Preparation method and application of sector hydroxyl zinc fluoride

A sector-shaped zinc hydroxyfluoride technology, which is applied in the field of preparation of sector-shaped zinc hydroxyfluoride catalysts, achieves good stability, is conducive to large-scale promotion, and has simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) After mixing 30ml of water and 5ml of absolute ethanol, under stirring conditions, add 1.75mmol of zinc chloride and 21mmol of sodium hydroxide, stir for 30min,

[0020] 2) Add the mixed solution of step 1) into an autoclave lined with polytetrafluoroethylene, conduct a hydrothermal reaction at a constant temperature of 140°C for 12 hours, centrifuge and wash for 3 times, and dry at 60°C to obtain zinc oxide product.

[0021] 3) Take 35ml of water, and add the zinc oxide product obtained in step 2) under stirring conditions

[0022] 4) Weigh 1 mmol of zinc oxide product, add 4 mmol of ammonium fluoride, stir for 30 min,

[0023] 5) Add the mixed solution of step 4) into an autoclave lined with polytetrafluoroethylene, conduct a hydrothermal reaction at a constant temperature of 180°C for 24 hours, centrifuge and wash 3 times, and dry at 60°C to obtain zinc hydroxyfluoride product.

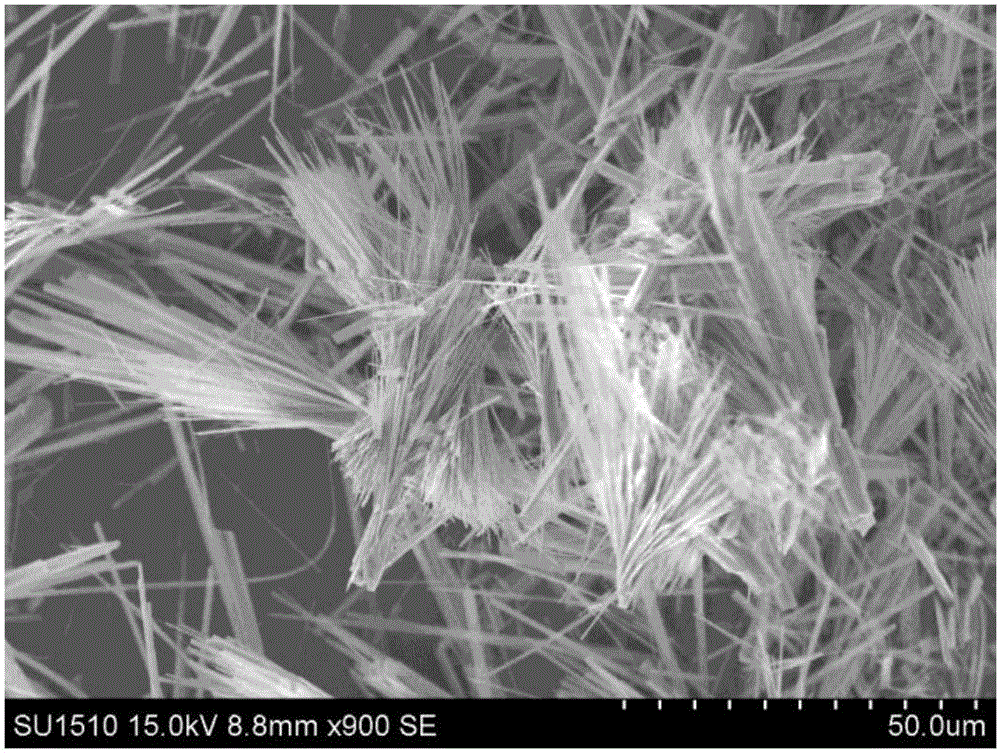

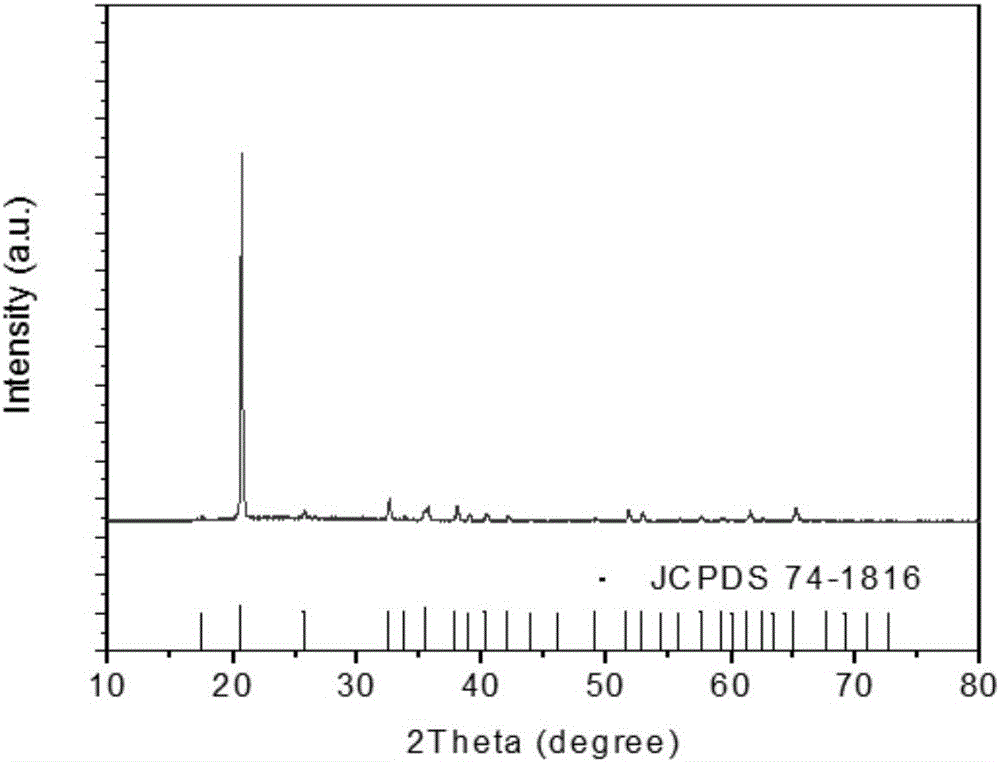

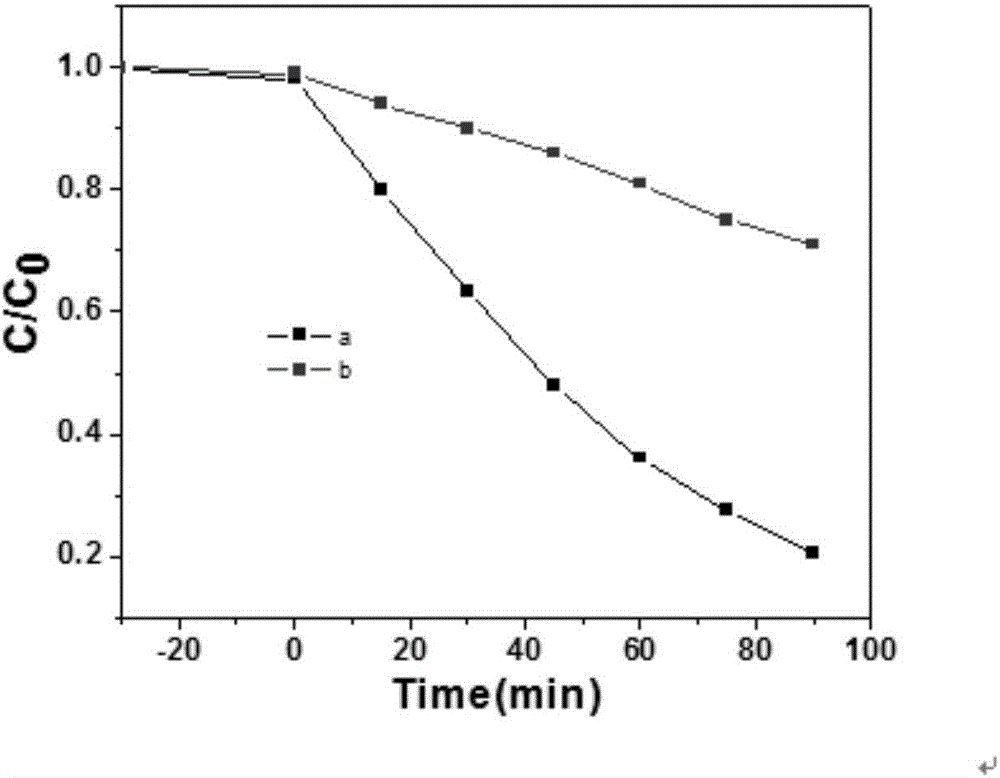

[0024] Depend on figure 1 It can be seen that the zinc hydroxyfluoride catalyst p...

Embodiment 2

[0029] 1) After mixing 30ml of water and 5ml of absolute ethanol, under stirring conditions, add 1.25mmol of zinc chloride and 17mmol of sodium hydroxide, stir for 30min,

[0030] 2) Add the mixed solution of step 1) into an autoclave lined with polytetrafluoroethylene, conduct a hydrothermal reaction at a constant temperature of 140°C for 12 hours, centrifuge and wash for 3 times, and dry at 60°C to obtain zinc oxide product.

[0031] 3) Take 35ml of water, and add the zinc oxide product obtained in step 2) under stirring conditions

[0032] 4) Weigh 1 mmol of zinc oxide product, add 4 mmol of ammonium fluoride, stir for 30 min,

[0033] 5) Add the mixed solution of step 4) into an autoclave lined with polytetrafluoroethylene, conduct a hydrothermal reaction at a constant temperature of 180°C for 24 hours, centrifuge and wash 3 times, and dry at 60°C to obtain zinc hydroxyfluoride product.

Embodiment 3

[0035] 1) After mixing 30ml of water and 5ml of absolute ethanol, under stirring conditions, add 2.5mmol of zinc chloride and 24mmol of sodium hydroxide, stir for 30min,

[0036] 2) Add the mixed solution of step 1) into an autoclave lined with polytetrafluoroethylene, conduct a hydrothermal reaction at a constant temperature of 140°C for 12 hours, centrifuge and wash for 3 times, and dry at 60°C to obtain zinc oxide product.

[0037] 3) Take 35ml of water, and add the zinc oxide product obtained in step 2) under stirring conditions

[0038] 4) Weigh 1 mmol of zinc oxide product, add 4 mmol of ammonium fluoride, stir for 30 min,

[0039] 5) Add the mixed solution of step 4) into an autoclave lined with polytetrafluoroethylene, conduct a hydrothermal reaction at a constant temperature of 180°C for 24 hours, centrifuge and wash 3 times, and dry at 60°C to obtain zinc hydroxyfluoride product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com