Method for growing p-type ZnO crystal thin film by Li-F codoping

A co-doping, p-type technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc., to achieve the effect of good electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

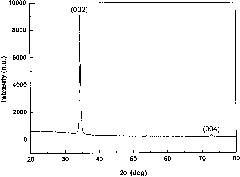

Embodiment 1

[0019] 1) get the zinc oxide, zinc fluoride and lithium carbonate powder that purity is respectively 99.99%, Li molar content is 0.6%, F molar content is 0.3%, ZnO, ZnF 2 and Li 2 CO 3 The mixed powder is poured into an agate ball cup, placed on a ball mill for ball milling, and the time of ball milling is 24 hours. There are two purposes of ball milling: the first is to make ZnO, ZnF 2 and Li 2 CO 3 Mix the powder evenly to ensure the uniformity of the prepared target; secondly, to mix ZnO, ZnF 2 and Li 2 CO 3 The powder is refined to facilitate the subsequent molding and sintering of the mixed powder.

[0020] After ball milling, the powder was pressed into discs with a thickness of 3 mm and a diameter of 50 mm. Pre-fired at 600°C for 1 hour, and then sintered at 1060°C for 3 hours to obtain the target.

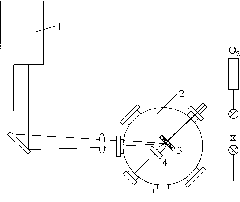

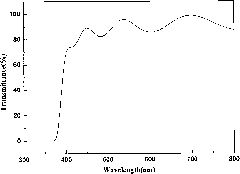

[0021] 2) Using glass as the substrate, clean the substrate surface and put it into the growth chamber of the pulsed laser deposition device. The vacuum degree of ...

Embodiment 2

[0024] 1) get the zinc oxide, zinc fluoride and lithium carbonate powder that purity is respectively 99.99%, the Li molar content is 0.9%, the F molar content is 0.3%, ZnO, ZnF 2 and Li 2 CO 3 The mixed powder is poured into an agate ball cup, placed on a ball mill for ball milling, and the time of ball milling is 24 hours. There are two purposes of ball milling: the first is to make ZnO, ZnF 2 and Li 2 CO 3 Mix the powder evenly to ensure the uniformity of the prepared target; secondly, to mix ZnO, ZnF 2 and Li 2 CO 3 The powder is refined to facilitate the subsequent molding and sintering of the mixed powder.

[0025] After ball milling, the powder was pressed into discs with a thickness of 3 mm and a diameter of 50 mm. Then sintered at 800°C for 3 hours to obtain ZnF-doped 2 and Li 2 O ZnO ceramic target.

[0026] 2) Using glass as the substrate, clean the substrate surface and put it into the growth chamber of the pulsed laser deposition device. The vacuum degre...

Embodiment 3

[0029] 1) get the zinc oxide, zinc fluoride and lithium carbonate powder that purity is respectively 99.99%, Li molar content is 0.6%, F molar content is 0.3%, ZnO, ZnF 2 and Li 2 CO 3 The mixed powder is poured into an agate ball cup, placed on a ball mill for ball milling, and the time of ball milling is 24 hours. There are two purposes of ball milling: the first is to make ZnO, ZnF 2 and Li 2 CO 3 Mix the powder evenly to ensure the uniformity of the prepared target; secondly, to mix ZnO, ZnF 2 and Li 2 CO 3 The powder is refined to facilitate the subsequent molding and sintering of the mixed powder.

[0030]After ball milling, the powder was pressed into discs with a thickness of 3 mm and a diameter of 50 mm. Pre-fired at 600°C for 1 hour, and then sintered at 1060°C for 3 hours to obtain the target.

[0031] 2) Using quartz as the substrate, clean the surface of the substrate and put it into the growth chamber of the pulsed laser deposition device. The vacuum deg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Mobility | aaaaa | aaaaa |

| Hole concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com