Deep ultraviolet magnesium fluoride crystal growth method

A technology of crystal growth and magnesium fluoride, which is applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of poor integrity of magnesium fluoride crystal growth, low transmittance in the ultraviolet band, and difficult industrial production, etc., to achieve Large crystal size, high yield and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

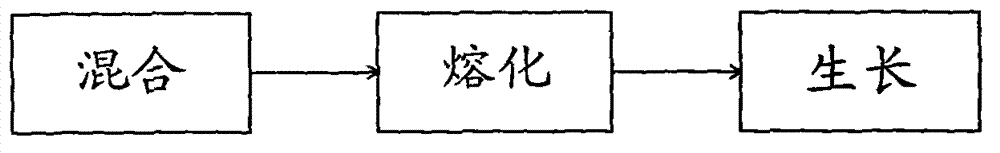

Image

Examples

Embodiment 1

[0018] Embodiment 1: the present embodiment carries out as follows:

[0019] 1. MgF with a purity greater than 99.99% and a molar ratio of 1:0.02 2 and ZnF 2 After the powder is mixed with MgF in [001] direction 2 Single crystals were placed in platinum crucibles with a thickness of 1 mm.

[0020] 2. Put the platinum crucible into the single crystal furnace and raise the temperature to 700°C for 2 hours to deoxidize 2 The generated ZnO is volatilized, and then the single crystal furnace is fed with nitrogen gas, and then the temperature is continuously raised until the raw materials are completely melted.

[0021] 3. When the raw materials are completely melted, control the furnace temperature at 900°C, and then use MgF 2 The single crystal is planted at a speed of 10cm / h, the growth temperature gradient is 60°C / cm, and the rising speed is 1.8mm / h. The open pulling method grows deep ultraviolet magnesium fluoride, and the growth cycle is 5 days to obtain deep ultraviolet m...

Embodiment 2

[0022] Embodiment 2: the present embodiment carries out as follows:

[0023] 1. MgF with a purity greater than 99.99% and a molar ratio of 1:0.02 2 and ZnF 2 After the powder is mixed with MgF in [001] direction 2 The single crystal was put into a platinum crucible with a thickness of 1.2 mm.

[0024] 2. Put the platinum crucible into the single crystal furnace and raise the temperature to 800°C for 2 hours to deoxidize 2 The generated ZnO is volatilized, and then the single crystal furnace is fed with nitrogen gas, and then the temperature is continuously raised until the raw materials are completely melted.

[0025] 3. When the raw materials are completely melted, control the furnace temperature at 1200°C, and then use MgF 2 The single crystal is planted at a speed of 10cm / h, the growth temperature gradient is 90°C / cm, and the rising speed is 1.8mm / h. The open pulling method grows deep ultraviolet magnesium fluoride, and the growth cycle is 5 days to obtain deep ultravio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com