High specific surface area catalyst, preparation method and applications thereof

A technology with high specific surface area and specific surface area, which can be used in the preparation of dehydrohalogenation, chemical instruments and methods, catalysts for physical/chemical processes, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

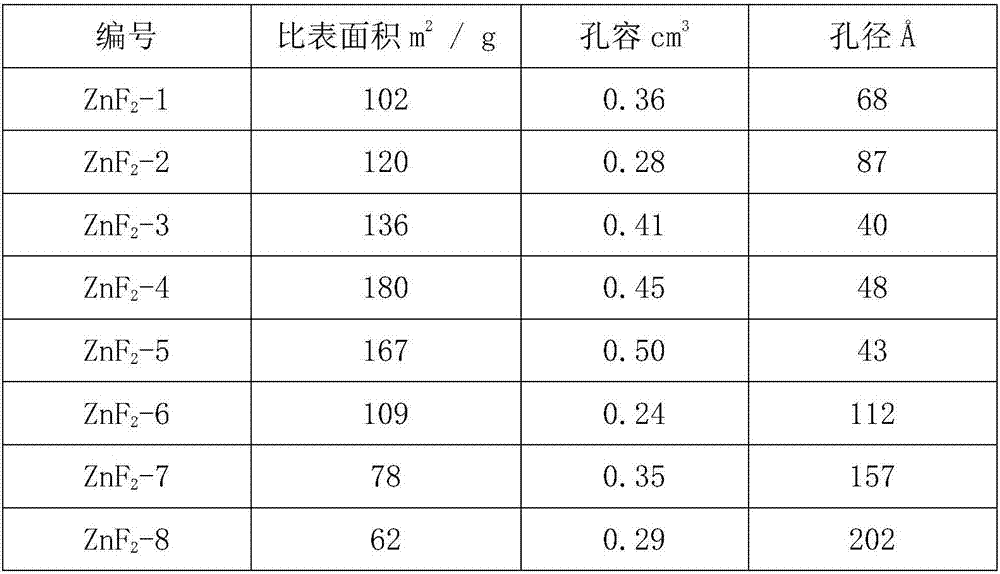

Embodiment 1

[0032] Take 39.54g Zn(CH 3 COO) 2 Dissolve in 500ml of methanol and stir to form a zinc solution. At room temperature, dissolve 10.0 g of anhydrous HF in HF-Et 2 O solution (12.5mol / L) was added to the above zinc solution, stirred vigorously, stopped stirring after 4 hours of reaction, and left to age for 4 hours. Use a rotary evaporator or a centrifuge to remove the volatile components in the product, and dry them in a vacuum oven to obtain zinc fluoride with a high specific surface area, which is recorded as ZnF 2 -1.

Embodiment 2

[0034] Take 51.08g Zn(MeO) 2 Dissolve in 500ml of methanol and stir to form a zinc solution. At room temperature, dissolve 20.0 g of anhydrous HF in HF-Et 2 O solution (12.5mol / L) was added to the above zinc solution, stirred vigorously, stopped stirring after 4 hours of reaction, and left to age for 4 hours. Use a rotary evaporator or a centrifuge to remove the volatile components in the product, and dry them in a vacuum oven to obtain zinc fluoride with a high specific surface area, which is recorded as ZnF 2 -2.

Embodiment 3

[0036] Take 52.72g Zn(CH 3 COO) 2 Dissolve in 500ml of methanol and stir to form a zinc solution. At room temperature, dissolve 10.0 g of anhydrous HF in HF-Et 2 O solution (12.5mol / L) was added to the above zinc solution, stirred vigorously, stopped stirring after 4 hours of reaction, and left to age for 4 hours. Use a rotary evaporator or a centrifuge to remove the volatile components in the product, and dry them in a vacuum oven to obtain zinc fluoride with a high specific surface area, which is recorded as ZnF 2 -3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com