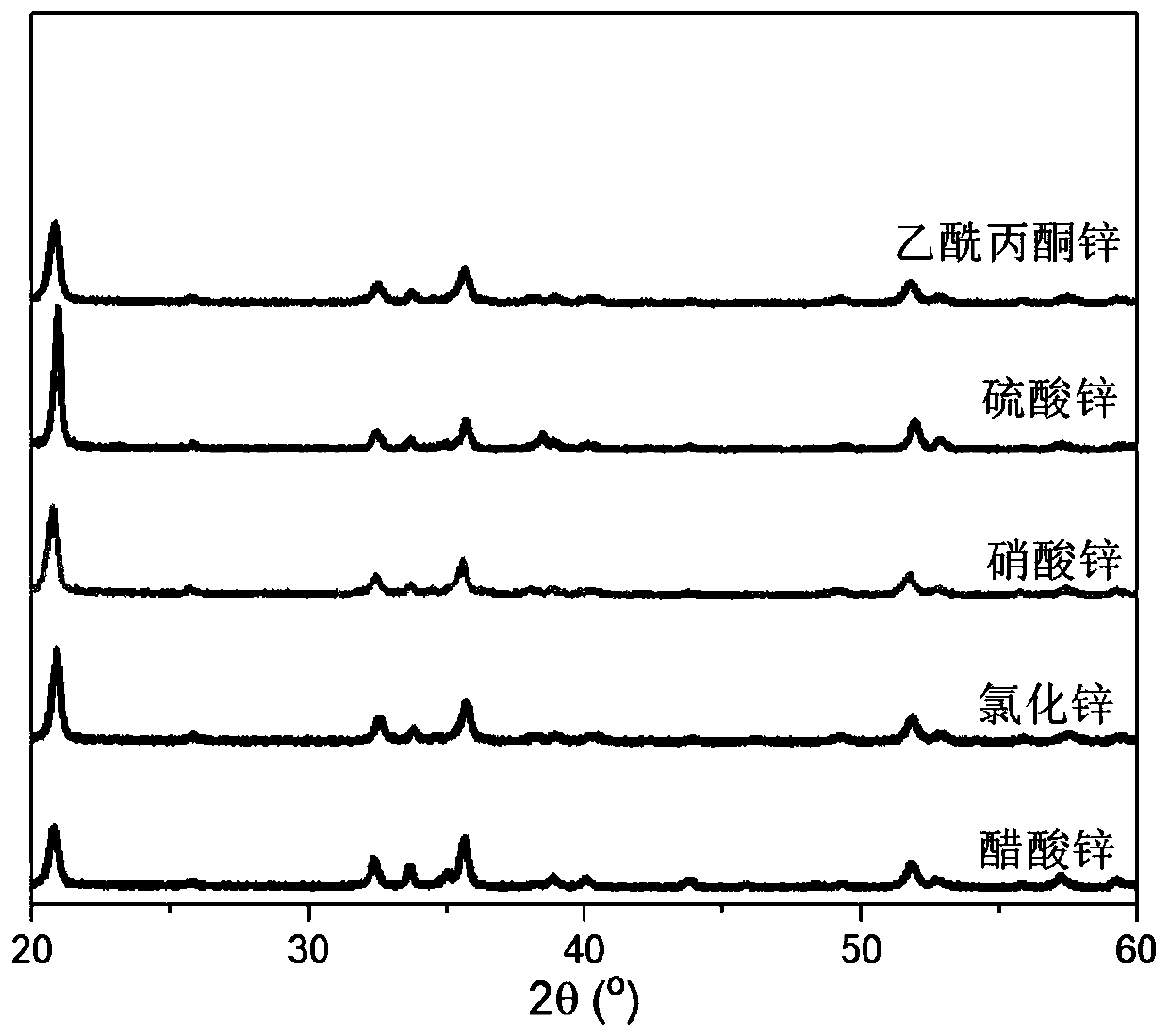

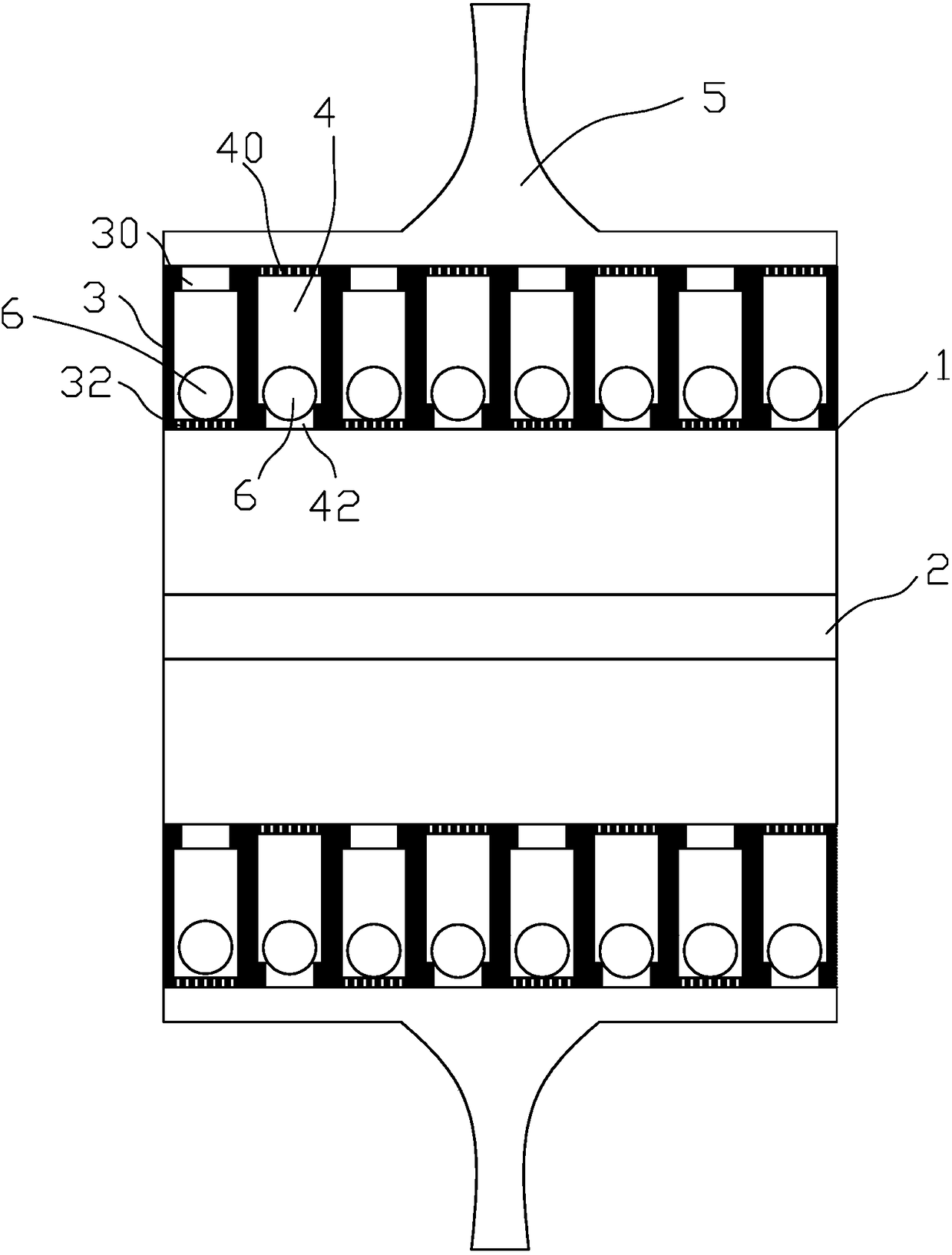

Preparation method of graphene-ZnO nanoparticle composite material

ActiveCN103482614ASmall grain sizeSimple methodMaterial nanotechnologyZinc oxides/hydroxidesZinc bromideFiltration

The invention discloses a preparation method of a graphene-ZnO nanoparticle composite material. The preparation method comprises the following steps: step 1): dissolving raw materials, namely graphene oxide and zinc salt, in water according to a certain mass ratio and uniformly mixing; step 2): separating the graphene oxide from the well mixed liquid, obtained in the step 1, by centrifugation or suction filtration and washing with water or alcohol; and step 3) performing heat treatment on the product, obtained in the step 2, in air or oxygen to get the graphene-ZnO nanoparticle composite material, wherein the zinc salt is one of zinc fluoride, zinc chloride, zinc bromide, zinc sulfate, zinc nitrate, zinc acetate and zinc phosphate, the heat treatment temperature is 150-1000 DEG C, and the heat treatment time is 5s-10h. The preparation method disclosed by the invention is simple, green and environment-friendly, and can effectively reduce the use of chemical reagents.

Owner:SOUTHEAST UNIV

Not corrosive soldering flux in use for high frequency induced pressure braze welding

InactiveCN101003110AImprove pass rateImprove liquidityWelding/cutting media/materialsSoldering mediaTin FluoridesPotassium

A non-corrosion solder for the HF induced pressure soldering between stainless steel and aluminum contains the eutecticevaporate of potassium tetrafluoroaluminate and potassium hexafluoroaluminate (42-97 Wt%), lithium fluoride (0.5-8.5), Zinc fluoride (0.5-4.5), silicon powder and / or potassium pluorosilicate (2-4.5), nickel fluoride (0-3), cesium fluoride or cesium fluoroaluminate (0-3), copper fluoride (0-0.3), tin fluoride (0-0.5) and cadmium fluoride (0-3.5).

Owner:李昕

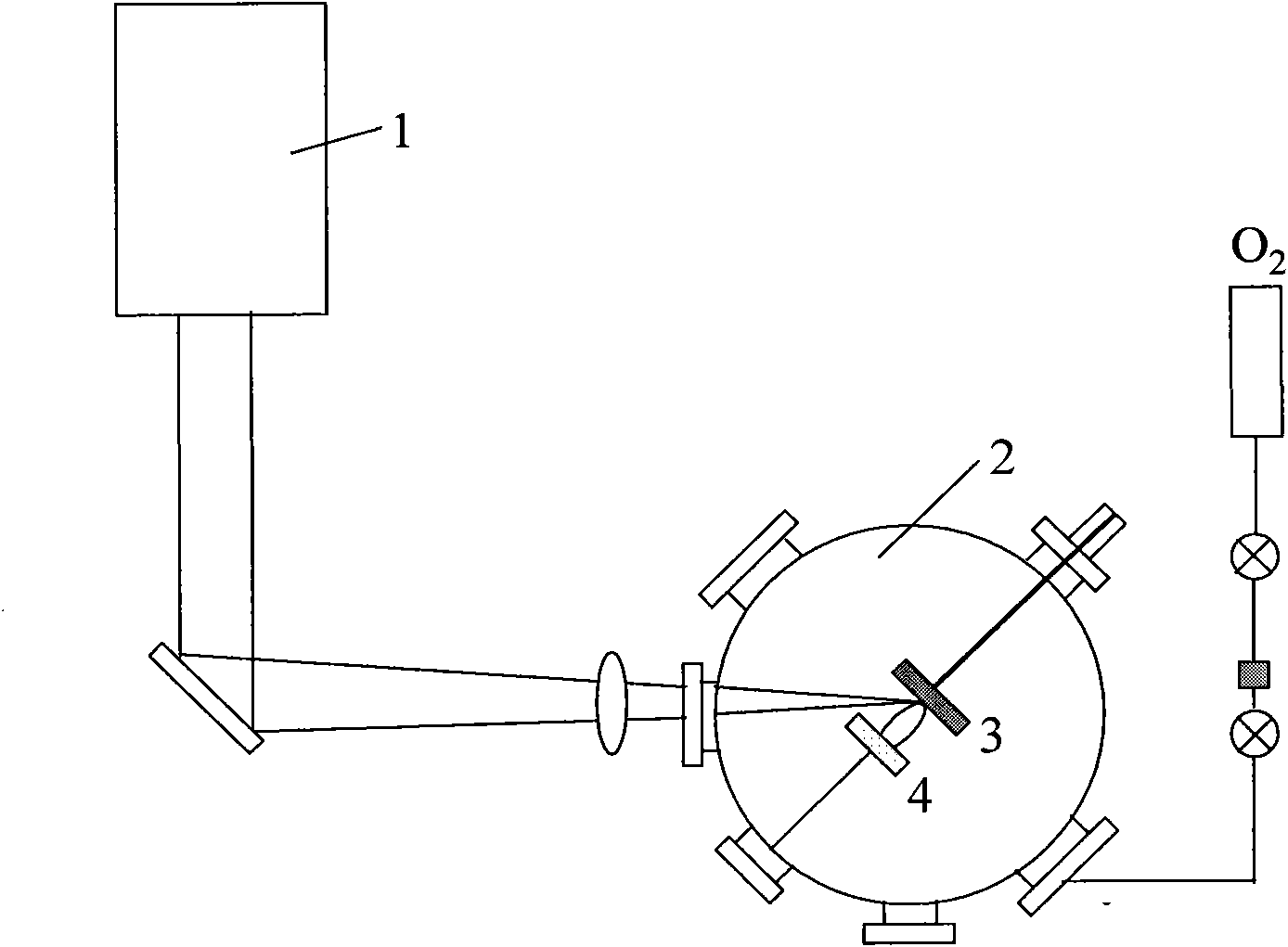

Method for growing n-type transparent conducting ZnO crystal thin film by F doping

InactiveCN101831701AAchieve n-type dopingReal-time dopingPolycrystalline material growthFrom condensed vaporsLaser frequencyPulsed laser deposition

The invention discloses a method for growing an n-type transparent conducting ZnO crystal thin film by F doping, which adopts a pulse laser deposition method. A target material is a sintering ceramic target moulded by pressing pure zinc oxide and pure zinc fluoride power subjected to ball-milling and mixing, wherein the molar content of zinc fluoride is 1-3 percent; and then the n-type transparent conducting ZnO crystal thin film grows on a substrate in a growth chamber of a pulse laser deposition device by adopting pure O2 as a growing atmosphere and controlling O2 pressure of 0.05-0.5Pa, the laser frequency of 3-5Hz and the growth temperature of 30-500 DEG C. The method can realize real-time doping, and the doping concentration is controlled by adjusting the growth temperature and the molar content of F in the target material. The n-type ZnO crystal thin film prepared by the method of the invention has favorable optoelectronic performance, repeatability and stability.

Owner:ZHEJIANG UNIV

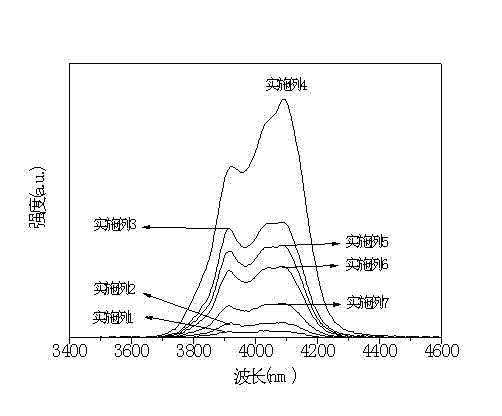

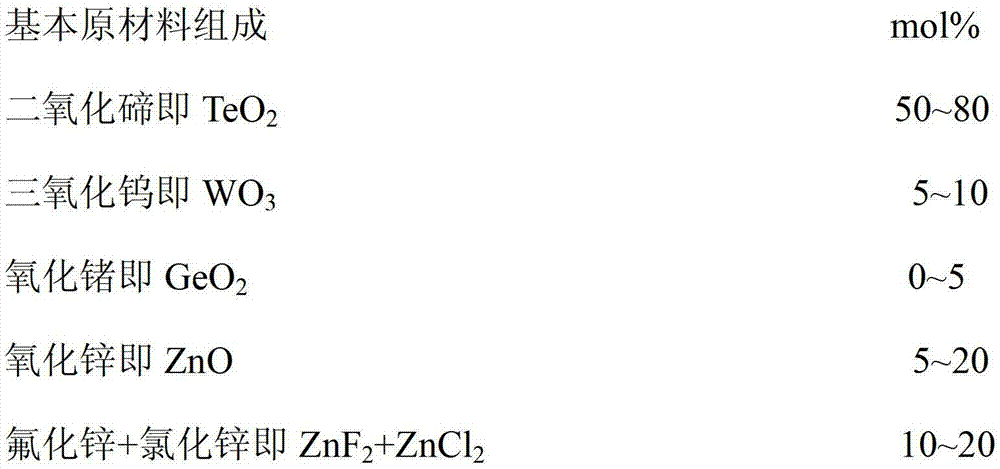

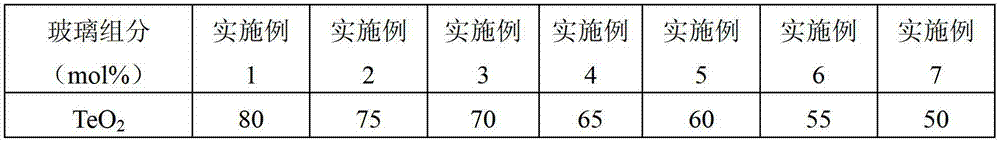

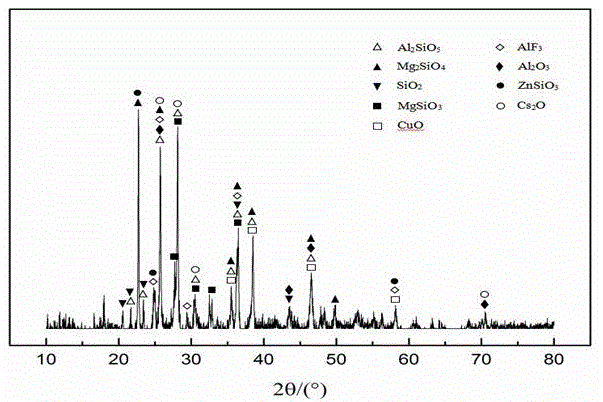

Method for preparing oxygen fluorine chlorine tellurate glass with intermediate infrared fluorescence output at 4 mu m

The invention relates to the technical field of intermediate infrared rare earth doped luminescent glass application, and aims at solving the technical problem of providing a method for preparing oxygen fluorine chlorine tellurate glass with intermediate infrared fluorescence output at 4 mu m. The glass is good in glass forming property, high in infrared light transmission rate, good in luminescence property and beneficial to output of fluorescence and laser of 4 mu m. The oxygen fluorine chlorine tellurate glass prepared by using a fusion method is tellurate glass which contains zinc fluoride and zinc chloride, and due to the appropriate amount of contains zinc fluoride and zinc chloride, the hydroxyl content and the phonon energy in the system are greatly reduced, so that the forming capability of the glass is effectively improved, the doping amount of rare earth ions is increased, and the fluorescence service lives of the rare earth ions are prolonged. By adopting the doping amount of the external doping rare earth ions, namely, Ho<3+> and Yb<3+>, the pumping efficiency of 980nm is greatly improved, and tests show that the oxygen fluorine chlorine tellurate glass has remarkable fluorescence output at 4 mu m.

Owner:CHINA ELECTRONICS TECH GRP NO 23 RES INST

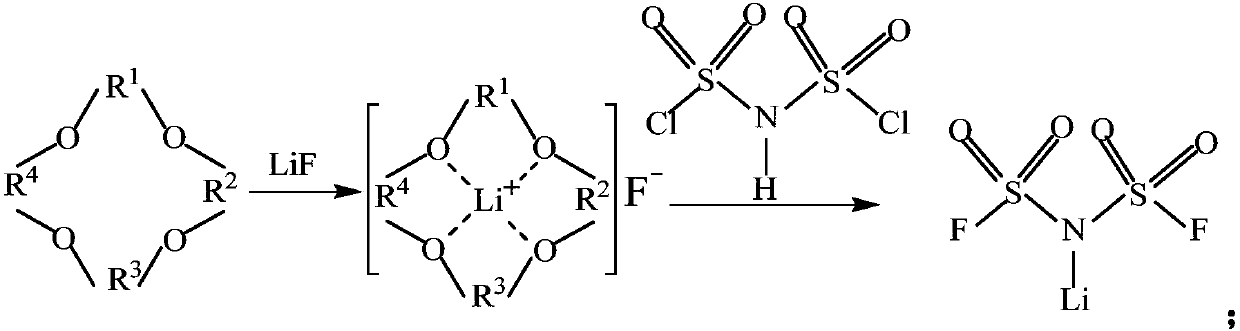

Synthesis method for bis(fluorosulfonyl)imide salt

The invention discloses a synthesis method for a bis(fluorosulfonyl)imide salt, wherein the method comprises the following steps: (one) under the protection of nitrogen, dissolving a bis(chlorosulfonyl)imide salt in a nonprotic organic solvent to obtain a bis(chlorosulfonyl)imide salt organic solution; (two) under a stirring condition, adding an excess compound fluridizer into the organic solution, then heating to a temperature being 8 DEG C-20 DEG C higher than an organic solvent boiling point temperature, and making the bis(chlorosulfonyl)imide salt to undergo an effective fluorination reaction in the organic solvent, wherein the compound fluridizer is selected from at least two substances of antimony trifluoride, potassium fluoride, zinc fluoride and aluminum fluoride; (three) after the reaction is finished, filtering the reaction liquid, and concentrating the filtrate to obtain a concentrated solution; and (four) crystallizing the concentrated solution, filtering, drying, and thus obtaining the high-purity bis(fluorosulfonyl)imide salt. The synthesis method has the advantages of simple operation, high product productive rate, no toxic reagent to pollute the environment, and high purity of the product, and is suitable for large-scale production in industry.

Owner:JIANGSU GUOTAI SUPER POWER NEW MATERIALS

Non-corrosive solder for soldering stainless iron and aluminium

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

Preparation method and application of sector hydroxyl zinc fluoride

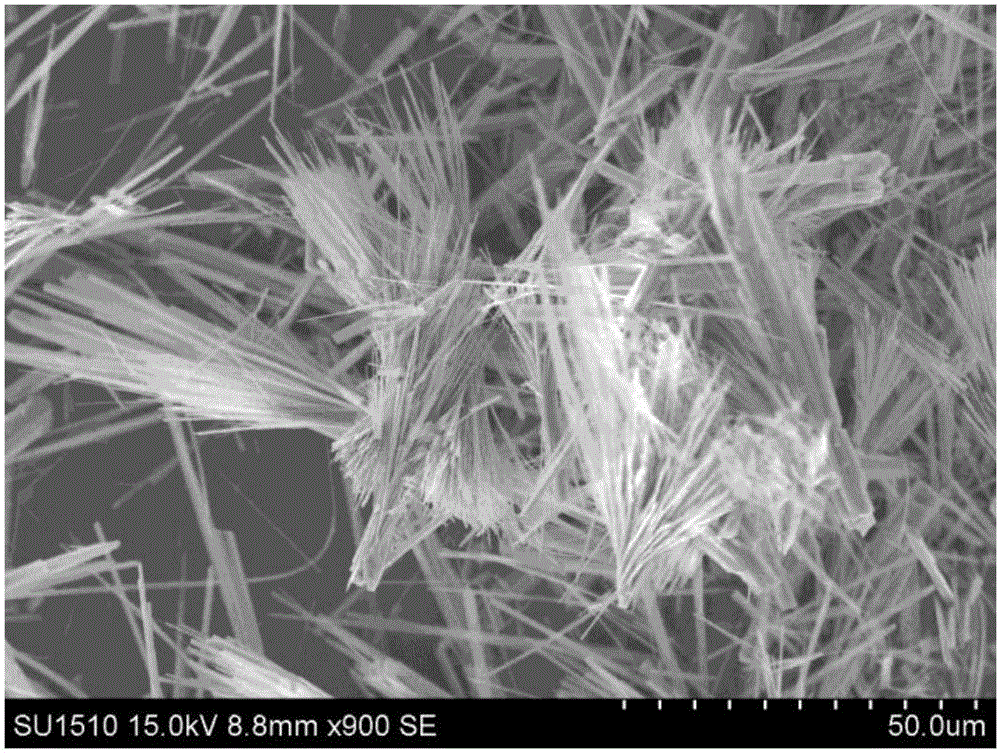

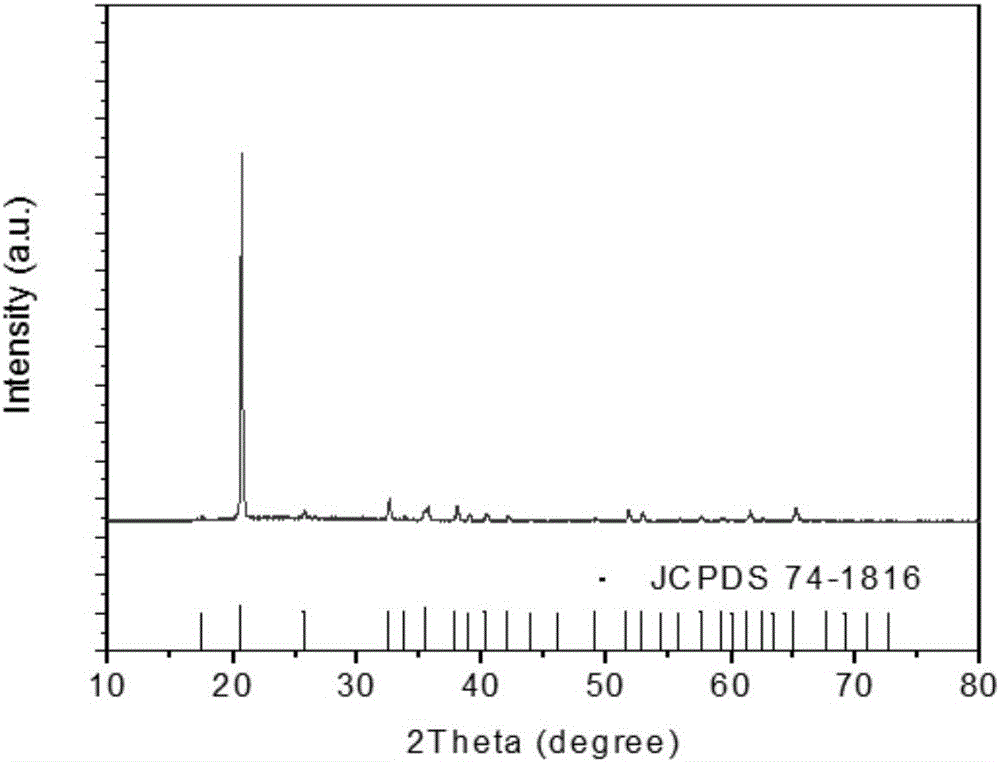

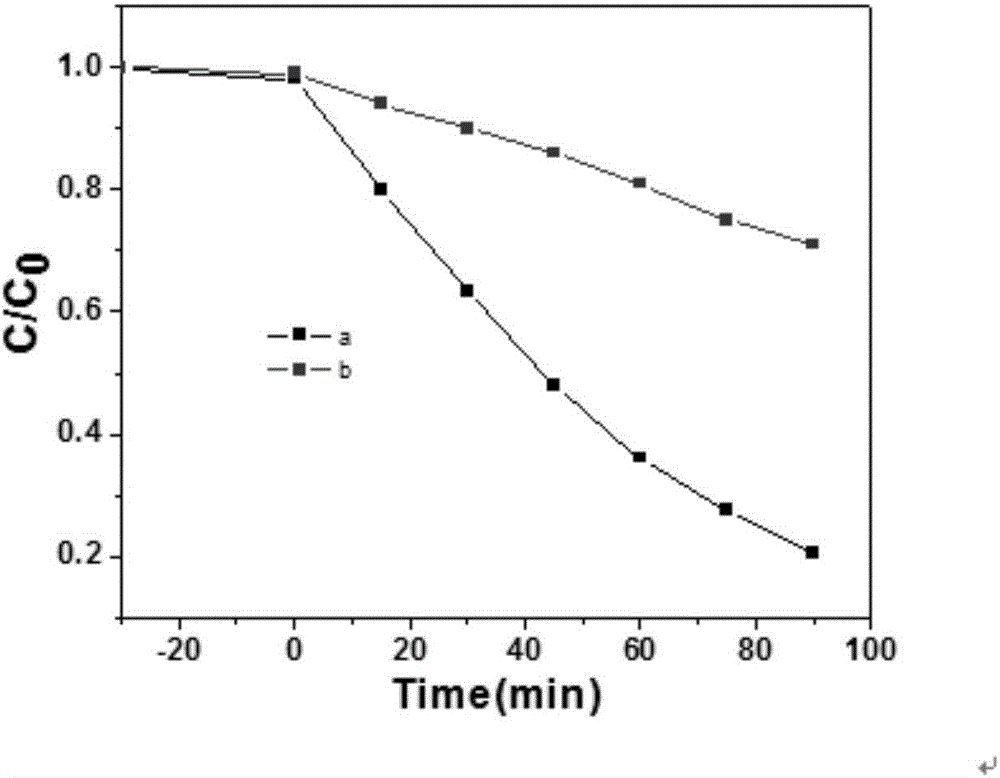

InactiveCN106044842ANovel structureNovel sector-shaped zinc hydroxyfluorides with novel methodsPhysical/chemical process catalystsZinc compoundsWastewaterHigh pressure

The invention discloses a preparation method of and application of sector hydroxyl zinc fluoride. The preparation method includes: self-making zinc oxide, taking 35ml of water, adding 0.7-1.5mmol of the zinc oxide under a stirring condition, adding 3-6mmol of ammonium fluoride, stirring for 30 minutes, adding the mixed solution into a high-pressure kettle with a teflon lining, performing constant-temperature hydrothermal reaction at 180 DEG C for 24 hours, and centrifuging, washing and drying to obtain the hydroxyl zinc fluoride. The preparation method has the advantages that the method uses the self-made zinc oxide as the raw material to prepare the hydroxyl zinc fluoride, the novel-structured sector hydroxyl zinc fluoride is obtained, and the method is simple, low in cost, good in reproducibility and stability, capable of efficiently degrading methylene blue waste aqueous solution, high in catalytic activity and capable of achieving large-scale popularization favorably.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

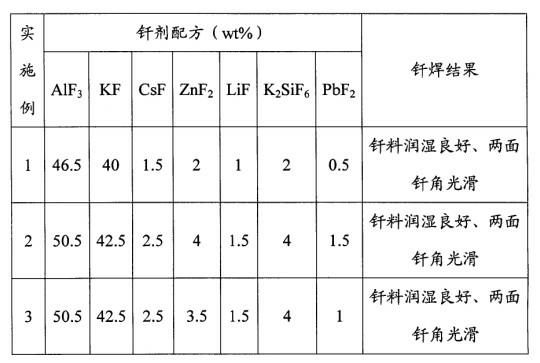

Highly-active soldering flux suitable for stepped brazing of magnesium-aluminum alloy and preparation method of highly-active soldering flux

InactiveCN102423834AHigh activityImprove efficiencyWelding/cutting media/materialsSoldering mediaAluminum fluoridePotassium fluoride

The invention provides a highly-active soldering flux suitable for stepped brazing of a magnesium-aluminum alloy, which comprises the following components by weight percent: 46.5-50.5 percent of aluminum fluoride, 40-42.5 percent of potassium fluoride, 1.5-2.5 percent of cesium fluoride, 2-4 percent of zinc fluoride, 1-1.5 percent of lithium fluoride, 2-4 percent of potassium fluosilicate and 0.5-1.5 percent of lead fluoride. The invention also provides a preparation method of the soldering flux. The invention has the advantage that the brazing temperature can reach above 590 DEG C. The soldering flux can be ground and prepared in atmosphere, has low preparation process cost, accurate finished product composition and high activity, is noncorrosive, is nonhygroscopic in air and can also be saved for a long time.

Owner:HOHAI UNIV CHANGZHOU

High specific surface area catalyst, preparation method and applications thereof

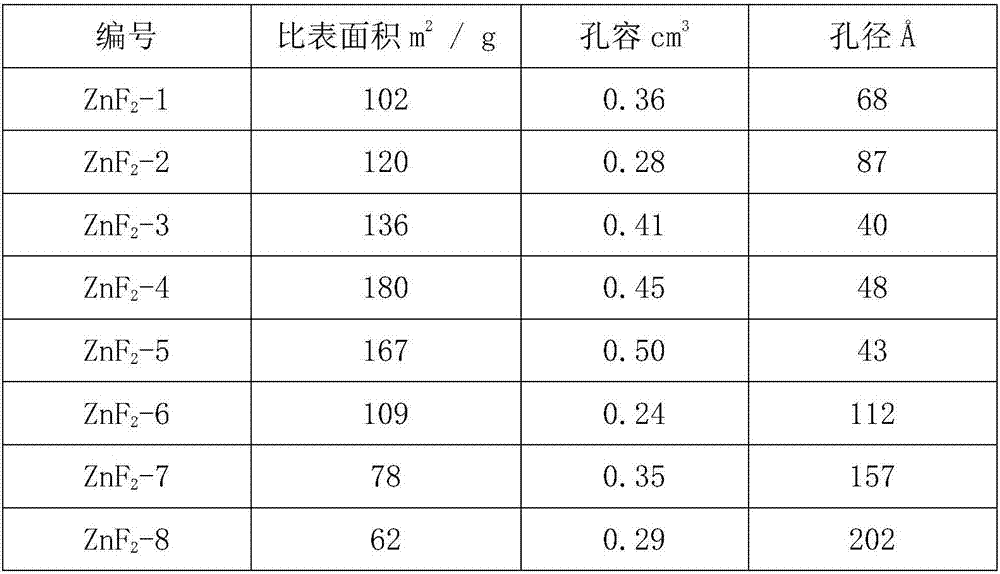

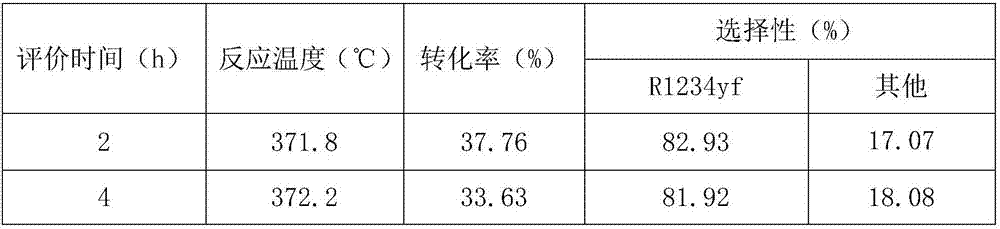

InactiveCN107540011AImprove conversion rateHigh selectivityZinc halidesPreparation by hydrogen halide split-offHigh selectivityZinc fluoride

The present invention discloses a zinc fluoride-containing catalyst having high specific surface area and used for fluorine-chlorine exchange reactions, wherein the specific surface area is 80-180 m<2> / g, the pore volume is 0.15-0.50 cm<3>, and the pore size is 20-100 angstrom. According to the present invention, with the application of the catalyst in fluorine-chlorine exchange reactions, the catalyst has advantages of high conversion rate, high selectivity and low cost in the.

Owner:SINOCHEM MODERN ENVIRONMENTAL CHEM INDAL XI ANCO +1

Chain plate material for pipeline chain plate conveyor

The invention relates to a chain plate material for a pipeline chain plate conveyor. The chain plate material for the pipeline chain plate conveyor is prepared from the components in parts by weight:67-90 parts of alloy steel, 20-35 parts of manganese, 5-11 parts of silicon carbide, 4-10 parts of zinc fluoride, 1-3 parts of magnesium fiber filaments with 1-5 mesh and 1-2 parts of mineral castinggrains. The chain plate material for the pipeline chain plate conveyor is excellent in performance, high in strength, high in wear resistance and easy to process.

Owner:宜兴市乐华冶金辅助材料有限公司

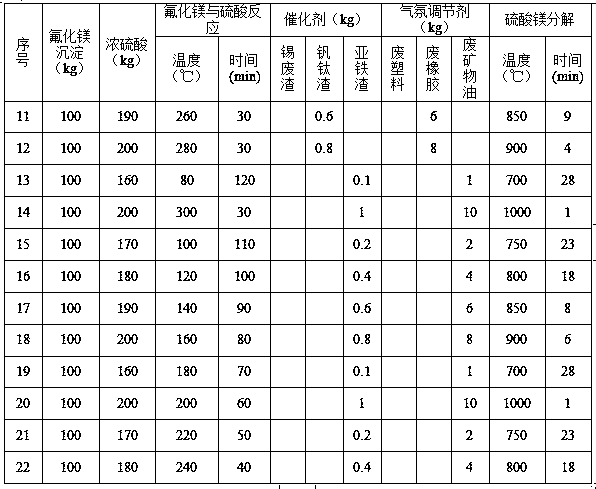

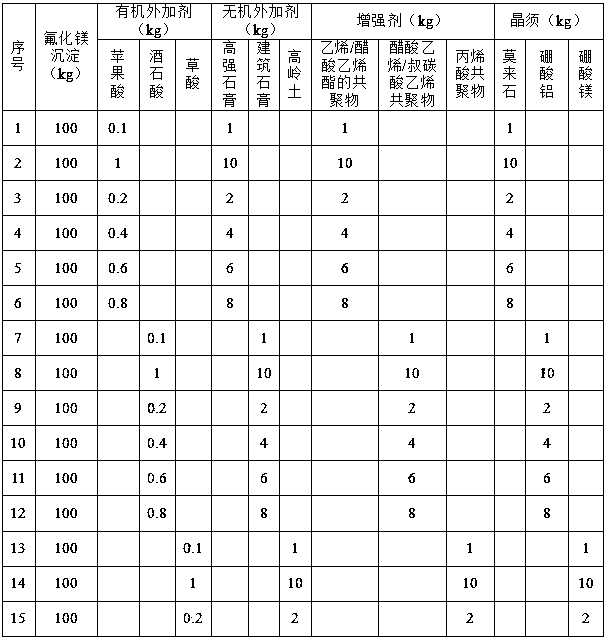

Method for utilizing magnesium resource in wet zinc smelting process

ActiveCN109867463AWide range of usesConducive to in-situ resource utilizationZinc halidesProcess efficiency improvementFiberSoot

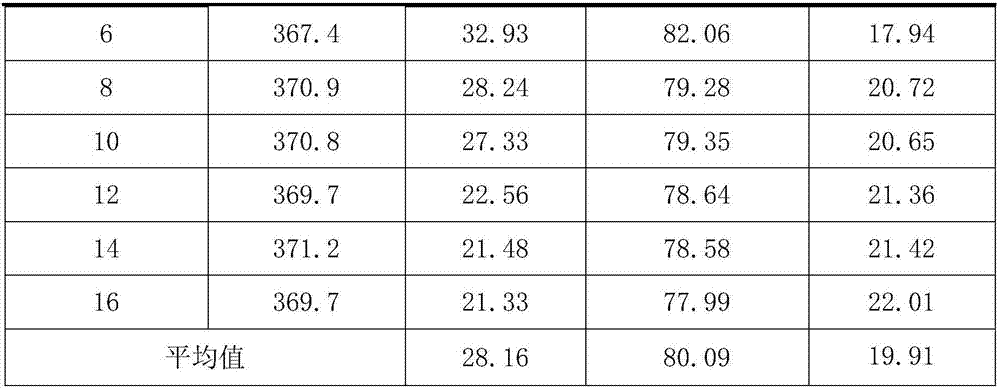

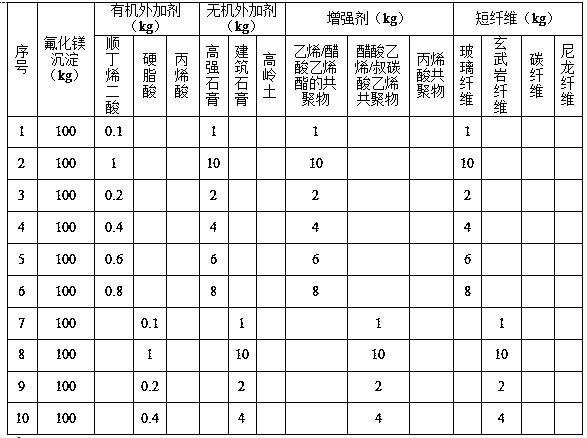

The patent discloses a method for utilizing magnesium resources in a wet zinc smelting process. The method comprises the steps of adding magnesium fluoride seed crystals and zinc fluoride to a magnesium-containing zinc sulfate solution to obtain coarse grains crystals of a magnesium fluoride precipitate, and conducting liquid-solid separation; adding concentrated sulfuric acid to the magnesium fluoride precipitate to obtain hydrogen fluoride gas and magnesium sulfate; introducing the hydrogen fluoride into a container containing zinc oxide soot to obtain zinc fluoride; adding a catalyst and anatmosphere regulating agent to the magnesium sulfate, and conducting heating and decomposing to obtain magnesium oxide; and adding magnesium sulfate, an an organic admixture, an inorganic admixture,a reinforcing agent and short fiber to the magnesium oxide, and conducting uniform mixing, so as to obtain magnesium oxysulfate cement. Compared with the prior art, the method has the advantages of low production cost, high production efficiency and good product quality.

Owner:SOUTHWEAT UNIV OF SCI & TECH

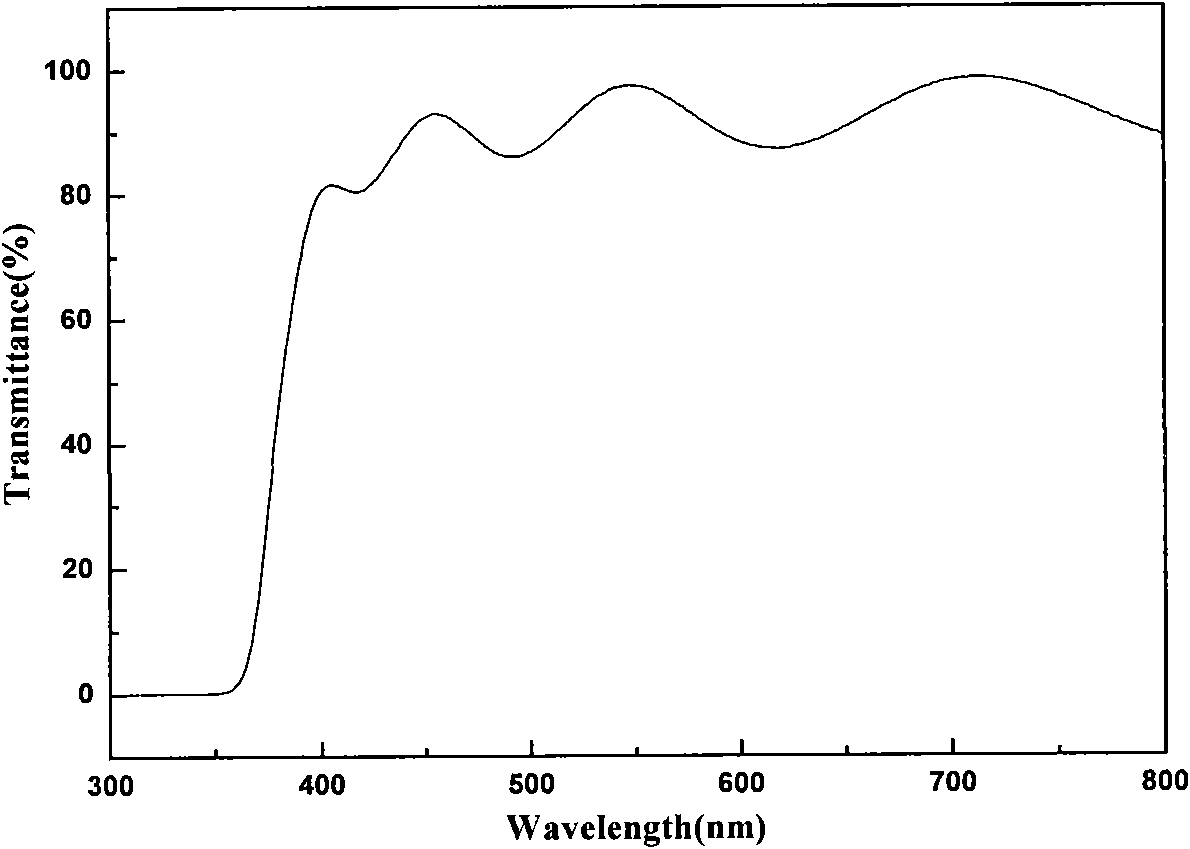

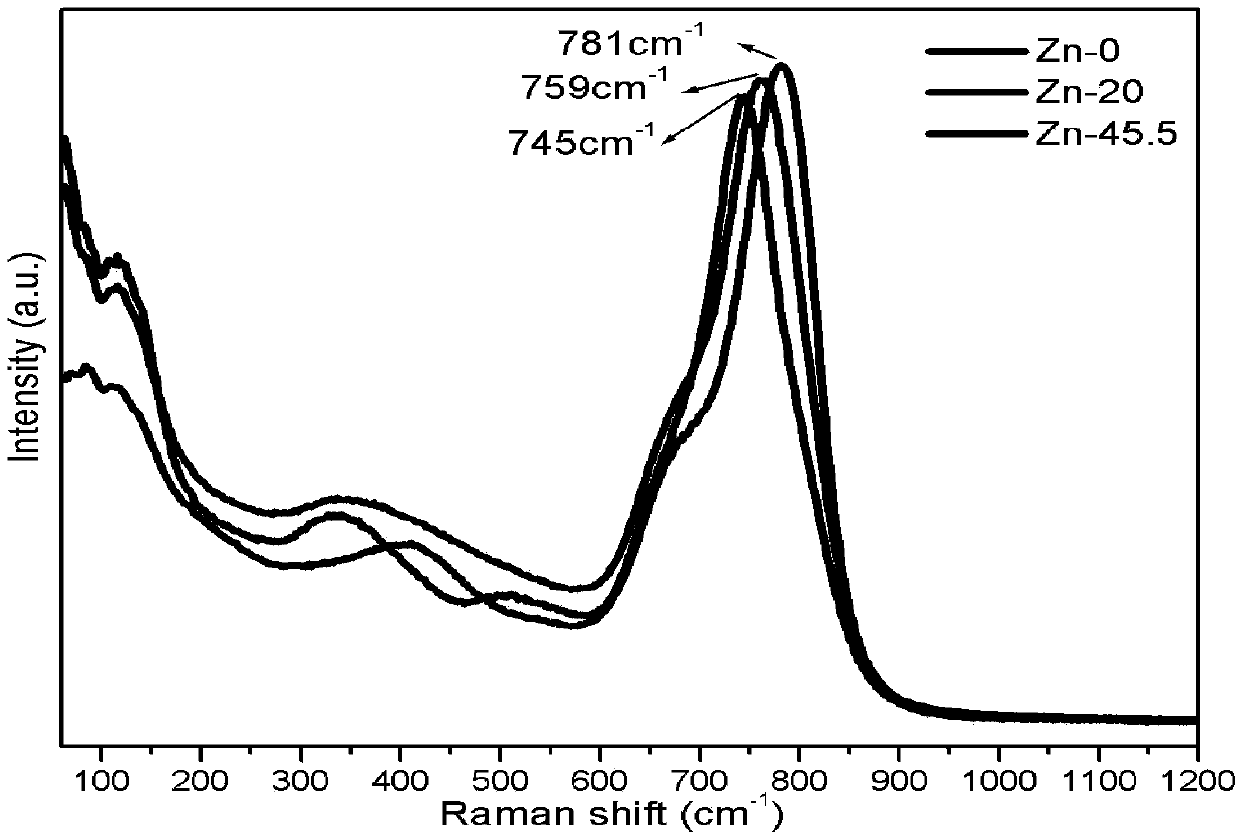

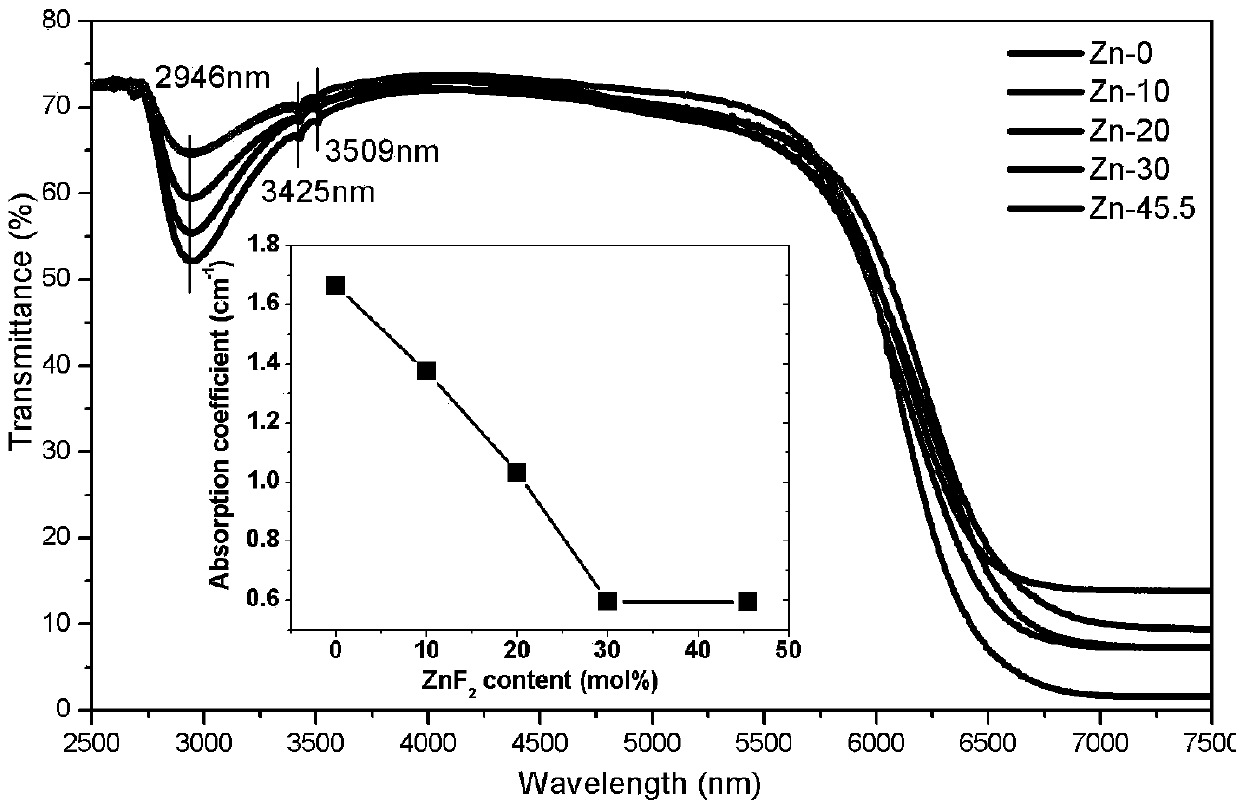

Application of zinc fluoride, mid-infrared wide transmission waveband zinc fluoride/tellurate glass, and preparation of glass

The invention belongs to the technical field of optical functional glass, and particularly provides an application of zinc fluoride. The zinc fluoride is added to a tellurate glass component as an additive in order to reduce the content of hydroxyl groups in the prepared tellurate glass and improve the transmittance of the prepared tellurate glass in the mid-infrared waveband. The invention also provides a mid-infrared wide transmission waveband zinc fluoride / tellurate glass. The mid-infrared wide transmission waveband zinc fluoride / tellurate glass comprises 50-54 mol% of TeO2, 45-49 mol% of ZnF2, 0-2.5 mol% (0 excluded and 2.5 included) of YbF3 and 0-2 mol% (0 excluded and 2 included) of HoF3. The present invention also provides a preparation method of the mid-infrared wide transmission waveband zinc fluoride / tellurate glass. The mid-infrared wide transmission waveband zinc fluoride / tellurate glass is prepared by melting at 950-1000 DEG C without a protective atmosphere and annealing at 320-340 DEG C in an air atmosphere. The functional glass of the invention has a high transmittance, and the preparation method is simple.

Owner:XIANGTAN UNIV

Fluoride brazing flux for copper-aluminum dissimilar metal and preparation method for fluoride brazing flux

ActiveCN103769776AReduce the temperatureLow melting pointWelding/cutting media/materialsSoldering mediaPotassium fluorideCopper fluoride

The invention relates to the field of brazing materials, in particular to fluoride brazing flux for copper-aluminum dissimilar metal and a preparation method for the fluoride brazing flux. The fluoride brazing flux consists of cesium fluoride, aluminum trifluorid, potassium fluoride, copper difluoride and assistant. The preparation method comprises the following steps: mixing the cesium fluoride, the aluminum trifluorid, the potassium fluoride, the copper difluoride, zinc difluoride and lithium fluoride powder with zinc powder or ZnAl alloyed powder in proportion, adding a proper amount of deionized water and grinding in a mortar to form paste, and then, drying and grinding.

Owner:ZHEJIANG XINRUI WELDING MATERIAL

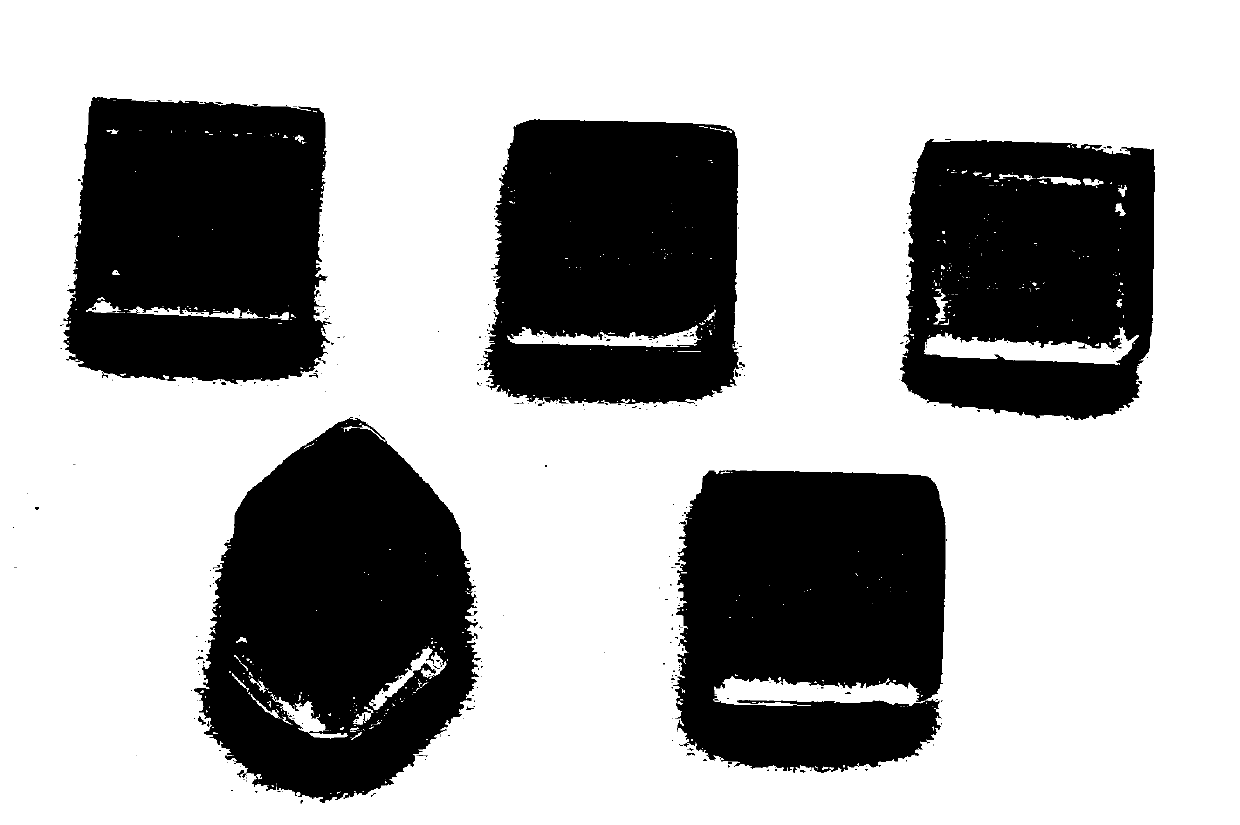

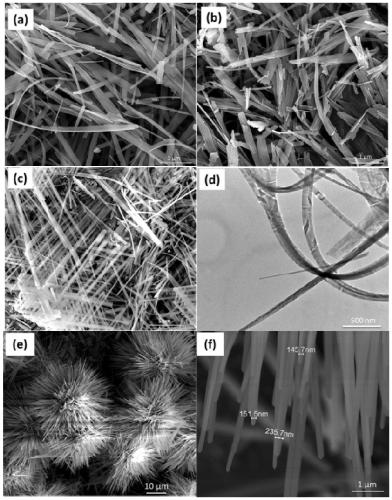

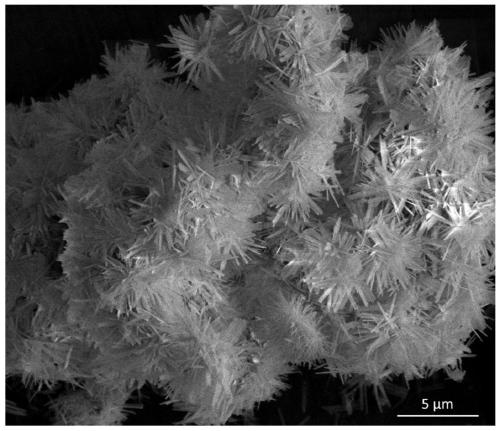

Controllable synthesizing method for hydroxy zinc fluoride nanometer materials with different morphologies and environmental photocatalytic application of hydroxy zinc fluoride nanometer materials

ActiveCN109970098AThe shape features are rich and diverseThe shape features are rich and diverse and can be adjustedZinc halidesPhysical/chemical process catalystsBenzeneCresol

The invention discloses a controllable synthesizing method for hydroxy zinc fluoride nanometer materials with different morphologies and environmental photocatalytic application of the hydroxy zinc fluoride nanometer materials. A hydrothermal reaction is adopted, by controlling a zinc source, a solvent, alkali and the temperature and time of the hydrothermal reaction, the morphologies of the hydroxy zinc fluoride nanometer materials are controlled, and the hydroxy zinc fluoride nanometer materials with different morphologies are obtained. The preparation method is simple, the reaction conditions are mild, and the yield is high. The morphologies of the hydroxy zinc fluoride nanometer materials obtained by using the method are rich, varied and controllable, and the hydroxy zinc fluoride nanometer materials are obvious in catalytic activity and capable of being used for photocatalytic degradation of various organic pollutants, such as brilliant cresol blue, rhodamine B, xylenol orange, bromocresol green, Congo red, methylene blue, phenol and benzene.

Owner:HUAIBEI NORMAL UNIVERSITY

PTC (Positive Temperature Coefficient) macromolecular composite heating material based on iron and copper powder and preparation method thereof

The invention discloses a PTC (Positive Temperature Coefficient) macromolecular composite heating material based on iron and copper powder. The PTC macromolecular composite heating material is prepared from the following raw materials in parts by weight: 20-30 parts of polycaprolactam, 50-55 parts of low-density polyethylene, 20-25 parts of iron powder, 10-15 parts of copper powder, 20-25 parts of aluminum nitride, 10-15 parts of maifanite powder, 3-5 parts of decabromodiphenyl ethane, 10-12 parts of silica, 4-6 parts of zinc fluoride, 12-14 parts of argil, 4-6 parts of methyl triethoxysilane, 3-4 parts of N-(beta-aminoethyl)-gamma-aminopropyl trimeth(eth)oxysilane, 5-6 parts of epoxy tetrahydro-dioctyl phthalate and 1-2 parts of sodium dihydrogen phosphate. The PTC macromolecular composite heating material and the preparation method thereof have the advantages that the PTC strength and PTC stability of the material are improved greatly, the resistance is stable, the temperature is uniform, the PTC characteristic is stable, and the service life of the material is prolonged.

Owner:ANBANG ELECTRICAL GRP

Method for directly electrodepositing zinc on magnesium surface

The invention relates to a magnesium alloy surface directly electrodeposited zinc method that includes the following steps: electrodepositing a layer of zinc on the magnesium alloy surface as protecting layer, adding complex agent into zinc fluoride deionized water until the suspension liquid becoming clear, putting the alloy into the solution to take electrodepositing zinc and putting the magnesium alloy to take thermal process in furnace. The method could realize industrialization producing and have no pollution to environment.

Owner:SHANGHAI UNIV

Brazing material for aluminum-steel dissimilar-material connection brazing

InactiveCN106903454AMelting fastImprove welding efficiencyWelding/cutting media/materialsSoldering mediaPorous grapheneCombustion

The invention discloses a brazing material for aluminum-steel dissimilar-material connection brazing. The brazing material for aluminum-steel dissimilar-material connection brazing is composed of tin, lead, zinc, porous graphene, copper, nitrilotriacetic acid, aluminum base powder, zinc fluoride, tetrahydrofurfuryl alcohol and hydrogenated rosin. The copper is made into a strip, and the tin, the lead, the zinc, the porous graphene, the nitrilotriacetic acid, the aluminum base powder, the zinc fluoride, the tetrahydrofurfuryl alcohol and the hydrogenated rosin are mixed and solidified on the surface of the strip-shaped copper. Compared with the prior art, the brazing material for aluminum-steel dissimilar-material connection brazing has the advantages that the copper is used as the main raw material, the tin, the lead and the zinc are mixed with an combustion improver composed of multiple assistants, so that the copper can be rapidly molten, the welding efficiency is improved, and the brazing material for aluminum-steel dissimilar-material connection brazing has application value and popularization value.

Owner:XIAN AERONAUTICAL UNIV

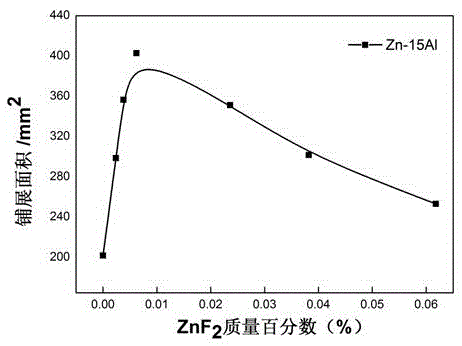

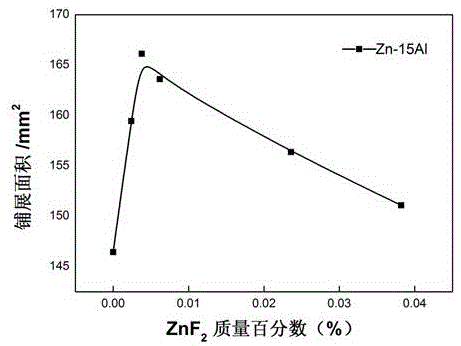

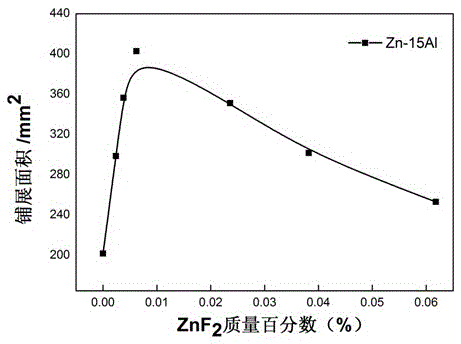

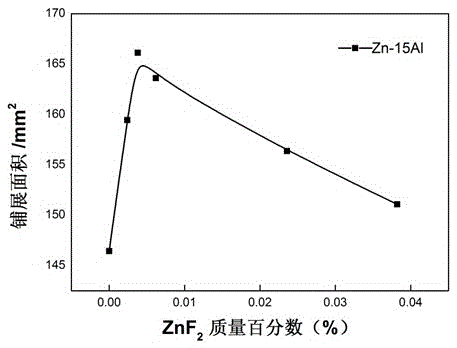

Brazing flux suitable for brazing aluminium and steel

ActiveCN105643144AHigh activityLow priceWelding/cutting media/materialsWelding/soldering/cutting articlesAluminum fluorideAluminium hydroxide

The invention relates to a brazing flux suitable for brazing aluminium and steel, and belongs to the field of non-metallic brazing materials. The brazing flux comprises the following components in percent by mass: 0.001-0.01 percent of rubidium fluoride, 11.0-45.0 percent of cesium fluoride, 0.01-2.0 percent of aluminium hydroxide, 0.01-5.0 percent of potassium fluoride, 0.01-0.04 percent of zinc fluoride, and the balance of aluminum fluoride. The brazing flux can meet the requirements of aluminium-steel brazing, aluminium-copper brazing and aluminium-aluminium brazing synchronously and is high in activity.

Owner:ZHEJIANG XINRUI WELDING MATERIAL

Method of directly electrodepositing zinc-nickel alloy on magnesium alloy surface

InactiveCN101054700ALow costEase of industrial productionHexamethylenetetramineVolumetric Mass Density

The present invention relates to a process for direct electrodeposition of zincium nickel alloy at electron alloys surfaces. According to the process, an electroplating method is adopted, electron alloys is selected as cathode, zincium nickel alloy containing nickel of 8-12% therein is selected as anode, the electric current density during electric plating is controlled at 1-2 A / dm2, and the electric plating time is 1 hour; finally, the electron alloys suffering an electrodeposition of zincium nickel alloy is put to a heat treatment furnace for a heat treating at the temperature of 150-200 DEG C and for 1 hours; the electrolysing solution adopted uses deionized water as solvent, wherein the components and their concentrations are as follows: ZnF2 8-12 g / L, NiF2, 15-25 g / L, ammonium citrate 80-120 g / L, potassium sodium 50-70 g / L, EDTA 8-12 g / L, hexamethylenetetramine 1-2 g / L, all the solutes are stirred to being entirety dissolved and into clear solution , in which the mole ratio of zincium ion to ion is controlled within 1:2-3. Said process for electrodeposition of zincium nickel alloy at electron alloys surfaces by adopting electric plating method is not dependant on the grade of electron alloys, in other words, surfaces of electron alloys of any grades can be electrodeposited with zincium. On one hand, the cost for electron alloys mat-forming treatment is reduced; on the other hand, the electroplating method is easy to realize industrialisation production. The fluorinion in zinc fluoride (nickel fluoride) plating solution exhibits an inactivating sheltering effect of the electron alloys, preventing the electron alloys being eroded in the solution. And the zinc fluoride (nickel fluoride) plating solution is of periodic duty and will not pollute the environment.

Owner:JIANGSU XINYE HEAVY IND

Soldering flux suitable for aluminum steel brazing

ActiveCN105618960AGood spreadabilityHigh activityWelding/cutting media/materialsWelding/soldering/cutting articlesAluminum fluorideMetallic materials

The invention belongs to the field of brazing material of non-metallic material and discloses soldering flux suitable for aluminum steel brazing. The soldering flux is characterized by being composed of, by weight, 0.001-0.01% of rubidium fluoride (RbF), 11.0-45.0% of cesium fluoride (CsF), 0.01-2.0% of aluminum oxide (Al2O3), 0.01-5.0% of potassium fluoride (KF), 0.001-0.04% of zinc fluoride (ZnF2) and the balance aluminum fluoride (AlF3). The soldering flux can meet the brazing requirements of aluminum-steel, aluminum-copper and aluminum-aluminum and is high in activity.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

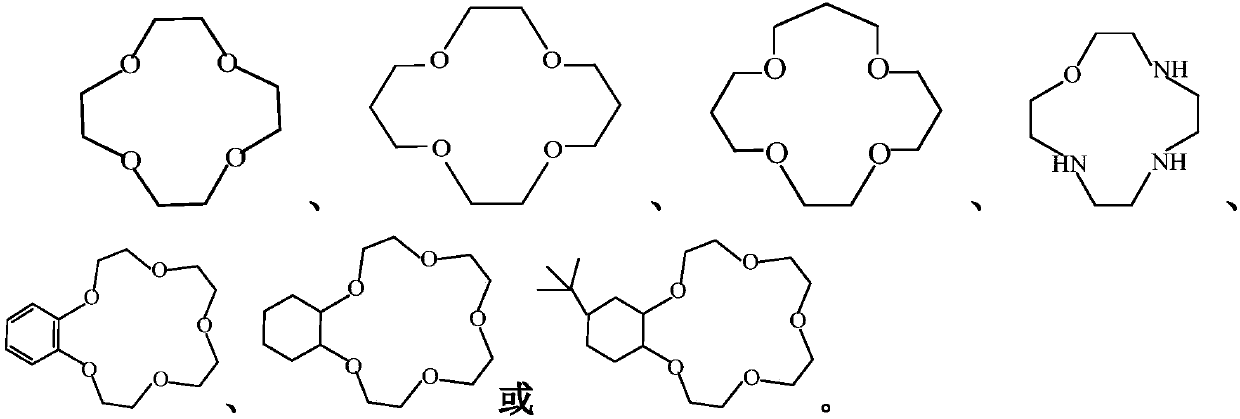

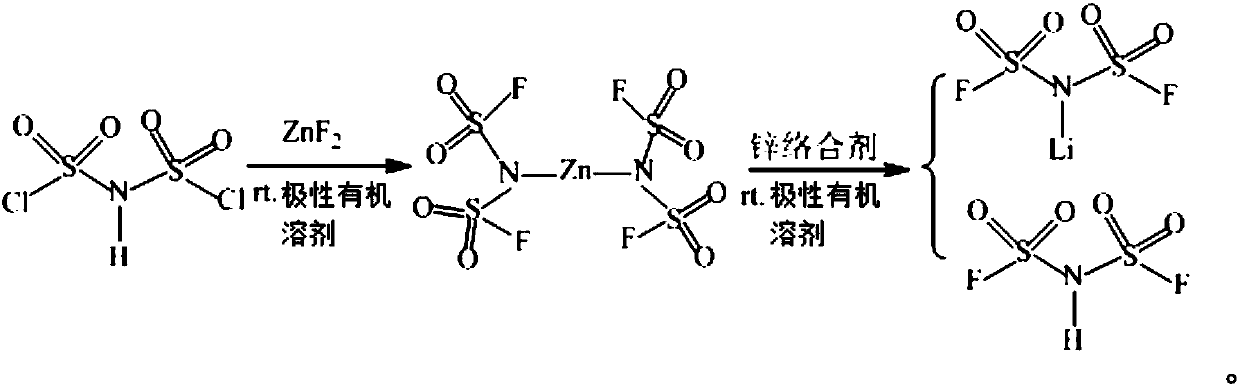

Method for preparing imidodisulfuryl fluoride lithium with villiaumite as fluorinating agent

InactiveCN107651654ALow equipment requirementsMild reaction conditionsNitrosyl chlorideLithiumOrganic solvent

The invention provides a method for preparing imidodisulfuryl fluoride lithium with villiaumite as a fluorinating agent. The method comprises the following specific step: by taking imidodisulfuryl fluoride as a raw material, and a fluorinating agent as a complexing agent, performing a reaction in a polar organic solvent, thereby obtaining the imidodisulfuryl fluoride lithium, wherein the fluorinating agent comprises lithium fluoride or zinc fluoride; the fluorinating agent is 2-4 times of the weight parts of the imidodisulfuryl fluoride; the complexing agent comprises a lithium ion complexingagent or a zinc ion complexing agent; the complexing agent accounts for 0.5-5% of the weight parts of the fluorinating agent; and the polar organic solvent is selected from one or more of saturated carbonic esters, fluoro saturated carbonic esters, acetonitrile or N,N-dimethyl formamide. The imidodisulfuryl fluoride lithium prepared by using the method is low in toxin of reagents used in reactions, gentle in reaction condition, free of extreme condition such as high temperature and high pressure, low in equipment requirement and easy to achieve; in addition, the method provided by the invention is small in middle reaction, simple in later treatment, small in whole product preparation influence and very high in reaction yield, that is, up to 70-88%.

Owner:JIANGSU LEE & MAN CHEM +2

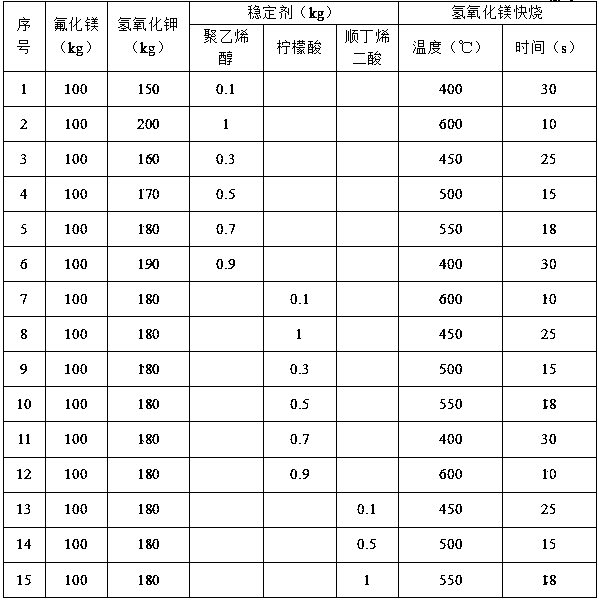

Magnesium fluoride electrochemical separating and utilizing method in wet-method zinc smelting technology

ActiveCN110041042AWide range of usesConducive to in-situ resource utilizationElectrolysis componentsElectrolysisPotassium fluoride

The invention discloses a magnesium fluoride electrochemical separating and utilizing method in a wet-method zinc smelting technology. The method is characterized by comprising the steps: adding magnesium fluoride seed crystal and zinc fluoride into a magnesium containing zinc sulfate solution to obtain coarse grain magnesium fluoride precipitate and performing liquid-solid separation; adding a potassium hydroxide solution into the magnesium fluoride precipitate to obtain magnesium hydroxide precipitate and a potassium fluoride solution, filtering and separating; adding the potassium fluoridesolution and a stabilizer into a diaphragm electrolyzer to be electrolyzed to obtain potassium hydroxide and zinc fluoride; quickly burning the magnesium hydroxide to obtain magnesium oxide; adding magnesium sulfate, an organic additive, an inorganic additive, a reinforcing agent and crystal whisker into the magnesium oxide and evenly mixing to obtain magnesium sulfate cement. Compared with the existing technical scheme, the method has the characteristics of short technological process, moderate reaction, high production efficiency and good product quality.

Owner:合肥名龙电子科技有限公司

Copper brazing paste for brazing

InactiveCN107052616AImprove wettabilityThe shape of the solder joint is fullWelding/cutting media/materialsSoldering mediaDiethylene glycol monobutyl etherCopper fluoride

The invention provides copper brazing paste for brazing. The copper brazing paste for brazing is prepared from the mixed materials comprising, by weight, 60%-70% of copper-based powder brazing filler metal, 2%-6% of brazing flux, 10%-30% of compound solvent, 0.5%-1% of corrosion inhibitor, 1%-3% of thixotropic agent and 4%-8% of activating agent. The brazing flux is zinc fluoride and stannous fluoride or copper fluoride. The compound solvent is composed of tetrahydrofurfuryl alcohol, triethylene glycol and diethylene glycol monobutyl ether, wherein the volume ratio of the tetrahydrofurfuryl alcohol, the triethylene glycol and the diethylene glycol monobutyl ether is 40-50:10-20:30-50. The copper brazing paste for brazing reduces the dosage of a corrosive brazing flux and even eliminates the corrosive brazing flux and has excellent spreading rate and welding performance.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

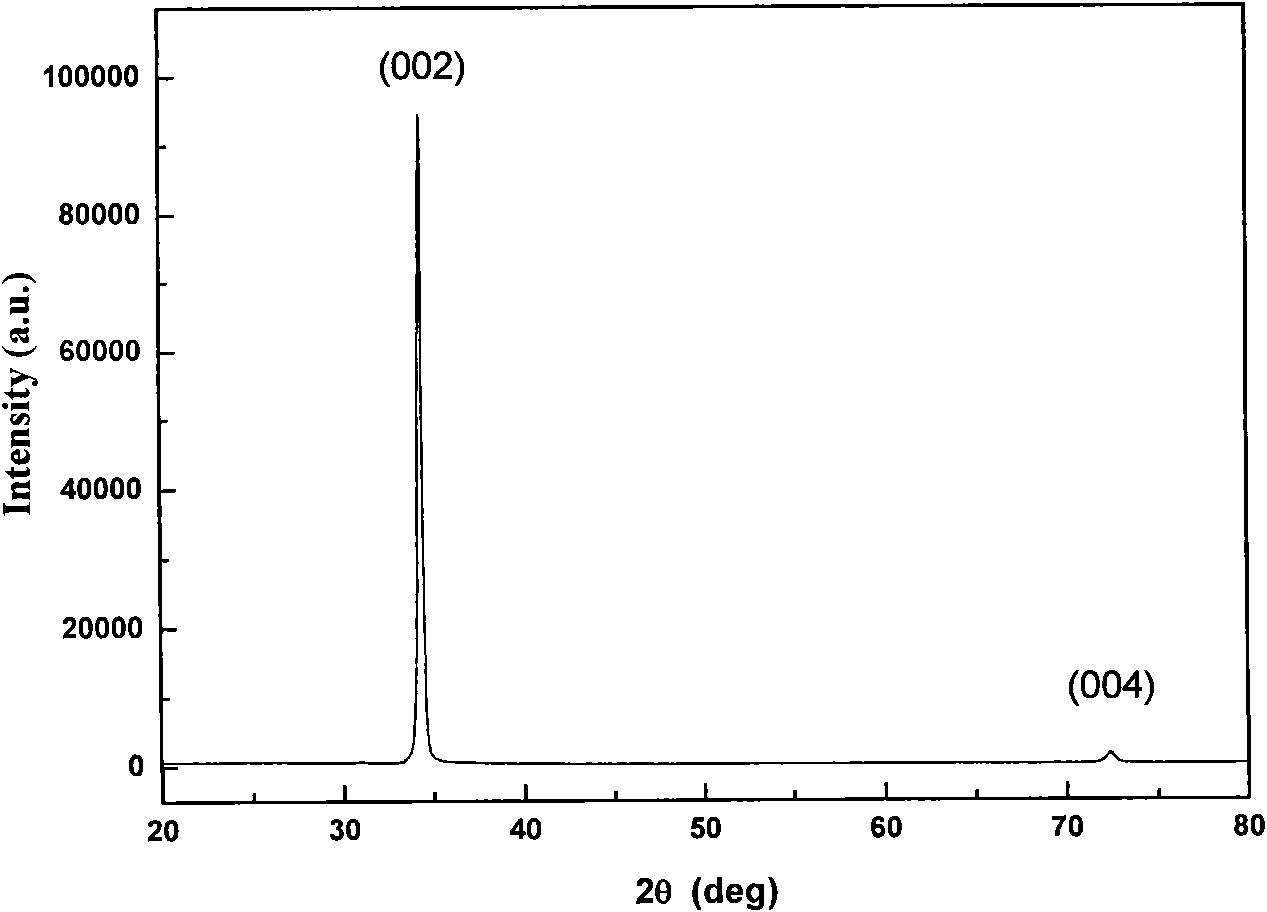

Method for growing p-type ZnO crystal thin film by Li-F codoping

InactiveCN101824597AAchieve p-type dopingReal-time dopingVacuum evaporation coatingSputtering coatingLithium oxideLithium carbonate

The invention discloses a method for growing a p-type ZnO crystal thin film by Li-F codoping. The pulse laser deposition method is adopted. A ZnF2-dooped and Li2O-doped ZnO ceramic target is used as the target and prepared from pure zinc oxide powder, pure zinc fluoride powder and pure lithium carbonate powder by ball milling, press forming and sintering, wherein the molar content of the zinc fluoride is 0.3 percent and the molar content of the lithium oxide is 0.3 to 0.9 percent; and the p-type ZnO crystal thin film is grown on a substrate in a growth chamber of a pulse laser deposition device under the growth atmosphere of pure oxygen, wherein the pressure intensity of the oxygen is 5 to 20Pa, the laser frequency is 3 to 5Hz and the growth temperature is 300 to 500 DEG C. The method of the invention can realize real-time doping, and the doping density is controlled by adjusting the growth temperature and the molar content of Li and F in the target. The p-type ZnO crystal thin film prepared by the method of the invention has high electrical property, high repeatability and high stability.

Owner:ZHEJIANG UNIV

Corrosion prevention method for aluminum-based metal component, and corrosion-proof aluminum-based metal product produced by the method

InactiveCN101041899AEasy to confirmFormation effect is goodMetallic material coating processesMetal layered productsSodium molybdateSulfate

The present invention provides a corrosion prevention method for an aluminum-based metal component, which makes it easy to check the presence or absence of a chemically formed film on the component, and a corrosion-proof aluminum-based metal product produced by the method. In the method, the following treatment agent (A) is brought into contact with a surface of the aluminum-based metal component to chemically form the following film (B) on the surface of the aluminum-based metal component: (A) a treatment agent comprising an aqueous solution of zinc sulfate, an aqueous solution of ammonium fluoride and an aqueous solution of sodium molybdate which are mixed together; (B) a chemically formed film (B) comprising zinc fluoride, molybdenum and aluminum fluoride.

Owner:SUMITOMO RIKO CO LTD

Preparation process and preparation device of polypeptide compound

InactiveCN108586568AImprove efficiencyImprove qualityPeptide preparation methodsFermentationZinc Acetate DihydrateHydrolysis

The invention discloses a preparation process of a polypeptide compound. The process comprises the following steps of freezing and crushing raw material slices; adding ethanol to obtain a mixture; adding the mixture into hydrochloric acid; performing stirring; performing filtering; cooling extraction liquid to the temperature of 3 DEG C or below; regulating the pH by stronger ammonia water to obtain basic extraction liquid; adding diatom ooze into the basic extraction liquid; performing press filtering; adding sulfuric acid for acidification; after the acidification, filtering away residues; adding zinc fluoride; adding hydrochloric acid for acidification; filtering away residues again to obtain extraction liquid filtered for three times and freezing to 5 DEG C or below; removing precipitates; regulating the pH to 5 to 6.0 by ammonia water; adding zinc acetate to obtain white precipitates; then, adding a mixture of hydrochloric acid, zinc sulfate and acetone; cooling crystalline liquid; performing alkalization by ammonia water; performing filtering to remove precipitates; performing stirring and crystallization; next, performing hydrolysis by pepsin and pancreatin; after enzyme deactivation, obtaining pilose antler protein hydrolysates; next, performing separation and purification to obtain a polypeptide mixture. The polypeptide mixture preparation efficiency of the process provided by the invention is high.

Owner:郑娟娟

Toothpaste capable of preventing saprodontia

InactiveCN103356399APrevent dental cariesPrevent bad breathCosmetic preparationsToilet preparationsFoaming agentToothpaste

The invention discloses a toothpaste capable of preventing saprodontia, which comprises a friction producing material, a washing foaming agent, a bonding agent, a humectant, a sweetening agent, an aromatic, a protein amylase accounting for 2-5 wt% of the paste, sodium fluoride accounting for 1.2-1.5 wt% of the paste, and zinc fluoride accounting for 2-3.6 wt% of the paste. The aromatic is mint or green tea. The toothpaste capable of preventing saprodontia has obvious antibacterial action and the effect of preventing saprodontia, and is low in cost and simple to prepare.

Owner:张斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com